Types of temporary adhesives

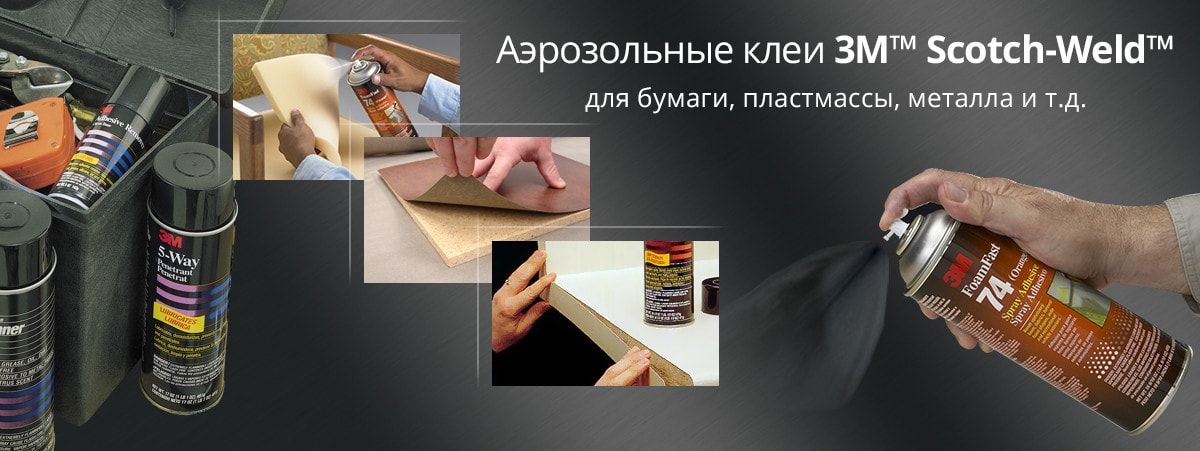

- In sprays.

- In the pads.

The most common adhesive is a temporary fixing spray. It is used when working with fine knitwear, leather, velvet. This tool provides a reliable short-term fixation of stencils without leaving marks on the surface. Temporary fabric glue is used for decorating with the ability to obtain non-blurred contours of the pattern. The workpiece with applied glue can be re-glued several times. The composition is washed off with ordinary, warm water. Temporary fixing glue for fabric, odorless, colorless and after a certain time completely evaporates from the surface

When choosing a spray adhesive, it is important to consider that the agent should not stick to the sewing needle, as this can make it difficult to work with creating an applique.

An aerosol temporary adhesive has proven itself well, which is intended for gluing stencils made of wood, cardboard, glass and paper blanks. Thanks to the aerosol system, the adhesive is evenly distributed on the material, without forming lumps. The spray makes it possible to correctly measure the adhesive composition, which is necessary for work. For best results, apply one thin layer of adhesive, spreading it over the back of the stencil blank. It is recommended to glue the product 5-10 seconds after spraying the adhesive.

Among specialists involved in decorating interior items, universal temporary adhesive spray is very popular. It is suitable for paper, broom, plastic, glass, fabric, felt, rubber and other soft and hard materials. Thanks to the aerosol spraying system, the adhesive is evenly applied over a large surface, without rolling into lumps and without creating drops on the material.

Universal temporary adhesive, can be used in three ways:

- One-sided long-term fixation with the possibility of correction.

- Double-sided contact application.

- Fixation for a short period of time.

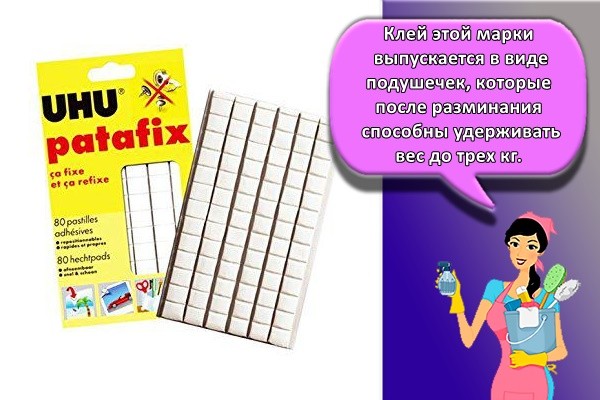

Temporary adhesives in pillows are very convenient when decorating premises for special occasions. They are used for fastening paper, cardboard, fabric blanks for a short time. It can be posters, calendars, decorative paper compositions, garlands. Adhesive pads are easily attached to glass, concrete, wood, plastered surfaces. Volumetric soft pillows can be used many times, and the product will not lose its qualities.

