Application

Before proceeding with the application of conductive varnish, the container with it must be shaken well. The surface to be treated must be pre-cleaned of contaminants such as dirt, dust, grease and moisture. The varnish should only be applied to dry and clean surfaces. The varnish mixture is applied in a small layer, you need to work quickly and accurately. After surface treatment, the container with varnish must be hermetically closed, and if a solution was used in a can, then the valve must be thoroughly cleaned, and then the can is closed with a lid.

Varieties of conductive glue, characteristics of the adhesive

The basis of the glue is a polymer (synthetic resin), on which the viscosity depends. The higher it is, the better the glue adheres to the treated surface. The current conductor is a metal, finely ground to a powdery state (gold, silver, nickel, palladium). To improve the conductive properties and increase the adhesiveness, the filler is treated with synthetic fatty acids, which improves its activity by 10 times. Depending on the components that have the ability to conduct current, the glue is divided into the following types:

- Silver based. The base of the glue is a synthetic resin (polyester, phenol-formaldehyde, polyurethane, epoxy, organosilicon), which provides low viscosity and elasticity. Finely dispersed powder of 999 silver is added to it, the specific gravity of which is several times higher than the amount of polymer resin. This low-toxic agent does not change its properties even at 110C, perfectly isolating and retaining heat or cold. Has a resistivity of 0.5-0.8 Ohm / cm. It is used in radio devices to create electrical conductivity on dielectric panels. It is the most expensive but effective adhesive.

- Based on gold. Such an expensive conductor is needed if an acid acts on the device or electrical circuit during operation. Glue with finely dispersed gold has the highest electrical conductivity, but its cost is much higher than analogues based on silver or nickel.

- Graphite based. It is an inexpensive adhesive with low conductivity. It has lower quality characteristics than a product based on silver or gold, but more affordable in price. It is often used to connect the threads of heating the rear window of a car, where a large amount of glue is required. The base is a copolymer consisting of vinyl acetate, which contains graphite, which has the property of passing current. Has a resistivity of 5 × 10-3 Ohm / m.

Polymer binders increase the adhesiveness of the adhesive, i. E. its ability to adhere firmly to various surfaces. High elasticity prevents it from spreading over the surface. If it is necessary to increase the viscosity of the glue, let it settle. Particles of metal filler will settle, and the excess adhesive base is removed from above. Adhesiveness suffers from this procedure. Also, polymers make it possible to withstand temperature extremes, vibration, shocks, so the glue is used in the repair of car electrics.

Regardless of the active filler, all conductive adhesives have low thermal conductivity. This means the temperature difference at the interface between the glued surfaces. If it is undesirable, certain components are added to the glue. Copper has the highest thermal conductivity, it is 0.940 × 10-5 W / cm, but the most common filler is beryllium oxide (0.142 × 10-5 W / cm). The lowest thermal conductivity is in asbestos (0.0008 × 10-5 W / cm) and titanium dioxide (0.014 × 10-5 W / cm).

Means for the repair of equipment

All devices powered by electric current have one big drawback: the ability to fail. And here you have to turn to specialists of different levels: from professional electronics engineers to home-grown radio amateurs.

All devices powered by electric current have one big drawback: the ability to fail. And here you have to turn to specialists of different levels: from professional electronics engineers to home-grown radio amateurs.

Their field of activity involves the repair and adjustment of an extremely wide range of equipment. And if in one case it is possible to do with quite standard and usual means, then in others it is necessary to find more rational and cunning approaches for the qualitative restoration of the operability of the failed equipment.

One of these means is conductive glue, or conductive varnish. Indeed, thanks to them, the repair of complex electronic equipment becomes much easier, and sometimes even the only possible one.

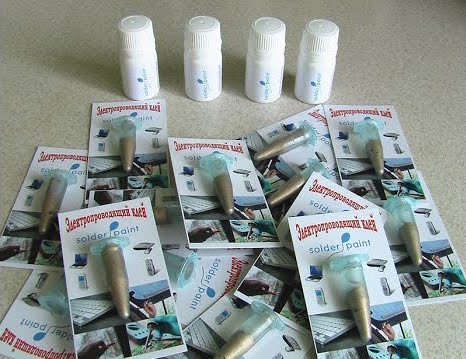

Types of glue "Kontaktol"

Electrically conductive adhesive Kontaktol is a product of the well-known concern Keller (Germany). The manufacturer offers the following modifications:

- “On silver” - a one-component composition based on purified silver for creating electrically conductive tracks on textolite and other solid substrates;

- glue "Radio" is created with graphite filler, therefore it is cheaper compared to the previous version;

- The adhesive marker is made of silver powder with PVC filler - this solution simplifies the handling of the reducing agent in difficult working conditions.

For your information. Glue Kontakol electrically conductive after hardening creates a moisture-resistant "track". Standard containers - 2, 5 and 10 g. Resistivity - 0.01 Ohm per cm cube.

Making conductive glue at home

The high cost and high consumption of an industrial adhesive often makes you think about how to make a conductive adhesive with your own hands.

