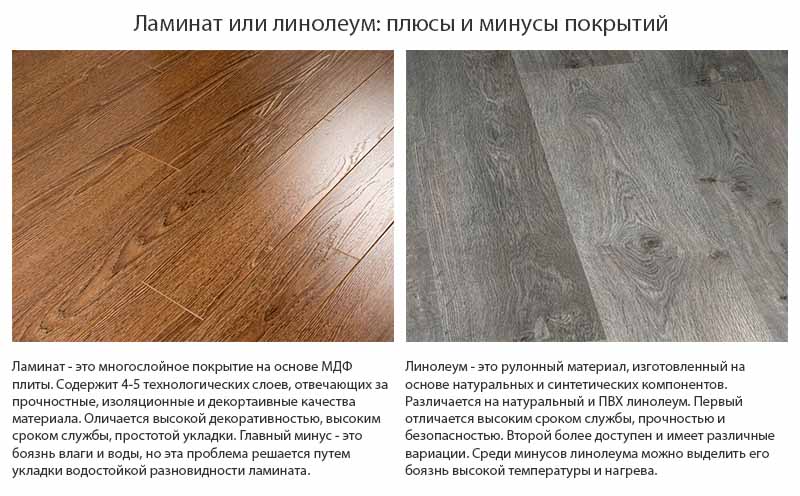

Overview of species with different properties

Tiles are selected according to different criteria than linoleum for your kitchen. But the roll coating can be synthetic, on a natural basis. Its thickness varies: single-layer and multi-layer options. There are also species that are different for their intended purpose, there is even a composition of a different structure, which is called liquid linoleum for its characteristics.

What to choose: natural or synthetic covering?

The difference between these options is significant, since one of them is environmentally friendly, and the second has an ambiguous composition and smells rather unpleasant. Basically, artificial linoleum is laid in the kitchen, guided by the price category - it is noticeably lower than in the case of a natural analogue.

Various colors of natural linoleum

Various colors of natural linoleum

This material is made of PVC. Its advantages: softness and high degree of elasticity. If you choose such linoleum in your kitchen, this option will help reduce heat loss from the room due to its low thermal conductivity.

Composition of natural linoleum, various species

Composition of natural linoleum, various species

The natural coating is made from natural ingredients: linseed oil, cork flour, lime powder, wood resin, pigments to give the desired shade. Linoleum for the kitchen in this version will contain a kind of base in the form of a jute mesh. This coating is notable for its rigidity, does not have an unpleasant odor, represents a group of fireproof materials, but it will cost much more, in some cases even more expensive than tiles.

One layer or several?

The thickness of the coating may vary depending on the following factors: the presence or absence of the base; parameters of each of the layers. If artificial linoleum is selected for the kitchen, you can consider two options: homo- and heterogeneous. In the first case, the material has no basis.

Depending on your own preferences, you can choose linoleum with a different texture, ranging from smooth glossy to matte rough

Depending on your own preferences, you can choose linoleum with a different texture, ranging from smooth glossy to matte rough

It is one-piece, and the pattern in it passes through the entire thickness of the coating. This property ensures long-term preservation of external qualities even with intensive traffic (on the floor of a corridor, kitchen, etc.), which allows comparing such material and tiles by this parameter.

Heterogeneous linoleum in the kitchen consists of several layers: a base, impregnated fiberglass, a layer of their foamed polyvinyl chloride on which a pattern is applied, as well as an upper transparent layer that performs protective functions, or transparency.

The basis of such a coating can have different densities, which will affect its wear resistance and appearance. For the corridor and kitchen, it is recommended to choose an option with a denser base structure. If you consider linoleum in your kitchen on a jute basis, then it will quickly lose its appearance under the influence of point pressure (heels, furniture legs, etc.). By the way, according to this criterion, the tile wins.

Household or semi-commercial option?

The protective coating, which is applied on top of the roll material and differs in transparency, determines the durability of the product without loss of external qualities. The service life is primarily influenced by the structure, but the top layer also plays a role in this.

It is not recommended to choose linoleum for household use in the kitchen, since the thickness of the transparency (top coating) varies from 0.1 to 0.3 mm. Under increased load, this layer abrades quickly enough. But semi-commercial linoleum in the kitchen is more suitable, since the transparency in this case is 0.4-0.5 mm.

What is Liquid Linoleum?

The official name of such a coating is a self-leveling floor made of polymer material. Given the structure of this composition and the characteristics of the decorative surface that is formed with its help, such a name has stuck among users.

