How to use correctly

The procedure for gluing tiles with EK 3000 or other varieties of this product is indicated on the packaging. In this case, the surface to which the material is fixed is prepared according to one algorithm in each case.

Preparation of the base

It is recommended to work with tile glue at a temperature of 10-25 degrees. This also applies to the foundation. Before proceeding with the decoration of walls or floors, the latter must be cleaned of dirt, dust and grease. Third-party substances negatively affect the adhesion of the tile to the surface. It is also necessary to repair defects over five millimeters deep. For this, plaster is used. If a porous material that absorbs water well is used as a base, a primer is pre-applied to prevent the appearance of mold.

How to prepare a solution

The solution is prepared according to the attached instructions. Depending on the required density, it is necessary to mix 5.75-6.75 liters of water and 25 kilograms of powder. It is recommended to pour and fill both components in a separate container, respectively. Use a drill or construction mixer for mixing.

Features of working with adhesive

The tile is glued according to the following algorithm:

- An adhesive is applied to the material.

- The tile is pressed tightly against the wall.

- Excess glue is removed immediately with a cloth. If necessary, the tiles can be leveled after gluing. This takes no more than 10 minutes.

- After completing the laying of the tiles on the wall or floor, the seam is cleaned.

- After 16-24 hours (depending on the type of adhesive), the seam is rubbed with the appropriate material.

EK 3000 glue is applied in the same way as other similar formulations. For this, a notched trowel is used. The adhesive solution is applied to the prepared surface. But before starting work, each tile must be dried.

How to calculate the expense

The consumption of tile adhesive depends on the brand of the product, the consistency of the composition and the thickness of the applied layer. On average, 1 m2 takes up to 2.5-3 kilograms of material.

How to calculate the consumption of Eunice glue?

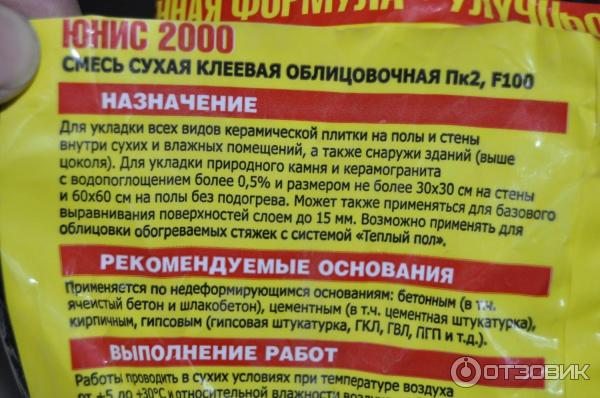

Many consumers are concerned about the question of how to determine the consumption of Eunice glue so as not to make a mistake with its quantity: to purchase not enough or, conversely, too many packages. To avoid such a nuisance, you will need to accurately calculate the total coverage area and orient yourself in the thickness of the applied adhesive layer.

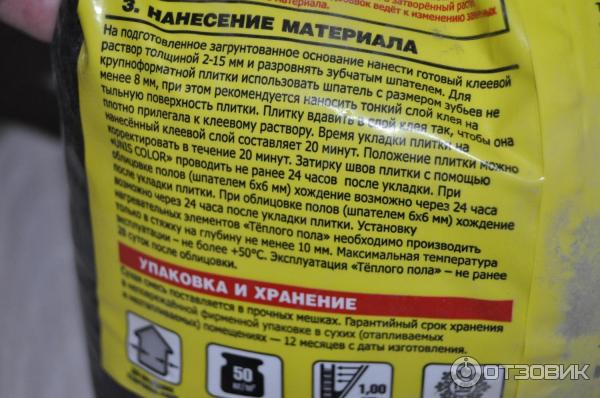

In addition, you can simply carefully study the instructions from the manufacturer, which is printed on each package of funds. The description in expanded form will make it possible to correctly calculate the volume of the required glue.

There are also calculators on the Internet that allow you to quickly and effortlessly calculate the required amount of adhesive. To do this, it is enough to drive a specific coverage area into the system. After that, indicate the type of product used, and the online calculator will give the estimated figure for the cost of glue in kilograms.

Consider a guide to using Unis tile adhesive. For error-free execution of finishing work at home, one by one follow the list of the following steps:

- Preparing the surface. We remove old remnants of building materials and degrease the coating. Align the base. We prime with special compounds to ensure a high-quality screed.

- We mix the glue solution in strict accordance with the manufacturer's instructions. The vessel in which this operation is performed must be perfectly clean and dry. You can mix the solution manually or with a construction mixer.