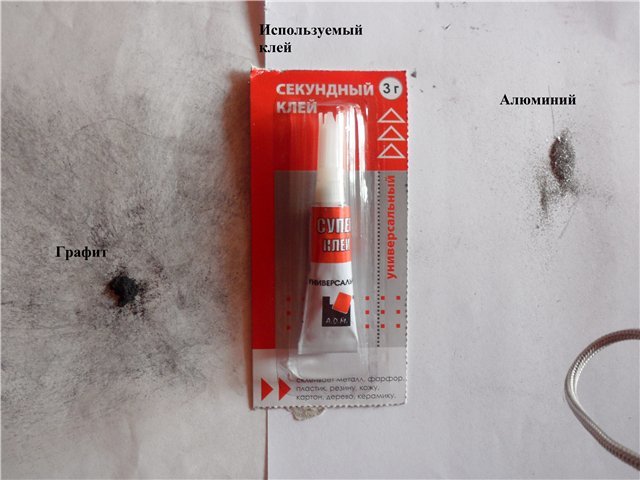

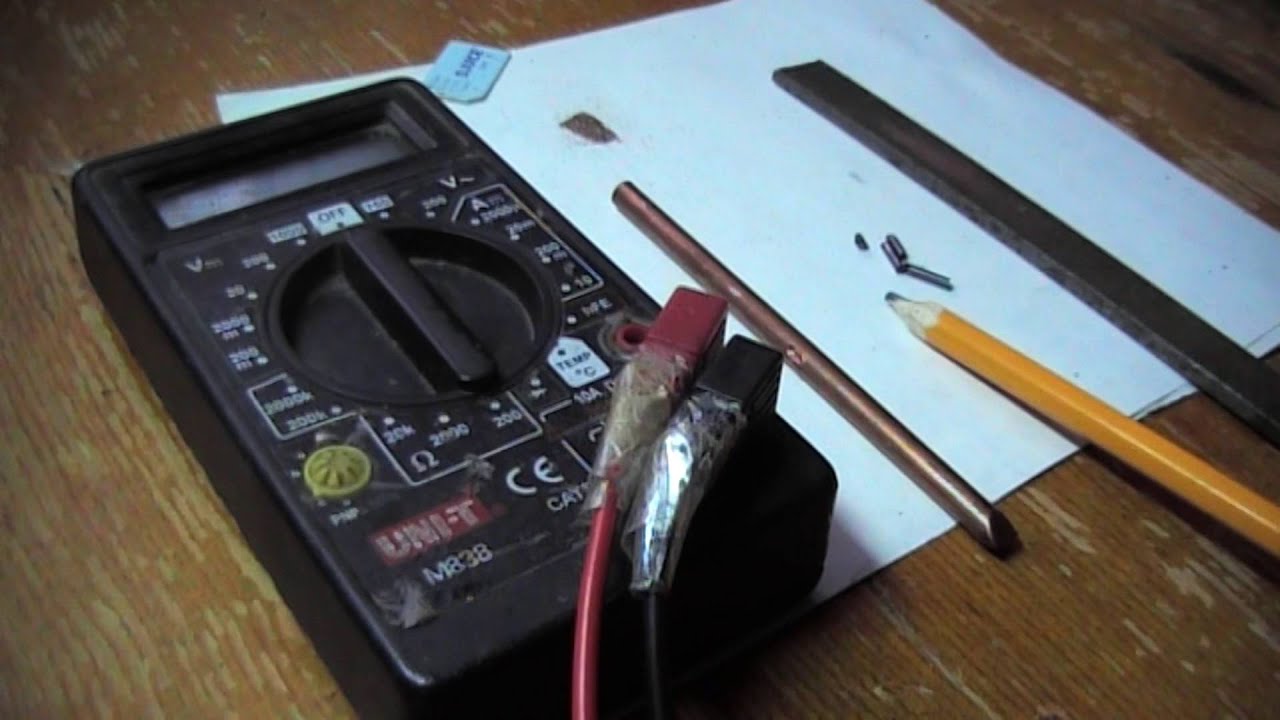

The simplest method is to enrich a conventional adhesive with an electrically conductive component, metallic or hydrocarbon, to form an electrically conductive adhesive. For this purpose, you can use any product based on cyanoacrylate. Graphite powder is used as a component providing electrical conductivity. The substance is easy to prepare from the lead of a simple pencil, which must be crushed to the desired consistency.

Watch the video to learn how to make glue yourself:

The volumes of glue and graphite powder must be equal. For ease of use of the substance, the components can be connected directly in the tube by unscrewing the lower part of the package. The graphite and glue must be gently mixed until smooth using a wooden or glass stick. This self-made conductive glue differs little in its qualities from the factory glue, especially when used to repair car glass heating filaments.

Tsaponlak can act as an adhesive base, which is used to cover the adhesion points in electronics. The electrically conductive powder is made from a graphite rod of a salt battery. Equal parts of the components are mixed.

The resulting substance is excellent for fixing small parts when repairing household appliances. Regular nail polish can be used as a viscous base. Such a composition can be easily removed with a solvent if applied incorrectly. However, good adhesion of the resulting product should not be expected.

