Choosing a glue for insulation

Which glue for penoplex to choose depends on the desire of the buyer, on his financial capabilities. The main requirement is that the glue for expanded polystyrene - the price of which depends on the selected brand - should not contain substances that destroy extruded expanded polystyrene:

- toluene, xylene and benzene;

- formalin and formaldehyde;

- acetone and other ketones;

- esters and ethers;

- gasoline, kerosene and diesel fuel;

- coal tar;

- polyester resins, which are used to harden epoxy adhesives;

- various oil paints.

When deciding what kind of glue to glue the penoplex, it is necessary to carefully read the manufacturer's recommendations regarding its suitability for reliable and durable fixation of this insulating material.

Modern adhesives for penoplex can be divided into the following groups:

- On a mineral (cement) basis:

- "Terracotta" from the "Terraco" company;

- "Teplokley" from the group of companies "Unis";

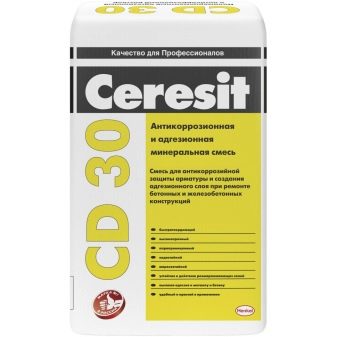

- Ceresit from Ceresit;

- quick-hardening adhesive mixtures "Sarmat";

- a number of other cementitious adhesives.

- Polyurethane based:

- glue "Titan" for penoplex;

- Izolemfi and Zenit 36 from Emfi.

- On mixed polymers:

- glue "Emfikol 225" from "Emfi";

- glue "Moment".

- Waterproofing adhesives include:

- glue "Uniflex";

- bituminous mastic, which can also be used as facade glue.

- For fixing the insulation in a dry room, gypsum mounting glue is also quite suitable.

According to experts, it is possible to glue penoplex with liquid nails, but the high cost of glue, the need to apply it on a large surface, make this option economically ineffective.

The choice of a binder, no matter whether it is a ready-to-use mixture or dry glue, largely depends on the individual sensitivity of the person performing the installation work. After all, many do not like the smell of polyurethane glue, and even the smell of bituminous glue - it can discourage any desire to continue work, and even cause complaints from households for an unpleasant smell that remains for a long time after the end of work

Mastic: the base of the foundations

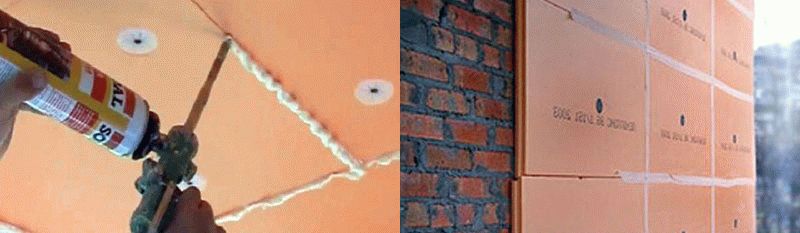

Bitumen-polymer mastics are one of the most common materials for their price and ease of work. This technology has found wide application when insulating the basements of buildings operating in extremely unfavorable conditions of constant humidity, the presence of reagents, and mechanical influences. They provide fast and reliable installation of the foam with stable resistance to harmful external factors. The mastics are sold in ready-to-use tubes. The tube is inserted into the sealant gun.

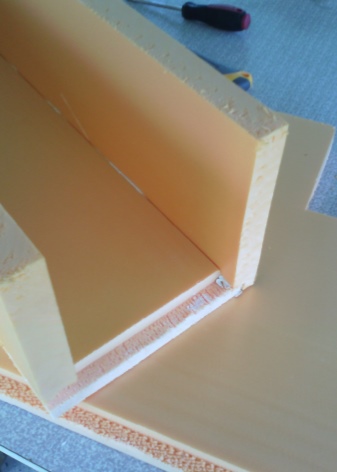

The composition is applied along the perimeter and pointwise to the center (when laying the second and then next to it, it is also applied to the grooves). Then the insulation to be installed is pressed for a short time. The glued insulation can be repositioned within one hour.

The glued insulation can be repositioned within one hour.