It is quite possible to equip this type of linoleum in your kitchen. After hardening, a sufficiently strong, wear-resistant coating is formed. It is easier to lay it on the floor than tiles, and according to its external characteristics, such linoleum will look even better in your kitchen. Pros: there are no gaps on the surface, any area is covered, impact resistance, variability of solutions in shade and pattern, resistance to moisture, fire safety.

Coating requirements for kitchens

Kitchen areas are classified as areas of intensive use with constant fluctuations in humidity and temperature. What can we say about the rate of appearance of various types of pollution, often difficult to remove. All this imposes certain restrictions on the choice of a suitable type of finishing material.

Linoleum for the kitchen must meet the following parameters:

Strength and wear resistance

Intensive movement, frequent movement of furniture elements, the fall of various objects, including sharp and breakable ones - all these factors negatively affect the integrity of the coating. And if, in addition, there are pets in the house, then the risk of damage to the floor finish increases significantly. Therefore, a high-quality linoleum with a durable protective layer and a guaranteed service life of at least 10 years is required (provided that it is correctly installed by gluing).

Strong transparency - protection from surprises.

Moisture and water resistance

Materials that are hygroscopic (carpets) or hydrophobic (wood products and wood products) are not suitable for the kitchen. Accordingly, the surface of the floor finish must be absolutely inert to spilled water, splashes and other liquids. The best option is linoleum with a durable protective coating (PU-transparency, wax) or ceramic tiles.

Hygiene

The kitchen is primarily food. That is, an excellent environment for the development of various microorganisms, including pathogens, molds and others.

When choosing a finishing material, pay attention to such a parameter as bacteriostaticity. That is, the ability of the product to inhibit the development of bacteria

So, all marmoleum from Forbo Flooring Systems is famous for this very quality. And Tarkett produces collections with Sanitized antibacterial protective coating.

Easy to clean

The choice of kitchen linoleum depends not only on its color or decor. For a good housewife, such parameters are important as: easy removal of dust and dirt, resistance to frequent wet cleaning, the formation of stains, and household chemicals.

Matching design

It is no secret that the floor covering can emphasize or, roughly speaking, "kill" the chosen style of interior decoration. For small rooms, light or neutral shades are preferable, while large kitchens do not limit the imagination of the owners. But do not try to determine from photographs how this or that linoleum decor will look in the interior of the kitchen, do not forget - the product looks different live than on the screen of a phone or tablet. In addition, a lot depends on the lighting, the color of the walls, furniture, even curtains. For example, see a photo of linoleum for the kitchen and hallway from the Internet catalog. For comparison, there are images of the same material in the interior.

The difference is obvious. Therefore, it is better to choose the color of linoleum for the kitchen and corridor, living room and bedroom exclusively in a store with good lighting. Based on the foregoing, the choice of floor elastic material should be made with an emphasis on technical characteristics.

Coating purpose

According to the purpose, the product is also divided into several types.

- Domestic.It differs in thickness of no more than 4 mm and a service life of about 2 years. Provided that there is no serious load on the coating. Is the most budgetary among all types of linoleum;

- Commercial. It differs from the previous one in greater thickness and good wear resistance. Consists of three words, which includes, in addition to the substrate, decor and protection;

- Semi-commercial. It features a reinforced protective layer, the thickness of which is 0.7 mm. Suitable for rooms with high and medium traffic levels;

- Special. It is used in special institutions, including sports, medical departments. Not used in living rooms.

Linoleum is not a favorable environment for the appearance of mold and the development of pathogens.

Linoleum is not a favorable environment for the appearance of mold and the development of pathogens.

The entrance hall and the kitchen have high traffic. The coating must be selected taking into account this feature so that it does not wear off and deteriorate faster. Therefore, it is better to choose a semi-commercial type for these premises.

Linoleum is considered one of the most versatile materials and has many advantages.

Linoleum is considered one of the most versatile materials and has many advantages.