The described compositions can be used to fix elements that are not mechanically stressed. More ingredients are needed to obtain a stronger adhesive.

Making conductive adhesive

Making conductive adhesive

A copolymer of vinyl chloride with vinyl acetate (CP-430, A-15) is used as an adhesive base. It is necessary to combine 35 g of the substance with the same amount of silver powder and add 15 g of graphite, crushed to a dust structure. In a glass container, the resulting bulk substance must be mixed with 35 ml of acetone.The finished product has a dark gray color and a molasses consistency. The viscosity of the substance can be adjusted by dissolving with acetone.

The glue made according to this recipe has a high electrical conductivity, and its use ensures a strong connection of the elements.

Unusual recipe for almost zero resistance conductive adhesive! - DRIVE2

I am posting for review the work of one dude for your fair trial! I want to prepare this glue and try it at myself too - restore 2 heating tracks. Let's go, I don't change the text and publish on his behalf.

At first, I had the hope of making glue in the traditional way - from a soft pencil lead, from brushes from an electric motor, from a central contact of a salt battery.

But every time I was disappointed - during drying, the resistance of the glue, at best, was in the hundreds of ohms.

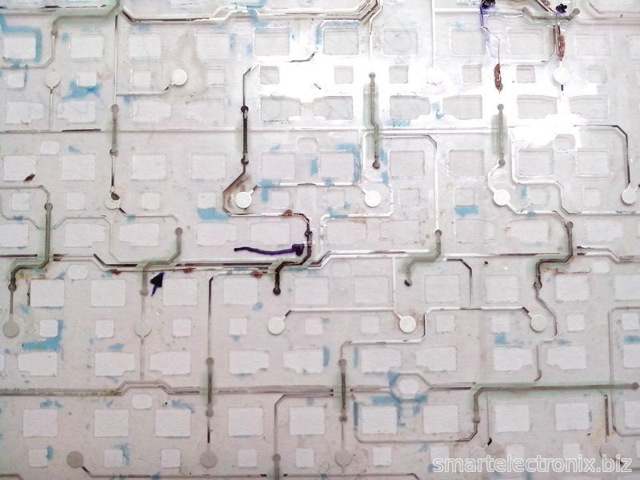

For a single button, it might have worked, but when an entire field of keys had multiple damages, the result was not hard to guess.

Googled like any experienced radio amateur. Yes, silver-based recipes are found on many sites. But the trouble is that I do not have the necessary chemical components and it is almost impossible to get them in Lugansk now.

I began to think about what to replace the silver with. And then it dawned on me: after all, ordinary copper is little worse than silver. It is present in many details and its resistance is not much greater than that of silver!

In order to get finely dispersed copper conductive dust, I decided to use a diamond circle from a grinding machine.

The source of copper was an eyelet from the recently failed stabilizer 7805. At low revs, the lateral surface of the disk sharpened a pile of copper dust in a few minutes.

The source of copper was an eyelet from the recently failed stabilizer 7805. At low revs, the lateral surface of the disk sharpened a pile of copper dust in a few minutes.

I began to try different binders for converting copper dust into a conductive track. After several unsuccessful experiments, I found a suitable option - Dragon glue for ceiling tiles.

It is sold in half liter plastic bottles in the same place where they sell ceiling tiles and wallpaper. It is not expensive, it glues very decently, so it will come in handy on the farm. Transparent, does not stink.

It can be easily diluted with ordinary alcohol to any consistency.

However, due to alcohol, another problem arose - the conductive glue dries too quickly. Having moved the convolutions a little, I realized that it was necessary to reduce the surface area of the evaporation of the freshly prepared glue.

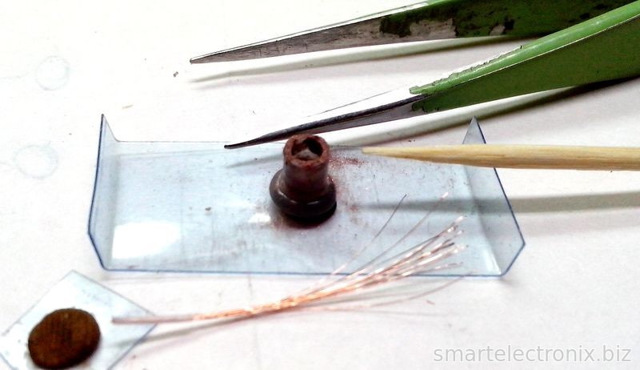

For this I made a mini-test tube from a piece of a gel pen rod. I glued it to a piece of plastic from a PET bottle with hot melt glue. The result is a stable design.

It is convenient to use wooden toothpicks as a stirring stick - they are smooth and with fine tips. Plus they cost almost nothing.

Since there were large pieces of missing tracks on the laptop keyboard, “shunts” from wires from MGTF-0.07 turned out to be a good option for restoring them.

