Alternative methods

To fix the polyethylene, you can use other devices.

Iron

It is possible to connect the sheets of polyethylene with the sole of the iron. In the process of heating, the material acquires a liquid consistency and combines at the molecular level. As a result, it is possible to achieve a strong fixation. To fasten the film with an iron, it is recommended to do the following:

- Find the right temperature. This is worth doing through practical trial.

- Place sheets on top of each other. To prevent the film from sticking to the iron, place a sheet of paper on it.

- Run over the sheet with an iron. As a result, the film should start to fuse.

It is important to ensure that the paper does not stick to the surface of the iron. If this happens, it is enough to moisten the sheet with a damp cloth and remove it after a few minutes

Soldering iron

To use a household soldering iron, you should use a special nozzle. Otherwise, the joint will have an uneven structure. To make the work more comfortable, the attachment should move like a roller. In addition, it is permissible to replace the sting with an aluminum bar. Its contact area should be 2 millimeters. It is permissible to weld with a copper bar with the same section.

To weld polyethylene, you need to do the following:

- fix the tip to the device with a screw;

- degrease the surface to be joined;

- combine sheets;

- run a hot soldering iron over the joint area;

- if it is necessary to fix a large area, a metal plate is used as a sting - it must be copper or aluminum.

Open flame

An open source of flame can be a gas burner or ordinary matches. You can also take a blowtorch or candle. By moving the fire source along the seam, it will be possible to achieve a strong fixation of the film.

To do this, you should do the following:

- degrease polymer sheets;

- fix the material with bars;

- the welding area should protrude 3-5 millimeters beyond the edge;

- draw the flame source over the protruding area;

- the film will melt and weld;

- as a result, a seam will form, which resembles a dense roller.

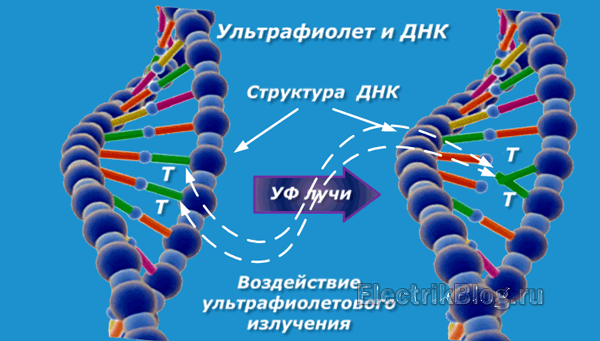

What is ultraviolet and how does it work in simple words

This is the name of electromagnetic radiation, which occupies an intermediate position between the waves of the visible spectrum and hard X-rays with wavelengths from 400 to 100 nm.

The range from 400 to 315 nm is considered long-wave (designated A), 315-218 - medium-wave (B), 280-100 - short-wave (C).

The bactericidal effect of ultraviolet radiation, as a high-precision weapon, is based on irreversible damage to DNA strands. As a result, cell membranes and RNA are also destroyed, which is much more profitable than chemical disinfection methods.

The long-wavelength range has the weakest biological effect. Medium-wave spectrum rays already have antirachitic properties, and waves of 280 ÷ 200 nm destroy the simplest microorganisms.

The main artificial sources of UV radiation are mercury and xenon lamps.

The spectra of DNA inactivation and protein absorption depend on the length of the electromagnetic wave acting on it.

In other words: not all have a bactericidal effect, but only those UV rays that are well absorbed by the plasma of microorganism cells. Moreover, they destroy not only the functional structure of microbes, but also their hereditary apparatus.

Ultraviolet:

- damages the structure of DNA;

- stops cellular respiration;

- excludes subsequent reproduction of cells.

Thus, microbes from UV rays die not only in the first, but also in the next, subsequent generations. They completely stop their development.Due to this, the air masses in the room are sterilized.

However, it should be borne in mind that if ultraviolet radiation is not used correctly, serious harm is caused even to the body of an adult:

- damage to the eye cornea and the subsequent weakening of vision in welders who have picked up "sunbeams" is one of the striking examples. Therefore, it is always necessary to work with germicidal lamps in safety glasses;

- redness and burns of the skin, its mutations leading to melanomas and cancer, premature aging are associated with excessive tanning. Therefore, in tanning salons, the mildest ultraviolet light is used, and its dosage is strictly regulated.