Dowel plugs: long-lasting strength

The use of disc dowels is justified in the case of a large area of insulation, or irregularities of the facade surface. To mount on dowels, you need: a perforator (impact drill), a drill of the appropriate diameter and length, a hammer. Holes are drilled with a 50-60 mm deepening into the base. The holes are filled with polyurethane foam. Then the dowel is hammered in so that the dowel fungi do not protrude above the surface of the plate. It is best to use dowels complete with metal screws to increase the reliability of the connection. Installation of 5 dowels is sufficient for one plate. Adjacent sheets are fixed with one dowel. It must be installed in the joint between the slabs.

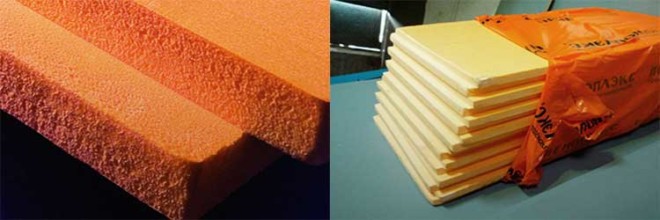

Penoplex features

Synthetic foam products from polystyrene have been made for a long time, for more than 70 years. Penoplex differs from traditional boards by its production technology, which uses extrusion. Blowing agents are initially added to the polymer to ensure an even distribution of cavities throughout the mass. As a result, after extrusion, a structure with closed microscopic cells is formed, the size of which does not exceed 0.2 mm.

The main qualities of the slabs are as follows:

- low density;

- light weight;

- well-pronounced ability to retain heat;

- minimal tendency to absorb moisture.

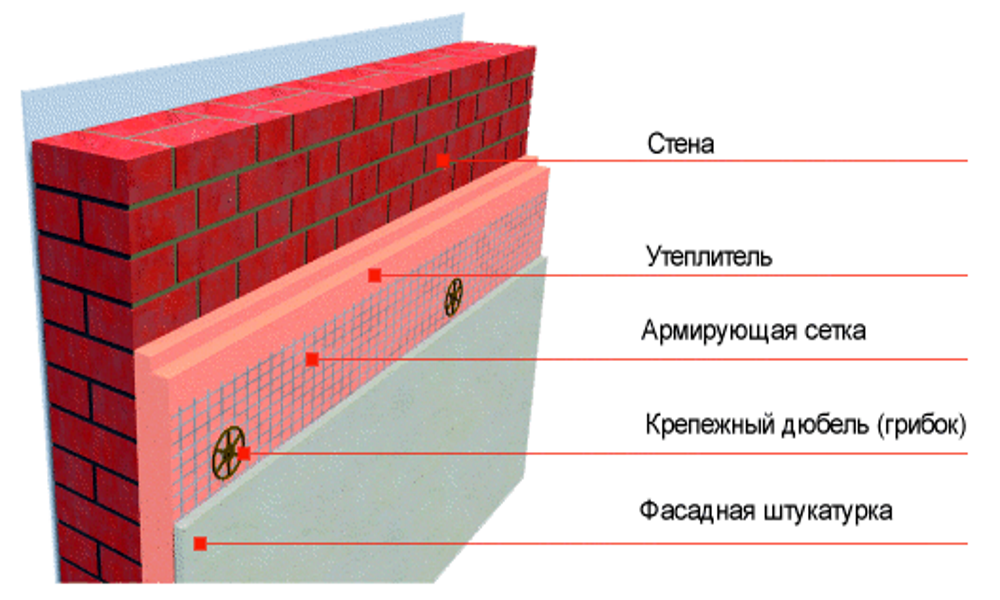

With all its advantages, the material requires increased attention due to its high flammability and poor vapor permeability. It is necessary to use penoplex correctly, taking into account the obligation to ensure good ventilation of the walls and the need for especially strict adherence to fire safety rules. To protect against external influences, plaster is applied to the penoplex.

How to glue the penoplex together?

The modern construction market offers its consumers penoplex of various thickness, density and stiffness. It is these characteristics that are taken into account primarily when attaching the material to the surface, namely when choosing an adhesive composition.

But besides the fact that polystyrene foam needs to be fixed to the walls, it may be necessary to glue parts of the material together. Penoplex sheets stick together easily and with almost any kind of glue. An important point in this process is the absence of acetone or gasoline in the adhesive composition.