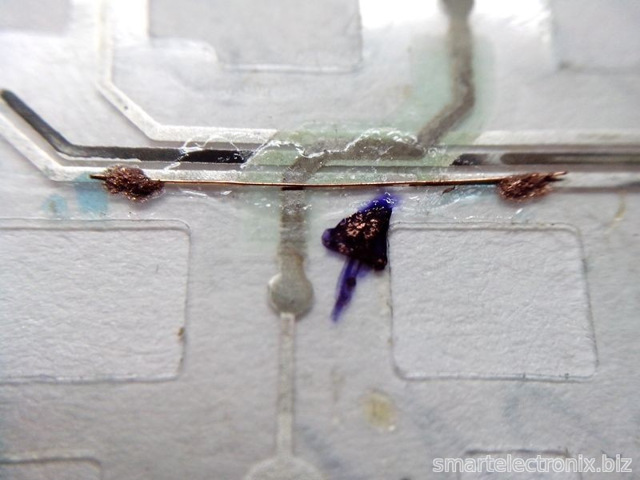

Since there were large pieces of missing tracks on the laptop keyboard, “shunts” from wires from MGTF-0.07 turned out to be a good option for restoring them. Unfortunately, I have not yet been able to complete the repair of my friend's laptop keyboard - I have not yet been able to figure out how to glue the "sandwich" - the lower film with tracks was glued to the upper with special glue and thus connected electrically. The contacts are very small and I have not yet figured out how to combine them blindly without causing the closure of adjacent tracks. But it was possible to restore the re-etching of the tracks.

Unfortunately, I have not yet been able to complete the repair of my friend's laptop keyboard - I have not yet been able to figure out how to glue the "sandwich" - the lower film with tracks was glued to the upper with special glue and thus connected electrically. The contacts are very small and I have not yet figured out how to combine them blindly without causing the closure of adjacent tracks. But it was possible to restore the re-etching of the tracks.

Types of conductive glue Kontaktol

Kontaktol is an innovative product of the German chemical concern Keller, which specializes in the manufacture of current and heat-conducting adhesives according to a patented recipe.

The glue of this brand is intended for mounting electronic parts of microcircuits, restoring tracks on printed circuit boards, eliminating gaps on contacts.

Today Kontakol glue is available in three versions:

Glue Kontakol on silver is a one-component viscous-flowing conductive composition designed to create electrically conductive communications on dielectric bases (glass, PCB, etc.).

Modified resins of synthetic origin are used as a binder; finely dispersed powder of pure silver (999 assay) serves as a conductive filler. The adhesive is heat-resistant, has a high covering ability, excellent moisture resistance.

The specific volumetric resistance of the solidified composition is 0.01 Ohm per cubic centimeter. Glue Kontaktol is available in 2 gram cones and costs about 300 rubles.

Contactol Radio is a completely ready-to-use one-component conductive adhesive designed to create conductive communications on glass, plastic and other dielectric substrates.

Modified resins are used as a binder base; finely dispersed graphite powder is responsible for the conductive properties. Kontaktol Radio glue is produced in miniature plastic flasks (2 grams) and costs about 150 rubles.

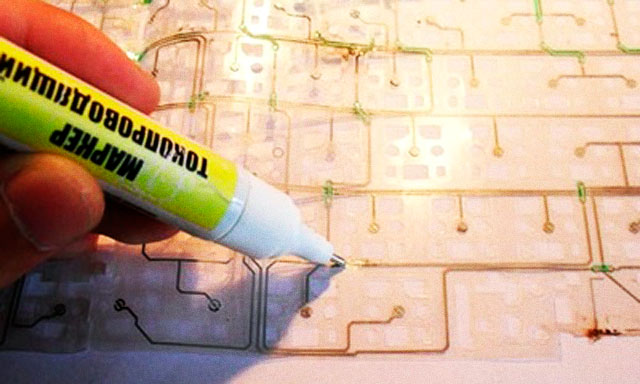

Conductive marker Kontaktol is an adhesive based on polyvinyl chloride resin and silver powder. Designed for applying conductive tracks, jumpers, etc. to boards. The unusual form of release of conductive glue greatly facilitates the process of applying the composition to dielectric bases.

It is enough to wrinkle the tube a little and shake it several times so that the filler is evenly distributed over the resin. A conductive pattern can then be applied to the panel immediately.

It sets quickly enough, and after 5-10 hours (depending on the thickness of the glue), complete polymerization occurs. To speed up the setting, you can dry the area of application with a hairdryer. The conductive marker is available in a 7 g blister pack and costs about 600-700 rubles.

VIDEO REVIEW

How to make a conductive adhesive with your own hands: making according to recipes

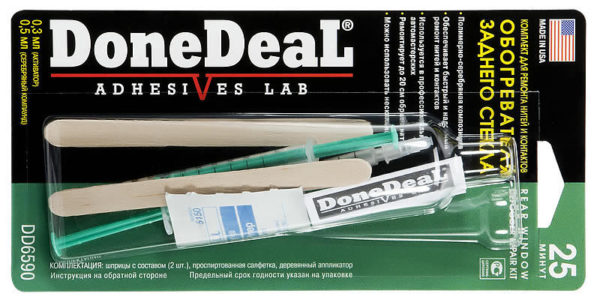

Today it will not be difficult to buy conductive glue from Done, Deal, or other brands on the market. However, its cost is not small. And, if you need a lot of this substance, then it would be wiser to think about trying to make this tool yourself.