Features of temporary adhesives

Temporary adhesive is an innovative development of the modern chemical industry. The main purpose of such compositions is a short-term fixation of different materials, with the possibility of subsequent detachment. Adhesives are produced in different versions, which allows you to choose exactly the product that will be convenient for use. All temporary fixing compounds comply with international quality standards and safety requirements. Adhesives can be used to bond paper, fabrics, leather, polyethylene, plastic without leaving any residue. If it is necessary to use temporary and permanent glue at the same time, it is recommended to purchase adhesives of universal value. This will save money and purchase a quality product for a wide range of uses.

The video shows the features of the use of temporary adhesives.

Thus, if you are decorating rooms, creating original applications on fabrics or other materials, it is recommended to choose one of the types of temporary adhesives.Taking into account the scope and features of use, you can easily find the right glue for short-term fixation.

Features of using various formulations

The reliability of the glued seam and the possibility of using the product in the future directly depend on the type of textile glue. There are many types of adhesives that are used for gluing textiles to other materials, fixing rhinestones and other decor. Their main characteristics:

- PVA - is considered a universal glue that is used for needlework, especially for decoupage, some types of polyvinyl acetate products are moisture resistant;

- rubber and latex - suitable for leather, fabric, foam rubber, do not damage the structure of the material, therefore they are suitable even for delicate structures;

- polyurethane - designed for thick fabric, PVC, other materials - metal, wood, plastic;

- nairite (based on neoprene) - transparent, waterproof composition, can glue all types of textiles, materials for shoes, gives a very strong seam;

- hot-melt adhesive - safe for humans, resistant to the action of water, chemicals, colorless;

- perchlorovinyl - intended for textiles, leather, rubber, most often used in shoe production;

- styrene-butadiene - an elastic agent that does not deteriorate from UV rays, high, low temperatures, water;

- nitrocellulose - used for gluing leather to fabric, as well as bonding complex types of matter together.

Useful Tips

help you avoid mistakes when working with adhesives for banner ads:

- Use the adhesive in rooms with forced ventilation.

- To degrease the material, use solvent no. 646 or a gun flushing agent from polyurethane foam.

- To avoid damaging the table surface when using the blade, place a sheet of plexiglass or industrial linoleum.

- Remove excess glue immediately with a clean cloth, without waiting for drying.

- For better adhesion of the edges, the seam can be heated with a hairdryer for 2-3 minutes.

- The width of the tape for joining the parts should not be less than 6 cm.

- When using two-component formulations, apply them to work within 5 hours. Then they lose their properties.

Tips for choosing an adhesive

Before buying, it is important to carefully read the description of the properties of the adhesives sold. The fabric has a flexible structure, deforms, is subjected to regular washing

Therefore, the adhesive connection must be very strong, withstand different loads - ironing, stretching, compression during washing, contact with water, household chemicals, UV radiation. Only an adhesive with such capabilities is able to ensure the proper quality of the product.

Also, when buying, you should pay attention to the following properties of textile glue:

- lack of unpleasant odor;

- transparency of the composition;

- optimal consistency, which does not allow the glue to drain;

- resistance to any damaging factors;

- the impossibility of penetration in the form of stains on the front side of the product;

- optimal time of hardening and complete drying.

The glue should create an elastic film on the fabric, which not only adheres firmly, but also provides protective properties, preserves a certain extensibility of the fabric without forming a rigid seam. The integrity of the adhesive joint should not be disturbed by the movement of the fibers of the fabric, therefore superglues and similar products are not suitable for textiles. The glue should be chosen depending on the type of fabric - silk, wool, cotton and other natural materials, synthetics, leather, etc. If necessary, you can buy a universal product that will be suitable for any textile.