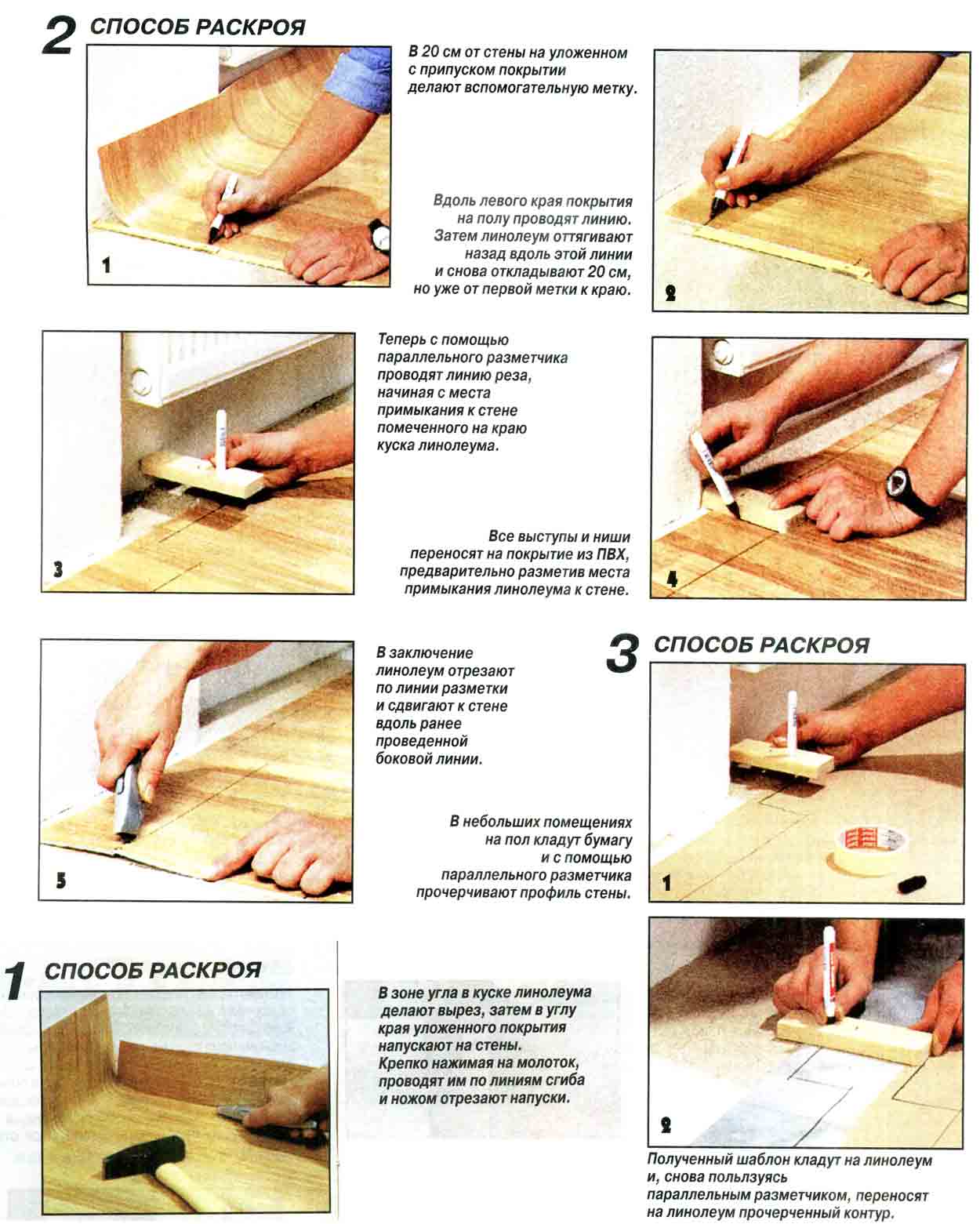

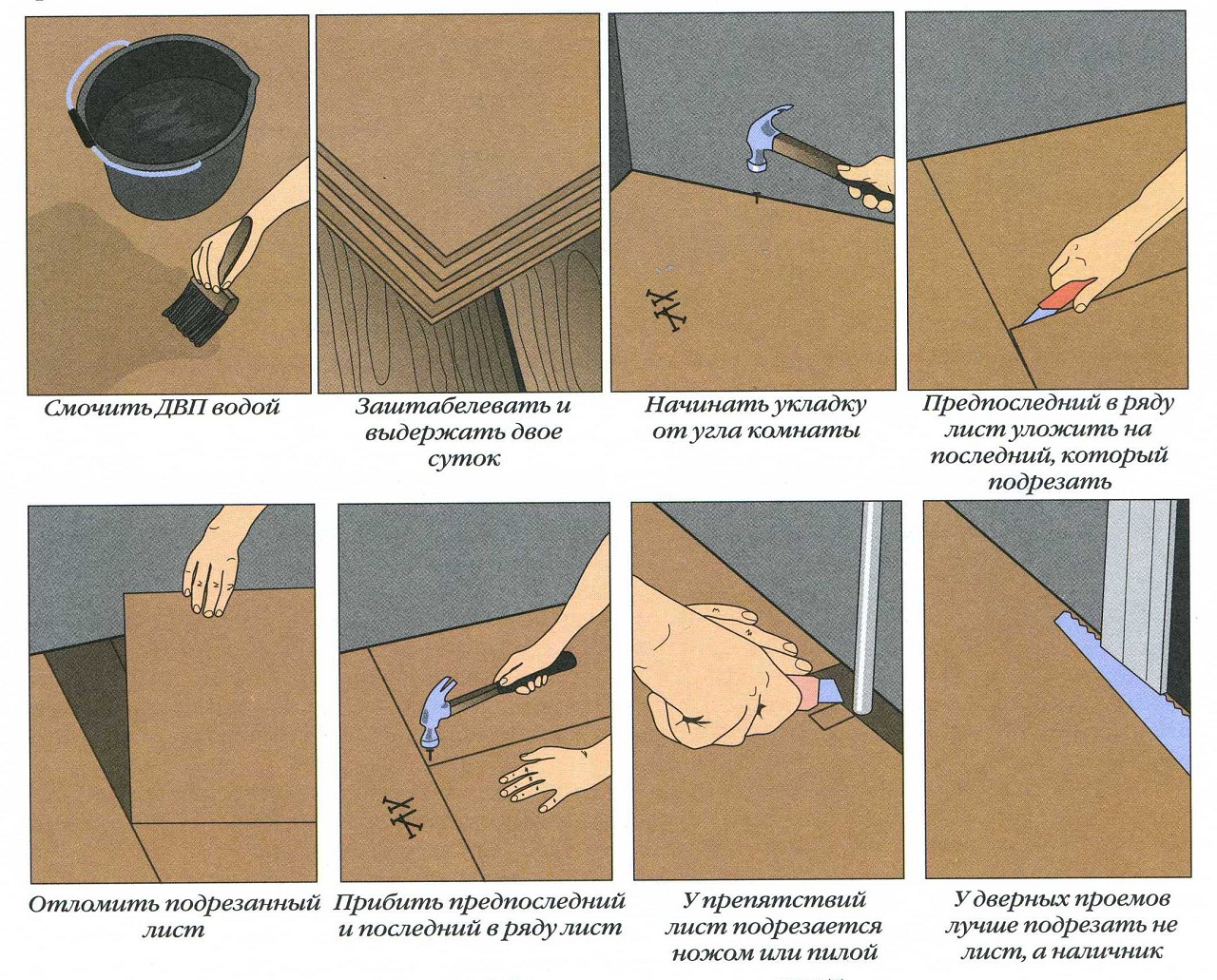

The nuances of laying linoleum coating

The work on laying linoleum is not particularly difficult, so it will not be difficult to carry out it. However, in order for the coating to look aesthetically pleasing and last a long time, several rules must be followed.

The first thing to do is to spread the canvas on the surface, since it should lie down and straighten, this process takes about a day. If necessary, in places where there are protrusions or recesses, neat cuts are made so that the material lies as evenly as possible.

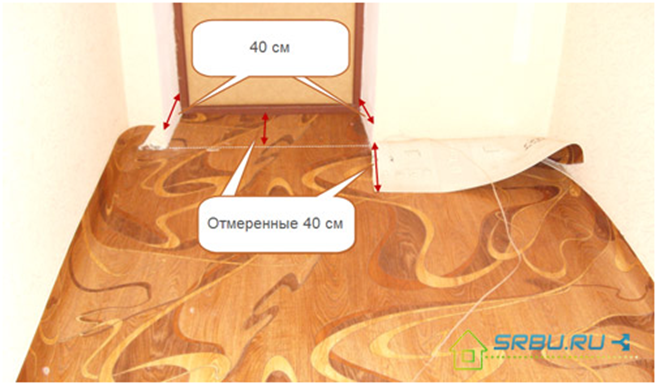

Trimming excess coating

After the above time, the edges of the coating that are on the walls must be cut off. In order for the linoleum not to swell over time, an expansion gap must be left between it and the wall, which will allow the material to expand when exposed to changes in room temperature.