Artificial UV sources in everyday life, in addition to medical purposes, are used for:

- degradation of paints and polymers during restoration work;

- disinfection of air and external surfaces of furniture from bacteria;

- disinfection of drinking water;

- catching blood-sucking insects;

- acceleration of drying of paints;

- cleaning swimming pools and a number of other tasks.

How to glue with epoxy glue

To properly glue the polyethylene, its surface should be properly prepared. To do this, it should be degreased and dried. It is recommended to treat both elements with special solutions. For this, it is permissible to use chromic anhydride with a concentration of 15-20%. You can also use potassium dichromate 20-30%. These substances have a caustic consistency and are classified as dangerous carcinogens.

It is also permissible to take another powerful oxidizing agent. A strong solution of potassium permanganate can play its role. It is practically not inferior in efficiency, but it is considered safer. After surface treatment it is recommended to dry it again. Then it is worth preparing the epoxy glue. To do this, it is recommended to use the instructions. Cover both fragments with a thin layer of glue and join them together. Keep for several hours. This should be done at a temperature of + 30-45 degrees. However, it is better to leave the product for a day.

Classification of adhesives

Adhesives differ in different characteristics. This helps you choose the right option depending on your tasks.

By the principle of action

According to this criterion, one- and two-component compositions are distinguished. The first category is used for fixing simple products. Two-component substances are used for volumetric structures that require a high degree of reliability and strength.

By composition

Depending on the components that are used to create glue, the following types are distinguished:

- silicone;

- polyurethane;

- acrylic foamed;

- ethylene vinyl acetate;

- hot hardening.

By the complexity of use

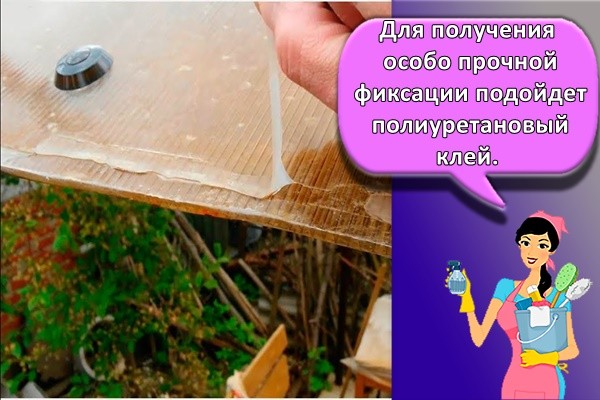

To create a small and not too strong bond, it is permissible to use an ethylene vinyl acetate adhesive or hot curing agent. They are applied quite easily - using special guns. For extra strong hold, use polyurethane adhesive.

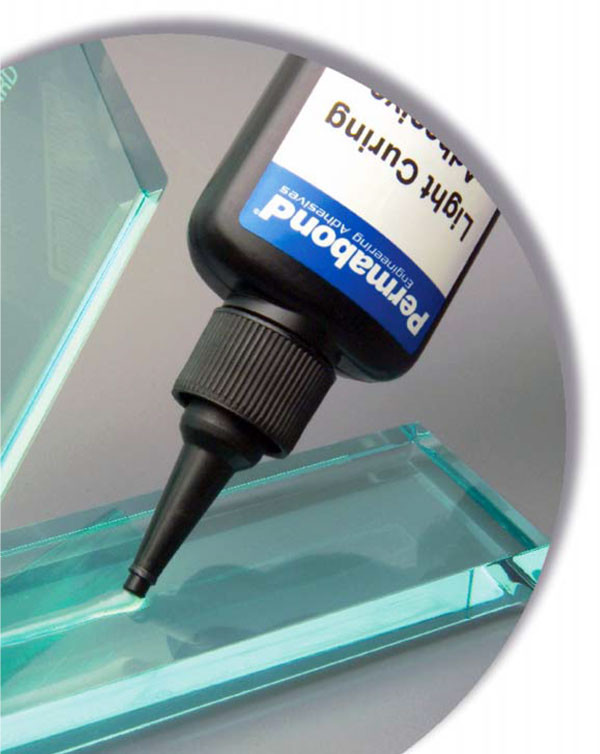

By the degree of transparency

All adhesives differ in transparency. The choice of color and texture is especially important when fixing transparent plastic.