-

Surface preparation. The process of surface preparation for applying foam on them involves, first of all, cleaning them from dust and other various contaminants. The remaining finishing materials should also be removed from the prepared surface. If the coatings are of a varnish-and-paint nature, then this is removed without the use of any construction tools, that is, with your own hands. If there is fungus or other mold lesions on the prepared surface, then they should also be removed. For these purposes, it is recommended to use special formulations. After the surface is cleaned, the coating should be impregnated with a special sanitizing agent with bactericidal properties.

If the surface to be prepared has irregularities, be sure to smooth them out. This can be done using a primer. -

Bonding to the wall. Gluing foam to the wall begins with applying glue to the slab along the perimeter and center. In the process of applying glue to the board, you can level them at the same time. This can be done by rotating the plate vertically and horizontally. In this case, it is worth pressing a little on the base. The correctness of the installation of the plates is checked by the building level.

And if there is excess glue, then it must be removed from the joint seams. If, when installing such plates, gaps are formed between them, then they should be filled with pieces of material, but the use of polyurethane foam is undesirable.

The order of installation of the plates is carried out according to the checkerboard principle, from top to bottom.

Consider several options for installing a penoplex:

1) Thermal insulation of walls with foam inside the room. The glue dries completely after three days, then the sheathing work can be continued. Penoplex is fastened with dowels with large caps. By means of such a dowel, two adjacent plates are connected, which are located vertically. Dowels are used on four sides, as well as in the middle of the material. 2) Sheathing of the building from the outside. This technology is considered the most common. Thermal insulation works are carried out at the time of the construction of the house, and such sheathing does not affect the usable area in any way. External thermal insulation can be carried out by ventilated or plaster facades.

In the first case, the facades allow to show design solutions.And plaster facades have less efficiency of steam penetration. When working outdoors with penoplex, it is recommended to lay it tightly enough, avoiding the formation of large gaps between the plates.

Varieties of adhesives

The choice of glue used to fix the foam, mainly depends on the type of surface on which the insulation is attached.

Mineral

Mineral compositions are characterized by the following features:

- increased adhesion (degree of fixation);

- plastic;

- suitable for concrete surfaces and bricks;

- increased moisture resistance and frost resistance.

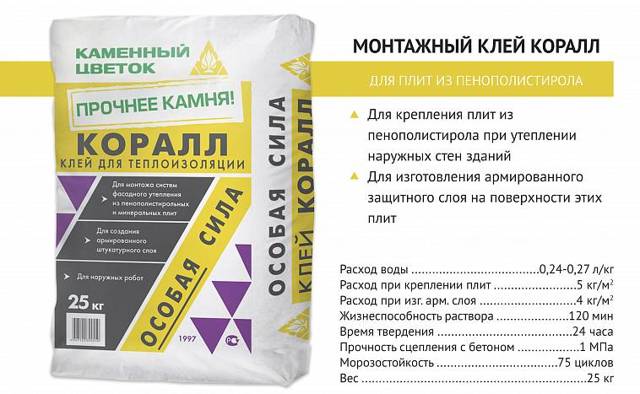

Mineral glue is produced in the form of a dry mixture, which is diluted in water to a homogeneous structure. Such formulations are applied to surfaces using a notched float.

Polyurethane

Polyurethane adhesives are available in easy-to-apply gun packaging. This composition is characterized by increased adhesion: the penoplex sets after 30-60 seconds after being pressed to the surface.

Polymeric

Polymer, like polyurethane, adhesives are suitable for interior wall decoration. This type of material is suitable for fixing foam on any surface.

Waterproofing

Waterproofing adhesives differ in composition. For penoplex, it is recommended to take those materials that do not contain aggressive components: solvents, oil products and others.

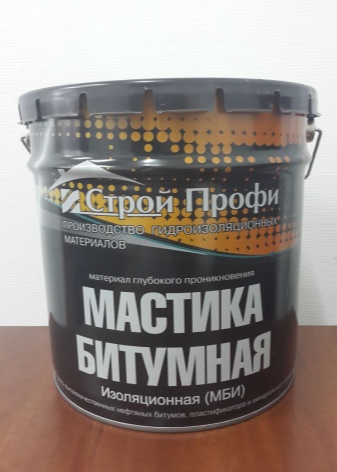

Bituminous mastic

The main feature of bituminous mastic is that this composition retains its original properties at negative temperatures. This material is used both for fixing the foam and for sealing the joints between the sheets.