Fixing linoleum to the floor can be done in two ways:

- along the perimeter by pressing it with plinths to the floor;

- the canvas is completely glued to the surface of the base.

The second option is more time-consuming and more difficult to execute, since the process will consist of several stages, one of which is squeezing out excess glue and air from under the newly pasted material.

When gluing linoleum to the base, it should be rolled up

Glue is applied to the floor surface from the corner of the room, approximately 500-700 mm, over the entire width of the coating. After laying the edge of the linoleum sheet on glue, excess glue and air are expelled from under it using a rubber wide spatula. Then the next section of the base is covered with an adhesive composition, the linoleum is straightened, glued to it and again glue is expelled from under the laid section. This process is repeated until the entire canvas is fixed to the opposite wall.

glue for linoleum

Cold welding of linoleum

If you have to connect two coating sheets, then the most affordable method that does not require the use of expensive tools is cold welding. In addition to the glue itself, the process will require double-sided and masking tape.

The first step is to glue the spread and aligned sheets together from the back side and fix them to the floor using double-sided tape. To do this, it is first glued to the base along all the joint lines. Then, the protective film is removed from the tape, in the course of fixing the linoleum, and the material is pressed against the glue.

Next, a masking tape is fixed on top of the joint, then it is carefully cut along the joint and the resulting gap is filled with a cold welding compound. After it has set, the adhesive tape is removed.

The final stage of work when laying linoleum, which is carried out after removing the tape, is the installation of skirting boards, which will press the edges of the covering to the floor.

All of the above recommendations will allow you not only to choose the right coating for the kitchen, but also to lay it yourself, thereby saving a decent amount.

Household, semi-commercial and commercial linoleum

If you have opted for PVC linoleum as a floor covering in the kitchen and in the corridor, then you should familiarize yourself with all its varieties, which differ in durability.

Household linoleum is the most popular type that is installed in household premises, including the kitchen. It is also subdivided into certain subgroups according to the level of wear resistance. For example, an ordinary household economy class has a protective coating of 0.1-0.2 mm and belongs to the 21-23 class of wear resistance. When operated in conditions of increased cross-country ability, its service life is 3-5 years. Reinforced household linoleum has a thicker protective layer of 0.35 mm. It features a huge number of drawings, you can choose both classic and super modern colors, its service life reaches 10 years.

Semi-commercial linoleum is used in premises with relatively high traffic - offices, boutiques, small hotels. If you are not confused by the "office" colors, then this is an ideal option for a kitchen floor. Semi-commercial linoleum will serve you for at least 15 years, and if it was laid on a primed and glued base, then such a floor guarantees you protection from leaks to neighbors, even if an emergency situation with pipes happened in the kitchen.

Commercial is intended for installation in large premises with a high degree of traffic - hospitals, schools, kindergartens. Incompetent or unscrupulous sellers can persuade you to buy it in an apartment, motivating it with its high technical characteristics, however, such linoleum is difficult to install, has a high cost, and most likely you will just get bored in 10 years (and its service life is about 20 years).

What are the main points you should pay attention to when choosing linoleum for the kitchen

Linoleum is an environmentally friendly flooring made from natural materials. This wear-resistant coating has a very long service life. Linoleum is resilient and antibacterial, making it an especially good choice for kitchens.

Four selection criteria will help you better know about the features of linoleum

Material. Linoleum is made from natural materials including linseed oil, resin, wood flour and pigments.

Since these materials are of natural origin, they are also biodegradable, which is considered a definite advantage when choosing an environmentally friendly coating.

In addition, flaxseed oil is a powerful antiseptic. Thanks to this property, throughout the entire service linoleum will protect the floor from harmful bacteria.

Thickness. The kitchen floor has a purpose rather than a decorative purpose. A suitable kitchen covering must withstand heavy loads without deforming, remain wear-resistant, while maintaining a flawless appearance.

The thickness of linoleum determines its durability. Especially for kitchens there is linoleum with a thickness of 4-5 mm. Such a high performance coating will withstand any intense load.

Coating. Unlike vinyl flooring, the pigments in linoleum go through the entire thickness of the material. Any scratches or heavy wear will be the same color as the surface, minimizing visual impact.

Slip. An important feature of linoleum is that, due to its coating, it usually has a rough surface. Therefore, linoleum is popular in places with high humidity.

The fact that this flooring is so easy to clean adds many benefits to it, but the benefits don't end there.

Varieties

Sometimes consumers are confused when it comes to choosing linoleum, as it differs in many ways. In fact, it is not difficult to understand its types even for a person who first encountered this issue.

