How to paint a radiator: the choice of paint and tools

Before proceeding with the main stage of work, you need to prepare. First, let's prepare soft brushes, which should be small and of two types - straight and curved. The straight brush is intended for painting external, easily accessible areas, and the curved brush is for painting the rear and internal surfaces of the radiator.

What paint to choose

The main role in this work is played by paint for radiators, which can be of the following types:

- water dispersion;

- alkyd;

- acrylic;

- oil.

Any paint for heating radiators must be resistant to abrasion, tolerate high temperatures well (up to 100 degrees) and not emit toxic compounds when heated. According to these parameters, the above options differ significantly from each other. For example, water-based paints do not have an unpleasant odor and dry quickly, but this type of coating is less resistant to abrasion, that is, it will have to be renewed more often.

Acrylic paint contains a chemical solvent, therefore, when used, an unpleasant odor is emitted, which has to be eroded from the room for a long time. The advantages of such a coating are considered to be high abrasion resistance and an attractive glossy appearance.

Alkyd paint for radiators also has an unpleasant odor, but is in high consumer demand due to its high abrasion resistance and a huge range of shades. In addition, the smell from modern building materials is not so strong.

As for oil paint, it is less and less used as a coating for batteries and pipes. The reason for this is an unpleasant odor, a long drying time and difficulty in applying an even layer.

How to paint radiators is up to you, but it is best to use alkyd paints from well-known manufacturers. You just need to choose the appropriate color for the coating.

Radiator paint requirements

To begin with, heating radiators are devices that emit a sufficiently high thermal energy. Hence the basic requirements for paint:

- Increased heat resistance. Experts recommend paints that can withstand temperatures not lower than + 100C.

- High resistance to various aggressive environments.

- Abrasion resistance.

- Safety in terms of impact on the human body. Simply, the complete absence of toxicity.

So, back to the question: what paint to paint the radiators? Manufacturers currently offer three main types.

Acrylic based enamels. This type is made on the basis of organic solvents. That is why, when painting, a peculiar pungent smell is released from the paint, which quickly evaporates. But the end result is a strong glossy film on the metal surface. This paint lasts a very long time.

Alkyd-type enamels. It is the most common type of radiator paint and is used by a large number of consumers. Its advantages are resistance to abrasion and very high temperatures. Let's add that this view has a huge color palette. True, when stained, a strong odor is emitted, which lasts for several days. Some of the alkyd paints emit a slight odor when heated, so it is worthwhile to use the recommendations of specialists when buying.

Water-dispersive species. All experts agree that these paints are the best choice.Firstly, they do not exude odors, and secondly, they dry quickly

The only thing you need to pay attention to when buying a label. On the label of the jar there must be an inscription "for painting heating batteries".

I would not like to bypass oil paints. More recently, radiators were most often painted with them. But their popularity is in the past due to low quality characteristics.

As you can see, the assortment is not that small, but each consumer decides for himself what to choose. After all, each species has its own advantages and disadvantages.

Radiator paints and necessary tools

Many people believe that only the front part of heating radiators should be painted, but, unfortunately, this conclusion is erroneous.

Often, especially on Soviet batteries, rust spots begin to appear, and if they are not removed, the corrosion can spread further.

A good paint will help get rid of unwanted corrosion. To find out what paint to paint radiators, you need to find out the characteristics of this product.

The purchased paint must be resistant to high temperatures, because radiators get very hot in winter and retain their natural color for a long time.

For the correct choice of paint and varnish material, you need to know what types are on sale.

Acrylic paint has a long-lasting natural color and is renowned for its lack of strong odor.

This option is well suited for painting radiators in the winter, because the apartment does not need much airing.

Alkyd paint is resistant to high temperatures and is therefore ideal for radiators. Of the minuses, an enhanced smell can be noted, so it is better to use it in the warm season, and not in the heating season.

There is another type of acrylic paint that is used in conjunction with a solvent. This material has good performance, firstly, the paint can be used without additional primer, and secondly, the coating has a good look and a glossy surface.

The well-known oil paint used to be a popular product, but with the development of the technological process, it receded into the background.

