How to prepare the solution?

The modern market offers ready-made variations of silicate substances and individual components that must be added to a specific building mixture. But ready-made mixtures are not cheap, so the use of individual components is considered the most profitable option. In its pure form, silicate glue is rarely used in construction; it is mainly used as an additional element in the manufacture of various mixtures. In this case, it is necessary to familiarize yourself with the rules for the preparation of liquid glass.

Before preparing this solution, the first step is to prepare all the necessary tools and building materials:

- bucket;

- electric drill with a special attachment;

- brush;

- cement;

- fine-grained sand mixture;

- pure water;

- putty knife;

- Remedies.

The mixing process of the ingredients is carried out according to the instructions. Cold water is used to dilute certain components. If the working surface, on which this mixture will be applied in the future, reduces the adhesion indicator, then experts advise adding less liquid or more cement mixture.

First of all, water is poured into a bucket, after which cement is poured. These ingredients are thoroughly mixed until completely dissolved. For faster mixing, you can use a construction mixer.

To prepare the waterproofing composition, 1 part of sand, silicate mixture and cement should be taken. Such components must be poured into a bucket into which liquid has already been poured. Waterproofing compounds are used for floor screed and when laying blocks.

The procedure for preparing a fire-resistant mixture consists of several stages:

- first you need to dilute the sand-cement mixture in water;

- then an adhesive mixture is added to the resulting mass (25% of the total mass of the solution).

You can also independently prepare an antiseptic special solution, which is needed for application on wood surfaces. In this case, the ingredients are mixed in a 1 to 1 ratio. This solution is suitable for concrete and plastered surfaces.

Sequential instructions for preparing a mixture for pouring a foundation:

- 250 g of adhesive solution is poured into a clean container, everything is mixed by means of a construction mixer;

- liquid glass is poured into a larger bucket, the cement mixture is gradually added to it, everything is thoroughly mixed;

- the resulting solution is poured into the formwork of the structure.

If liquid glass is used as an antiseptic special agent for wooden bases, then the proportion of liquid and glass will be 1 to 1. With this tool, experts do not advise treating all surfaces (concrete, plaster), because the applied silicate glue forms a sliding film that will not allow paint or putty the surface. These finishing building materials are not able to hold on to such a foundation.

According to most experts, it is better to mix the necessary components first, and then pour in the liquid.

Manufacturers of glue KMTS

In hardware stores, in the markets, there are Russian, imported TMs for sale. The price of the former is much lower, but the technical characteristics are not inferior.

Famous manufacturers:

- Pennant 75B is produced in Russia. The finished solution has a high viscosity, water-retaining qualities. Suitable for all types, types of wallpaper on all surfaces, including metal. No toxic substances, safe. Packing in bags.

- Carbocel produces a universal CMC product for all types of canvases. It is an environmentally friendly product with high levels of solubility.Highly effective filler-free product. Available in packages of 0.3 kg, 0.5 kg, 15 kg.

- Omega produces an adhesive based on carboxymethyl cellulose with the addition of antifungal components. Suitable for various wallpapers in structure, width. The solution is prepared within three hours, as a result, a homogeneous mass without lumps is formed. Shelf-life Unlimited.

- Polycell CMC-7 is a white fine-grained powder, readily soluble in water at any temperature. It is used in construction as a thickener for putties, increases the plasticization of solutions, adhesion strength.

- Malva produces glue designed for fixing multilayer wallpaper (foam), cloths on a paper, fabric basis. Fastening is carried out on painted, concrete, plastered, wooden surfaces.