Liquid Nails

Compared to other adhesives, liquid nails are expensive. This material has a high degree of adhesion and is available in an easy-to-apply package. If you plan to install foam on external walls, then it is recommended to purchase liquid nails that can withstand sub-zero temperatures.

Acrylic

Acrylic adhesives are universal adhesives. That is, such compositions are used to fix the foam on the inner and outer walls. Also, acrylic provides additional waterproofing. But these mixtures cost more than two thousand rubles.

Foam adhesive: quick installation

Foam glue allows you to insulate smooth stone surfaces very quickly. Thanks to the high adhesion of the adhesive, the smooth slabs adhere perfectly to flat concrete surfaces without subsequent displacement. The application technology is as follows. Foam adhesive is applied around the perimeter and in the middle of the board along the long side with a foam gun. With glue-filled grooves, the board is pressed down for 30 seconds. The setting time of the adhesive foam is on average 20 minutes. Further work with penoplex, installation on dowels and grouting is possible after 2 hours.

Further work with penoplex, installation on dowels and grouting is possible after 2 hours.

What do you need to glue penoplex?

When choosing one or another adhesive for fastening, it is necessary to take into account the composition and chemical properties of the heat-insulating product.

The most effective adhesives are:

Atlas Stopter K-20. This material has a high level of quality, so it is very often used for gluing boards. The adhesive is used to restore facades. The product is also used for reinforcement. Has a high level of resistance to low temperatures and humidity. Saves a lot of money.

Atlas Stopter K-20

Atlas Stopter K-20

Main article: how and with what to paint polystyrene?

- Atlas Plus. It is a universal adhesive. The main distinguishing features of this product are elasticity, as well as excellent adhesion (adhesion to the surface). You can use the glue on a wet surface.

- Mineral glue.On the construction market, you can find a lot of similar composition, among others "Sarmat" stands out, which has an acceptable price.

- Titan polyurethane adhesive. The mixture copes well with the installation of expanded polystyrene boards. The composition has a fairly high price on the market.

Titanium

Titanium

- Compositions for waterproofing. Popular is the tool of the company "Uniflex", which has become widespread among builders and masters of installation work. One of these materials is bituminous mastic.

- Moment glue. This is a composite compound. It is also often used for working with foam boards.

When choosing an adhesive, it must be borne in mind that it should not contain some components in its composition. These components include benzene, formaldehydes, formalin, gasoline, diesel fuel, and solvents.

When purchasing an adhesive, you need to take into account the stock. The base is not always even, so the expense of funds becomes much higher. Choose a quality product so that you get an excellent fixing of the plates to each other.

We glue penoplex - quickly and conveniently

In order for the work on the insulation of the room to not take a lot of time, you should decide how to glue the penoplex to the wall. This can be either the final version of the fastening (on the floor) or temporary, in order to be able to fix the insulation with traditional means (dowels). In this case, it all depends on what kind of adhesive mixtures are used for penoplex. For example, substances with astringent properties of the world famous brands Ceresit or Knauf or Isofix are capable of providing reliable and durable fixation of insulation boards to any surface.

In order for the work on the insulation of the room to not take a lot of time, you should decide how to glue the penoplex to the wall. This can be either the final version of the fastening (on the floor) or temporary, in order to be able to fix the insulation with traditional means (dowels). In this case, it all depends on what kind of adhesive mixtures are used for penoplex. For example, substances with astringent properties of the world famous brands Ceresit or Knauf or Isofix are capable of providing reliable and durable fixation of insulation boards to any surface.

Based on where it is planned to carry out the insulation - it is chosen how to glue the penoplex. Warmglue for penoplex - allows not only to securely fix the insulation plates, but also to glue the ceramic tiles on the penoplex. This is facilitated by the rough surface of the insulation, which ensures better adhesion of the adhesive mixture to the surface. In this case, a prerequisite is the reinforcement of the insulation with a mounting mesh before fixing the facing tiles on it.

Relevance of the question: "How to glue the penoplex?" is explained by the desire of the buyer to quickly and efficiently perform insulation work without hiring installers for these purposes. After all, a number of works are quite capable of doing yourself. Moreover, the process of fixing the insulation plates by mechanical fastening means violates the insulating layer of the insulation used. The metal mount, being an excellent conductor of heat, creates a "cold bridge", which can reduce the level of thermal protection of the room. Therefore, mounting glue for penoplex is needed, as an excellent alternative to the noise of a drill, dust that appears when drilling walls.