This is the main list of cast iron radiator paints and varnishes that can be purchased. For panel radiators, you can use spray paints (preferably auto enamel).

It is no longer fashionable to have white batteries, so do not be afraid to experiment with colors, the main thing is that the coating fits into the design of the apartment.

In a children's room, you can decorate radiators brightly, especially panel batteries, on which you can reproduce the whole landscape.

So what to paint radiators and in what style, it's up to you.

But it should be remembered that in order for the coloring material to lay down well, you must have a special tool, such as:

- sandpaper for pre-cleaning;

- a sharp object or knife to remove old paint;

- several types of brushes;

- small roller;

- unnecessary rags for cleaning the room.

This entire set is needed for high-quality work and will help transform old and ugly radiators into a luxurious piece of furniture.

What paint is better to paint radiators?

Heating radiator paint

In Soviet times, we covered traditional cast-iron "accordions" MS-140 or steel heating radiators with two types of paints: oil and aluminum (silver). Somewhat later, pentaphthalic enamels PF-115 and the like appeared, they also went into use. However, the listed coatings “smell” for a long time after application and lose their appearance quickly enough. As a result of almost annual renewal, a layer of paint on cast iron batteries for the entire period of operation could reach 3-5 mm.

In the current conditions of a huge selection of various paints and varnishes, there are many coloring materials intended for heating devices or simply hot surfaces, we will talk about them below. And now we list the compositions that are unacceptable to be used as paints for radiators:

- oil (MA-25 and others);

- pentaphthalic (PF-115);

- nitrocellulose (NTs-132 and others);

- ordinary aluminum (silver);

- water-based paint for interior work.

All types of coatings from this list have one common drawback - they work under atmospheric conditions, that is, they are not heat-resistant. If you study the technical characteristics of the same PF-115, it turns out that the temperature range of its operation is from -50 to +60 ºС. It is not surprising that very soon it is peeled from the battery, whose temperature reaches 80-90 ºС. The same applies to chemically resistant nitrocellulose enamels with a coating that is susceptible to high temperatures.

Therefore, it is quite simple to figure out what paint to paint the battery with. It must be heat-resistant, otherwise after a couple of heating seasons it will be the same. Below is a list where we denote the recommended coatings for batteries:

- alkyd;

- acrylic;

- silicone-aluminum;

- aluminum based on heat-resistant varnishes.

Glossy or matte

When choosing paint for heating radiators, you need to choose what type of surface you want to get - matte or glossy. It is necessary to choose taking into account the type of surface. The fact is that glossy paint emphasizes the unevenness of the surface. Most often they paint cast iron batteries, and their surface is far from ideal. Covering it with a glossy composition, you will only emphasize its imperfection.

Matte compositions are better in this regard - they visually hide many irregularities. So this is not a bad option. But there is also a drawback here: the matte white paint quickly takes on a grayish tint. This happens due to the fact that dust and dirt are clogged into the pores, and they are wide in matte paint. This dirt is not washed out from there. The way out is a fresh coat of paint or coloring in a color other than white. A smart choice is to match the paint to the color of the walls. From a design point of view, this is a better solution than white radiators.

If there is a pattern on the cast-iron radiator, the gloss will accentuate it and make it stand out

There is another way out - to close up the irregularities of the radiator. This is done with a putty for metal, you can use an automobile one. First, old paint, rust and other contaminants are removed, then the surface is degreased and then all irregularities are sealed with putty. After it dries with medium-grain sandpaper, then fine-grain sandpaper, the surface is sanded to a smooth state. Then it is dedusted, primed and painted. In this case, you can safely use glossy enamels for heating radiators. If the surface is leveled carefully, the result will please you.

