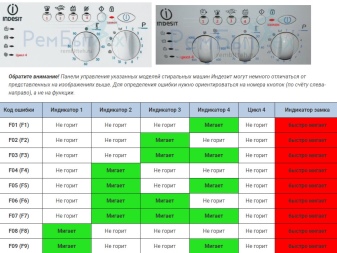

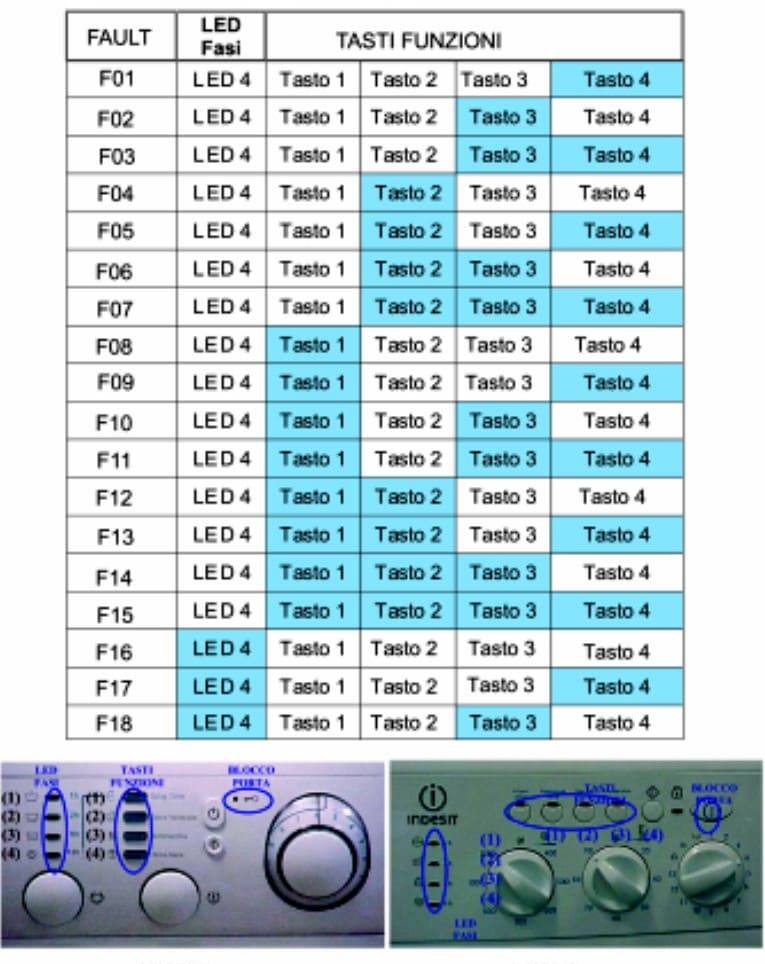

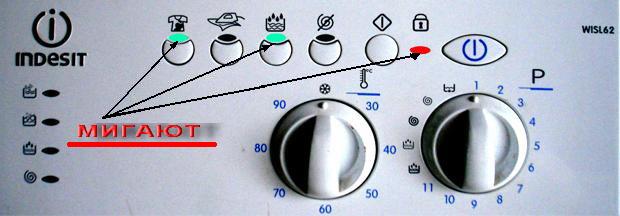

Determine codes for: WIU, WIN, WISN, WIUN

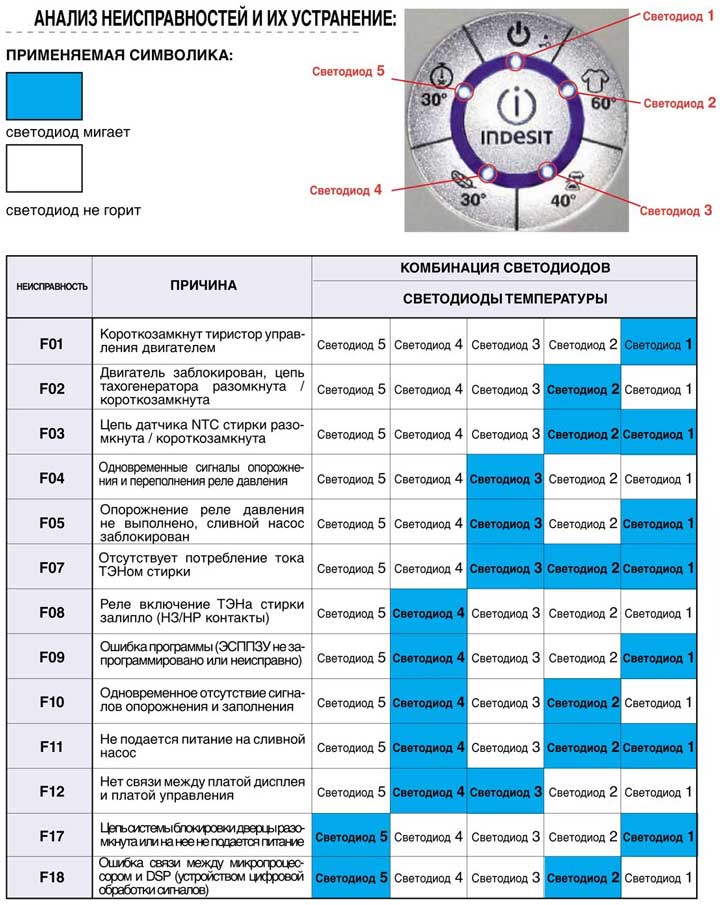

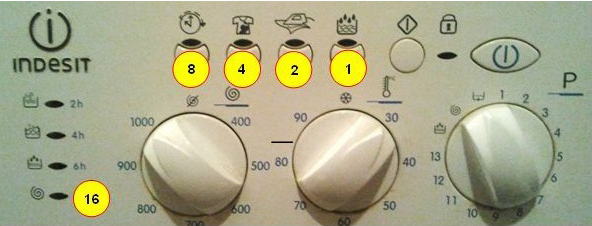

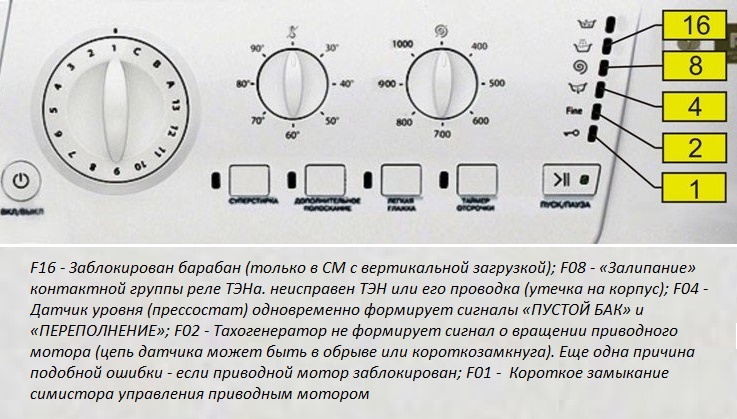

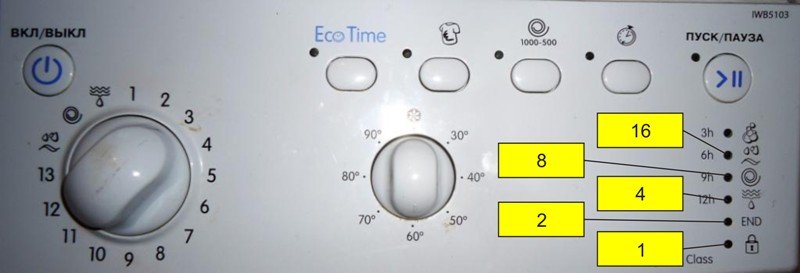

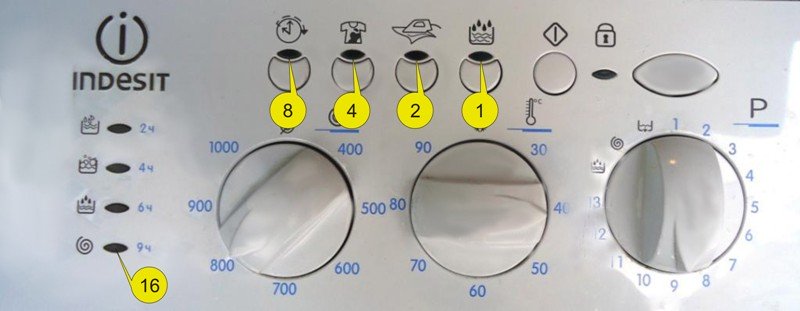

As for these models, here the indicator of the buttons for additional functions and the device for locking the hatch will also notify about the error. The lock indication for any of the malfunctions will quickly blink red. Here is a complete list of the breakdown symbols programmed into the intelligence, and the corresponding blinking indicator numbers:

- F01 (F1) -1;

- F02 (F2) - 2;

- F03 (F3) - 1 and 2;

- F04 (F4) - 3;

- F05 (F5) - 1 and 3;