Natural and artificial

Natural linoleum in quality and prestige is in no way inferior to parquet or cork flooring. Its basis is non-woven fabrics or tow fiber. For the manufacture of the top layer, the following materials can be used:

- cork or wood flour;

- resin;

- linseed oil;

- lime powder;

- natural dyes.

Compared to the synthetic analogue, natural linoleum has a higher cost, but is able to maintain operational properties for 20-40 years. In addition to high strength and resistance to household chemicals, it is antistatic, fire resistant and environmentally friendly.

The raw material for the production of budget synthetic linoleum is polyvinyl chloride. Despite this, a high-quality coating that meets the requirements of GOST is safe for human health and can be used to decorate a kitchen.

How to distinguish natural from artificial linoleum:

- by smell. Natural material has an oily smell, artificial smells like chemicals;

- on the basis. On the seamy side of natural linoleum, jute fiber is clearly visible;

- by elasticity. Unlike elastic vinyl covering, natural material is much tougher and, if desired, you can break off a piece from it.

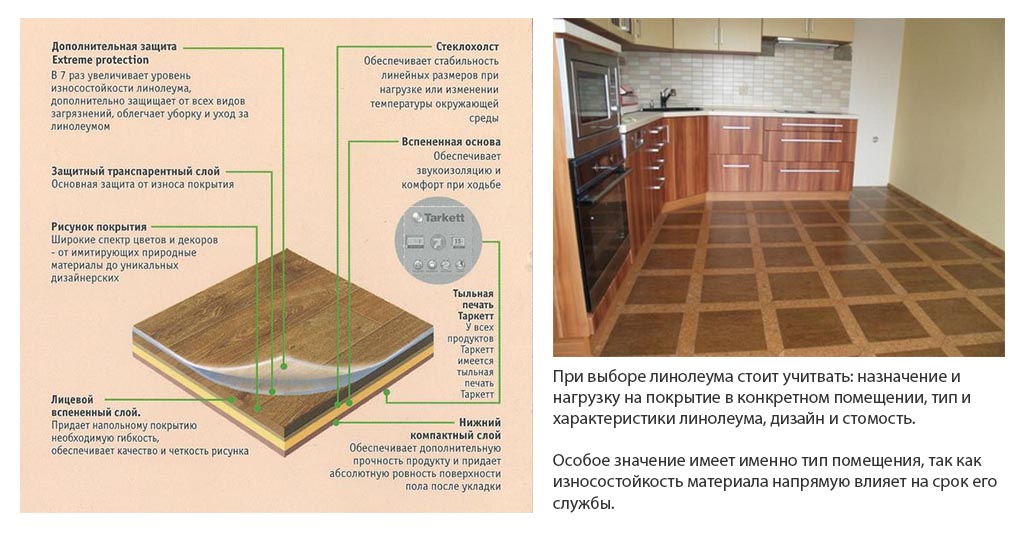

Uniform and multi-layered

A uniform (homogeneous) coating has no base. Its thickness is insignificant, but the coating is resilient and durable. The service life is about 7 years, it can be increased by applying a protective layer. Due to the fact that the pattern permeates the entire thickness of the coating, the appearance of the material does not deteriorate even with uneven wear. A distinctive feature of a homogeneous coating is a rough surface, on which dirt is almost invisible.

Homogeneous linoleum

Homogeneous linoleum

Multilayer (heterogeneous) coating consists of several layers:

- the foundation. Felt and jute bases retain heat well, but heavy furniture and heels leave noticeable marks on it. For the kitchen, linoleum on a foam basis is suitable, which is elastic and resistant to moisture and dirt;

- fiberglass. The layer is designed to strengthen the heat and sound insulation of the material, as well as to resist mechanical stress. The wider it is, the more resistant the material is to deformation;

- PVC. A layer of polyvinyl chloride is the basis for applying a decorative pattern;

- protective layer. Protects material from abrasion.

The number of layers and their quality may vary from manufacturer to manufacturer.

The structure of multilayer linoleum

The structure of multilayer linoleum

Household and commercial

The class of linoleum is determined by the thickness and density of the protective layer, on which the service life of the material depends:

- household - up to 3 mm, class 21-23;

- semi-commercial - 4-5 mm, class 31-32;

- commercial - 6 mm and more, class 33.