Penoplex fastening methods

This issue is important, since the durability of the structure depends on the quality of the glue and all materials.

Before proceeding with the installation, it is important to decide how the work will be performed and what glue is needed in a particular case.

Methods for fixing the material

Correct fixation of the foam on the working surface of the wall is important for the further use of the room and for the implementation of other construction and finishing works.

Such fixation is of two types:

- mechanical;

- physical.

In the case of mechanical installation of the surface, a punch and other devices are assumed. In the process of work, dowels are driven into the holes in the wall, which are subsequently fixed with steel pins. The work is very laborious and not the most reliable, as it seems at first glance. In addition, a lot of fastening material will be required, which will increase the cost of installing the foam. From the point of view of material costs, it is much more profitable to glue the material.

The physical method involves gluing surfaces. Today there are many adhesives, mastics and numerous mixtures with which you can quickly and reliably fix penoplex on the wall surface of any material.

How to cut penoplex?

Each person in the process of working with penoplex could face such a problem as dividing the plates into parts. The easiest way to do this may seem like a simple rift. Despite the fact that this material breaks easily, it is not worth doing this due to the fact that you will never be able to get smooth edges of the material, it makes no sense to talk about dimensional accuracy.

If we talk about the possibilities of cutting material such as penoplex, then I would like to highlight several of the most effective methods:

- Cut with a utility knife or paint knife. The advantage of this method is noiselessness, availability and speed of work. The quality here will depend on how sharp the knife is.

- You can also use an electric jigsaw. The disadvantage of this method is not quite straight edges, but the speed is at a high level. Plus, the jigsaw can handle any material thickness.

- Used when cutting foam and an ordinary kitchen knife. To do this, it is first sharpened well, and then heated. Penoplex is cut with a hot knife. A clear advantage of this method is the complete absence of debris and perfectly straight edges of the cut material.

- For curly cutting, a heated nichrome wire is used. To do this, it is connected to the wires from the 24 V transformer. When the current is applied, the wire heats up, which can be determined by its reddening.

From all of the above, we can conclude that penoplex is not only a material with excellent thermal insulation properties, but also a material that is easy to use, and its installation does not require professional knowledge or skills.

The use of this material in the process of wall insulation allows you to achieve maximum results in solving issues of heat conservation. Such high rates are achieved due to such properties as minimal water absorption, high material strength and low thermal conductivity.

- Sizes of sheets of penoplex

- Comparison of penoplex with other materials

- Penoplex plaster

- Wall insulation with foam

- Insulation of the loggia with penoplex

Types of adhesives

All adhesives for penoplex on the market have a high level of adhesion. Thanks to this, there is a reliable adhesion of the composition to the surface, thereby hardening the finish and increasing its quality.

As a rule, adhesives come with instructions for use and a brief description of the technical characteristics, which include:

- temperature parameters for installation and further operation;

- air humidity indicators;

- what type of surface is this material intended for;

- type of surface to be insulated.

The range of adhesives for penoplex is divided into several types.

Bituminous mastic

This material is a thick bitumen-based mixture that retains its original properties even at sub-zero temperatures. Bituminous adhesives are widely used in construction, in particular, for waterproofing foundations. In addition to its direct purpose, it is an excellent hydrophobic joint filler during the installation of foam.

It is preferable to work with a spatula or a spatula.

Liquid Nails

This material is suitable for working with any surface. However, the work should take into account the peculiarity of the place where the repair work will be carried out. For installation inside a building, conventional compounds are used, but for external insulation, specialized means are used that are resistant to frost and temperature extremes.

On sale the composition is presented in tubes.It is best to apply to the base with a "snake" over the entire surface of the sheet. For gluing the foam to the surface, just 10-20 seconds is enough - "liquid nails" have time to grab during this time.

The only negative is the rather high price of the material.

Mineral

Mineral adhesives are presented in the form of dry mixes and are diluted with water to the desired consistency before use. They are distinguished by high adhesion and combine well with concrete, brick and gas silicate surfaces. Their advantage is their high plasticity, which allows the material to be applied in a thin layer.

Apply with a notched trowel. After drying, they do not "shrink", retaining their volume.

For outdoor work, there are special moisture and frost-resistant compounds.