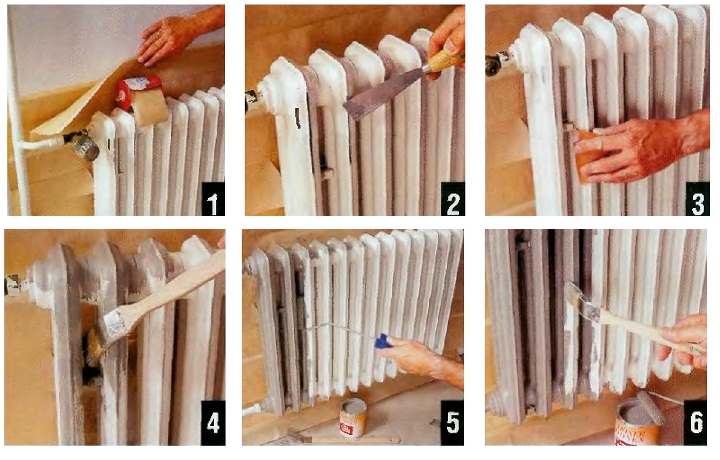

How to paint a battery with your own hands

If the manufacturer does not indicate in the instructions the possibility of applying the composition to the old paint, then the radiators require preliminary washing, cleaning from the old paint layer, then priming and painting in 2 layers.

Work is carried out in goggles, a respirator and gloves.

Attention! A set of workwear is the best protection against harmful dust and chemicals. To protect the space around the radiator from accidental splashes, the surfaces are protected with plastic wrap, cardboard or paper.

Radiator wiping

The accumulated dust, small debris is removed with a brush or vacuum cleaner.

All internal and external surfaces are thoroughly washed with detergent.

Remove the old paint layer in one of 3 ways:

- washed off with a chemical composition;

- removed mechanically with a drill and special nozzles - brushes;

- soften old paint with a building hair dryer or burner, remove with a spatula.

Removing old paint

Chemical compositions for removing old paint (removers) are released in the form of liquid or aerosols.

Important! When choosing a cleaning solution, pay attention to the composition: it must include components that prevent corrosion. The softened paint layer is removed with a spatula; a rag is also suitable. Removal of paint without softening is done using a drill with a brush attachment with metal teeth

Having cleaned the old paint, the surface is dedusted: manually - with a brush, brush or vacuum cleaner

Removal of paint without softening is done using a drill with a brush attachment with metal teeth. After cleaning the old paint, the surface is dust-free: manually - with a brush, brush or vacuum cleaner

The softened paint layer is removed with a spatula; a rag is also suitable. Removal of paint without softening is done using a drill with a brush attachment with metal teeth. Having cleaned the old paint, the surface is dedusted: manually - with a brush, brush or vacuum cleaner.

Surface sanding

The surface of the radiators is sanded to metal. This work can be done manually, with sandpaper, but cleaning with a sander can be faster and better.

The dust-free surface is degreased if it is planned to paint with alkyd compounds - gasoline or white spirit, when painting with acrylic - acetone.

Primer

Before priming, flaws, large irregularities are putty. Apply a putty for metal, designed for high (from 80 ° C) temperatures (epoxy, automotive). The dried layer is sanded, dedusted and degreased.

The primer is selected in accordance with the paint. Some manufacturers allow the use of paint thinned with water or solvent (5% by volume) instead of primer. This moment should be described in detail in the instructions for the paint.

Dyeing

To paint the battery correctly, you need flute brushes: medium width with a straight handle and a narrow one with a curved handle.

Attention! Instead of a flute with a curved handle, you can make a pad from a piece of foam rubber fixed to a wire. The wire is easy to bend at the desired angle, all hard-to-reach places are easy to paint over

The primed metal base practically does not absorb paint.

Therefore, in order to avoid drips, a little paint is collected on the brush, carefully distributed over the surface with a thin layer.

A spray paint can is held vertically at a distance of 30 cm from the surface, the composition is applied in a zigzag motion.

The sequence of staining is the back surfaces from top to bottom, then the top, sides and inner parts, lastly the front side and bottom of the battery.

The second layer of paint is applied over the dried first layer.

Choosing odorless paint

There are two types of water-based paints:

- water emulsion (liquid polymer in a liquid solvent);

- water-dispersive (solid polymer in a liquid solvent).

Hammer paints are also gaining popularity. They are characterized by the absence of a pungent odor, despite the presence of an organic branded solvent in the composition.