- We apply glue with a trowel. The thickness of the layer and the size of the teeth of the notched trowel are selected taking into account the dimensions of the sides of the tile covering.Make sure that Eunice tile adhesive is applied over the entire surface of the wall with the same thickness.

- We carry out orderly styling. To do this, carefully press the tiles one by one to the tile glue so that the coating is flush in all respects. The optimal width of the joints is also determined by the dimensions of the tiled coating. For convenience, we use crosses, as a rule, and other specialized devices.

- If the tile is laid on the floor, you can walk on it only after a day.

Recommendations for selection and use

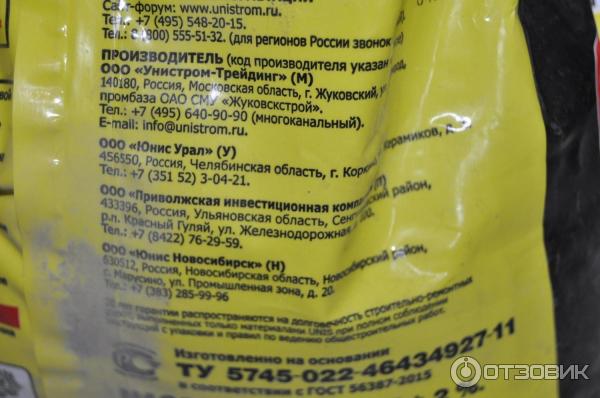

If you are planning to purchase Eunice glue for porcelain stoneware or other coatings in Moscow, we strongly recommend that you study some tips on choosing a product. So, always look at the expiration date of the product, it should not be overdue. Otherwise, the tool will not have to expect the full performance of the required functions.

In addition, the product should be purchased exclusively at verified points of sale.

It is important that, upon request, employees of specialized markets provide a product certificate to ensure high quality in accordance with the established requirements.

Pay attention to the storage conditions: if the seller does not comply with them, you risk buying a damaged product

Naturally, consult the seller before buying. Study the information about each type of tile adhesive from TM Yunis. Take your time, carefully select the mixture to exclude the purchase of the wrong product.

It is necessary to work with such means in strict accordance with the instructions from the manufacturer. Read the recommendations regarding preparation, application layer thickness and final hardening time of the mortar.

Following the usual rules, it will be possible to make a truly masterful renovation of the interior. Before starting finishing work, we advise you to watch a video on how to properly lay a tile covering with your own hands:

Instructions for use

Eunice

First of all, it is necessary to prepare the surface to be laid on. It needs to be cleaned of moisture and dirt, as well as to wipe out irregularities. Traces of paint and stains are also removed. Also, the surface must be leveled as much as possible.

In order to improve adhesion, you can treat the base with a primer. The tile and work surface must be dry.

Only clean tools should be used to mix the solution. In a container, mix the dry mixture with water in the proportions indicated by the manufacturer and mix well.

Leave for 3-5 minutes and then stir again. The mass must be homogeneous. Further, the glue must be used within 3 hours.

The glue is applied to the prepared surface with a spatula. Grouting is done every other day.

Eunice tile adhesive is one of the most important tools in construction. It allows you to work with large tiles and greatly simplifies the process of laying them.

Features and scope of use

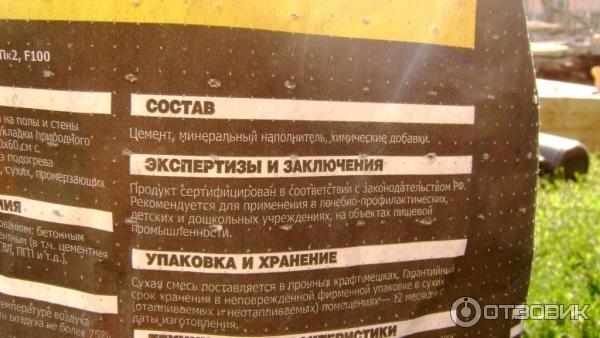

The basic composition of Yunis tile adhesives is approximately the same. It includes cement and mineral fillers: ordinary and quartz sand, gypsum, dolomite and others. To improve the technical parameters, each product is enriched with various chemical additives: modifiers, plasticizers, adhesion enhancers, etc.

Many compositions are suitable not only for ordinary tiles, but also for porcelain stoneware, since they have a high degree of adhesion to the following substrates:

- plaster;

- concrete, including cellular concrete;

- cement screed;

- asphalt;

- brick;

- drywall (PGP, GKL, GVL);

- cinder concrete;

- aerated concrete.