By viscosity

When choosing a material for fixing, be sure to take into account the degree of its viscosity. It is chosen depending on the product that is planned to be fixed.

Selection rules

The Spectr company produces transparent adhesives of various viscosities:

- Low (K-59N, K55N). Suitable for bonding glass to metal, stone, wood, plastic, rubber or other glass surface. Least strong of all glue structures, well suited for gluing cookware, cell phone repairs, or rubber gaskets.

- Medium (K-22V, K-24S). Not suitable only for bonding rubber to glass base. Used for gluing most household items.

- High. At this viscosity, it is possible to connect glass only with plastic, metal and stone.The most durable connection that can withstand high temperature and physical stress. High viscosity UV glue is usually used when replacing a windshield, for a stronger bond of the glass edges to the metal.

Under what physical and temperature loads you need to use this or that viscosity, and how to correctly calculate the polymerization time using a UV lamp, you can find out in more detail in the instructions attached to the glue.

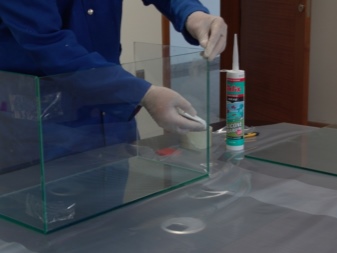

How is gluing done

Each package with glue is accompanied by instructions on how to use it, depending on the material glued to the glass. For example, you can consider how glass and plastic are glued during the repair of the phone display:

The surfaces are cleaned with any alcohol-based solvent (ethyl alcohol, white spirit) and dried.

UV glue is applied evenly on the glass surface or on the phone

It is important to ensure that the glue is not exposed to sunlight during application. Sunlight contains a UV spectrum that causes the adhesive structure to polymerize.

The glass and the phone display are neatly joined together, and any loose glue is removed.

Wearing glasses with UV filter

It is impossible to use a UV lamp without protective glasses - the rays have a negative effect on the retina of the eye.

Pre-gluing is carried out, which takes 10-60 seconds, depending on the power of the UV lamp. At this time, the strength of the glue line reaches 70%. After completing the preliminary gluing, you need to re-inspect the product and remove any excess glue that has come out.

After minor flaws are eliminated, the final polymerization is carried out, the duration of which is 1-5 minutes, depending on the lamp.

Important: to obtain a strong adhesive seam, the entire surface covered with glue must be irradiated at the same time. If individual areas are heated, then the resulting connection will be fragile.

A well-chosen UV glue ensures a long-term and reliable connection of glass to any surface. Today, the products developed by the Spektr Research Center are considered the best for bonding glass substrates to metal, wood and other materials.

Rules for choosing an adhesive for auto glass

For the repair of windshields, it is necessary to use compounds that provide maximum bond strength. Experts recommend that beginners choose high-density adhesives that, when dried, give the best quality result. Also, the tool must have an indication of its good penetrating ability, otherwise it will not be able to repair microcracks on the glass.

To choose the right glue, you need to pay attention to the following characteristics:

- the degree of transparency;

- resistance to UV rays;

- elasticity, ability to withstand vibration;

- frost resistance and heat resistance;

- resistance to temperature extremes.

You should also make sure that the shelf life of the glue is normal, and that the composition contains polymer resins. For a small, shallow scratch, you can choose a very thick glue, since sealing the defect does not require a high degree of penetration of the composition into the depths. For cracks of considerable depth and length, products with the highest degree of adhesion are purchased. If the defect exists for a long time, the repair may not bring the desired result, since it will not be possible to completely clean the crack of dust. In such a situation, it is better to go to a car service to a professional master.

Device and principle of operation

An ultraviolet light bulb consists of the following parts:

- housings (tubes or flasks of a special shape);

- tungsten electrodes;

- plinths made of durable plastic or glass;

- molybdenum current-carrying filaments;

- reflex and phosphor layers.