- F06 (F6) - 2 and 3;

- F07 (F7) - 1, 2, 3;

- F08 (F8) - 4;

- F09 (F9) - 1 and 4;

- F10 - 2 and 4;

- F11 - 1, 2 and 4;

- F12 - 3 and 4;

- F13 - 1, 3 and 4;

- F14 -2, 3, 4;

- F15 - 1, 2, 3 and 4;

- F16 - indicator 5 is blinking;

- F17 - 1 and 5;

- F18 - 2, 5.

So, having calculated the combination of flashing lights, it is easy to determine the front of the upcoming repair work. Having learned the source of the malfunction, you can find a solution to the problem and return the washing machine to its previous performance.

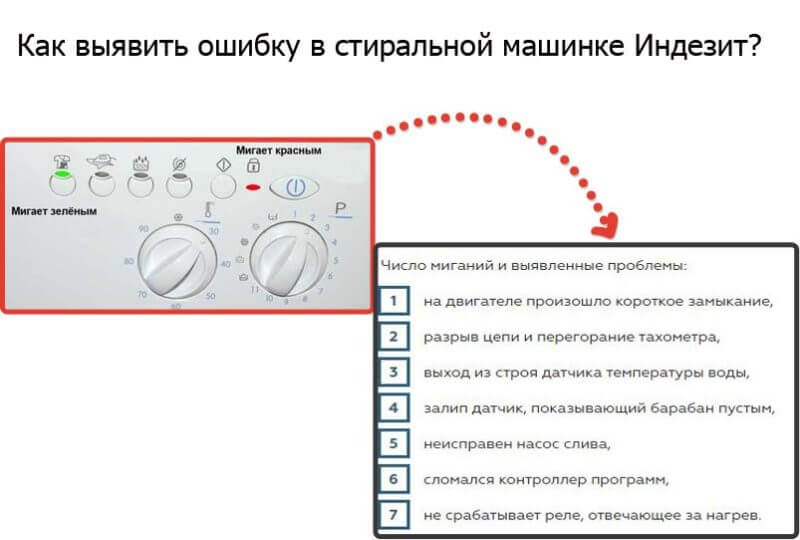

How to determine the breakdown code?

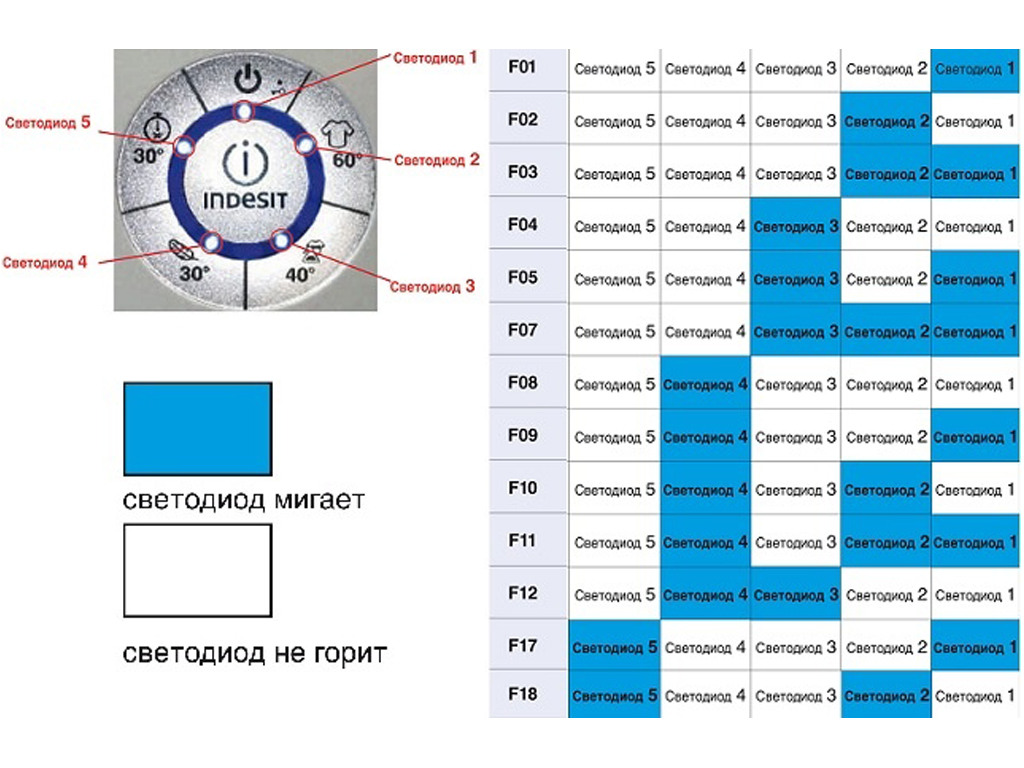

In order to understand exactly what kind of malfunction has occurred, it is necessary to decipher the combinations of flashing lights that mean error codes.