Therefore, many resort to making a conductive paste or glue for the car on their own. Today it is quite possible to do this without unnecessary expenses at home, and, moreover, to get a high-quality composition.

How to make homemade non-drying conductive glue:

- A universal method designed for the main property of conductive glue - high electrical conductivity. To make it, you need to buy the most common transparent Chinese superglue in tubes. (If the amount of glue you need is large, then go to the auto shop where you will find the amount of Chinese super glue you need.) Next, we take an ordinary simple pencil, or graphite plates, and grind the substance into powder, making graphite dust from it. To speed up the process, you can use an unnecessary blender. But you can turn graphite into dust by hand only under pressure. After achieving a 1: 1 ratio, mix the ingredients thoroughly, and your electrically conductive glue or paste is ready. The properties of superglue after mixing with graphite are slightly reduced.

- For this recipe, more ingredients will need to be prepared. You will need: powdered graphite - 6 g, powdered silver - 65 g. Mix these ingredients and crush them in a mortar. Then to the resulting mixture you need to add: a binder - nitrocellulose in an amount of 4 g, rosin 3 g, ethyl acetate or acetone 25 g, Mix all this thoroughly and grind until smooth. After a while, this glue will thicken, so acetone must be added to it just before use. This will give the formulation the required viscosity.The glue prepared in this way is just perfect for repairing heated rear windshield and seat. This do-it-yourself composition is considered the ideal conductive glue for auto repairs. However, it can only be used to connect mechanically unloaded elements of a car.

- This recipe is suitable for those moments when you need to achieve the perfect consistency and balance between the reliability of adhesion and the quality of electrical conductivity. To make such a wonderful composition, you will need graphite powder, close to dust, in an amount of 15 g, vinyl chloride-vinyl acetate weighing 30 g, powder silver - 35 g, and pure acetone with a capacity of 35 ml. In a porcelain or glass container, thoroughly mix all the necessary components until a black-gray syrup is obtained. Stir the glue well with a strong glass stick before use. The viscosity of the resulting glue can be adjusted with acetone. To do this, all available components are thoroughly mixed in a porcelain mortar. Pour the finished glue into a glass container with a ground-in cork. This type of adhesive is excellent for repairing heating strips on the rear window. This adhesive is also used in applications where strong adhesion and good electrical conductivity are required.

- To get the composition according to this recipe, we need to prepare a chainolac and a regular graphite rod from any battery. Grind the core to a powdery state, then mix thoroughly with the first ingredient until a gel consistency is obtained. This type of glue is great for repairing home appliances that have problems with small parts, as well as for flaws in the heating of the rear windshield of a car.

All types of glue that conduct electricity must be stored in glass containers that have a neck with a lapped lid.

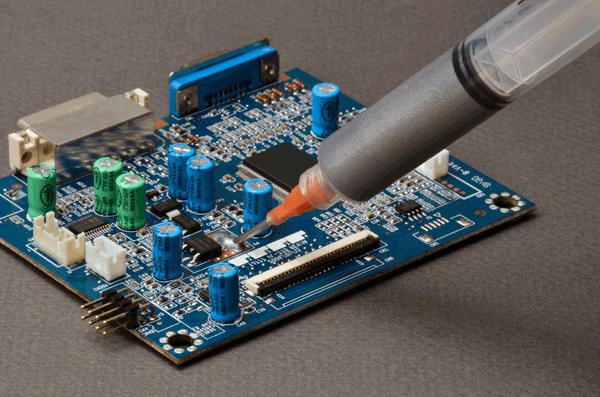

Where is it applied

Thermal conductive glue is simply irreplaceable where it is impossible to use an electric soldering iron, otherwise the threat of deformation of microcircuits increases. Some parts are so tiny and delicate that the tip of the soldering iron exceeds the size of the surface, so its use is impossible.

Thermal conductive glue is simply irreplaceable where it is impossible to use an electric soldering iron, otherwise the threat of deformation of microcircuits increases. Some parts are so tiny and delicate that the tip of the soldering iron exceeds the size of the surface, so its use is impossible.

The conductive adhesive has a wide range of applications:

- glues heating threads on the rear or front glass of a car;

- connects piezoceramic plates in radio devices;

- it is used if two dielectrics are connected through which communication will pass;

- for "cold" soldering;

- for soldering wires of small cross-section, which cannot be connected with a hot method;

- connects the torn off tracks of remote controls, keyboards, etc.;

- is a base for paint or enamel with conductive properties;

- in the repair of computers, mobile devices and other high-tech equipment, it is used to attach crystals and microcircuits to the board;

- restores conductivity in damaged areas (remote control buttons from the TV, keyboard;

- when installing electrical heating systems (warm floor systems);

The Kontol tool is used in the manufacture of its own printed circuit boards, in the repair of heating wires for the rear window, in the connection of wires by cold soldering. Silver-based glue has a high viscosity, is actively used in the process of repairing radio equipment and computers.