The form

Depending on the form of release, linoleum is divided into the following types:

- tiled. Available as square, rectangular or polygonal panels. For the opportunity to create an original floor design, you will have to pay with the complexity of installation and sanitary maintenance;

- rolled. The width of the rolls varies from 1.5 to 5 m, and the length can reach 45 m. This allows you to apply linoleum in one piece even in large kitchens with minimal losses during cutting;

- liquid. A modern building material with which you can create a perfectly flat surface without seams and an unsurpassed decorative effect. Liquid linoleum, also called self-leveling flooring, is a polyurethane or epoxy resin and a polymer with a hardener.The disadvantages include the complexity of dismantling the coating.

Dimensions and shape

Linoleum for household and semi-commercial purposes is produced in rolls with a width of 1.5 to 5 m. However, there are other variants of shapes and sizes, many of which are more convenient for installation in comparison with rolls. For example, a square or rectangular flooring perfectly imitates laminate flooring, parquet boards and tiles, and can even be installed by housewives. The main thing is to correctly apply the markup and strictly adhere to it during the installation process.

Moreover, linoleum of this form is the most maintainable: to replace the damaged area, it is enough to dismantle several fragments and install new ones in their place. And since in kitchens the wear of the flooring is very uneven, the tiled option in this case is a completely suitable option. The disadvantages of this material include a large number of seams during installation, and, as a result, the likelihood of accumulation of grease and dust in them. This requires more frequent and thorough cleaning with the least amount of liquid.

Types of linoleum

Once upon a time, linoleum was considered a fairly "budget" option for flooring. However, this is not at all the case at present.

It is put both when they are trying to save money, and when the question of the cost of repair is not worth it - and in both cases the coating turns out to be practical, durable and beautiful.

The choice of linoleum in hardware stores is truly the widest - all types, colors and shapes. How and which option to choose?

According to its composition and method of production, linoleum is divided into two main types:

- natural;

- polyvinyl chloride.

Natural linoleum for the kitchen. As the name implies, it is based on natural ingredients - lime and wood powder, natural resin, linseed oil, natural dyes.

It is the highest quality linoleum available. It does not fade from sunlight, has antistatic properties, and is very resistant to aggressive environments.

Of course, like any natural material, linoleum also requires careful maintenance - it must be protected from microorganisms. However, this "minus" is more than redeemed by the "plus" - with proper care, natural linoleum can last a very long time, as the reviews show - up to 40 years, and at the same time remain in excellent condition.

The linoleum substrate is selected based on the need. If the floors in the kitchen are cold, then the substrate should be warm.

Of course, it costs a lot - however, taking into account all its properties, the high price is fully justified. Its cost usually starts from 1000 rubles per 1 m2. You can choose any color and coloring.

Polyvinyl chloride linoleum, or PVC. Unlike the natural look, PVC linoleum is made on the basis of an artificial substance, polyvinyl chloride. It is almost not inferior to its natural "brother" - it is also resistant to household chemicals and sunlight, dust does not accumulate on it. There is also an interesting variety - PVC tiles, which imitate a tiled floor, while having all the properties and advantages of linoleum.

And, what is important, bacteria on polyvinyl chloride reproduce poorly. It is almost impossible to distinguish it from the photo, because

colors and patterns are usually identical.

Contrary to popular belief, artificial linoleum is not at all harmful to humans and does not emit any hazardous substances - modern manufacturers are very closely monitoring the environmental safety of their materials.

It can be put in an unheated room, in a summer house, in a country house, on a veranda, etc.

The basis of linoleums can be completely different: felt, foamed, or even textile.

Another plus of PVC linoleum is its low cost. The average price for 1 square meter is only 500 rubles. And with minimal maintenance, such a coating can last up to 20 years.Which type is better to choose and buy in this case is up to you.

The big plus here is that it is very easy to change linoleum. The replacement process consists only in removing the old coating and the new flooring.

There is also the so-called liquid linoleum, but due to its rarity and relative high cost, we excluded it from our review.

Prices for work differ depending on the regions, so it makes no sense to indicate it.

Scope of application and class of resistance, technical characteristics

All types of resilient floor coverings can be classified according to their area of application. Depending on this criterion, linoleums are distinguished:

- household, whose service life is from 7 to 12 years, intended for use in living rooms, kitchens and small offices;

- semi-commercial, operating life of at least 10 years, intended for large offices and sales areas;

- commercial, designed for use for more than 15 years, intended for premises with high traffic;

- special especially durable, which will last more than 50 years, intended for use in gyms, hospitals and other specialized areas with a large crowd of people.