Rules for use

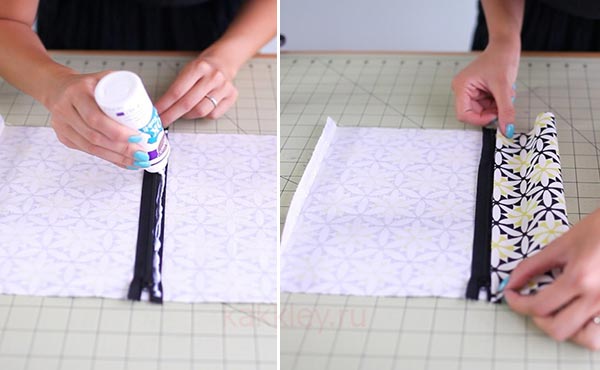

Before starting work, you need to clean and dry the base. If it is fabric, it should be clean, flat (ironed). The aerosol adhesive should be shaken well for 10 seconds and, at a distance of 20 cm from the surface, perform the following actions:

- spray the glue onto the material with a thin layer, accurately determining the direction of the jet and not capturing unnecessary areas (for this, turn the spray gun to the mark made by the manufacturer on the neck);

- if you bring a can of glue close to a fabric or other material, the jet will turn out to be too concentrated;

- wait 1-2 minutes, then lean the part, stencil, applique or other product against the main surface, press firmly, preventing glue from dripping and displacement of the part;

- do not apply glue to the second surface, it is enough to cover only one side of the joint;

- you can glue the elements an unlimited number of times - the mass will be sticky until it hardens.

When working with glue with your own hands, you need to pay attention to safety measures. Aerosols are highly flammable, so any actions with them are carried out away from sources of fire

Do not store the product so that the sun's rays do not fall into it, the glue may deteriorate. Work in a well-ventilated area wearing a respirator. This will help prevent inhalation of glue vapors and the ingress of tiny spray particles into the lungs. If glue has dripped onto the skin, wash it under cool soapy water. In case of contact with eyes, in addition to rinsing, consult a doctor!

Work technology

Working with the substance is quite simple, so that this task is within the reach of any person. Textile glue for gluing fabrics is used as follows:

- 1. Bonded patches are cleaned of threads and other foreign objects that could negatively affect the quality of the hitch.

- 2. The following procedure depends on the type of adhesive selected. When working with rubber material, both surfaces should be lubricated and allowed to dry. When the process is complete, they are moistened with acetone and pressed against each other using a special press machine. The whole thing freezes for 10 hours. The use of polymer-based adhesives implies the application of the substance in two layers, after which the fabrics are immediately combined with their subsequent pressing with a press for several hours. For convenience, you can use a special gun to squeeze the glue straight from the tube.

- 3. Subsequent processing consists only in checking the quality of the connection. It will no longer be possible to fix blemishes or remove random stains.

The most important part of the job is being neat. There will be practically no chances to correct your mistakes, so you need to carefully prepare for work and protect the rest of the product from accidental drops.

When working with aerosol sprays for gluing fabrics, this is especially important, since it is not possible to completely control all sprayed particles

It is also important to protect the employee who will deal with the procedure. If it enters the respiratory tract, small particles can cause irritation of the mucous membranes and severe edema, so you need to work in a special respirator

As a last resort, a gauze bandage will do.

How to make it yourself at home

At home, you can make two types of fabric glue:

- casein;

- dextrin.

Dextrin

It is obtained by heating starch to a certain temperature, which can be found in almost any kitchen or store. Algorithm of actions:

- Take a small baking sheet and cover its bottom with a thick layer of foil.

- Sprinkle the foil with starch.

- Preheat the oven to 200 o and remove the baking sheet with starch there.

- We are waiting for 2 hours.

- We take out the baking sheet and sift the yellowed starch through a fine sieve.

- We mix dextrin with water in a ratio of 5 to 7.

- Mix thoroughly and filter the resulting glue through cheesecloth.

Casein

To prepare casein glue you will need:

- five tablespoons of casein;

- ten tablespoons of liquid;

- mix them in a separate container until we get a substance of uniform consistency.

Such glue is stored for no more than six hours, after which it begins to lose its adhesive properties.

Varieties and scope of adhesives

Different adhesive components have their own areas of application. They must be selected based on the specifics of the materials to be fastened, as well as their properties (density, hairiness, elasticity).

Rubber compounds

Provides tensile adhesive bonds. Rubber mixtures set when heated, and at room temperature. These are rubber adhesives familiar to everyone.

They are suitable for working with products from any natural materials: jacquard, jeans, satin, gabardine, drape in various combinations. Several options for rubber compounds:

- Sekunda fabric glue - transparent.

- Moment "Rubber".

- NBH "Rubber".

PVA compositions

The most common and available for use. They are used in cases where it is necessary to connect combined, non-uniform surfaces. Low consumption required when applied to fabric.

The stationery version of this composition has minimal water resistance and is more suitable for working with paper or cardboard.

You should choose special types of PVA glue for better fixing of the fabric:

- PVA super (PVA-M).

- Universal polyvinyl acetate (PVA-MB).