Polyurethane

Such adhesives are produced in special metal cylinders and can only be used with the help of special equipment - a gun for polyurethane foam. When applied correctly, the material will lay flat on the substrate in even zigzags, allowing a bond to be achieved over the entire surface area.

Such compositions are distinguished by quick setting - it is enough to hold for half a minute, and the material will be firmly glued. But at the same time, the elasticity of the material remains for about 15 minutes.

Types of glue

Penoplex glue is the consumable that should be purchased with special attention, since the quality of the work performed depends on its composition.

ATLAS PLUS is also highly praised by professionals. The indisputable advantages of the glue are its increased elasticity and adhesion. It is very convenient that this product can be glued even in damp rooms, where the walls are not dry. These are complex surfaces that this type of glue can be easily applied to.

The main representative of mineral adhesives is "Sarmat". A fairly universal tool, the advantage of which is its low cost.

Among polyurethane mixtures, Titan is often purchased, however, its cost is much higher.

It is also possible to perform work on gluing penoplex with "Moment". This versatile tool has proven itself quite well among consumers. Glue "Moment" is able to glue quickly and efficiently.

When choosing an adhesive, it is important to understand that its composition should not contain substances hazardous to health such as benzene, formaldehydes, solvents. Working with such mixtures can be very dangerous.

In addition, when buying, it is best to choose a tube of a larger size, since the surface of the foam is often uneven, which leads to increased use of the material and mixture for gluing.

Waterproofing compounds

This group of materials that will glue the penoplex include adhesives on bitumen, acrylic, rubber, they are produced in the form of mastics. Simple ones cannot be bought, they corrode the material, like waterproofing agents with petroleum products. The best thing that can be used to glue penoplex is Bitumast XPS. The mastic does not include solvents, sets in 2 days, has a high pull-off force - 500 kPA.

Acrylic adhesives will easily attach penoplex to wood, concrete, brick, connect penoplex with penoplex, glue penofol with penoplex. They are suitable for indoor and outdoor use and have a very low consumption. Bituminous mastics have the most pronounced waterproofing properties and are resistant to low temperatures.

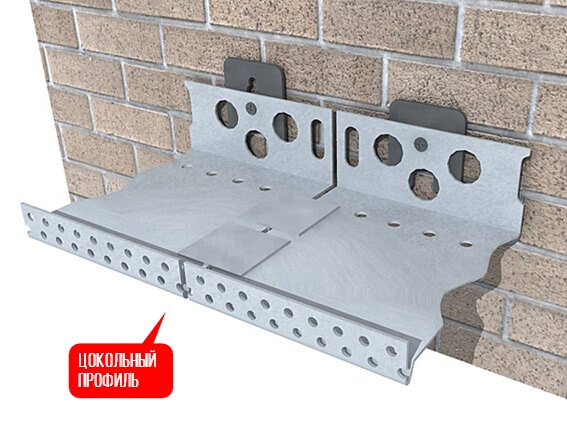

General installation rules

Correctly fixing the penoplex is very important to obtain a high-quality layer of thermal insulation. First of all, you need to secure the starting bar.

It can be made independently (we use a wooden beam), or it can be prefabricated from perforated metal. In the second case, it is better to purchase a bar in accordance with the width of the insulation, complete with the required number of corners (the corner can be external or internal).

Plank installation is carried out as follows. A horizontal line is bounced along the perimeter of the building. It is better to use dowels for fastening the "start"

Its use will prevent the insulation from sliding down and observe the “geometry” of laying the insulation, which is especially important when doing work with your own hands.

The side of the penoplex to which the adhesive will be applied must be rolled with a needle roller to create a roughness. It is necessary to mount the slabs from the bottom upwards with an offset of half the slabs of each horizontal row.

The side of the penoplex to which the adhesive will be applied must be rolled with a needle roller to create a roughness.

During installation, the plates are pressed against each other as tightly as possible. For a stronger and "warmer" connection, the second row is inserted into the grooves of the first. In order to save the adhesive composition, it is possible to seal the joints with polyurethane foam at the end of the installation.

How to glue at home

The general procedure for gluing foam sheets is as follows:

- The working surface is cleaned of paint and other materials, and then degreased.

- A primer is applied to the walls, which will prevent the formation of fungus.

- The glue is prepared according to the attached instructions. Then the material is applied with a layer of 2-3 millimeters on the surface to be treated and the foam sheet.