To find out the error code, you need to find out the code using the table on errors of burning lamps.

In certain Indesit models, the blinking lights for the program cycle phases and the door lock light are responsible for the error. When an error occurs, the option lights and the power indicator are usually on.

The oldest models with several indicators (on / off and door lock) signal a malfunction by an error in the selection of programs and a flashing on / off LED.

The error code in the Indesit washing machine is not displayed for every malfunction. With hidden breakdowns:

- the control panel is off;

- not all indicators on the unit are on at the same time.

A disconnected control panel usually signals a problem with the power supply to the washing machine. All blinking indicators indicate a breakdown of the switching power supply of the unit control board.

We fix the problem ourselves

There are some generally accepted rules to help you deal with the problem. They use them in certain situations:

- The hatch did not close tightly - it is necessary to check, most likely, when closing, you did not apply the necessary force, or some thing got between the door and the rubber seal that interferes with the closure. We recommend that you perform the action again, you should hear a characteristic click.

- The voltage has dropped in the network - check. If there is no 200 volts in the network, the door lock does not work. But the problem can be solved - a relay is installed that controls the voltage.

- The door latch hole in the lock is clogged - make sure everything is in order.

- The hinge fasteners of the door are loose - from this the tongue does not always fall into the lock, the hatch may not close. We'll have to tighten the fasteners.

- There was a failure of the control or display unit - when the error appears for the first time, just unplug the machine from the socket, wait ten minutes, and turn on the device again. The unit will reboot, it is quite possible that the error will disappear.

- Bad contact - it is necessary to check the area from the hatch blocker to the block responsible for general control. It happens that the vibration of the CM during operation caused the contact connections to "come off".

If your actions were unsuccessful, then the machine has received a serious breakdown and needs professional repair.

Meaning of codes and causes of malfunctions

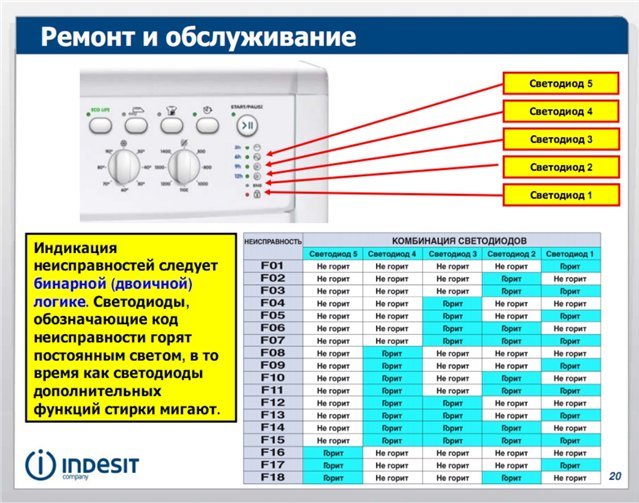

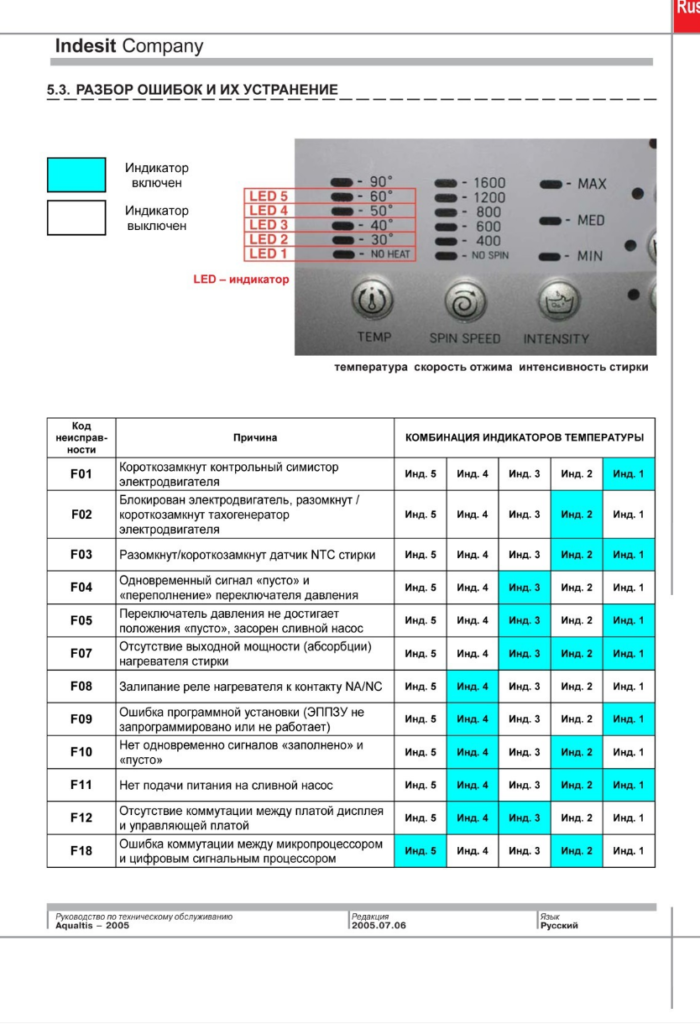

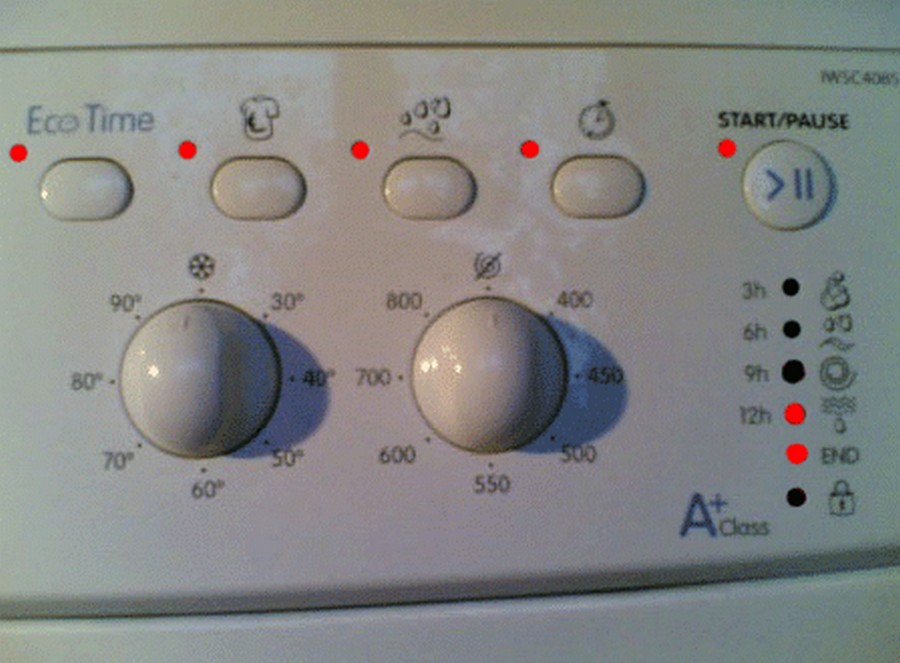

When the device is in working order, the lamps on the module light up in a certain sequence in accordance with the execution of the selected program. If you find that the device does not start, and the lamps light up inappropriately and blink at frequent intervals, then this is a breakdown alert. How the CMA reports the error code depends on the model line, since the combinations of indicators differ in different models.