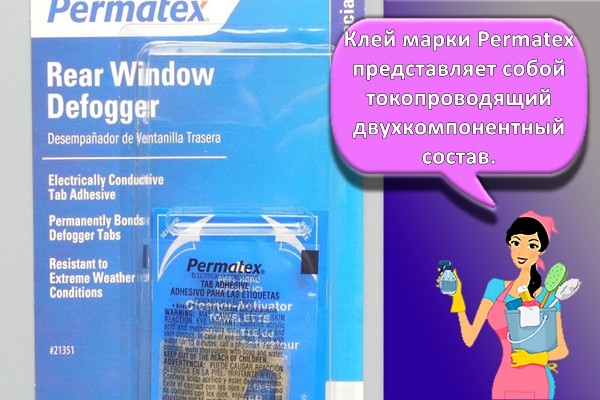

Glue Done deal two-part, one syringe has an adhesive base, the other is conductive. It is actually used in the repair of the heating system of car windows.

Homakoll is a conductive base on which the heated tarpaulin is laid. It is also an excellent antiseptic, as well as a thermal insulator. It is used for the installation of the "warm floor" system.

Industrial adhesive TPK-E can withstand temperature drops from -190C to + 200C. Perfectly connects electrically conductive elements even to steel surfaces without losing technical characteristics.Bonds aluminum alloys, glass and carbon fiber.

Famous brands

There are not many brands on the market from manufacturers of conductive adhesives. Among them there are both Russian and foreign companies. Below we list the most proven brands of adhesives:

- The brand of glue conductive Kontakol on silver 2g is designed to create highly elastic durable surfaces. It is made on the basis of silver. Differs in fast drying, which makes it easy to work with. You can buy "Kontaktol" at any radio store or on the market. However, it should be noted that most of the reviews for this brand are negative.

- Elecont is an epoxy-based conductive compound, often used by motorists. Reviews about this product are also far from always positive.

- Done Deal glue of foreign production. Done Deal is highly durable and reliable. This brand has good reviews from professionals.

- Homakoll is a popular conductive brand that has been on the market for a long time. Most often it is used as a conductive adhesive for linoleum by large manufacturers. It has anti-static properties.

- "Mastix" is an electrically conductive lubricant for repair work with the rear window of a car. Mastix is considered the best choice in its segment.

- TPK-E is a brand of glue from a Russian manufacturer. The peculiarity of the composition is the ability to maintain operational characteristics with a wide temperature range - from minus 190 to plus 200 degrees Celsius. Most often this brand is used in an industrial environment.

Features and properties

Before use, you need to carefully study the composition of the glue and do not use products containing water. The composition and instructions for use are indicated on the original packaging of the glue. For microcircuits, wire contacts, loops, and other elements of electrical engineering, the water base is destructive. Such a composition will dry out for a very long time.

The current-carrying component in the adhesive is often graphite or nickel powder, silver, or any other metal. The higher the content of the electrically conductive component, the worse the adhesion of the adhesive to the surface.

- you can repair computer cables, microcircuits;

- used when installing heating skirting boards;

- it is used as an adhesive for linoleum when laying an antistatic floor covering;

- defects in automotive electrics are eliminated, rear window heating is repaired;

- piezoelectric elements are fastened in radio equipment;

- used when replacing soldering light emitting diodes.

The composition of the conductive adhesive

Another feature of this glue, which is mentioned much less often, is such a concept as drying. Perfect solutions tend to freeze in one moment.

Instant drying is mandatory for conductive compounds. With a long drying time, the work of the master slows down. In addition, areas on the microcircuits may suffer, which will be filled with this glue, if it is liquid and is not localized in one necessary area.

The conductive adhesive, made in accordance with the technology for better conductivity, contains the following elements:

- Gold;

- Palladium.

The news of this at one time prompted some to think about the remelting of unusable microcircuits and the extraction of valuable substances from them. However, their presence in the elements is so small that enterprising gold prospectors had to abandon this venture. In addition to its basic functions of gluing, conductive glue must have a very high safety index both in relation to the environment and for the master himself.

Conductive adhesive: what is it and where is it used

Conductive glue can easily be called a universal substance that is used in almost all areas of mechanical engineering.

Due to its heat resistance, conductive glue is used in the repair of various heating mechanisms, as well as in the arrangement of the underfloor heating system and tiles.

Where conductive glue or paint is used:

- In the manufacture and repair of computer and household appliances, consoles, loops, tracks in the keyboard board;

- It is with the help of it that boards and microcircuits are repaired;

- They are used when installing heating systems and arranging a warm floor and heating baseboard;

- It is irreplaceable in the process of car repair;

- Sometimes it is used at home instead of soldering for metal products;

- During nail extension;

- It is used as a sealant for elements when arranging rear windshield heating and when repairing heating threads.

In an electrician, such a composition of glue is especially needed. There is practically nothing to replace it, and sometimes it is simply impossible to do without it. In addition to glue, spray, paste, varnish and marker can be conductive.