The products form a durable layer that does not break down over time in dry or damp rooms. Near building mixtures, you can level the floor with small differences in height, other tools are suitable for stairs and floors in shopping centers with high traffic.In addition, the use of Unis adhesives is possible in bathrooms, saunas, baths, because moisture-resistant adhesives can withstand even direct contact with water.

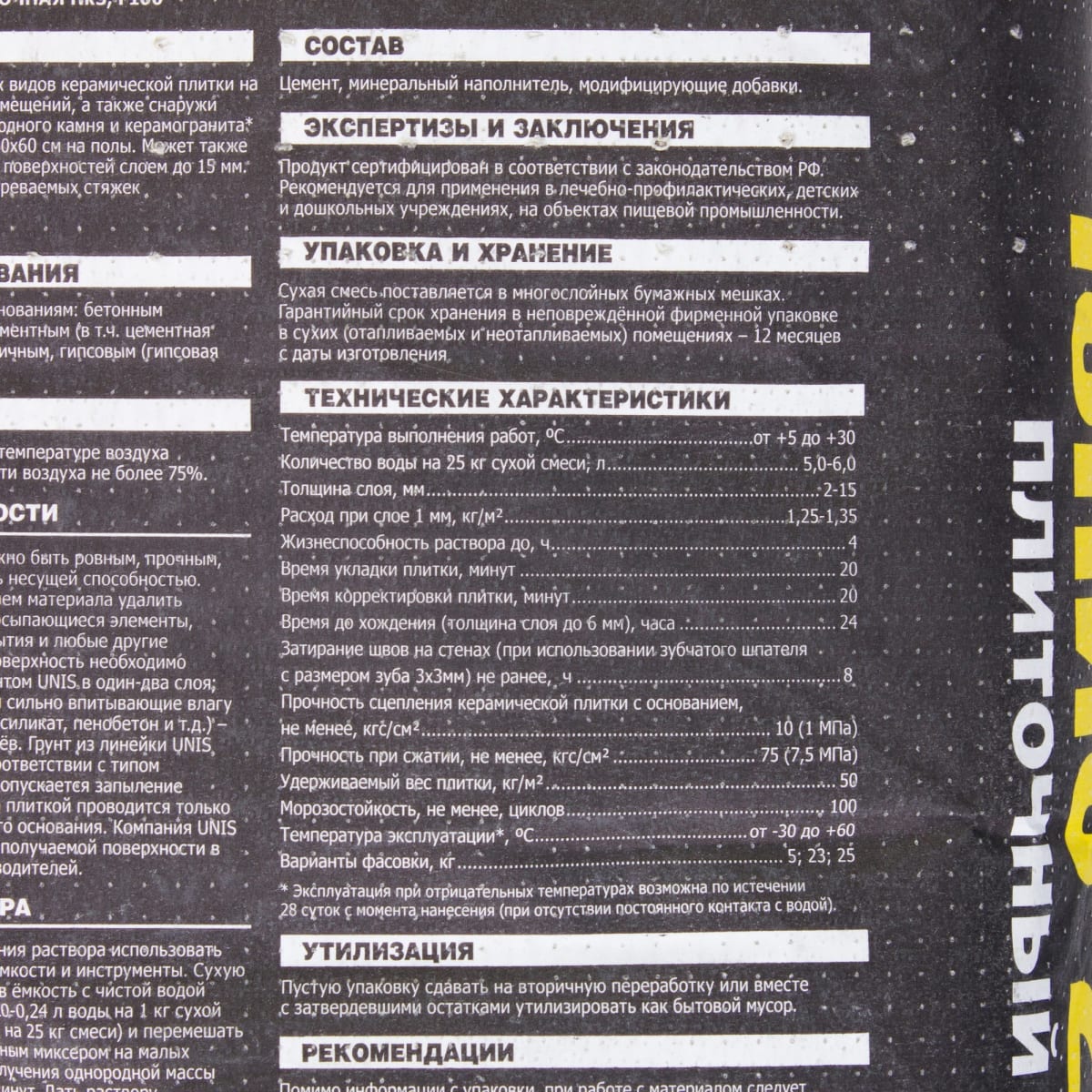

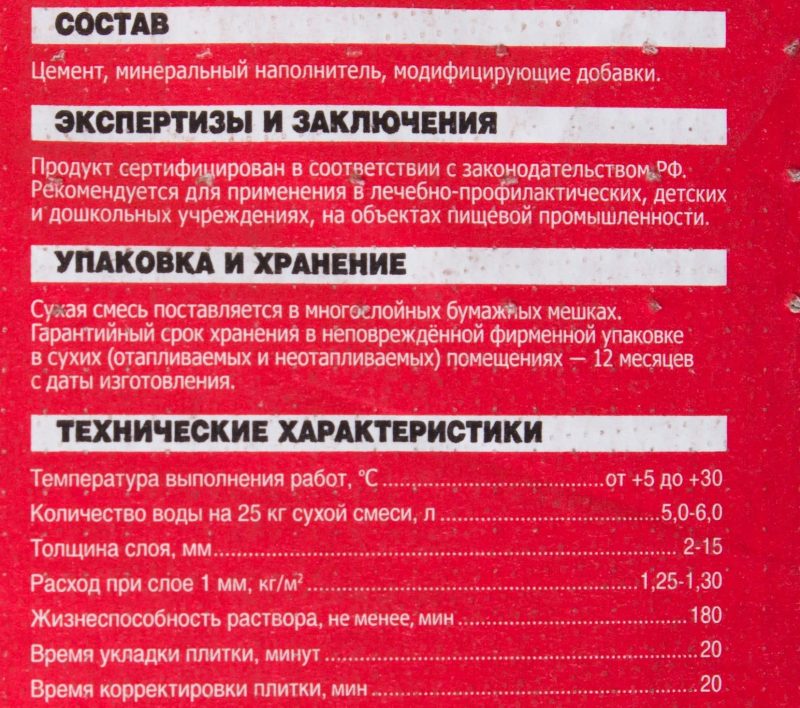

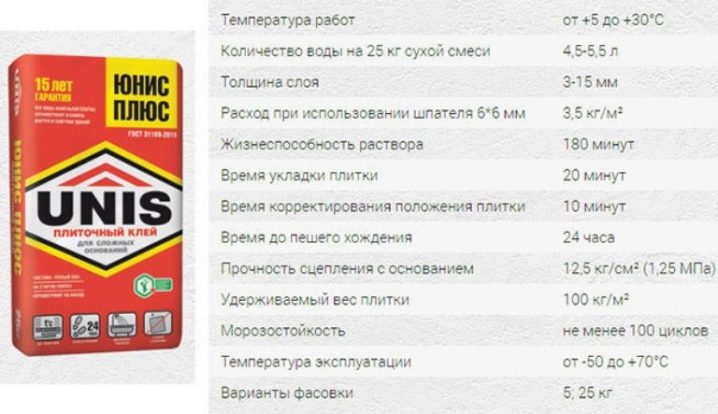

Specifications

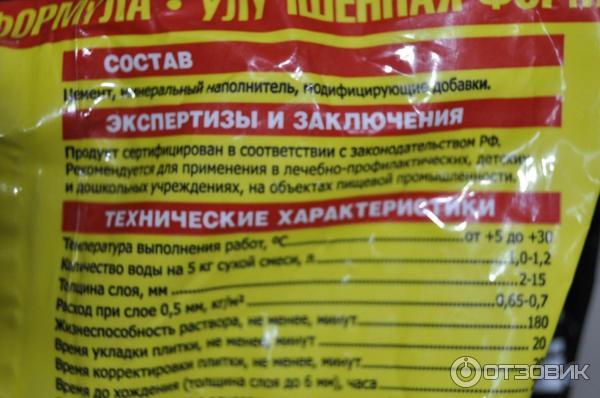

The main characteristics of the most popular adhesive of the Unis Plus series are presented in the table.

| Characteristic | Index | Possibilities |

| Adhesion | 1.25 MPa | Provides strong adhesion to the substrate not only of tiles, but also of heavier materials such as porcelain stoneware and natural stone |

| Consumption of the mixture (when applying a layer of 1 mm) | 3.5 kg / m2 | Economical packaging, low material consumption |

| Operating temperature | - 50 to 70 degrees | High level of thermal and frost resistance |

| Usage time | 180 minutes | Recommended to be diluted in small portions |

| Permissible layer thickness | 15 mm | |

| Drying time | About 24 hours | |

| Work performance temperature | +5 - +30 degrees | |

| Average laying time | 20 minutes | |

| Supported weight | Up to 50 kg / m2 |

Craftsmen without experience in carrying out repair work of this type are often mistaken in choosing a suitable adhesive solution.

To ensure a strong adhesion to the base, it is better to seek advice from a specialist in the store, and also carefully read the characteristics indicated on the product packaging.

Choice

Unis is available on the market in several formats, each of which is suitable for a specific type of renovation, material, temperature and many other factors. The name of the glue or on its packaging always says what this or that type is suitable for.

Unis Plus

The scope of application of the glue is very wide. Yunis Plus is suitable for renovation work inside and outside the building, securely fixes it to the base.