Hot melt adhesive for fabric

This type of glue can withstand washing, dry cleaning, and does not contaminate the surface. It has a high setting speed. Adhesion compounds require heating before being applied to fabric, and can be used for coton, suede, corduroy, synthetics, acrylic, bologna. They melt at temperatures from 120 to 170 ℃. There are 2 types of hot melt joints:

- Hot melt powder. Provides a secure connection of parts. Forms an elastic seam. The most common: PRYM 987157 thermal powder, Termoteks and Griltex textile powder.

- Hot melt adhesive in the form of rods. Special pistols are used to melt it. It is convenient for attaching small items. Types of rods: cores for the 11 mm AT-S TK-1101 gun, Rexant and Proskit 61103 hot melt glue rod.

For temporary bonding of textiles, there is an aerosol fabric adhesive. It differs from others in the principle of application. The adhesive spray is sold in an aerosol can with a spray bottle. It spreads evenly and does not require a waiting time before gluing. The number of sprays can be adjusted to achieve permanent tissue fixation. It is suitable for less dense and light fabrics: chiffon, lace, satin, nylon.

In addition, there are professional textile adhesives. They are based on styrene-butadiene, it creates a strong, elastic fixation of matter with each other and with other textures - plastic, foam rubber, wood. It is used commercially in the production of textile products.

We recommend watching the video:

How to properly glue banner fabric

Tools you need for gluing:

- Mounting blade.

- Double sided tape.

- Glue.

- Degreasing agent.

- Elements of the web for gluing.

- Backing material (width not less than 20 cm. Length allowance - 2 cm on each side of the canvas).

- Smooth, solid surface.

- A clean cloth to remove excess adhesion.

To properly fasten two canvases of banner fabric, do the following:

- Cut off excess irregularities and protruding fibers along the edge of the mount.

- On the back of the canvas, carefully (without folds) glue the tape.

- Join the edges of the canvas to match the pattern.

- Remove the protective film from the tape and join the ends butt-joint.

- From the wrong side along the edge of the seam, distribute the adhesive evenly along the entire length.

- When the glue sets, repeat the procedure.

- Attach a backing from above and press down along the edge of the joint of the two lower canvases.

- To prevent the material from deforming, leave under a press until the glue is completely dry (8-10 hours).

We advise you to watch the video instruction:

Popular temporary adhesives

The adhesives can be supplied in spray, aerosol and pad form.The spray is ideal for leather, velvet, knitwear, it provides temporary fixation of patterns and stencils. A workpiece with such glue can be re-glued several times.

If the product will be machine-stitched, it is important that the glue does not clog the needle hole, otherwise the needle may deteriorate.

It is more convenient to use aerosol adhesives when working with stencils and blanks made of cardboard, glass, paper, wood. The products are quickly distributed over the surface, without forming lumps, and the layer is very thin. Temporary adhesives in pillows are usually used to decorate premises for holidays, special occasions, and they can also be used to fix patterns, calendars, posters, garlands for a short time. More expensive pads are used many times, since they do not lose their adhesive properties for a long time.

Also, temporary adhesives are divided into special and universal. The first ones are intended for fastening only one group of materials - textiles, wood and cellulose derivatives, glass, etc. The universal ones are suitable for any surfaces and can be applied in the following ways:

- fixation until the moment the product is washed;

- one-sided fastening with the possibility of correction;

- double-sided fastening for a longer period.

The most popular brands of temporary adhesives are:

- 3M Scotch Weld. The aerosol is suitable for bonding dissimilar and homogeneous materials, allows for multiple bonding. Great for labels, silk-screen printing, does not warp paper, does not harden over time.

- Marabu-Fix it. Colorless spray for cardboard, wood, paper and plastic. It is also used to secure fabrics when decorating.

- Prim. Provides temporary fixation of textiles, removes the need for pins. Washes off without residue with plain water.

- Idea Decoupage. Made in Italy, high quality. Helps to repeatedly glue and remove film, fabric and cardboard images, stencils. It is widely used in design.

- KK. Transparent non-toxic glue, used for attaching non-glue interlining, small parts that are difficult to attach with a hoop when embroidering. Suitable for knitwear and stretch fabrics.

- UHU Tac Patafix PROPower, heavy-duty temporary attachment pads. They are capable of holding objects weighing up to 3 kg, suitable for internal and external surfaces. Resistant to moisture, not affected by UV rays. Can be used multiple times.