- Units of the IWUB, IWSB, IWSC, IWDC line without a screen and analogs report a malfunction with luminous lamps for blocking the loading door, spinning, draining, rinsing.The network indicator and the upper auxiliary indicators blink at the same time.

- Models of the WISN, WI, W, WT series are the very first models without a display with 2 indicators (on / off and locking of the loading door). The number of times the power light blinks corresponds to the error number. In this case, the "door lock" indicator is constantly on.

- Models Indesit WISL, WIUL, WIL, WITP, WIDL without display. The breakdown is recognized by the burning of the upper lamps of the additional functions in conjunction with the "Spin" button, in parallel, the door lock icon flickers quickly.

It remains only to determine by the signaling lamps which part of the unit is inoperative. The error codes reported by the system self-diagnostics will help us with this. Let's look at the codes in more detail.

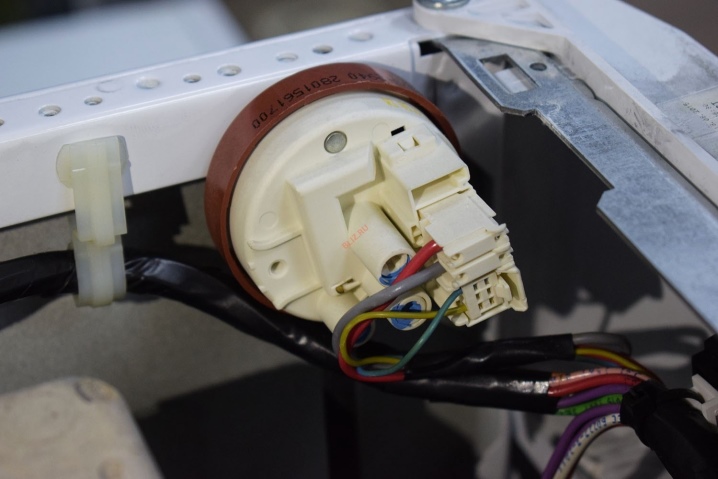

F01 - malfunctions with the electric motor. In this situation, there may be several options that indicate damage: the "Door Lock" and "Extra Rinse" buttons are lit simultaneously, "Spin" blinks, only the "Quick wash" indicator is active.

Clogged water supply system

If there is water in the system, the pressure is sufficient, the tap is open, but the H20 error does not disappear, and water does not flow into the Indesit washing equipment tank, it is worth checking the inlet hose and the intake filter mesh. To do this, do the following:

- turn off the Indesit machine, turn off the water supply;

- unscrew the hose, rinse it thoroughly;

- remove and wash the filter mesh.

In addition, you should inspect the hose for kinks, it often happens that trying to rationally use the modest space of the bathroom, the Indesit machine is pressed against the wall. This can be the cause of error H20, because the hose is kinked, thereby creating an obstacle to the free flow of water. If there is a kink, the hose will most likely need to be replaced.

How to start a repair

When an F01 error appears, the first step is to verify that the electrical outlets are working. After making sure that everything is in order with the network, you can proceed to further steps.

It should be noted that a failure and the occurrence of an F01 error does not necessarily indicate a malfunction. In some cases, there may be a coincidence of circumstances. In order to check this, you need to turn off the washing machine, unplug the power cord, wait about twenty minutes and turn on the Indesit machine again. There is a chance that everything will work fine.

Suppose that the failure that caused the F01 error could not be corrected by simple means.

Here's how to fix error F01 in this case:

- It is necessary to carefully examine the outlet and cord of the Indesit washing machine.

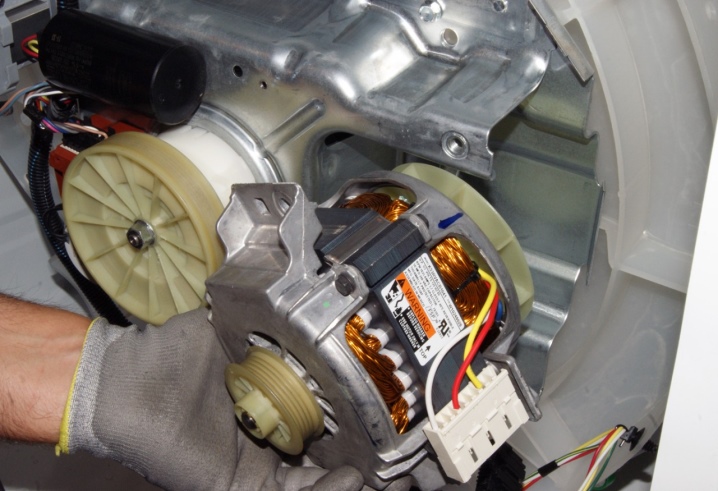

- Next, proceed to direct inspection of the washing equipment engine.