How to make silver-based conductive adhesive

To avoid these problems when working with non-ferrous metals, you can make a conductive cream on silver, but this is much more difficult than working with a pencil lead. Before starting work, you need to acquire nitric acid silver, but this can be more difficult than replacing it with nitric acid; it also conducts electricity.

At the pharmacy, you need to buy a 1% formalin solution and a bottle of ammonia (ammonia).

Having carefully measured out equal proportions, you first need to mix formalin and nitric acid silver, and then add a couple of drops of ammonia to the resulting mixture.

If the actions were performed without errors, after some time a black precipitate will form in the resulting composition - silver powder, which must be removed from the liquid (you can use distilled water or a filter) and use for electrical conductivity. This is followed by the drying of the sediment extracted from the liquid at a high temperature of 105-150 degrees Celsius. The resulting dried black powder must be added to any quick-drying glue similar to the previous recipe. Professionals advise to first mix the glue with a small amount of alcohol. Due to the high drying rate of the composition, it requires periodic stirring.

There are a lot of similar recipes, but they are all based on the same processes. It is enough to recall the lessons of chemistry or physics at school in order to highlight which elements conduct current, and later, on their basis, prepare an ideal adhesive paste for the product.

Obtaining silver powder for making conductive glue

To obtain powdered silver, we need:

- Silver

- Nitric acid

- Soda

- Formalin (1% solution)

- Ammonia (5% solution)

First, we dissolve silver in nitric acid, as a result, we get silver nitrate (lapis)

I think it will not be superfluous to say that nitric acid must be handled with extreme caution so as not to get severe burns.

Currently, every apartment has electricity-powered devices. There are large household appliances, and there are very small ones like a TV remote control or a clock. All of them have long become a part of everyday life, and without them it is difficult to imagine the usual state of affairs in everyday life. Every device can break.

Many radio amateurs, and ordinary users of electrical appliances, in the process of repairing devices, are faced with the need for conductive glue, varnish, gel or grease for contacts. In principle, electrically conductive glue can be purchased at electronics stores, connoisseurs already know about the presence of the so-called kontaktol. At the same time, it is not so easy to find it. Sometimes you have to look for a long time and in vain, which is worth the nerves and efforts.

This conductive glue, varnish, gel, or grease can be made with your own hands. How to make it at home? The main thing is that there is nothing difficult in this.You should be aware that the composition of most of these adhesives contains certain binders. These include the following: polyurethane, polyester, epoxy and others. Conductive metal powders are added to these substances: silver-plated, silver, gold.

When preparing conductive glue with your own hands, you can adjust its consistency. This is achieved by adding certain solvents to the glue - isopropyl alcohol, acetone, ethyl cellosolve. And also to create such a sticky substance, you can watch various videos for a better understanding.

To begin with, it is worth listing the components that will need to be used in the process of obtaining powdered silver:

- silver;

- nitric acid;

- ammonia (solution 5%);

- soda;

- formalin (1% solution).

First you need to dissolve silver in nitric acid. The output is silver nitrate

It is worth noting the fact that working with nitric acid presupposes caution and accuracy, since as a result of careless actions with this substance, you can get serious burns.

After heating, a few drops of the ammonia prepared in advance should be dropped into the solution. As a result of these manipulations, a dark precipitate is formed. It will need to be rinsed with distilled water and then dried. Drying temperature should be about 110 degrees.

Radio amateurs more often than others have to deal with electric current, and the current, in turn, is very selective in terms of the compositions through which it must pass. In this case, electrically conductive glue acts as a real salvation, and it is he who is used for electrical circuits, useful for its ability to conduct current.

The adhesive can be used to work with electrical circuits (for example, in keyboards or consumer electronics), in the creation of heating tools and flooring. But not only radio amateurs will find it interesting. This type of glue is really necessary when repairing cars: it is used with glass, as a conductive paste for sealing, etc. Let's take a closer look at how to make a conductive glue with your own hands and how you can replace it.

Features and properties of conductive adhesives

For the first time, electrically conductive glue was made in Germany in 1940. Later, it began to be actively used in various fields of mechanical engineering, and now it is considered a universal tool at all. Real conductive glue can be used instead of soldering, for arranging underfloor heating, heating systems: it withstands high temperatures perfectly. Other properties of the product are as follows:

- fast drying speed, the need for work without pauses;

- high viscosity (allows you to exclude the flow of glue into the electrical circuits);

- excellent adhesion to surfaces;

- safety for the environment and the user;

- elasticity (allows spot application).

The main property of the glue is its low electrical resistance. The use of electrically conductive glue helps to make parts resistant to damage, shock, vibration. Also, the composition will protect the microcircuits from temperature extremes.

It is important that the electronics glue does not contain water. The water base will only spoil the electrical circuits, wire contacts, and the product itself will dry for too long.

Usually, the composition includes nickel or graphite powder, silver or any other conductive metal.

The fields of application of conductive adhesives are varied:

- repair of loops, computer boards, gadgets;

- installation of heating skirting boards;

- laying antistatic linoleum;

- elimination of electrical defects in a car, the use of heating the rear window, heating threads for repair;

- replacement of LED soldering.

How to make conductive adhesive at home

There are several recipes for making do-it-yourself conductive glue.