A paint composition for painting radiators or plumbing pipes must meet certain basic requirements:

- resistance to high temperatures;

- increased resistance to mechanical influences;

- ability to withstand aggressive liquids when cleaning surfaces;

- good water repellency.

It is also desirable that the paint does not emit unpleasant odors during its application and during the operation of the painted surface.

The following types of paints differ in the absence of pungent odors:

- acrylic;

- hammer.

For aluminum radiators, if it becomes necessary to paint them, it is better to use auto enamels in spray cans. Car enamels perfectly fit on an aluminum surface, have high heat resistance and thermal conductivity.

Acrylic paints

In addition to the absence of unpleasant odors, water-based acrylic paints and varnishes have many advantages:

- durability, wear resistance;

- fire safety;

- good covering ability and low consumption;

- fast drying;

- ease and safety of application;

- washable of not dried composition;

- beautiful glossy appearance;

- high resistance to moisture.

Disadvantages of acrylic paints:

- insignificant adhesion in the absence of primer;

- some types of paints strongly change their qualities during drying (color, gloss).

Note! If acrylic paint is not based on water, but on an organic solvent, an unpleasant odor cannot be avoided when applying the paint and varnish material and drying it

Hammer paints

Hammer coatings are decorative enamels, when applied, rough relief surfaces are formed. Externally, the painted surface resembles an embossing obtained as a result of hammer blows on the material.

In the manufacture of hammer paints, acrylates, epoxy resins, alkyds, silicone and styrene are used. Also, the composition of hammer mixes includes fine-grained glass, aluminum powder and metallic pigments.

Due to their composition, hammer mixes have a wide range of positive properties:

- lack of a strong odor;

- resistance of the painted surface to high temperatures (up to 80 degrees and above);

- excellent adhesion;

- high resistance to external influences (humidity, mechanical stress);

- high density of paintwork materials, which results in increased resistance to corrosion processes;

- fast drying;

- variety of color palette;

- color fastness;

- dirt-repellent qualities;

- it is possible to paint even on rust without preliminary cleaning of the surface.

The main disadvantage of hammer mixes is their high cost.

Preparatory work and battery staining process

To understand how to paint a heating battery, you need to know the principle of the work performed.

As with all types of construction work, the painting process begins with the preparation of the batteries. First of all, it is necessary to eliminate the contaminated areas and check the product for the presence of corrosion spots.

Swollen places must be cleaned with sandpaper, and if rotten places are found, they must be eliminated.

At the final stage, the radiator should be coated with a primer, but only the characteristics of the further material should be taken into account, because some types of paints and varnishes do not require a primer.

To clean heating devices from dirt and old paint, several types of cleaning are used. The first method is called chemical, and the second method (using a special tool) is called mechanical.

To remove dirt chemically, solutions consisting of acids and solvents are used. You can make this mixture yourself or buy it at the store.

To prepare the solution at home, you will need the following ingredients:

- sodium carbonate (soda ash), about one kilogram;

- slaked lime, in the same proportion;

- water, about five liters;

- large capacity, more than ten liters.

The solution is prepared as follows. Soda is dissolved in hot water, the water temperature is about 60 degrees, after which lime is added in small doses. This is done to prevent strong foam.

The mechanical method involves the use of a special tool or ordinary sandpaper.

The process is long and dusty, but for acceleration, you can use a special drill attachment or use a grinder.

In this case, you must follow the safety rules and carry out such work carefully so as not to damage the radiator.

Before starting work, you should equip the workplace, cover the floor with paper (or other material), protect the walls with a gasket (you can put a large sheet of cardboard), prepare the necessary tools.

The paint is applied to the radiators with a brush, preferably from top to bottom - so there will be no drips. The layer should be thin and uniform. After the paint has dried, a second coat must be applied.

The inner parts of the radiators must be painted over first so as not to get dirty in the process. Small parts and difficult areas should be painted with a sponge or roller.

That's the whole principle of painting radiators.