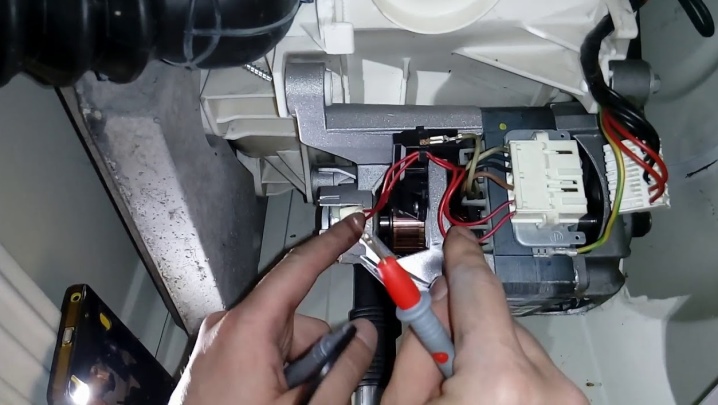

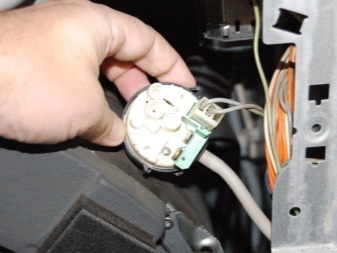

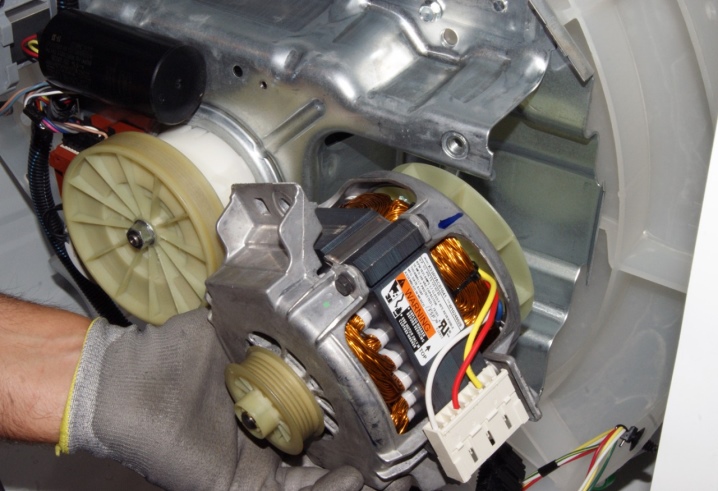

- The service hatch is opened first. The Indesit washing appliance motor is disconnected using an 8 mm wrench.

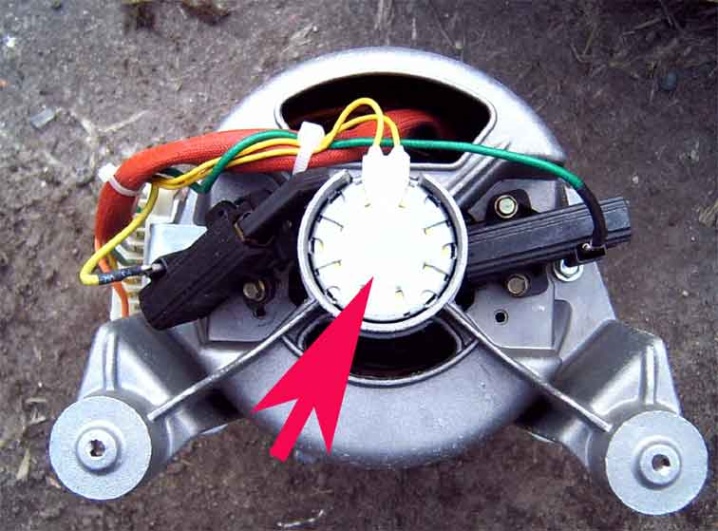

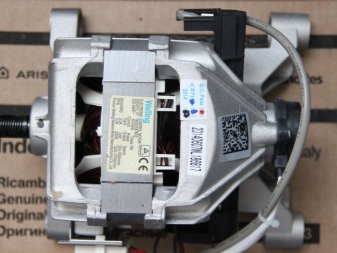

- Next, to correct error F01, you need to remove the engine and inspect its brushes. To do this, unscrew it with a screwdriver. Then it is necessary to inspect for possible damage or wear. If problems are found, it is recommended that these parts be replaced.

- After replacement, everything is installed back.

Then the Indesit was turned on to see how it worked. Occasionally, a clearly audible crackling sound is heard, which means there is no cause for concern. This noise is due to the grinding in of the brushes.

If the problem that caused the F01 error is not related to the operation of the brushes, the inspection of the motor of the Indesit machine must be continued:

Now you need to pay attention to the control module. Considering the board, you need to determine if there are traces of corrosion here.

If they are found, they will need to be carefully cleaned.

The motor winding is now inspected. If it burns out, then the motor cannot be repaired - it will have to be changed. This is a rather expensive operation. If it is not financially feasible to do this, it is more profitable to buy a new, more modern model of the car.

One of the possible causes of the F01 error is a malfunction of the control module. If all other reasons are excluded, you will need to pay attention to this node. You cannot repair it yourself. This should be done by specialists who use the appropriate equipment.

One of the breakdown options is a situation when the drum suddenly stops during operation. In this case, the washing machine indicates the error code F01.

In this case, it is recommended to take the following actions:

- When error F01 appears, the first step is to shut down the Indesit machine.

- Now you need to carefully drain the water from the tank of your Indesit washing machine.

- After there is no water left, you must try to rotate it with your hands.

- If it moves normally, the cause of the F01 error is probably too much laundry to be washed. Now you need to divide the amount in half and try to wash half of the original amount.

- If these attempts are unsuccessful, you need to inspect the motor of the Indesit machine.

- Perhaps the F01 error appeared due to the fact that the motor pulley broke. Over time, it can wear out and weaken. In addition, it may not have been damaged, but simply slipped off. In the latter case, it is enough just to carefully install it in place.

- In the event of a malfunction of the electronic control board, the motor of the Indesit device may simply not receive a start signal. In some cases, you can fix it yourself. To do this, it makes sense to try to reset the programs. If this does not help, then with such a malfunction you will have to contact the workshop.

- If the brushes are worn out or damaged, they will need to be replaced.

- Power surges can damage the motor of the Indesit machine and cause error F01. What to do in this case? It will not be possible to carry out repairs on your own. Only a master can fix this problem.

Door error in washing machines of various firms

Let's consider more specific actions for SM from leading manufacturers.

Indesite

You can often hear complaints about the models of this company, as if they often break. We will not argue about the quality of the product, but we will deal with the door error code - as the most common problem.

The peculiarity is that the lock located inside the door is poorly thought out. The axle holding the spring hook pops out from time to time. From this, the hook cannot fix the hatch in the “closed” position. If this happens, do not get angry and hammer the door. Just follow a few simple manipulations:

- disconnect the machine from the electrical network;

- we remove the water in the washing machine using the garbage filter;

- unscrew the fasteners, remove the door;

- unscrew the self-tapping screws that fix the parts of the hatch together;

- we insert the axis into the place intended for it;

- in the reverse order we carry out the assembly.

If everything is fine with the mechanism, but the hatch does not close, you should check the sunroof control unit, module, etc.

Atlant

Such machines have not only mechanical latches, but are also blocked by an electronic device. It works from impulses - the plates in the device expand, press the lever. Sometimes they wear out and the device needs to be replaced. But first, it is recommended to check using a multimeter.

We also examine the opening of the lock, remove the debris that has accumulated there. We check the wiring connecting the lock and the control unit. It is likely that this is where the problem lies.

The final stage is to check the module for the resistance indicator of the board. It may need to be repaired or replaced entirely.

There are other mechanical problems as well. To eliminate them, we check certain places:

- we inspect the position of the hinges - the hatch could be skewed due to poor installation or prolonged operation. In these cases, the latch will not reach the lock.We check the evenness of the installation, tighten the hinges to return the door to its normal position;

- check the handle - if the element is broken, remove the door and replace the element;

- retainer - it may move due to the fact that the retaining pin falls out. To fix the problem, the lock mechanism will have to be disassembled;

- the guide element made of plastic is worn out - when the characteristic click of the lock closing is not heard, the guide should be replaced.