- Penoplex sheets are stacked. If the installation is carried out on the walls, then you need to press it from the bottom up; if on the floor or ceiling - from left to right.

Penoplex sheets must be leveled immediately after being applied to the wall, without waiting for the glue to dry.

The ways

Penoplex sheets can be glued using a point, solid or boundary method.

Point

The point method involves applying dense drops of glue to the wall material at a distance of 30 centimeters. If a liquid composition is used, then the latter is leveled with a spatula. The result should be strips 100 millimeters wide.

Solid

To glue the sheets of foam in this way, it is necessary to apply the material with L-shaped stripes in the corners and two in the center.

Borderline

This option is suitable for those cases when you need to fix the sheets on the outside of the walls. According to this method, the glue is applied along the perimeter in a continuous strip, with an indent from the edge by 3-4 centimeters.

Consumption

The consumption of glue is indicated on the package. The most economical in this regard are materials produced in cylinders (polyurethane, liquid nails). In this case, one package is enough to glue 10 square meters of sheets.

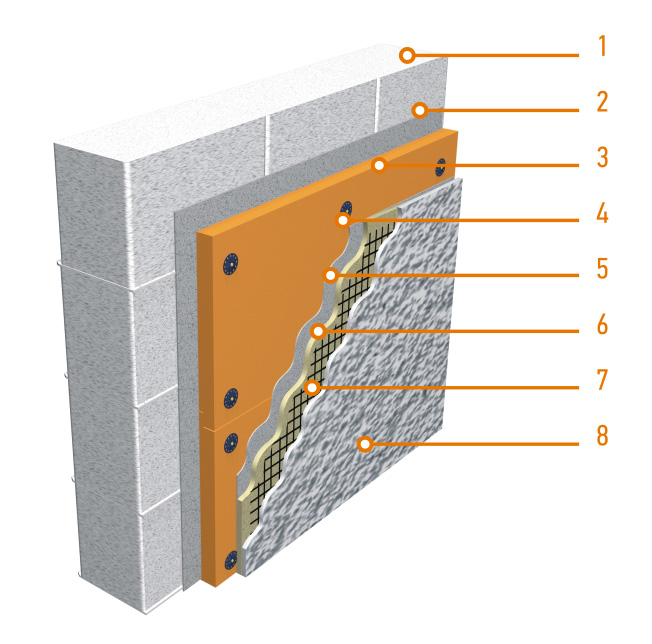

Puttying

The putty is applied in two even layers after the glue has dried. The thickness of the first does not exceed one centimeter. Then a reinforcing metal or plastic mesh is fixed on the penoplex. After that, a second (if necessary, third) layer of lesser thickness is applied.

Outdoor protection

If foam sheets are attached outside, then for this case it is recommended to buy specialized adhesives: Giprok, Cerezit, Polimin or Master. The first option is considered the most preferable, since this material is characterized by increased resistance to external factors.

After the glue under the insulation has dried, finishing materials made of wood, stone or OSB can be applied to the penoplex. Also, ceramic tiles are often attached to the sheets. In this case, 2 layers of plaster with a reinforcing mesh must be applied. Finishing materials are attached with tile glue.

Houses are different, and they need to be insulated in different ways.

The use of various technologies and materials in construction leads to the fact that it is impossible to give a universal answer to the question: what should be taken into account when fixing the foam to the walls of the house? Methods of fastening and surface preparation have been developed for different surfaces and operating conditions. You need to know this in order to control those who carry out the insulation of the house.And even more so for those who insulate the house with their own hands, using their potential.

Methods of fastening and surface preparation have been developed for different surfaces and operating conditions.

Homes can be made from stone and wood building materials. Already at the stage of surface preparation, the features in the work begin to appear.

When preparing concrete and brick surfaces, it is necessary:

- clean the walls from dirt, layers, paint, fuels and lubricants, and then remove dust;

- treat with copper sulfate (antiseptics) the places where the fungus is spread;

- remove efflorescence on brick;

- to clear and repair cracks in the insulated wall;

- apply a deep penetration primer;

- smooth out irregularities with putty;

- apply a deep penetration primer after filling.

Preparing a tree is much easier. It is treated with impregnations that prevent wood decay. Wall material such as oriented strand board or thermowood can be omitted. Then the base is equipped with impregnated timber, which provides ventilation of the facade.

How to choose for different surfaces?