The choice of paint for radiators. comparison table

To paint the elements of the heating system, high-quality paint for heating radiators is used, which meets high requirements. It must be safe, resistant to overheating, cracking and fading. Experts recommend choosing the following types of paints for heating pipes and radiators:

| Types of paintwork materials (paints and varnishes) | Types of surfaces | Benefits of paints | Disadvantages of paints |

|---|---|---|---|

| Oil paints | Cast iron | Affordable cost, wide range of colors | Long drying time, strong odor, susceptibility to yellowing, cracking and chipping |

| Acrylic enamels | Cast iron, steel, bimetallic | Virtually no pungent odor, high drying rate, attractive glossy shine, rich color gamut | High demands on the surface to be treated: thorough cleaning and pre-priming |

| Water based alkyd enamels | Cast iron, steel, bimetallic | Subtle chemical odor, color fastness | The presence of titanium white for resistance to high temperatures, which increases the cost of production |

| Solvent-based alkyd enamels (organic) | Cast iron, steel, bimetallic | Withstand high temperatures, wide color gamut, affordable cost | Persistent chemical odor, tendency to yellowing |

| Alkyd hammer enamels | Cast iron, steel, bimetallic | High protection of surfaces from damage, resistance to high temperatures, durability, affordable cost | The presence of a mild chemical odor that disappears upon drying |

| Powder paints | Cast iron, steel, bimetallic | High strength and durability, resistance to temperature effects | The powder composition is applied by professional equipment in a special chamber |

| Silicone paints | Cast iron | Increased heat resistance, durability, wear resistance | High cost, pungent odor |

| Water-based paints | All kinds | No pungent odor, wide range of colors, high environmental friendliness and safety | High requirements for surface preparation - obligatory degreasing and priming |

| Serebryanka | Cast iron | High temperature resistance, low cost | Persistent chemical odor |

| Aerosol paints | All kinds | Wide range of colors, ease of application, affordable cost | Bad smell |

Useful Tips

You can do the work efficiently and beautifully on your own, you just need to take into account all the nuances and follow the rules.

Here are some more helpful tips from the pros:

- the painted radiator should not have drips - for this, apply the paint with a thin layer and smooth movements;

- the back of the heater is best painted with a curved brush with a long handle;

- if a chemical method is used to clean radiators, then personal protective equipment must be used;

- after completing the painting work, the room must be well ventilated. If work is carried out in winter, then paints should be taken without a pungent odor;

- pipes and hidden elements do not need to be painted, which will help preserve heat transfer;

- in order to understand which paint is better to paint, it is necessary to study all the characteristics of the product.

Video:

There is nothing difficult in this type of work, therefore, you can paint the heating system yourself.

You just need to listen to the advice of experts, and your radiator will be as good as new.

If you play with imagination and change the color of the radiators, they will become even better than the new ones.

New shades of the restored battery should be chosen based on the interior of the room: if it is a children's room, then it is better to choose light colors, and the radiator in the bathroom should be made in a neutral color.

What paint to paint the batteries in the kitchen or in other rooms is up to you personally.

Video:

It should be remembered that new bimetallic radiators are very capricious, and to paint their surface, you should contact a specialist (preferably at a service station), in case of self-repair, you must use autoenamel in the form of an aerosol.

For panel radiators, both aerosols and ordinary paint can also be used, only it should be taken into account that it is necessary to paint the grille, and not just the panel itself.

Restoration of radiators is a primitive work, so feel free to update the design of your heating devices and enjoy the result.

Calculation of the required amount of paint

Manufacturers of paint and varnish products always indicate the consumption of paint per 1 m2 on the packaging, and therefore, knowing the total area of the painted surface, it is always possible to determine how much material is needed to apply one layer of coating.

For new devices, this information is usually indicated in the product passport, and for old radiators and riser pipes, the painting area will have to be calculated independently.

To determine the area of the pipe, it is necessary to recall the formula for the circumference, which is equal to 2PR or the number P (3.14) multiplied by the pipe diameter. The resulting circumference should be multiplied by the length of the riser, which will give the desired result - the area of the pipe surface to be painted.

When determining the area of steel, bimetallic and aluminum batteries of a rectangular shape, there will be no difficulties - it is enough to multiply the width and height of the element, but to find the area of a sectional cast-iron radiator, you will first have to calculate the area of one section, adding the areas of individual elements, and then multiply the result by the number of sections ...