The safe composition and the absence of a sharp unpleasant odor allows the use of an adhesive solution when lining medical and children's institutions, houses.

Main factors:

- Adhesion - 1.25 MPa.

- The maximum load capacity is 100 kg / m2.

Scope of application - interior and exterior cladding, complex substrates.

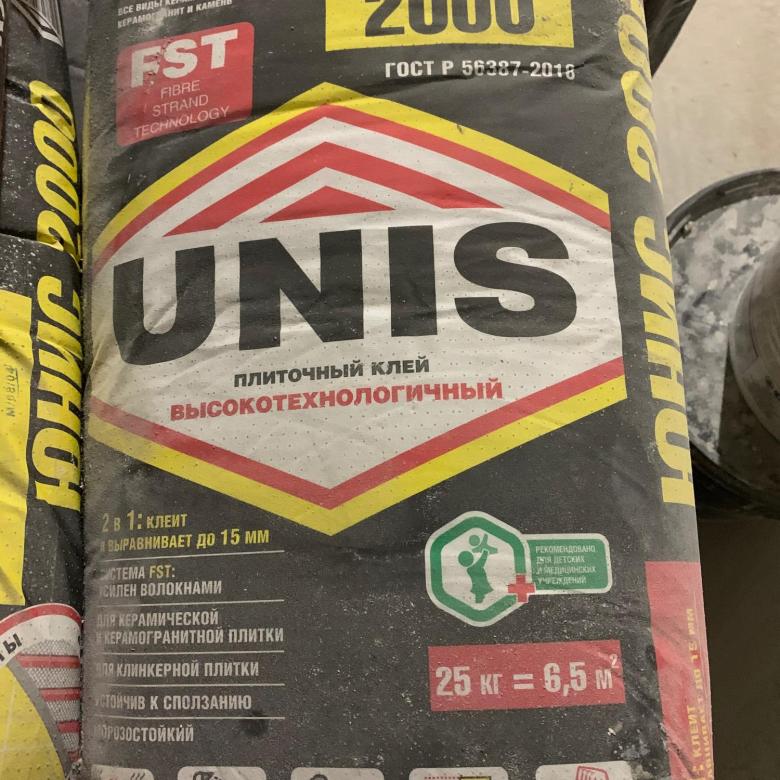

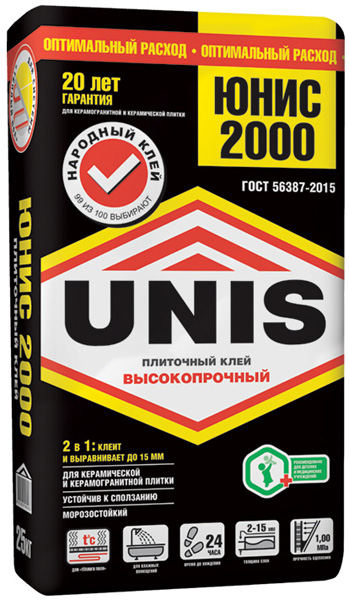

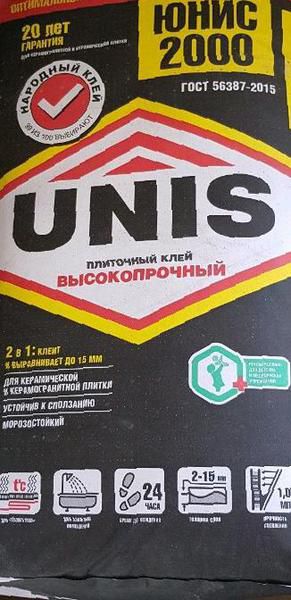

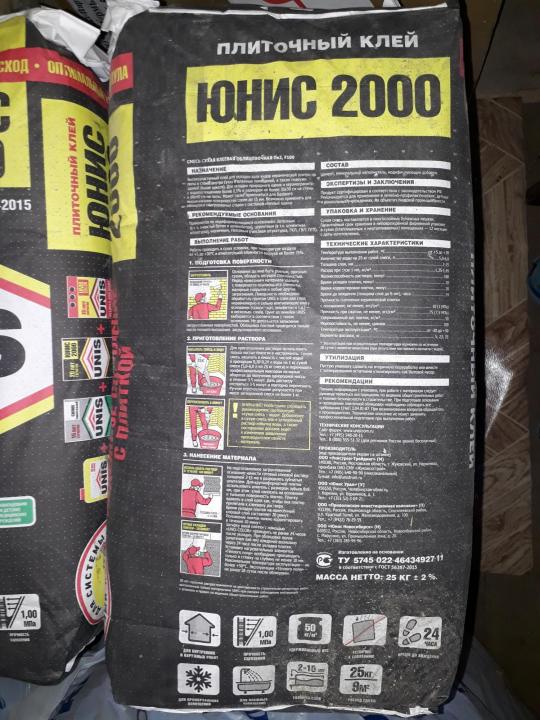

Unis 2000

Allows to cover the floor and walls without prior leveling, well fills in irregularities and cracks.

