Bone glue

Application area. The best option for the restoration of old furniture, including antique ones.

Working properties. The adhesive material is designed for drying under high pressure. Bone glue provides a reversible gluing of wood to wood: the connection can be disassembled using water or alcohol.

Compatible with finishing compounds. The glue is tinted with aniline dye to match the final finish.

Open time: 30 minutes.

PUR glue Kleiberit 501.0, D4

One of the best universal adhesives is considered to be products from the German brand Kleiberit 501.0. The basis of the product is polyurethane, which makes the material resistant to moisture and resistance to temperature extremes. The 1-component composition is easy to use, it is permissible to use it to connect 2 elements made of wood, as well as other combinations, for example, polyvinyl chloride, miniplates, ceramics, concrete, etc.

The operation of the formed nodes is possible indoors and outdoors, in the rain or scorching heat. Excellent adhesion quality is confirmed by international standards. The compound is completely cured after 24 hours.

Advantages:

- Ease of operation;

- Short hardening time;

- Elasticity;

- Versatility of application;

- Resistance to aggressive environments;

- Resistant to temperature changes.

Disadvantages:

- Long-term drying;

- Corrosive aroma.

In the reviews of domestic buyers, mainly positive characteristics are noted. This composition is convenient to use, it will not drain, the seam will turn out to be reliable. However, it is difficult to wash your hands after work; in the process of gluing, it is necessary to ventilate the room.

Composition of various resins has many beneficial properties. It will not change the shade of the processed wood, has excellent adhesion, high strength and electrical insulating qualities. However, when working with adhesive, proper ventilation of the room and the use of personal protective equipment are required. When comparing 7 products, it was found which is better. The list contains 3 of them.

Application technology

Before wallpapering (no matter what kind of glue you use), the wall surface must be thoroughly cleaned (from whitewash, old wallpaper, dust, paint residues, etc.)

If there are cracks on the wall, then they should be repaired and patched.

Before use, dry adhesives are diluted with water in the proportion recommended by the manufacturer for a certain period of time (indicated on the package) and thoroughly stirred until the lumps disappear. Next, the glue is defended until the necessary swelling of the adhesive component, after which it is filtered through a regular nylon stocking to avoid undissolved lumps from falling on the wall or wallpaper. The diluted ready-to-use glue is applied to the walls and wallpaper with a wide swinging brush.

You should know that there are two types of dry adhesives:

• for gluing thin and light paper wallpaper;

• for gluing dense and heavy vinyl wallpaper.

The Russian market offers a wide range of dry adhesives from domestic manufacturers.

Wallpaper adhesives, both ready-made and dry, should be used at an air temperature not exceeding + 50 ° С, otherwise the filler water will quickly evaporate. All wallpaper adhesives are made from environmentally friendly substances.

The Russian market offers dry adhesives of the MOMENT type produced by ERA-TOSNO under a license from HENKEL (Germany), a series of GLU-TOLIN adhesives manufactured by HOECHST (Germany), CMC (Russia), etc.

After drying, the edges of the wallpaper may come off, you can glue them with PVA glue, which should be slightly diluted with water.

Synthetic based adhesives

Most artificial adhesives are based on

polymer compounds. The most popular of the synthetic solutions are

PVA-based adhesives, resinous and polyurethane compositions.