To obtain the required volume of paint, the total area found to be painted must be multiplied by the consumption rate indicated by the manufacturer on the bank. If you plan to apply more than one layer, the result should be multiplied by the number of layers.

How to paint yourself at home

To paint radiators, you will need brushes, brushes with a metal base, a primer for metal, a degreaser (alcohol or acetone), and coarse sandpaper.

How to clean old paint

To remove the old paint, you need to clean the battery with sandpaper or treat it according to the instructions with specialized softening compounds and remove it using a spatula.

Preparation

To paint the radiators, it is recommended to remove the latter. Then you need to clean up the places with traces of rust using sandpaper, and degrease with acetone or alcohol.

Coloration

To paint a cast iron or other battery beautifully, you will need to fulfill the following conditions:

- ambient and battery temperature must exceed +15 degrees;

- start painting from the inner edges, avoiding smudges;

- you need to paint the battery in two layers;

- you can connect the radiator to the general network after 5-12 hours (the period is indicated on the package).

Provided the above conditions are met, the paint will last for at least five years.

4 Tools for work

To carry out staining, it is not enough to buy a suitable, quick-drying, odorless battery paint.

You can get a high-quality result if you have the necessary equipment, which should include:

- primer;

- dye;

- solvent;

- rag;

- sanding paper No. 2;

- paper or polyethylene to protect other surfaces from enamel ingress;

- respirator;

- gloves for hand protection;

- two brushes: simple and curved for interior work.

Working with a new product is much easier than working with the old one. If you need to renew the coating of a radiator that has been used for its intended purpose for more than a year, then you should first remove the old paint residues from the surface.

The best tool for this is considered to be an electric sander with a metal brush in the form of a nozzle. A construction hairdryer is often used to remove the old coating inside the battery. It allows you to soften old raw materials and easily remove them later with a scraper.

In the absence of a power tool in the house, it is permissible to use a gel wash, which is sold in hardware stores. The mixture is applied to the surface and waited for the time indicated on the label. After the required time interval has elapsed, the old paint will soften and can be easily removed with a metal or wood spatula. When working, it is advisable to use rubber gloves to protect hands.

Upon completion of the preparatory work, they begin to paint the product itself. The sequence of actions in this case is as follows:

- 1. The previously prepared surface is washed and dried, then degreased.

- 2. After that, the product is primed with a special compound.

- 3. Start painting from the top of the heater.

- 4. Gradually move to the inner parts of the radiator.

- 5. Color the middle and bottom of the battery.

The procedure for painting heating radiators

Just a few phrases about the order in which it is more convenient to paint heating radiators. To make it easier to work, first paint the inner surface. If you are right-handed, move from right to left, if left-handed - vice versa. This is less likely to get dirty. Then the outer surface is painted over in the same direction.

Do not forget to cover everything around with newspapers or paper (and on the floor too)

The composition is applied from above, rubbed with up and down movements. Rub the paint thoroughly, not trying to immediately achieve a perfectly painted surface. After the first coat, slightly less colored spots are acceptable. This is much better than drips. They will close when the second layer is applied, and the drips will have to be cleaned off with sandpaper after they are completely dry.

Paint application on aluminum radiators

The need to paint aluminum heating appliances is very rare, but it is important to know and understand how to paint an aluminum heating battery correctly. The fact is that the painting of radiators is carried out by professional craftsmen at one of the stages of production, while using a special powder paint

It is almost impossible to achieve such a high-quality result at home. In addition, home staining may void the manufacturer's warranty.

However, during transportation or during the installation of aluminum heating devices, small cracks or chips may appear, due to which the appearance of the radiator loses its attractiveness. In this case, it is recommended to use auto enamel. Drying of this coloring composition occurs quickly enough, at a surface temperature of 130 degrees, one layer of paint dries in 20 minutes. When working with auto enamel, it is recommended to use personal protective equipment, while the windows must be open. To obtain a high-quality result when deciding how to paint the battery correctly, the spray gun is held at a distance of about 30 cm from the surface to be treated. It is not recommended to keep the jet in one place, as it may cause streaks.