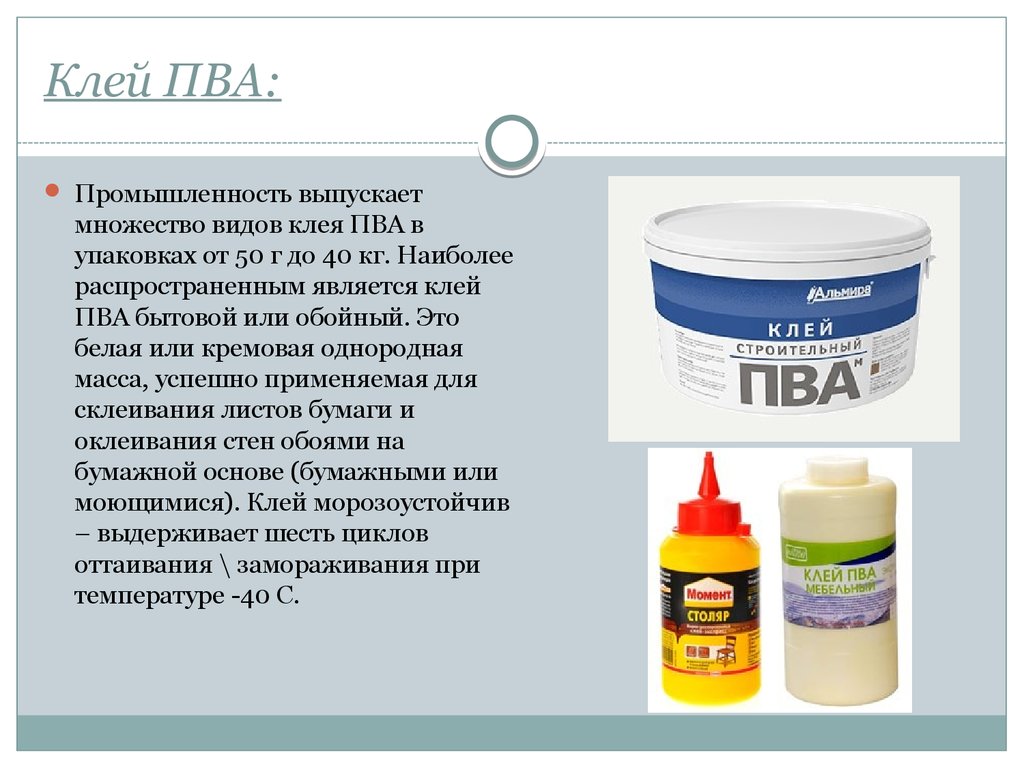

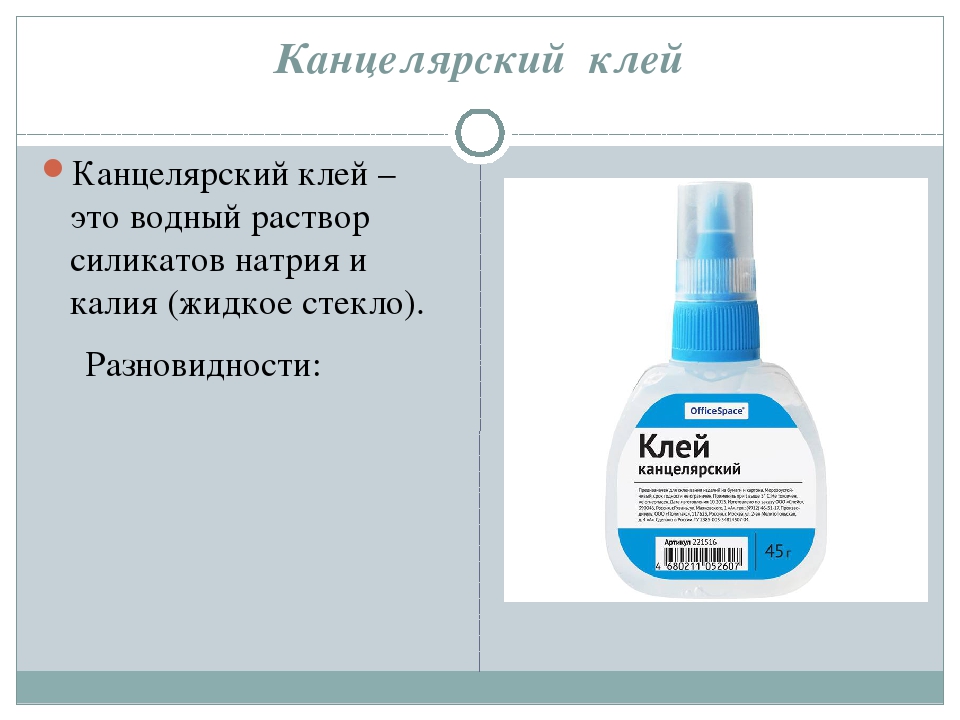

Material composition and properties

From a chemical point of view, the composition of silicate glue is quite complex. It is a melt of sodium and silicon oxides that form polynomial bonds in an aqueous medium. Moreover, the metal oxide molecules are surrounded on all sides by non-metal molecules. The formation of silicates is possible only with very active elements of the metal group; therefore, sodium or potassium is used to obtain the glue. In rare cases, lithium may be used. Sometimes special flavors are added to the composition, which do not affect the properties, but give the substance a pleasant smell.

Silicate block glue is a completely different substance. In its appearance and structure, it looks more like a solution than a glue in the usual representation. It does not contain silicates and acids. There, completely different substances are used, which give the connecting material the properties necessary for construction. Therefore, you should not confuse glue and blocks: although they have a common adjective in their name, they are not intended to interact with each other.