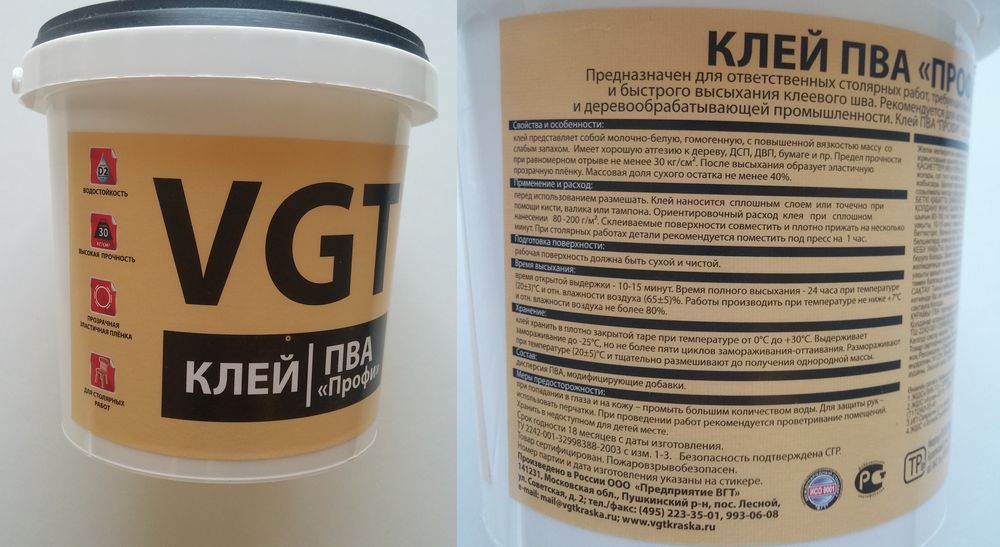

PVA based adhesives

PVA glue is made from polyvinyl acetate. Considered one of

the most environmentally friendly compositions, due to the absence of a toxic odor. Resilient

to temperature extremes, has high elasticity. Retains properties

at high humidity, remains transparent after drying.

There are two types of PVA glue - one-component and two-component.

The first option is a universal remedy and is used indoors for

internal works. The second type contains an additional component

hardener, as a result of which it can be used outdoors.

Polyurethane adhesive

Polyurethane compounds are capable of withstanding significant

dynamic load. Moisture resistant, well tolerated ultraviolet

radiation and sudden changes in temperature. The mixture can be used in difficult

weather conditions. The additive in the form of resins increases resistance to aggressive

solutions (acids, alkalis), oil products.

Provides a good connection between wood and other materials. Front

the beginning of work, the surface of the product must be cleaned of dirt and dust. V

special gloves must be used during the process, as the glue leaves stubborn

spots on the skin. Polyurethane mixtures are considered one of the most expensive.

The adhesive composition is one- and two-component. They differ

by gluing. The one-component composition is presented ready to work.

It grabs 30 minutes after application to the surface under the influence

humidity. Before using the two-component mixture, the components

must be mixed in a special container.

Difficult to bond surfaces and materials are treated with special

polyurethane hot melt adhesives. The solution dries quickly and does not

requires additional pressure. Good for gluing oily

wood. There are a large number of types of adhesives on the market.

polyurethane base, which have special properties and qualities.

Epoxy adhesive

It is a two-component formulation containing epoxy resin

and a hardener. It is a universal remedy and can be used not only

for wood, but also other materials. Possesses high strength and resistance

to moisture and oils. Does not shrink when solidified.

When diluting the glue, the recommended proportions must be observed.

If the appropriate filler and plasticizer are added to the hardener, then

you can get a composition with the desired properties. Unlike other types of mixtures,

epoxy bonding process does not require any effort to

connections of individual parts.

There are two types of epoxy that

differ in the percentage of components.

Standard glue. Complete hardening of the mixture occurs in a day, depending on the thickness of the applied layer. The mixture can be used for the manufacture and repair of large-sized products and objects experiencing heavy loads. They are also used for gluing dissimilar surfaces.

Five-minute glue. Fast-drying compound, used for gluing parts that are difficult to fix for a long time. A high proportion of hardener reduces the fixing time to 10-5 minutes. However, the strength of such a mixture may be lower than standard. Excess glue, after drying, leaves noticeable stains that are poorly stained with stain.

BF based adhesives

For bonding wood surfaces as well as wood with other

the materials used are BF-2 and BF-4 mixtures. The basis of the composition is

polyvinyl butyral, acetone or ethyl alcohol serves as a solvent.

The adhesive is a thick yellowish or reddish mass.

colors.

BF-2 is used indoors, as it is resistant to prolonged exposure to moisture. BF-4 is characterized by frost resistance and elasticity and is more suitable for outdoor use. BF series adhesives tolerate the influence of aggressive liquids and a sharp temperature drop. They have a high strength index, however, with a strong impact on the glue seam, the strength of the latter is significantly reduced.

Go to groups and Odnoklassniki

The most common types

Many tools are suitable for a tree, which differ in several criteria. Let's take a look at the methods of using some of the most common mixtures.

PVA

A variety of such glue for wood is the most common. In addition, it holds joints very firmly with a load of approx. 60 kg per cm2. It has no shelf life and can be applied to a variety of surfaces.

PVA is used for gluing wood materials, as well as for the manufacture of furniture. But there is one drawback: the glue is not resistant to moisture.

Epoxy

The product contains resins and a hardener. But for gluing wood material, you must follow the instructions. Before applying the glue, mix the components thoroughly for five minutes. The surfaces to be glued are treated with a thin layer and pressed.

Can be used to join wood and other materials. The epoxy mixture dries up in almost a day.

Versatile and stable, but you need to be extremely careful when handling it - if it comes into contact with unprotected skin, it can cause itching and irritation.