Ariston

It should be noted here that the actions with Atlant and Indesite are relevant for this brand as well. But there are still some peculiarities. In the Ariston machine, this signal has nothing to do with the door lock. A similar error can manifest itself from poor contacts on the brushes of the electric motor.

In this case, you should get to the motor, unscrew its fasteners, disconnect the chip with the wiring. Having removed the motor, we check the integrity of the brushes, inspect the wires supplying them. Perhaps the brushes are worn out from prolonged use and need to be replaced.

Samsung

On washing machines of this company, not only such an error signals problematic issues with the door. Signals de, Ed, de 1, de 2 may appear.

The problems are related to such features:

- the hatch is not blocked from the very beginning;

- the door does not open after the end of the wash;

- first, the blocking is triggered, then it disappears. The machine "freezes", gives the appropriate signal;

- the door tongue did not hit the lock;

- the signal can appear and disappear several times during the wash, from five to seven times.

What should be done in such cases? Let's analyze the simplest option, when the hatch closed and a click was heard, but the machine signals a problem. In this case, it is necessary to check and, if necessary, repair the locking device.

And if the door does not open after the washing process, the problem should also be looked for in this place. But first it is recommended to wait ten minutes. The bollard may open automatically.

The error can also be caused by mechanical problems. If the hook just did not hit the lock, you should make sure that the hinges that hold the hatch are properly fastened. They get loose quite often and need a complete replacement. By the way, it is best to install a new "reinforced" analogue made of a special alloy. We guarantee that there will be no more such problems.

It is bad if the signal appears and disappears by itself. The problem will have to be looked for in the contact group or wiring, and this is already a task for an experienced craftsman.

The simplest ways to fix

What to do if the washing program that you are constantly running is out of order? Firstly, do not panic, call the service center right away, invite a technician to repair the equipment, and disassemble the machine yourself.

You can try to return the washing machine to work:

- by rebooting the machine. To begin with, turning off / on is done from the button, if it does not help, you should unplug the power cord from the outlet and leave the device for 15-20 minutes;

- by including a test wash;

- by running the self-diagnosis system of the MCA.

So, the first thing to do is to reboot the hardware. First try turning off the clipper by pressing the power button. Wait 20 seconds, then start the washing machine. Set the required washing mode. It was not possible to set the desired program, unplug the device from the outlet. Here you will have to wait a little more - about 15-20 minutes. In some cases, a banal restart of the washing equipment helps to cope with the failure of the washing mode.

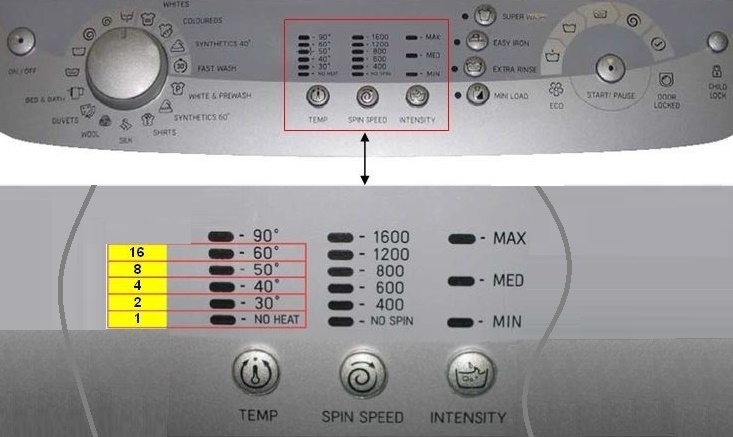

In certain models of Indesit washing machines, test wash modes are programmed. Also, most washers are equipped with a self-diagnosis system for emerging malfunctions. The manufacturer has provided these additions so that users can independently identify the cause of the failure.These programs will be able to solve the problem only in 10% of cases, since, after all, their direct purpose is to indicate a breakdown, and not to eliminate the malfunction. However, finding the cause of the problem will also be useful, this will save you time and tell you in which direction to move on. How do I set up and run a test? To enter the diagnostic mode, you should:

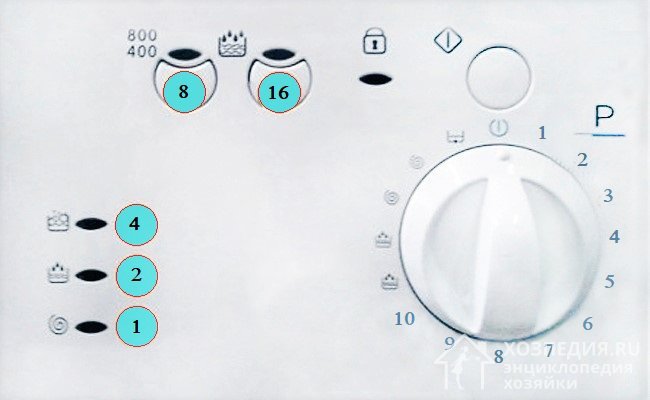

- set the programmer knob to position 1 and press the "On" button;

- move the selector to position 2 and turn off the machine;

- re-switch the programmer to position 1, turn on the machine;

- after - by 3 and turn off the CM;

- again set the selector knob to position 1, press the start button;

- turn to drain and start the service test.

The pause between performed switchings should not exceed 3 seconds. After starting the test, the washing machine will issue a fault code. Cars that are not equipped with a display will notify of an error by flashing indicators on the control panel. You can see the interpretation of errors in the user manual supplied with the equipment.