The classification of UV lamps is made according to the following criteria:

- operating principle (open, closed, special);

- power;

- a method for producing UV radiation (high or low pressure);

- dimensions;

- installation method (portable, mobile and stationary);

- the composition of the spectrum;

- the principle of ozone formation (ozone and ozone-free);

- service life;

- place of installation (floor, wall, ceiling, table).

Life hack for gluing glasses

Before talking about how to glue glass to glass, it is necessary to mention the importance of surface preparation. It is cleaned of grease and dirt using a solvent or special cleaner.

After that, before applying the composition, the surface must be warmed up to a temperature that will be about 30 degrees above room temperature.

Regardless of whether you use optical glue or any other, you need to apply it in a minimum amount. After the parts are glued together within the time specified in the instructions, as a rule, it is 60-120 seconds. If UV glue was used, then the connection is additionally trained.

It is not difficult to restore your favorite glass item if you correctly approach the repair. But what kind of glue for glass is better, everyone decides for himself. Among the many different compositions and brands, experts prefer UV, and ordinary people prefer the usual Moment. It will be doubly pleasant if you share your experience in the comment below.

Practical advice

And finally, a few important recommendations:

- Do not rush to glue the parts with the first composition that comes across, choose the one that is suitable for your specific situation;

- Read the recommendations carefully when buying glue;

- If you need to glue large areas, then it is better to apply the composition with a brush, and then the glue must be poured into a convenient container;

- During work, you can not be limited to the use of gloves, but also wear a protective mask or goggles;

- If the adhesive contains a solvent, ventilate the room.

The glue should be suitable for the type of glass that will be glued, therefore, before purchasing, you should familiarize yourself with the manufacturer's recommendations on the product label.

The glue should be suitable for the type of glass that will be glued, therefore, before purchasing, you should familiarize yourself with the manufacturer's recommendations on the product label.

The well-known saying: “You cannot glue a broken cup” is no longer relevant today. There are many different compounds with which you can glue all sorts of parts, and this can be done almost imperceptibly.

When working, you must protect your eyes by wearing goggles. If the glue contains a solvent, then the room should be ventilated by opening a window or window.

When working, you must protect your eyes by wearing goggles. If the glue contains a solvent, then the room should be ventilated by opening a window or window.

How to use glue correctly

Before proceeding directly to the connection of parts, you need to prepare detergents, rags, preparations for degreasing. If the item being repaired needs to be heated or irradiated, you will need an ultraviolet lamp, press, or vise to hold the item in place.

Preparation of the base

For perfect adhesion, it is important to clean the surfaces to be bonded. Even a small amount of dust, dirt or rust will greatly reduce the strength of the joint

If there is no decorative coating on the metal part, it is simply wiped with a rag dipped in white spirit or acetone. They can be replaced with regular rubbing alcohol or vodka.

The glass part is degreased in the same way. This procedure can be replaced by washing the glass in a soapy solution and then rinsing off the foam.

Important!

If the part was washed with soap, you need to additionally wipe it with alcohol. This will wash away the film formed on the surface from household chemicals. If the parts are coated with paint or varnish, the coating is cleaned with sandpaper, washed and degreased. The surfaces must be completely dry before applying the adhesive.

Gluing

To ensure the strength of the connection, the parts are heated to a temperature of +40 degrees

In this case, the glass must be heated carefully so that it does not burst from a sharp temperature drop. An open flame is not used for this.

Blowing hot air from a regular hair dryer will do.Such manipulation will simultaneously dry the part and remove invisible condensation from the surface. In addition, the internal stress of the cooled parts will be minimal. This has a positive effect on the strength of the joint.

↓↓↓

Then the work is done in the following sequence:

- Both surfaces are covered with glue.

- The product is rubbed, creating a layer of minimum thickness.

- Especially carefully distribute the glue along the edges of the part.

- Fold the surfaces together.

- The product is fixed in a vice or placed under a press, creating even pressure.

If, after loading, drops of glue come out of the seam, they are immediately removed. After drying, it will be difficult to clean the surface. The press should not be too heavy so that the product does not break.