Polyurethane

Due to its practicality and endurance, it enjoys immense popularity. Polyurethane adhesive is resistant to increased moisture, heat-resistant. In addition, it provides high-quality bonding of hard materials.

Casein

It is often used to bond different materials to wood, such as paper, cardboard, fabric or leather. One of its main advantages is its high resistance to moisture. To prepare the glue mixture, casein (powder) must be diluted in cold water until “sour cream” is formed.

The product dries up within five minutes, after which the surfaces can be joined. After 6-8 hours, the glue sets, it will take 20 hours to dry completely. It must be applied very carefully, as unpleasant marks can remain on the wood.

Syndeticon

It is used to connect wood with other materials. The composition includes dry wood glue, sugar and hydrated lime. The mixture should swell before use, then it can be applied to the surface in a thin layer.

Hot glue

It comes in special rods inserted into the gun, so it is quite convenient to use. With the help of heat-resistant glue, even small parts can be connected, since it is fed from the gun in a thin stream. The product hardens within a few seconds after application. As the name suggests, the adhesive cures at a temperature.

Joiner

It differs in the preparation procedure, but adheres the wood perfectly. It is applied to the wood along the grain and dries completely up to eight hours.

Paste

To prepare it, you need to mix hot wood glue with ash or chalk. This mixture can be used for primer or putty on wood, for gluing parts.

The BF series also allows you to glue wood and other materials together, but for its best efficiency, you will need special ovens or thermostats.

Liquid Nails

This type of connection is considered to be very strong. The main advantages of the product are resistance to high humidity, heavy loads, and safety. Such "nails" can glue porous and loose materials.

Urea resin

Urea-formaldehyde resins are used for the production of furniture, plywood, particle boards, OSB, foam, sawdust beams. The product contains urea and formalin.

Phenol-formaldehyde resins are also used for gluing wood. They are very resistant to external influences and are used in the production of waterproof plywood, load-bearing structures, parts from press crumb.

The best conventional wood adhesives

This substance has the widest application from everyday life to workshops. It is good to have such a tube always at hand in order to quickly repair a broken wooden part.

Titebond II Premium Wood Glue - Moisture Resistant

This is the best glue for wood, since its composition has increased resistance to moisture, which makes it possible to use it even for structures located on the street (subject to the subsequent general processing of wood with varnish). It contains polyaliphatic components that penetrate deeply into the parts to be joined.

Pros:

- suitable for all types of wood;

- can successfully glue MDF, chipboard, fiberboard;

- used in the manufacture of windows and doors;

- it is easy to control the balance of the product through a transparent container;

- convenient lid with a spout for feeding glue into narrow places;

- will hold veneer, plastic and paper films on wood;

- American production;

- after drying, the quality of the connection becomes stronger than the wooden material itself;

- can be supplied in containers of 118, 237 ml or 3.8 l at once.

Minuses:

- the cost of 118 ml is 145 rubles - the amount is not small when compared with PVA;

- when gluing parts, a long-term rigid fixation is needed, otherwise the sides will fall apart from mechanical stress.

Moment STOLYAR - German quality

This is the best wood glue from the renowned German manufacturer Henkel. The substance is specially formulated for carpentry work.

Created on a water-dispersed basis, therefore, it is safe for humans and long-term use. Has a pronounced water resistance. Suitable for all types of wood.

Pros:

- fast hardening and setting time;

- convenient spout with a closure cap for thin application and reusable use;

- suitable for all breeds and even leather, fabric, laminate, plywood;

- water resistance level D2;

- can be stored at temperatures from +5 to +30 degrees for 24 months;

- does not contain phthalates;

- well tolerates mechanical stress, for example, on glued chairs.

Minuses:

- with prolonged exposure to moisture, the connection may weaken;

- 175 rubles for 250 g;

- the yellow color of the glue can stand out on light wood species.

KIILTO PVA D3 - familiar from childhood

Such a product is familiar from childhood for its white color and thick consistency. This is the best glue for wood, as it is water-repellent and can withstand up to five freezing cycles down to -40 degrees, while retaining all its properties. Today it is produced by many manufacturers, one of which is Kilto.

Pros:

- based on water dispersion, therefore safe;

- the cost is 195 rubles for 500 ml;

- there are packages of 1 and 3 liters;

- economical consumption up to 120-150 g / m2 in case of impregnation;

- complies with Euro Class B in terms of fire performance;

- contributes to sound insulation of 0.25 dB;

- thermal resistance 0.17 m.