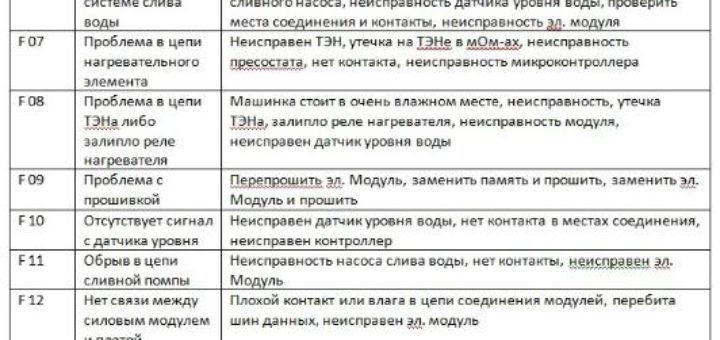

Meaning of F type faults

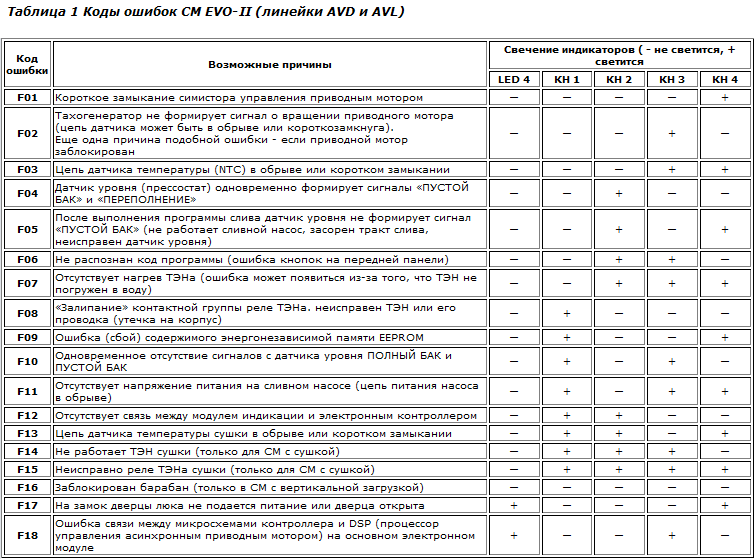

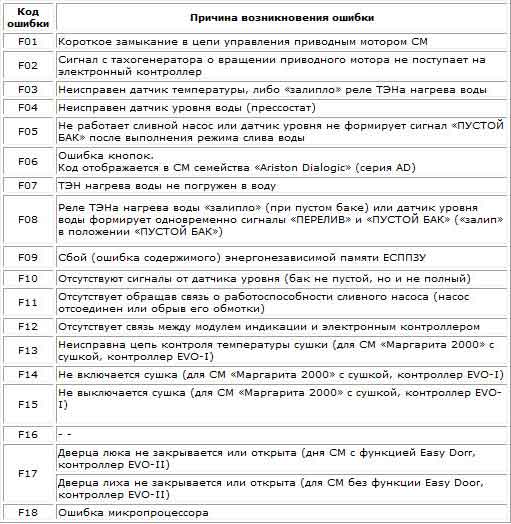

If all lights are blinking, you should carefully examine each error. To understand the essence of the malfunction that has arisen, you need to know the meaning of the designation of breakdowns:

- F01 - breakdown of the electric motor. Such an error appears in Indesit washing machines with an electronic screen, if the unit does not spin the drum and does not include washing. You can check the mains voltage, socket and unit cord yourself. You can reboot the machine.

- F02 - improper operation of the engine. The rotation signal of the drive motor is not sent to the electronic controller. In such cases, the drum does not spin, the machine does not start. It is necessary to reboot the board, check the contacts of the tachometer and the electric motor, the resistance of the sensor.

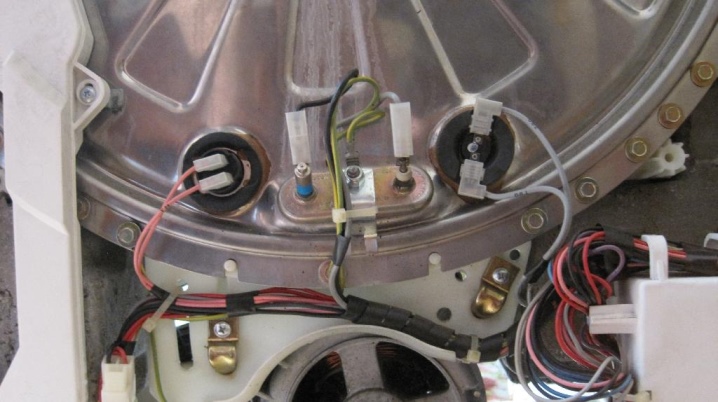

- F03 - breakdown of the temperature sensor. The unit does not heat up the water, and after the start of washing it does not work. It is necessary to check the sensor contacts, restart the unit, turn on rinsing.

- F04 - breakdown of the water level sensor. In the event of a malfunction, the washing machine does not reproduce the wash and does not fill with water. It is recommended to check if the water tap and the inlet filter are open for clogging.

- F05 - breakdown of the drain pump. There are malfunctions with the water supply, the unit does not rinse and does not wring out the laundry. It is necessary to check the drain filter, sewerage.

- F06 - command error. The unit does not respond to commands and does not start the washing process. It is necessary to check the contacts on all buttons, the health of the outlet and the power cord. It is recommended to restart the machine.

- F07 - the water level sensor does not work after it is filled. An error may mean that there is no water, the filter is clogged, the drain valve is closed. It is necessary to check the pressure in the water supply system, replace the drain valve.

- F08 - breakdown of the heating element. The control module has a closed circuit in contact with the heating element. The unit does not heat the water, the washing process does not end. It is necessary to independently check the contact of the temperature sensor and the heating element, the water level sensor and the blockage of the drain.

- F09 - memory error of the control module. The washing machine does not start and does not respond to touch. It is necessary to disconnect the device from the power supply, then turn it on.

- F10 - low water flow rate. The unit took in water and stopped further work. It is necessary to turn off the power supply for 15 minutes, and then restart it (the program may have crashed). It is necessary to check the fine filter.

- F11 - drain pump circuit malfunction. After the start of washing, the process stopped, the unit does not wring out and does not drain the water. It is necessary to check the drain filter, restart the device.

- F12 - there is no connection between the display and the module. The unit does not respond to commands and buttons. It is necessary to check the contacts between the control module and the lamps. Disconnect the machine from the network, restart.

- F13 - breakdown of the drying temperature sensor. The washing machine does not dry the laundry after washing. It is necessary to disconnect it from the network for 15 minutes, reboot.

- F14 - breakdown of the heating element for drying. The laundry is wet after washing. It is necessary to disconnect the machine from the network for 15 minutes, reboot.

- F15 - breakdown of the drying heating element relay. The washing process is over, but the laundry is not dry, an error is displayed. It is necessary to disconnect the machine from the network for 15 minutes, reboot.

- F16 - drum blocking (observed in top-loading washing machines). The unit does not start or has stopped in the middle of the program. The drum is not spinning. It is necessary to turn off the machine and check with your hand whether the drum is spinning. If it does not spin, a foreign object may have fallen. When opening the machine, make sure that the hatch is in place. If it is not there, then it could open during the operation of the washing machine and block the drum. If it is spinning, then you can turn off the device from the network for 15 minutes.

- F17 - breakage of the hatch locking device. The machine does not wash, the lock light is on. It is necessary to check if there is power. You need to open the door and see if there is a foreign object.

- F18 - breakdown of the control board processor. The washing machine does not respond to commands. It is necessary to unplug it from the network for 15 minutes.

Causes

Unfortunately, the F12 error on the Indesit washing machine can occur quite often, especially in the models of the previous generation. Moreover, if the device is not equipped with a digital display, the device issues the code in a slightly different way.

In this case, the indication of two buttons lights up simultaneously. Usually this is "Spin" or "Super wash". The equipment itself does not react to any manipulations - programs in this case do not start or turn off, and the "Start" button remains inactive.