Recipe 1: instant glue + simple pencil

- We take any cyanoacrylate glue (the so-called super-glue) in a metal tube, add graphite powder to it in a ratio of 1 to 1 and stir until a uniform consistency is formed.

- For ease of use, you can prepare the glue directly in the tube.

- To do this, carefully unfold it from the end, add powder, stir with a match or a toothpick and wrap it up again.

- The required amount of graphite powder can be easily obtained by grinding the core of the most ordinary simple pencil with a blade, file or sandpaper.

Recipe 2: Battery + Tsaponlak

For this recipe, you need an ordinary salt finger-type battery, or rather not the battery itself, but a graphite rod from it.

- The graphite is crushed and mixed with zaponlak in equal proportions.

- Tsaponlak is a clear solution that is used in electronics to coat soldered electrical connections. You can buy it in a store for radio amateurs, a 30 ml glass bottle costs about 50 rubles.

- You can prepare glue directly in the bottle, and you can store it in it for a long time.

Recipe 3: Epoxy + Aluminum Powder

Conductive adhesive can also be prepared using epoxy resin.

- For this, the cheapest two-component EPD brand glue of domestic production is suitable (it costs about 150-200 rubles per 280 g.).

- Aluminum powder is usually used as a conductive filler.

- The recipe is simple: the resin is mixed with aluminum powder until it becomes thick sour cream. Immediately before gluing, the prepared composition is mixed with a hardener in a ratio of 10: 1.

- Powdered graphite and silver, vinyl chloride-vinyl acetate copolymer and acetone are thoroughly mixed in a porcelain mortar.

- You will need any regular nail polish.

- Then you can fill the crumb with varnish and mix it with a match, for example.

- The result is a black-gray liquid, similar in consistency to syrup.

- You need to store it in a glass container under a tight-fitting lid.

- Stir the glue before each use.

- On the product, it dries for about fifteen minutes.

VIDEO INSTRUCTION

All of the above recipes allow you to quickly and at minimal cost prepare glue at home, which is suitable for repairing heating threads for the rear window of a car and solving other problems.

An important point: The more conductive filler there is in the adhesive solution, the better the conductivity will be, but the strength of the connection will inevitably decrease.

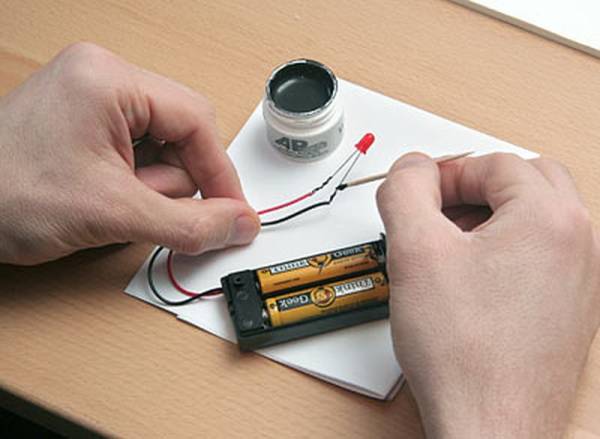

Consider the use of conductive glue using the example of auto glass heating repair:

- wipe the gap with a solvent;

- glue tape on top and bottom of a thin thread;

- we apply an adhesive to the gap;

- after the glue has completely dried, remove the tape.

High-quality conductive adhesive ensures the passage of electric current with normalized losses. Such compositions are used to restore the tracks of printed circuit boards, and other repair measures. This publication discusses factory products and functional analogs that you can make yourself at home.

Additional options

Less commonly, users try to make other types of adhesives that serve as alternatives to store-bought products.

Glue stick

The glue stick is made from PVA. For the case, you need to take the old packaging from the deodorant-antiperspirant, which is tightly closed. Stir in laundry soap (2 parts), add water (1 part). Dissolve in a water bath, pour in 4 tablespoons of PVA, cool. Then put the mass in the package, let it harden.

Super glue

Of course, you won't be able to make a real super-glue - it is prepared from cyanoacrylate with the addition of a number of complex chemical components.But you can still create a very reliable composition with your own hands. For this you will need:

- 125 g wood glue;

- 100 g sugar;

- 35 g of slaked lime;

- 450 ml of water.

Sugar is dissolved in water, lime is added, heated for 30 minutes in a water bath. Next, crushed wood glue is placed in the solution, boiled until the mass is homogeneous. The tool can be used for bonding metal, ceramics, porcelain.

Foam Adhesive

Carpentry glue is best suited for gluing foam. Casein glue is also suitable, which is mixed in equal parts with slaked lime. Such a tool is ideal for attaching foam when insulating a house.

Styrofoam adhesive

Acetone and foam are used to make glue for connecting elements of glass, metal, wood. The foam is crushed into crumbs, poured with acetone to completely cover it. A viscous mass is obtained almost immediately, it can be used as a regular glue, after mixing it well.

When making adhesives with your own hands, you can seriously save money, especially if a major renovation is planned in the house or apartment. The quality of the finished product may be somewhat inferior to the store product, but it will definitely be safe for health and affordable!