Minuses:

- supplied in buckets, therefore requires a brush or roller for application;

- can only be used at +10 degrees.

Choosing the best all-purpose adhesive

The most reliable formulations include:

- Epoxy adhesive - has good strength. Regardless of the brand, the epoxy is resistant to mechanical and chemical attack.

- PVA - comes in many varieties with additives and precise concentrations. There are options for each material. Reliable and inexpensive formulation for household use.

- Montagekit Extreme Grip. It is based on acrylic dispersion, which provides a high degree of adhesion to various surfaces.

For certain materials, special adhesives are produced.For example, for a tree, one of the most durable is Ground Hide Glue.

Useful video on the topic:

DIY making

You can independently prepare wood glue at home in several ways, but they are based on a single principle - soaking dry matter and subsequent cooking. For manufacturing, you will need to use granules or dry composition, water and a cooking container.

Recipe 1

Step-by-step instruction:

- Pour the dry composition into a container and pour boiled cold water so that it completely covers the substance. After 8-12 hours, a gelatinous consistency should form.

- Heat the mixture in a water bath at a temperature of 60-80 degrees, stirring regularly. As a result, the lumps must completely disappear so that the mass becomes liquid and homogeneous.

- During the cooking process, hot water can be added to the mixture. If you plan to process end or spike joints, the composition should be thicker.

- Once a film has formed on the surface, the joiner's glue is ready to use.

Recipe 2

Step by step process:

- The adhesive composition in a dry state is mixed with water, observing equal proportions.

- The resulting mixture is boiled until a dense material is formed.

- Before direct use, the workpiece is dissolved in water and alcohol, and then boiled.

The best glue for wood based on PVA

Rakoll ECO-4

One-component German glue Rakoll ECO-4 d4 PVA is designed for working with joinery, including window beams, rafter systems, chipboards, etc. containers from 1 to 30 kg.

- Adequate cost.

- Convenient packaging.

- High quality of adhesion, efficiency.

- Thermal, water resistance.

- Fast setting (about 12 minutes).

- It doesn't take long to press.

- Cold / hot gluing is allowed.

- Deep penetration (adhesion) into hard varieties such as larch, oak.

- Hot pressing does not change the color of the bonding seam.

- A shade of blue may appear when the glue comes into contact with ferrous metal.

- It is not allowed to store at temperatures below +10 degrees Celsius.

Moment Joiner

In the retail network, wood glue "Moment Joiner" can be found in bottles of a characteristic shape of various sizes from 125 to 250 ml and in cans weighing several kilograms. This product has a characteristic shade, after drying it takes on the color of light wood species. "Moment joiner" is most often used for gluing wood parts with veneer, foam rubber, cardboard, plywood, rough fabrics, plastic.

- Relatively low cost with excellent quality.

- Water resistance, heat resistance.

- Large selection of packages by weight.

- Extended scope of use.

- Fast bonding, drying.

- Versatility.

- The color of the glue line is adapted to the structure of natural wood.

- Environmental friendliness, the glue does not contain toxic impurities.

Artelit WB-330

Artelit WB-330 wood glue is characterized by increased water resistance. The Polish-made product is recommended for high-quality gluing of wood of any species and types by cold-hot methods. Most often, WB-330 is used in the manufacture of kitchen furniture, bathroom cabinets, doors, window frames, openings, parapets, balustrades. Materials to be glued: particle boards, plywood sheets, wood of various hardness species.

- High level of water resistance - class D3.

- The glue line is colorless, durable and reliable.

- Versatility of application.

- Affordable price.

- Convenient packaging.

- Excellent efficiency.

- Ease of application of the composition, ease of gluing.

- Non-flammability.

- Lack of unpleasant pungent odors, non-toxic.

Eskaro PVA B3

High quality wood glue Eskaro PVA B3 made in Estonia. The basis of this product is polyvinyl acetate dispersion D3.With the help of Eskaro PVA B3, you can make garden furniture, window frames, entrance doors, interior doors, lay parquet, linoleum, restore the integrity of porcelain products, repair leather shoes and other works. After drying, a characteristic film is formed on the surface, which has elasticity and water-repellent properties.

- Adequate price.

- High-quality, reliable fast bonding.

- Strength, invisibility of the glue line.

- Maintaining the flexibility of materials.

- Convenient packaging.

- Universal application (a wide variety of materials to be glued in any combination, indoors and outdoors).

- Economical consumption (one liter of glue is enough to treat surfaces with an area of at least seven square meters).