Withstands ceramic tiles and porcelain stoneware up to 60x60.

Unis 21

Typically used for interior wall and floor tiling with standard sized ceramic tiles. Differs in increased moisture resistance, is used in the repair of bathrooms and kitchens.

Able to withstand small-sized porcelain stoneware slabs (up to 30x30).

You only need to lay porcelain stoneware with Eunice 21 glue on the floor so that they are firmly pressed and the grip is strong.

Unis hitech

Hitech adhesive mixture is characterized by increased strength and does not dry out so quickly in comparison with other types. Allows you to lay it from top to bottom, and not just the standard method - it provides reliable adhesion to all types of surfaces.

Unis granite

By the name of the glue, it is clear that its main purpose is wall and floor cladding with heavy materials: natural stone, porcelain stoneware.

Provides tight adhesion and is suitable for laying tiles on floors, walls, plinths, facades.

Unis belfix

Suitable for complex cladding works, reliably holds natural stone, marble, granite, mosaic, porcelain stoneware. The main advantages are a high level of elasticity, frost resistance.

It is often used for grouting, cladding the exterior of a building, and decorating heated floors. The most expensive option presented.

For more information about frost-resistant glue, read the article - Frost-resistant glue for outdoor use

Unis fix

Cheap glue that is rarely found in hardware stores. In terms of strength characteristics it loses to other types, it is usually used for cladding walls and floors with standard small tiles.

Well repels moisture, suitable for cladding rooms with high humidity - kitchens, bathrooms.

Unis pool

Suitable for decoration, swimming pools, water tanks, ceramic tiles, mosaics, natural stone. Indoors, it can be used for cladding with high humidity, heated floors.

New tiles can be laid on top of old ones, also suitable for cladding untreated surfaces. Fills cracks and irregularities well.

Instructions for use

Works can be carried out at air temperatures from +5 to +30 ° C and relative humidity less than 75%.

Surface preparation

Before starting work, it is necessary to carry out the traditional preparation of the base:

Laying on flat walls and floors will be faster and better

Remove old finish, old flaking plaster or screed.

Level the base. Height differences of 1 mm per 1 meter are permissible. Cracks and defects with a depth of more than 10 mm must be leveled with plaster. The manufacturer recommends using Eunice "Silin", "Teplon" or "Standard" plaster, depending on the situation.

When laying on old tiles, in order to improve adhesion, notches are made on the old cladding every 5 cm in a checkerboard pattern.

Dry and degrease the surface.

In damp and basements, it is recommended to apply waterproofing coating using UNIS HYDROPLAST.

To improve adhesion, the surface should be primed 1-2 times with UNIS primer. Highly absorbent surfaces (gas silicate, foam concrete) should be treated especially carefully.

It is not necessary to wet the base or tile beforehand.

On an uneven base, the layer of glue will be uneven, which means it will set and shrink at different times. This can cause peeling or cracking in the tiles.

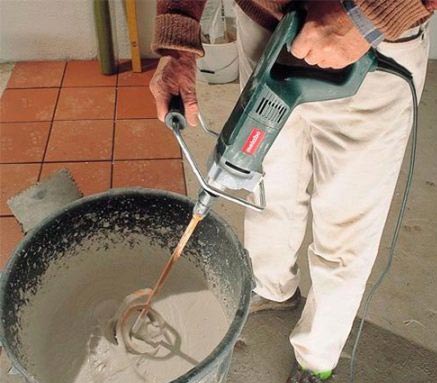

Stir until smooth without lumps

To mix the solution, use a clean tool and container.

The dry mixture is poured into a container with clean water in the specified proportions (see the table of technical characteristics or instructions on the package). The solution must be mixed until a homogeneous consistency is obtained for 3-5 minutes.

The solution should ripen in a calm state for 3-5 minutes, after which it must be mixed again.

Mixing can be done by hand or using a construction mixer / drill with a nozzle at low speed. When manually mixing, the portion of the mixture should not exceed 1 kg by weight.

The prepared solution must be used within 180 minutes (300 minutes for the HiTech mixture). If the mixture thickens within this time, it must be stirred without adding water.

If the specified proportions are not observed when mixing or adding other components, the properties of the glue may deteriorate.