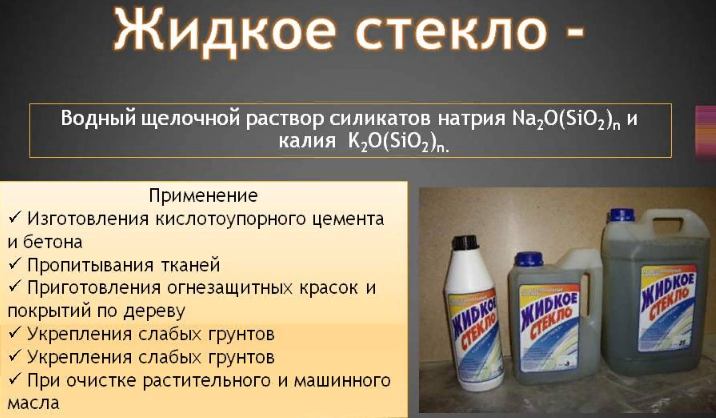

For its properties, silicate glue is called liquid glass. This is due to the fact that when solidified, it becomes very hard, but at the same time brittle. It will no longer be possible to dilute it with water. In fact, after hardening, the glue can be safely thrown away, since it can be returned to life only with the help of complex chemical manipulations, which will be absolutely inexpedient from an economic point of view.

You can buy silicate glue at any stationery store. Its cost in comparison with other accessories looks purely symbolic. A standard package with a capacity of 300 milliliters will cost about 25-30 rubles. When buying a large batch of goods, the unit price will be even less.

The use of "miracle glue" in modern construction

The main consumers of the described material are considered to be enterprises in the construction industry. The use of liquid glass in concrete is widespread. Silicate glue is characterized by a relatively low cost. And at the same time, it significantly improves the operational properties of the concrete solution, guaranteeing the latter excellent waterproofing. In addition, liquid glass has high antibacterial properties.

Due to this, mold never appears on the concrete to which it is added, and fungus does not start. All pools today, as well as structures operating at constantly high humidity, are concreted with compositions containing the "miracle glue" we are considering

It should be borne in mind that the solidification of liquid glass occurs quickly enough. And in some cases, you cannot mix it with concrete before starting work.

The builders found a way out of this situation.

They use a "tricky" method, which involves processing an already erected concrete structure with a solution of water and liquid glass (the components of this mixture are taken in equal amounts). Silicate solutions are well suited for combating soil subsidence under erected buildings and structures.In this case, it is recommended to use liquid glass, the use of which does not require any large-scale work.

Surface treatment with liquid glass

In the fight against subsidence, silicate glue is pumped into the ground under the building according to one of two schemes:

- One-step method - a mixture of a special hardener and liquid glass is formed, which is fed under the building.

- A consistent technique - the glass is pumped first, then the composition for hardening.

Impregnation of plaster and wood with liquid silicate solutions is common (we will discuss this below). Silicate glue is also added to zinc silicate paint, which protects metal products from corrosion for 25-30 years! Liquid glass is also included in the composition of modern particle boards. Their impregnation with "miracle glue" makes any wood product strong and very resistant to compression.

Manufacturers

A wide range of silicate glue from different manufacturers allows you to choose the most convenient option for use. The composition of all adhesives is approximately the same. Basically, the differences relate to packaging and prices. Some manufacturers add flavorings to the solution.

- Officemag. Silicate solution of the manufacturer of the same name, has a yellowish tint, is intended for work with paper and cardboard. Has a liquid structure. Available in a 110 g tube. with an applicator, which allows economical use of material. Price from 12 rubles.

- inFORMAT has a high adhesive capacity, colorless, odorless. Suitable for fixing and processing cellulosic substrates. Produced in a transparent, soft bottle with a dispenser of 75 g. Packing price from 11 rubles.

- ERICH KRAUSE - high-quality office glue for working with paper, fabric, cardboard. Has a transparent, odorless, homogeneous consistency. The bottle has a plastic tip with a cap for even application of the composition. Available in a package of 50 ml., Costs from 40 rubles.

- BRAUBERG is a German squad. Has a gel-like structure, odorless and colorless. Suitable for medium-weight paper and textile substrates. Comes in a tube with an applicator cone for even and economical distribution of the component. Packing 110 gr. costs from 12 rubles.