Interesting: Bathroom with artificial stone

The best resin based joinery adhesives

Composition of various resins has many beneficial properties. It will not change the shade of the processed wood, has excellent adhesion, high strength and electrical insulating qualities. However, when working with adhesive, proper ventilation of the room and the use of personal protective equipment are required. When comparing 7 products, it was found which is better. The list contains 3 of them.

Moment Joiner

Composition based on epoxy resin, an excellent product from domestic manufacturers. With the help of the composition, it is permissible to combine various wood species, plywood, MDF, fiberboard, chipboard, plastic with paper inclusions. The surfaces to be glued must be pressed for a quarter of an hour with a clamp or a vice. The full drying time of the elements before use will be 1 day. The tool does not change the shade of the processed material, which will increase the scope of its use. The tool can be used at positive temperature readings from +5 to +30 degrees.

Experts and amateur craftsmen note the following characteristics of Moment Joiner: short drying period, reliability, availability, transparency at the end of solidification. The disadvantages include sensitivity to moisture and low temperature indicators.

Advantages:

- Transparency at the end of drying;

- Convenient use;

- Fast drying;

- High initial adhesion.

Disadvantages:

Poor moisture resistance.

It is made on the basis of epoxy resin, therefore it is not toxic to the user. Economical consumption is noted, effective for all types of wood.

Titebond moisture resistant joinery

1-component adhesive for gluing wood materials. Possesses a high class of water resistance, it is effectively used for outdoor work: assembling furniture in the garden, birdhouses, mailboxes. The composition is distinguished by strong initial adhesion, fast hardening, creates a reliable seam, and is well processed. The downside will be susceptibility to moisture and negative temperature parameters.

Advantages:

- Connection reliability;

- Versatility of operation;

- Fast setting;

- Exposure period in clamps;

- Cutting tools do not deteriorate during the processing of the joint.

Disadvantages:

- Weak water resistance;

- Large spending.

Users note a strong adhesion of the adhesive in a short period. The disadvantage is the rapid expenditure of funds.

Uhu Plus Endfest 300

Two-component universal glue for wood has good adhesion performance. It is made of epoxy resin, which will allow materials of different origins to be glued to the processed wood object. An exception will be glass items. The composition hardens for 1.5 hours, the compounds are completely ready for use within 12-24 hours. The seam will acquire shock resistance, wear resistance and moisture resistance.

To make a working solution, you need to mix 2 ingredients, following the instructions of the developer. Then the components are thoroughly mixed until a homogeneous consistency is formed. The finished composition is applied with a brush or a spatula.Among the advantages of the glue from the German brand, the emphasis is on high strength, resistance to mechanical influences, moisture. Differs in reliable initial adhesion, high adhesion.

Advantages:

- Reliability;

- Immunity to moisture;

- Strong hitch;

- Connection with wood of any objects;

- Does not conduct current.

Disadvantages:

- Proportions must be observed;

- It is necessary to prepare a working solution.

Based on the reviews, the adhesive composition has increased strength, immunity to mechanical influences, moisture.

Floor adhesive

For floors - used for bonding floor coverings, linoleum, plastic-backed cork, textile foam backing in dry and damp rooms.

For parquet - designed for gluing parquet and laminate boards. There are several types:

water-dispersion adhesive - for laying materials that are resistant to moisture (oak, moisture-resistant plywood). The advantage is environmental friendliness. The disadvantage is a narrow scope of application, since it cannot be used to work with pear, cherry, apple, beech, pine, etc. wood;

solvent-based glue - for laying materials that are not resistant to moisture (pear, cherry, apple, beech, pine, etc.). Advantage - they harden faster than water-dispersive ones, are easy to use. Disadvantage - fire hazard, toxicity;

two-component adhesive (reactive) - for extra adhesion strength, for example, for gluing parquet directly onto the screed. Advantages: high strength, resistance to mechanical stress, suitability for any substrate

An important advantage is that this glue hardens quickly. The disadvantage is toxicity, but after hardening it becomes safe

It is necessary to work with personal protective equipment.

My services

I have the opportunity to help in organizing my own cooking of urea-formaldehyde resin. In this case, this glue will cost 3-6 rubles per kilogram. I provide various consulting services for resins and adhesives for wood.

In addition, there is a book on the manufacture of this glue, it is no longer even a book, but a technology. It has everything from equipment information to cooking technology. Everything is chewed, it is told about the dosages and parameters when cooking the resin.

In fact, the cost of such information costs about 100 thousand rubles. This is exactly how much my friend takes for setting up the technology. I give it away almost free of charge, in more detail about the technology in the "BOOKS" section.