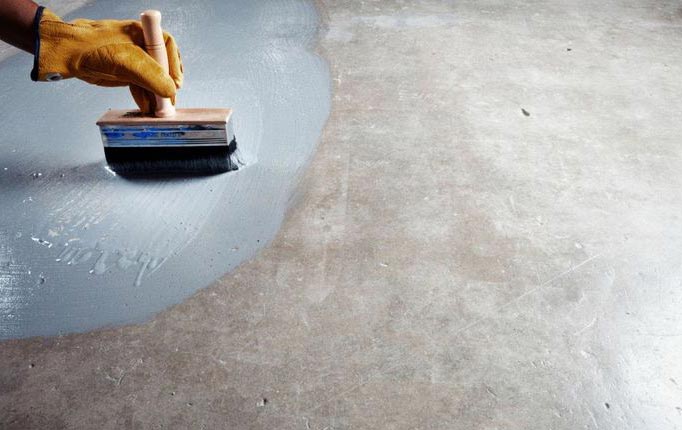

Glue application

Application of glue with a comb

- On the prepared surface, using a trowel or an ordinary spatula, the prepared mortar is applied with a layer of 3-15 mm and leveled with a notched trowel or a trowel-comb.

- For large tiles and porcelain stoneware, the size of the teeth must be at least 8 mm. The weight of large tiles should not exceed the maximum allowable weight.

- The tile is pressed onto the layer of glue. The glue should be evenly distributed underneath, avoiding voids. To do this, you can press the tile in wave-like movements, or tap it with a rubber hammer. After pressing, the adhesive thickness must not exceed the maximum permissible value (see table of characteristics).

- Apply glue to the area that you will have time to veneer during the pot life of the solution (10-20 minutes). Thereafter, adhesion will deteriorate.

Press down firmly on the tile to spread the grout

For outdoor work or for fixing marble slabs, light limestone, large tiles or with different thicknesses and reliefs, the mixture must be additionally applied to the working surface of the tile.

After laying, there is another 10-20 minutes for adjusting the position of the tiles. Level its plane. Use plastic crosses to maintain uniform seams.

After 24 hours, you can start walking on the tiles and start grouting with UNIS COLOR colored grout mixes.

The underfloor heating system can only be used 28 days after tiling.

comments powered by HyperComments

How to mix the solution?

A suitable container is required for this procedure. All tools must be clean.

Algorithm of work.

- The glue must be diluted in a ratio of 250 ml of water per 1 kg of dry composition.

- Then the resulting mass must be stirred for three to five minutes. It is best to do this with a special mixer or drill, which has a special attachment. If none of the above is present, then you can stir the glue with your hand. As a result, a homogeneous consistency should be obtained.

It is important to remember that the properties of the mixture after preparation are retained for only three hours, therefore it is important to correctly calculate the amount of glue required for a certain amount of work. When thickening, the mixture is mixed again, no need to add water.

If you do not observe the proportions, add additional components to the solution, do not follow the recommendations in the instructions, then the resulting mixture may not correspond to the declared characteristics.

Instructions for use

Before use, read the instructions indicated on the packaging by the manufacturer. This is especially true for beginners who do not have experience in cladding work. Instructions for use:

- Remove the old surface with a drill or wide spatula. If the wall is painted, the paint can be left and tiled, pre-level the surface with a putty.

- Differences in the base of the surface should not exceed 1 mm per 1 m. Seal especially deep cracks with plaster and cover with a primer mortar on top.

- If it is applied to a surface covered with paint, notches are made for every 5 cm of the wall to increase the level of adhesion of the material to the wall.

- At the end, the surface is well dried and degreased.

Surface preparation

The optimum temperature for facing work is from plus 5 to plus 30 degrees, the air humidity should not exceed 75%.

The most difficult thing is to properly prepare the surface. At the same time, it depends on the preparatory work how smoothly the tiles and the appearance of the room as a whole will lie. The base should be not only even, but also strong (it should not fall through or crack under the weight of tiles or natural stone), dry.

The surface to which the glue will be applied must be free of oil stains, paint coatings and all sorts of dirt.

Cracks and uneven sections of the wall are leveled with plaster. A thin layer of putty is applied on top to make the surface perfectly flat. In addition, coat with a primer mixture to ensure reliable adhesion to the adhesive.

For facing surfaces in basements, rooms with high humidity, swimming pools, apply two layers of primer, each well dried. It may be necessary to install a coated waterproofing barrier.

Before tiling, the tile or base does not need to be additionally moistened with water.