Error F12 signals that a failure has occurred and the key connection between the control module of the automatic machine and its light indication has been lost. But since the connection is not completely lost (the device was able to signal a problem), you can try to eliminate the error yourself.

But for this it is necessary to correctly determine the reasons why it appeared at all.

- The program crashed. This usually happens due to a sudden power surge, a change in the water pressure in the line or its shutdown.

- Overloading the device itself. There are two options here: too much laundry is placed in the tub (more than allowed by the manufacturer of the equipment) or the machine washes more than 3 cycles in a row.

- There is no contact between the elements of the control module and the indication of the machine itself.

- The buttons of the device, which are responsible for this or that cycle of operation, are simply out of order.

- The contacts responsible for the indication burned out or came off.

Of course, the solution to the problem and the elimination of the F12 error in such cases will be different.

How to fix the breakage?

Fixing error F08 is much more difficult than it might seem at first glance. As practice shows, a breakdown can consist in malfunctions of various parts. When the code appears, it is impossible to use household appliances until the problem is completely resolved. Even if the machine turns on and starts a wash program, operation can be dangerous.

Also, if an error occurs, it is recommended to do the following.

- Check the electrical outlets and the integrity of the power cord.

- Modern washing machines run on special software. A reboot will help solve the problem. To do this, turn off the equipment, disconnect it and leave it alone for about 20 minutes. After that, you should restart the washing machine.

- Check the water supply. The machine may give an error due to insufficient water supply.

- Listen for third-party sounds during the wash. A foreign object may have fallen under the cabinet.

How to fix it?

If the H20 code appears on the screen of the Indesit machine during washing, you do not need to immediately panic and call the master. Any housewife can independently eliminate such a malfunction. To do this, follow these steps.

Check the water supply in the water supply

First of all, it is recommended to make sure that the valve is fully open.If it is closed, then the water will not be supplied, and if it is partially open, then the water intake is carried out slowly. This all leads to the appearance of such an error.

Then you need to check if there is any water in the system at all, if not, then the problem is not with the washing machine. The same applies to a very weak pressure in the water supply system, which is often accompanied by a long intake of water and the appearance of an H2O error. The way out in this situation would be to install a pumping station in an apartment or house.

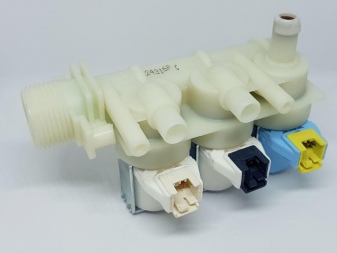

Check the filter mesh on the inlet valve

With long-term operation of the equipment, the mesh can become clogged, after which the flow of water into the machine slows down. To clean the filter, you need to carefully unscrew the inlet hose and remove the mesh. It is enough to rinse it with water under the tap, but cleaning with a solution prepared on the basis of citric acid will not interfere (the filter is placed in a container for 20 minutes).

Make sure that the drain is connected correctly.

Sometimes a constant flood of water can be observed, but self-draining does not occur - as a result, an error H20 appears. To fix the problem, hang the end of the drain hose to the toilet or bathtub and try starting the wash mode again. If such an error on the screen disappears, then the reason lies in the incorrect installation of the equipment. You can fix it yourself or use the services of experienced craftsmen.

If there are no problems with the water supply and the filter, and an error appears, then most likely a failure has occurred in the operation of the indication and control board. To solve the problem, it is recommended to unplug the plug for half an hour and then plug it back on. Since the bathroom is characterized by a high level of humidity, the electronic components of the machine often fail or malfunction under this negative influence.

All of the above breakdowns can be easily eliminated without a master, but there are also serious malfunctions that require repair.

The Indesit washing machine does not draw water for any selected program and constantly displays an error on the H20 display. This indicates that there are problems with the filler valve, which should automatically open when water is drawn. You will have to buy a new valve even when the machine is constantly taking water or pouring it over. Additionally, you should check the serviceability of the water level sensor, which may also break, become clogged (covered with a coating) over time, or fly off the tube.

It is also impossible to fix problems with the wiring or electrical contacts in the circuit responsible for controlling the valve on your own. They are manifested by vibration during the operation of the equipment. This is mainly due to damage to the wiring, which in private homes can be gnawed by rats or mice. As a rule, wires and all burnt-out contacts are replaced with new ones.

It is best to do with the initial diagnostics, and if the malfunction is serious, then immediately call the wizard

In addition, it is important to take into account that the equipment under warranty cannot be opened independently, it is available only to service centers.

How to fix it?

Before proceeding with the elimination of the breakdown, it is necessary to check the voltage level in the network - it must correspond to 220V. If there are frequent power surges, then first connect the machine to the stabilizer, in this way you can not only diagnose the operation of the unit, but also further extend the operating period of your equipment many times, protect it from short circuits.

If after a restart, the error code continues to be displayed on the monitor, you need to start troubleshooting. First, make sure the outlet and power cord are intact. In order to make the necessary measurements, you need to arm yourself with a multimeter - with the help of this device, it will not be difficult to find a breakdown. If the external monitoring of the machine did not give an idea of the cause of the breakdown, then it is necessary to proceed with an internal inspection.To do this, you will have to get to the engine by following these steps:

open a special service hatch - it is available in every Indesit CMA;

supporting the drive strap with one hand and rotating the second pulley, remove this element from the small and large pulley;

carefully disconnect the electric motor from its holders, for this you need an 8 mm wrench;

disconnect all wires from the motor and remove the device from the SMA;

on the engine you will see a couple of plates - these are the carbon brushes, which must also be unscrewed and carefully removed;

If during visual inspection you notice that these bristles are worn out, you will have to replace them with new ones.

After that, you need to assemble the machine back and run the wash in test mode. Most likely, after such a repair, you will hear a slight crackle - you should not be afraid of this, so the new brushes rub in. After several wash cycles, extraneous sounds will disappear.

If the problem is not in the carbon brushes, then you need to make sure the integrity and insulation of the wiring from the control unit to the motor. All contacts must be in good working order. In high humidity conditions, they can corrode. If rust is found, it is necessary to clean or completely replace parts.

The motor can be damaged if the winding burns out. Such a breakdown requires quite expensive repairs, the cost of which is comparable to buying a new motor, so most often users either change the entire engine or even purchase a new washing machine.

Any work with wiring requires special skills and knowledge of safety precautions, therefore, in any case, it is better to entrust this matter to a professional who has experience in such work. In such a situation, it is not enough to be able to handle a soldering iron, it is possible that you will have to deal with reprogramming new boards. Self-analysis and repair of equipment makes sense only if you are repairing the unit in order to acquire new skills. Remember, the motor is one of the most expensive parts of any SMA.

How to repair electronics, see below.