The choice of the optimal adhesive depends on the type of surface.

Dry compounds are suitable for outdoor insulation. Adheres well to stone and brick substrates, as well as plaster

When choosing dry mixes, you should pay attention to the release date and the integrity of the package - it must be hermetically sealed. Otherwise, the quality of the composition may suffer.

Polymer and bitumen mixtures are used in waterproofing works.

There are special polyurethane adhesives for reinforced concrete surfaces

And also such compositions can be used for wood bases.

For metal work, liquid nails, silicone sealants, and polyurethane foam are suitable.

Liquid nails are used when laying foam on plywood, corrugated board, plastic.

If you plan to install thermal insulation on the walls and ceiling, then it is better to use polymer mixtures. Mineral adhesives are intended for outdoor use, but for indoor use it is better to choose polyurethane. The latter are especially effective for arranging floor insulation.

If the work is planned to be carried out on a dry surface, then high-quality gluing is given by compositions based on gypsum and cement. The only drawback is that almost immediately after mixing, they begin to harden, so the work must be carried out quickly. This creates some inconvenience in the work. Therefore, it is better to knead the composition in small portions.

The speed of drying of the glue creates certain conditions during internal work. In addition, almost all adhesives for penoplex have an unpleasant odor, which is difficult to erode later.

There is a universal composition suitable for almost any surface - glue-foam. Suitable for interior and facade work, floor and ceiling insulation. For a strong "setting" of the material with the base will be enough only 15 minutes, and you can work even at sub-zero temperatures.

Penoplex: wall mounting technology

It is not so important where the insulation is made - from the outside of the house, or in the interior. In any case, the surface to be insulated must be flat.

Its quality is checked with a level and a plumb line, if necessary, the surface is plastered.

When finishing a newly built building from the outside, it is necessary to prime the walls with a primer containing quartz sand. Such processing will significantly improve the ability of the glue to connect the insulation to the base.

For the same purpose, old walls should be thoroughly cleaned of dirt, traces of the old coating. Before starting the installation, it is necessary to treat the surfaces with antifungal agents.

If the wall of the building is not too flat, then the best way to level it is to completely plaster the entire surface to be insulated.The technology of insulating the walls of the building with penoplex fully corresponds to the conduct of such work using foam. A detailed description can be found in the article "Technology of insulation of building facades with foam: recommendations of experts."

First of all, the surface of the foam sheets is prepared. The surface to which the glue will be applied must be rough. To roughen the surface, it can be wiped with sandpaper, or rolled with a special toothed roller.

There is no need to completely cover the foam boards with glue, but the adhesive composition must cover at least 50% of their surface.

Usually, the glue is applied in strips with a step of about 30 cm. The insulation sheets are laid from the bottom up. In each row, bandages are made similar to brickwork. Each joint of the top row should be located in the middle of the slab in the previous row.

Important! If there are metal elements on the surface to be insulated, they must be coated with an anti-corrosion primer before installing the foam!

Do-it-yourself Penoplex installation technology on the wall, look at the video:

Cover decoration

After grouting, the plastering of the foam is easy and relatively fast. To decorate the coating, you can use a sponge with large pores or a special float.

There are ready-made decorative plaster compositions that create an unusual texture for the outer surface.

Bark beetle plaster, in addition to the usual basic components, contains white powder and small stones with a diameter of up to 2.5 mm. With certain skills, the master can make different patterns from the same mixture, directing the movements of the spatula in a certain way. Thus, the work of the plasterer turns into the work of the decorator.

If the mixture contains larger pebbles, with sizes up to 4 mm, the relief is completely different. Granules are crumbs made from natural raw materials: granite, marble. Pebble plaster gives the facade an unusual, beautiful look, provides shine in the rays of sunlight. On sale are white cement plaster mixes with additions of large granules of quartz, dolomite, marble. For some unknown reason, she was called a lamb. Perhaps, to someone, the view of the facade reminded the wool of lambs.

An interesting version of the decor created by mosaic plaster based on polymer acrylic interspersed with natural colored chips.

Penoplex is a high-quality insulation, the initial installation of which requires an investment of money. The costs will quickly pay off thanks to the savings in space heating costs. At any time they will be protected from bad weather. Aesthetic considerations are complemented by practical considerations about the appropriateness of using penoplex. Using decorative mixtures, painting surfaces, you can create a unique look for every home.