An important indicator for flooring is the wear resistance class, which characterizes the degree of permissible load on the material and is always indicated by the manufacturer on the inside of the roll or label, so the buyer can quite easily determine the scope of its application.

The product class is always indicated in the certificate and is designated by two numbers. The first number means the type of room:

- 1 - for premises;

- 2 - for residential premises;

- 3 - for office buildings.

The second digit means the intensity of the possible load and can take values from 1 to 4. The presence of the fourth class means that the material has the highest degree of wear resistance.

For the kitchen, it is recommended to pick up household linoleum with class 22 or 23, as well as semi-commercial class 31 or 32. The choice of species depends on the number of family members. When living in an apartment for more than two people, it is recommended to give preference to a semi-commercial type of coverage.

Common mistakes

Some consumers make mistakes when choosing and installing material, which ultimately leads to the formation of a poor-quality and short-lived coating. The most common mistakes are:

- styling immediately after delivery - the material does not have time to level out;

- ignoring surface preparation - as a result, the canvases bristle;

- storage of the roll in a horizontal position - waves are formed;

- installation on dirty and wet floors - the canvas does not stick, over time a fungus appears;

- trimming material without a gap - waves remain.

For thin sheets of linoleum, a high-quality flat base is required. Otherwise, any defects or imperfections will be visible.

Which linoleum is better to lay in the kitchen

There are only two types of elastic flooring on the building materials market today:

- natural, made from raw materials of natural origin;

- synthetic.

Each species has its own advantages and disadvantages. Everyone selects the most acceptable option depending on financial capabilities and personal preferences.

Natural material

It contains natural ingredients, a mixture of which is applied to a linen or jute base. All components are ground to a powdery state before being applied to the base. In the manufacture are used:

- lime conglomerate;

- cork conglomerate;

- wood resins;

- linseed oil;

- coloring pigments of natural origin.

The technology for making natural coatings has existed for over a hundred years and has not changed much. The innovations affected only the drawing technique, color palette and durability.

Its advantages are considered to be:

- environmental friendliness and safety for use;

- long service life: from 25 to 45 years;

- resistance to ultraviolet rays;

- high degree of wear resistance;

- ability to withstand exposure to chemicals;

- possession of antiseptic properties due to the content of linseed oil in the composition;

- resistance to various types of dirt and moisture;

- ease of care.

A significant disadvantage of natural materials is considered to be the high cost, therefore, in most cases, preference is given to cheaper artificial turf. However, it is worth remembering that the state of human health depends on the quality of living conditions.

Artificial material

Synthetic material can be made from various raw materials. Depending on the composition, the following types are distinguished:

- PVC;

- alkyd;

- rubber;

- colloxylin.

Not all types of synthetic linoleum can be used in domestic premises. The colloxylin coating has a nitrocellulose base, which is considered to be highly flammable. Due to the high risk of fire, it is forbidden to use it in residential buildings.

The rubber coating is recommended for use on the floors of warehouses or industrial premises.

Alkyd linoleum has a fabric base and can be used to cover the floor in an apartment, but it is rarely used for this purpose, since it is very difficult to install and does not have sufficient resistance to temperature extremes.

The most popular in the apartment is PVC linoleum. Experts say that this species is absolutely safe for humans, with the exception of intolerance to individual components.

The types of linoleum on the market may differ in the presence of layers. Homogeneous and heterogeneous are distinguished. A homogeneous material has one layer. If a drawing is present, then it is applied across the entire thickness. Its advantage is considered to be very high abrasion resistance. However, it is very rarely used in apartments, as it has a rather high cost.

High-quality multilayer PVC has a rather complex structure, consisting of several components. Its structure includes:

- the lower compact layer, which acts as a base;

- elastic backing made of polyvinyl chloride;

- a layer for imparting strength, in most cases it is fiberglass;

- printed film;

- transparency, which provides protection and is responsible for wear resistance;

- protective film.

The abrasion resistance and service life of PVC linoleum largely depends on the protective layer, the thickness of which can be from 0.14 to 0.7 mm.

It has a number of advantages:

- ease of cleaning and maintenance;

- moisture resistance;

- resistance to mechanical stress;

- long service life, which can be from 10 to 15 years;

- much cheaper compared to other types;

- a wide range of patterns, textures, realistic imitation of natural coating;

- with a slight relief on the surface, the material is a good way to prevent slipping.