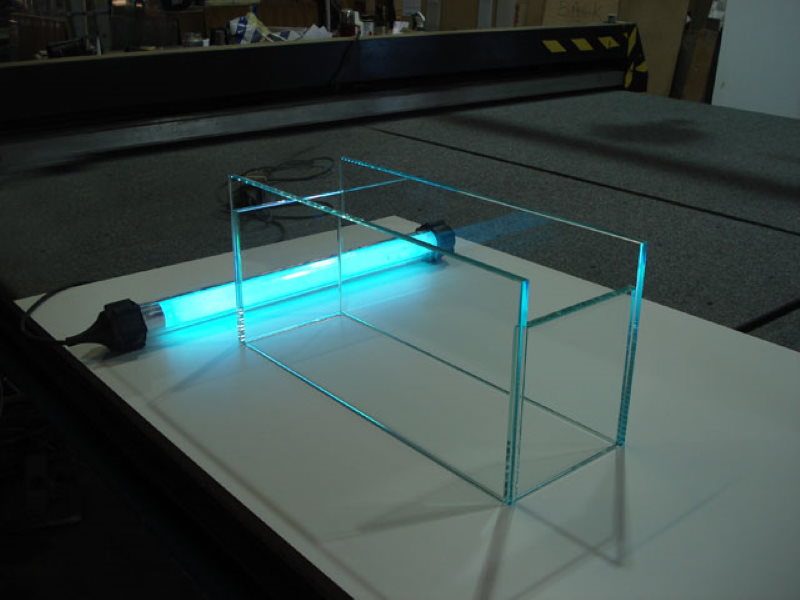

How to use a UV lamp

To create a stronger and more reliable connection, ultraviolet irradiation is used. Before this, the parts are heated to a higher temperature. It should be +60 degrees. After that, the selected agent is applied and smeared with a thin layer. Then the parts are aligned and the joint is irradiated with an ultraviolet lamp in two passes. After the first irradiation, a strength of 70% is achieved. Subsequent processing increases this figure to 100%.

Important!

The duration of exposure depends on the power of the lamp. For the first time, 10 to 120 seconds is sufficient. Then, with repeated processing, this time is increased to 1-5 minutes. This technology provides a very strong and tear resistant joint.

How to glue

It turns out that this is only at first glance gluing - a process without much wisdom.

In fact, it is important to know exactly what and how to do, otherwise the result will disappoint you.

The subtleties of the glass bonding process depend on what material the parts are made of.

The subtleties of the glass bonding process depend on what material the parts are made of.

First of all, before starting work, prepare the parts to be glued, latex gloves and adhesive. Cover the table (floor or curbstone) on which the work will be carried out, then it will be easier to remove the drops of glue. Wash the surface of the parts to be glued with soapy water or degrease with alcohol. If you are gluing broken pieces, be careful not to injure yourself on sharp edges.

The surfaces of the parts must be washed in water and soapy water or degreased with alcohol.

The surfaces of the parts must be washed in water and soapy water or degreased with alcohol.

After drying, apply glue to one of the parts and press the other firmly against it. If you are using a cyanoacrylate compound, then the pressing time is a few seconds. If the glue is silicone, it will take a few minutes.

If you use UV glue, then after the above steps, you will need to heat the parts to 40 degrees. To do this, you can use a hairdryer

It is important to position the part so that the glue does not drip from it, firmly fix the surfaces to be glued, and then place it under a UV lamp for 30 seconds. If you do not have a special lamp, leave the aligned parts in direct sunlight.

Of course, in this case, it will take more time, but the quality of gluing will be decent. If excess glue appears at the edges, then they are cut off with a knife or removed with a special scraper, but only after hardening.

The protruding glue is removed with a scraper or cut off with a knife after hardening.

For bonding glass and metal, the main thing is to choose the right composition. Either UV glue or another adhesive will do, but always with a gel-like consistency. This will prevent the glue from flowing around the edges. The surfaces are degreased and heated up to +40 degrees. The seam is positioned horizontally and glue is applied to it. After that, the parts are tightly pressed and fixed with special clamps.

In the absence of a lamp, the parts can be placed on a window in the sun, it will take more time to polymerize, but the result will be the same.

In the absence of a lamp, the parts can be placed on a window in the sun, it will take more time to polymerize, but the result will be the same.