How to make glue yourself

Handicraftsmen often prefer to use quality Mod Podge Fabric glue. But its price is quite high, and the consumption is large, so you can try to make the composition with your own hands.

There are two options for making fabric glue. For the first recipe you will need:

- 225 ml of any PVA;

- 112.5 ml of water;

- 2 tablespoons of glitter (if needed)

- 2 tablespoons of varnish (acrylic or other water-based).

It is necessary to take a jar with a tightly screwed lid, wash it clean, dry it. The volume must be at least 350-400 ml. Pour measured PVA glue into the jar (instead of it, it is allowed to take acid-free glue for scrapbooking, it is more resistant). Add water to PVA, mix, add varnish and glitter. The last component is optional. Close the lid, shake the glue again. Keep refrigerated.

For the second version of the glue, the following ingredients are needed:

- 210 g flour;

- 56 g sugar;

- 225 ml of cold water;

- ¼ a teaspoon of vegetable oil;

- ¼ teaspoon of vinegar.

Prepare a jar for 350-400 g, wash. Sift flour into a saucepan, add sugar, add water. Beat the mixture with a whisk to remove any lumps. Turn on the fire, heat, but do not let it boil. If the glue is thick, it can still be thinned with water. At the end of cooking, add vegetable oil. Remove from heat, pour in vinegar. Cool glue, store in a jar in the refrigerator.

You can also make a dextrin glue for your fabric with your own hands. To do this, the starch is fried in the oven at a temperature of +160 degrees for 2 hours. The finished dextrin is combined with boiling water 1: 1, stirred until dissolved. It must be applied immediately as the glue hardens very quickly.

The fabric can also be glued with a casein compound. To make it, mix 2 parts of casein powder and 1 part of water, heat without boiling until the mass becomes homogeneous. Casein is sold in stores in the form of a dry powder, it is inexpensive, but the finished glue has a drawback - it hardens soon. Therefore, you need to prepare the composition in small portions.

Basic fabric joining methods

In addition to gluing, there are other ways of attaching advertising canvases:

- Firmware. This variant of connecting banners is used to fasten several layers of fabric. Stitching allows the installation of large diameter fastening structures. This method of attaching banners creates the most durable seam between the layers of the canvas. The method has its drawbacks. When sewing the canvas, the upper layers are damaged. In this case, lamination of advertising materials is not possible. The ingress of moisture into the puncture sites during stitching leads to blurred images. Therefore, this kind of connection is used for indoor banners. The number of stitches when sewing should not exceed 6 x 2 cm.

- Welding. It is used when the components of advertising structures are less susceptible to adhesion and do not create reliable adhesion (plasticized polyvinyl chloride). Two layers of canvas are cleaned of dirt and overlapped. Its width should not be less than 10 cm. Then the joints are heated by a welding device until the seam adheres. To prevent waves from going along the welding boundary, a press is additionally used. When the banner cools down after welding, temperature fluctuations should be avoided.

- Fastening with eyelets. A fold is made along the edge of the product. Holes are prepared along the perimeter of the banner and special bushings (eyelets) are fixed in them. Corner holes are additionally secured with durable spacers. A cable is passed through the holes and the banner is fixed on a metal frame.

- Gluing. This type of connection is used when it is necessary to fasten two parts of the banner fabric together. The second option: for temporary fixation of element folds or preliminary work. Adhesive does not provide reliable fixing of banners to a metal profile or frame outdoors.

How to glue the fabric

The adhesive composition of German production allows you to glue and process the edges of most types of fabric: coarse calico, flax, felt, overcoat, thin materials, as well as leather and others.

It dries without heating in air in about 4-6 hours; for thick fabrics, you additionally need to warm up the gluing site with an iron. The adhesive is also suitable for temporary joint bonding.

For gluing light-colored fabrics and attaching large applications, it is better to apply along the edge, since the composition tends to shine through after drying.

After gluing, clothes are washed at temperatures up to 40 degrees. When working with glue, it is advisable to ventilate the room, since it has an unpleasant odor until it hardens.

Textile hot melt adhesive "GRILTEX"

Powder adhesive from a Swiss manufacturer. Ideal for gluing thick fabrics, securing folds, patches on clothes, appliqués and making toys.

The downside is the impossibility of working with thin and transparent matter, as well as rigidity in the place of gluing.

To activate the powder hot melt glue for fabric, it is necessary to iron the fabric with a steam iron. After gluing, the clothes can be washed at temperatures up to 60 degrees, and can also be dry cleaned.