After installation, the excess glue is removed with a spatula. This should be done immediately, since Eunice of different types dries very quickly. Upon completion of the work, grout is applied to it in a tone or transparent color. Residues can also be removed with a spatula or damp sponge.

Mixing the solution

The glue solution is mixed in a bucket of water and mixed with a construction mixer.

It is important to observe all proportions and dosages indicated by the manufacturer on the packaging.

If you don't have a construction mixer, mix it by hand. In this case, the amount of glue should be no more than 1 kg, otherwise the mixture will not work out homogeneous, and it will not fit well. The prepared composition must be applied within 3 hours, otherwise it will begin to dry out and lose its basic properties.

The amount of water must be accurate, otherwise the mixture will be too thin.

Glue application

The application of Eunice glue takes place in several stages:

- To begin with, prepare the surface, patch up cracks and irregularities, cover with a layer of primer. Some adhesives will work well on uneven surfaces, but leveling will save you some time. This is especially true for beginners.

- It is better to apply the diluted solution with a spatula so that it is more convenient to distribute it over the surface. The thickness of the mortar should not exceed 15 mm, otherwise it will start to "sink" and will not adhere closely.

It is not necessary to fill the entire wall with glue; it is necessary to apply the mixture to an area that can be revetted in 15-20 minutes. - The position of the tile can be adjusted within 20 minutes after applying the adhesive. It should be leveled clearly.

- It should be applied not only to the wall, but also to the tiles.

Additional tips and tricks

It is not recommended to apply the EK brand adhesive solution immediately to a large surface area. This material hardens quickly. Therefore, the installers, if too large a layer is applied, will not have enough time to level the tiles. It is always recommended to prime the base during preparation. This must be done in order to avoid the appearance of mold in the room. This recommendation is especially relevant for cases when the walls in the bathroom are finished.

The thickness of the adhesive layer should be 1-4 millimeters. This indicator is usually indicated on the packaging with the material. But at the same time, the thickness can be varied in order to level the walls. The consumption of tile adhesive is not constant. This indicator depends not only on the type of material, but also on the characteristics of the treated surface. In particular, when finishing rough surfaces, the consumption of glue solution is reduced.

Share link:

How much dries

Curing of the glue takes place in 3 stages:

- The stage of the working structure is 15–25 min. During this period, the solution stops spreading under its own weight. The laid claddings can be adjusted and moved without cracking the mortar.

- Primary coupling stage. Usually it is 24 hours. After that, you can walk on the tiles and process the inter-tile space with grout. But the solution still contains a lot of moisture.

- Final curing. Depending on the type of glue and the location of the work, it can take 7-18 days. At this stage, the glue dries completely, gaining maximum strength and adhesion.

Varieties and technical characteristics of EK tile adhesives

There are several adhesives in the EK line, each of which differs in composition. Thanks to this variety, consumers can choose the material for a specific type of tile. EK 3000 belongs to the group of universal adhesives, the rest are highly specialized.

Regardless of the type of product chosen, it is not recommended to use the dissolved powder of this brand with large-format tiles, heavy tile cladding and porcelain stoneware.

3000

EK 3000 universal adhesive has the following characteristics:

- recommended operating temperature - 10-25 degrees;

- the strength of the adhesion of the material to the surface - 1 megapascal;

- the time required to prepare the adhesive composition - 4 hours;

- average material consumption - 2.5-3 kilograms per square meter;

- drying speed - 20 minutes.

Other types of EK glue have similar characteristics.

2000

EK 2000 glue is characterized by the following features:

- suitable for fixing tiles on external and internal walls;

- adheres to mineral materials, plastered walls, concrete and bricks;

- used for the restoration of minor defects;

- used for gluing medium and small tiles;

- the adhesion index is 0.7 megapascals;

- hardening time after application - 10 minutes.

EK 2000 is characterized by increased frost resistance and plasticity. The finished glue must be used within three hours.

4000

Means used for gluing heavy slabs and porcelain stoneware. EK 4000, due to increased adhesion, reaching 1.2 megapascals, fixes the material well on horizontal and vertical surfaces.With this tool, it is permissible to fill the voids and glue mineral wool with polystyrene foam.

1000

The tool is used to fix porous materials: aerated concrete, foam concrete and others. EK 1000 adheres well to tiles on various types of vertical and horizontal surfaces.

6000

This type of glue is used for mosaic surfaces. The material is used for finishing:

- swimming pools;

- baths;

- warm floors;

- joints and other surfaces.

EK 6000 glue is not picky about the level of water absorption of the tile.

5000

This type of adhesive is designed for tiling swimming pools, fountains and other water tanks. The material is suitable for exterior walls.