Top brands

Craftsmen most often use themselves, recommend to others two brands of UV adhesive:

- LOXEAL UV 30–20 glues glass, metal and plastic coatings.It cures quickly when exposed to ultraviolet radiation, resulting in a completely transparent, durable seam. The compound resists moisture, vibration, shock, temperature fluctuations, chemical elements.

- LOCA TP-2500 ensures the formation of a seam capable of transmitting the entire spectrum of light. Curing occurs within 10 minutes when exposed to an ultraviolet device. In the future, the layer remains transparent throughout the entire operation stage of the product without loss of properties.

Cheap options

If you do not want to spend a lot of money on gluing the desired surfaces, then you can use "Superglue", a component of which is cyanoacrylate.

It is very easy to glue glass to metal with it. The main thing in working with this glue is polishing metal surfaces and applying the product in a very thin layer. The adhesion will be strong if you apply a little glue. After a few seconds, the surfaces will be glued.

Although there is a significant disadvantage - if the environment is humid, then the tool will not help.

So, we have disassembled the means for gluing metal and glass surfaces. Which tool is better to choose is up to you. The main thing is not to neglect the rules of working with glue. Only in this case the structure will last a long time.

How to glue metal to metal? Instructions

So, you seriously intend to start gluing metal products. But, before gluing metal to metal, choose the glue that suits the tasks.

Choosing the right adhesive

- If you need to connect large enough metal parts and cannot do without overlap, epoxy glue is ideal.

- Would you like to connect the "tunic to the tunic", that is, to glue the small parts? Use adhesives containing cyanoacrylate.

- Need to repair a thread? Feel free to buy anaerobic glue.

- If you need the "gluing" to go as quickly as possible, cyanoacrylate glue will help.

- In a situation where you can have the right to correct errors, epoxy glue is needed, which does not freeze immediately and makes it possible to move the adhesive surface.

Preparation of the adhesive surface

After the glue is selected, it is necessary to prepare the surface to be used, get rid of rust on the metal. Thorough cleaning allows the adhesive to adhere better, which means the result will be more reliable. You can clean the surface with materials such as sandpaper or a metal bristle brush. It should be noted that when cleaning coarse dirt on large surfaces, it is allowed to use a grinder with an abrasive brush.

Preparing the glue

If the glue requires preliminary preparation (for example, to get epoxy glue, you must first mix its components), then use a plastic bucket to make it, mix the mass, preferably with a plastic spatula.

Application of adhesive mass

At this stage, focus on your needs. On large, bulky materials, glue is best applied using a plastic spatula, and when gluing small parts, you can do with a regular match.

Protected from moisture

In the process of hardening the adhesive, try to avoid exposure of the glued surface to moisture. If the glued surface is constantly in the "fresh air", then it would be best to additionally cover it with a water-repellent solution. If the gluing process takes place on the street, stock up on an awning or umbrella, which will protect the uncured surface from excess moisture.

The ideal climatic option for the work performed will be room temperature with minimum air humidity.

Safety engineering

Following this simple instruction - how to glue metal to metal, and you will achieve the desired gluing quality. In the process of work, it is best to protect yourself from direct inhalation of the vapors of the hardening adhesive mass, since it is they that have the maximum toxicity.

The ideal and safest option would be to use a special respirator, which can also be purchased at a hardware store. Remember, your safety is in your hands.

Popular brands

For gluing plexiglass, agents are used that include solvents, acids, polymers.

Acrifix 116

A one-component solvent based compound (dichloroethane) suitable for bonding cast and molded plexiglass. Viscous, transparent adhesive, resistant to high and low temperatures. When connected, it fills cavities between parts.

Acrifix 117

Adhesive similar to Acrifix 116, with which it mixes easily. The consistency is liquid. Does not form cavities with PLEXIGlAS GS (high molecular weight material).

Glue COLACRIL-20

Liquid product. Does not contain solvents. The connection is transparent, but not as strong and durable as Acrifix.

Moment

The special instant adhesives contain cyanoacrylate. The tools allow you to firmly glue plexiglass parts, small in volume and weight.

Cosmofen

Liquid superglue for gluing plexiglass. The composition is similar to the Moment. The disadvantage is a short-lived, noticeable seam.