In general, all powder adhesives adhere well to fabric and have similar properties. To replace this powder, you can use dry glue: "Patch", "Termoteks", "Gold zack".

Aerosol glue Krylon high strenght spray adghesive

Suitable for working with dense fabrics and leather. This glue is designed for fixing heavy materials and allows you to work not only for gluing fabric to fabric, but also with wood, papier-mâché, plaster and others.

Spray adhesive for fabrics can be of different degrees of fixation and allows you to choose the format to suit your needs.

So, Hobby Colle Permanent aerosol adhesive for fabric is convenient for gluing using decoupage technique and allows using the adhesive composition even in hard-to-reach places.

Vliesofix (Flizofix)

Adhesive spacer on paper, similar to adhesive tape for fabric, but only in a larger format. Allows you to glue appliqués on clothes, create a patchwork product and perform other work with large format fabric.

After the glue has completely set, fabrics can be safely washed at up to 60 degrees and dry-cleaned.

Check the compatibility of the composition, and also make sure that after hardening, the material in the place of gluing has not compacted and the glue does not shine through.

The first wash of clothes with glue is desirable after a lapse of at least a day; some seamstresses prefer to carry out the first wash after a longer period of time.

VIDEO REVIEW

How to glue fabric to fabric with liquid glue

Plastic adhesives from tubes allow you to use two types of gluing: simple and thermal. There is no need to rub in the glue as it can seep onto the front side.

Let's consider the application of liquid glue using the example of Gutermann HT-2.

- With simple gluing, glue is applied to one side of the fabric in a dotted manner or in a thin zigzag and leave for 4 minutes to wait for the film to form, then apply the other half of the fabric and press.

- When working with thick fabrics, apply the glue with a brush in a continuous layer on both surfaces - leave it for 15 minutes, then apply the second thin layer on one layer, now fold and press the fabrics.

- Thermal bonding involves the application of glue for 20 minutes with an open exposure to air, then the fabrics are connected and ironed with a steam iron (at the temperature of the corresponding fabric) for no more than 20 seconds.

Which glue to choose

The composition for bonding sections of advertising banner fabric must meet the following requirements:

- After drying, a flat, colorless seam should form.

- The adhesive must not damage or deform the underlying fabric.

- It must be moisture-repellent.

- Adhesion time is not less than 10 minutes. This allows you to adjust the position of the elements relative to each other during operation.

- Wide operating temperature range.

- Maximum reliability and flexibility of fastening.

The following types of adhesives are suitable for binding banners:

- Cyanoacrylate.

- Cosmophene for PVC.

- Super-NN.

- Bostik Vinycol.

Review of popular brands

If you are too lazy to choose the right glue on your own, paying attention to a thousand different little things, trust the opinion of buyers who recommend buying the following brands for everyday use:

- JAVANA;

- DECOLA;

- Mod Podge:

- Second.

JAVANA

It is used when working with thin, sensitive fabric, leaving a transparent matte film when drying. The product is expensive, but it fully pays for the money spent on its purchase.

DECOLA

A budget product with the following features:

- holds materials of different textures well;

- dries quickly;

- is cheap.

Of the shortcomings, a strong density of the substance is distinguished, which is why its consumption is not very economical.

Mod podge

When dry, it forms an eye-pleasing, transparent, glossy film that provides additional protection to the treated fabric. The glue is not damaged during hand or machine wash, reliably performing its intended functions.

Second

A cheap domestic product that, despite its cost, has a pleasant versatility and reliability. Used for gluing:

- fabrics of various textures;

- skin;

- foam rubber;

- ceramics.

Basic requirements for the adhesive composition

Nail glue is a translucent viscous liquid that is designed for manicure. It is used for several purposes:

- to repair natural nails (broken or damaged);

- to restore accrued;

- to stick rhinestones on the plate;

- for gluing tips.

You can use it at home, but it is better if you entrust this work to professionals. The glue has a protective effect that allows you to protect the nail plate from drying with ultraviolet light. It includes:

- cyanoacrylate;

- exfoliator;

- panthenol;

- vitamin A palmitate;

- antioxidants.

The glue is non-toxic, non-flammable, does not contain components harmful to the skin. The base substance (cyanoacrylate) is used for skin grafting. The main characteristics of the glue include viscosity, which can be of several types:

- thick, strong viscosity - does not take much time to solidify;

- liquid, low viscosity - you need to keep it longer, pressing the tips to the nail.

But the second type has more opportunities to adjust the position of the nail plate.