Specifications

Liquid glass has a number of performance characteristics, thanks to which it is in demand among owners:

- used in almost any construction work;

- has the ability to protect surfaces from moisture - liquid glass does not allow moisture and water to penetrate into the structure of the material;

- minimum hardening period;

- liquid glass has an antiseptic effect, that is, it protects against the appearance of mold and mildew;

- liquid glass for floor and wall surfaces is often used as a refractory material;

- products do not contain harmful substances, which allows it to be used in all rooms;

- such adhesives have a long service life;

- ease of application - liquid glass lies on the work surface in an even layer;

- if we compare silicate glue with similar waterproofing building materials, then the first option will win;

- the shelf life of building materials is about 2 years, and constant frosts / defrosts do not affect the performance of the product, but during long-term storage, a sedimentary layer may form, which is considered the norm;

- the insulation, made on the basis of silicate glue, is able to withstand temperatures up to 1300 degrees.

Despite most of the positive characteristics, silicate glue also has negative sides when applied:

- The composition of liquid glass contains a large amount of alkali, which negatively affects human skin. When working with such a product, you must stock up on high rubber gloves.

- The adhesive solution is able to harden within 20 minutes, after which the use of this building material is prohibited. Therefore, experts recommend that construction work be carried out at a fast pace.

How is liquid glass made?

Stationery glue was first made in Germany in 1818 by chemist and mineralogist von Fuchs. At the moment, this material is produced using a variety of technologies.

The most common ones are:

- Tripoli, diatomites, flasks or other types of siliceous raw materials are placed in special alkaline solutions, where they dissolve under normal pressure and relatively low temperatures.

- Silicon-containing compounds are treated with concentrated sodium hydroxide. This procedure is performed on a special autoclave.

- Quartz sand and soda are fused for construction work.

Silicate glue (liquid glass) is sold in the form of a ready-to-use solution or in dry form; it resembles a powder that must be diluted with water in certain proportions. Each composition is accompanied by instructions, which clearly describe how and in what proportions to dilute it:

- In everyday life, of course, it is better to use a prepared solution.

- Industrial and construction companies often order this product in dry form.

Glass is dried at natural and elevated temperatures. As a rule, manufacturers, in order to speed up this process, the finished products are dried at a temperature of 375 degrees. The glue dissolves in water completely, no sediment or particles remain. If ketones, salt compounds, aldehydes, ammonia, alcohol-containing substances are added to the solution, then a salting-out effect can be observed.

Production technology

Liquid glass is produced using several technologies that are not difficult in practical implementation. You can even make your own silicate glue. One way to prepare an adhesive is firing. A mixture of baking soda and quartz sand is melted in a special container.

In order to obtain a thick silicate glue, you can use the method of exposure to silica containing raw materials with solutions saturated with Na, K or Li hydroxide. In this process, it is necessary to maintain the boiling temperature regime.

When answering the question, what is silicate glue and what are its properties, one should not forget the following: depending on the composition, certain qualities of the substance itself are manifested. Potassium silicate is highly resistant to chemicals or weather conditions. Another component of the mineral compound will give different properties to the resulting substance. When using sodium silicate in the composition of fire retardants, their characteristics are improved. This liquid glass has antifungal, antiseptic properties.

Usage

Silicate is added to many building mixtures where it provides greater strength. Also, the glue adds lasting qualities to weather conditions and open fire. The mixture is also used to impregnate fabric materials and wood products.

Plant breeders use this composition when pruning trees, treating wounds with it.

Glue can be used for priming brick, concrete or wood surfaces. Pools or other objects in contact with water can be waterproofed. You can glue paper and glass, fabric, porcelain or leather products. It is also used for interior renovation work.

This mixture can be combined with other materials. It can be used as a detergent or as a cleanser. The industry also uses silicate glue, because it is a very good antiseptic, has an antifungal effect and protects against mold or mildew.

- Mounting glue is well mixed for a start. Working with glue involves the use of brushes, brushes and rollers;

- First, the surface is cleaned of dust, dirt, grease.Then it would be nice to clean everything with sandpaper;

- Apply by applying it to the surface. The parts to be glued are connected to each other;

- If you plan to priming the surface, for a start, a tightening mixture of equal parts of cement and liquid glass is applied. If a well is being dug, waterproofing is created by treating the walls of the well with glue. After the glue, the surface is treated with a solution of liquid glass, cement and sand;

- If it is necessary to prepare waterproof plaster, take sand and cement in a ratio of 2.5 to 1 and add glue (fifteen percent). In principle, the same recipe is taken as a basis when building fireplaces, stoves and chimneys.

The mixture is used for aquarium breakdowns, for gluing glass panes and removing greasy and oily contaminants.

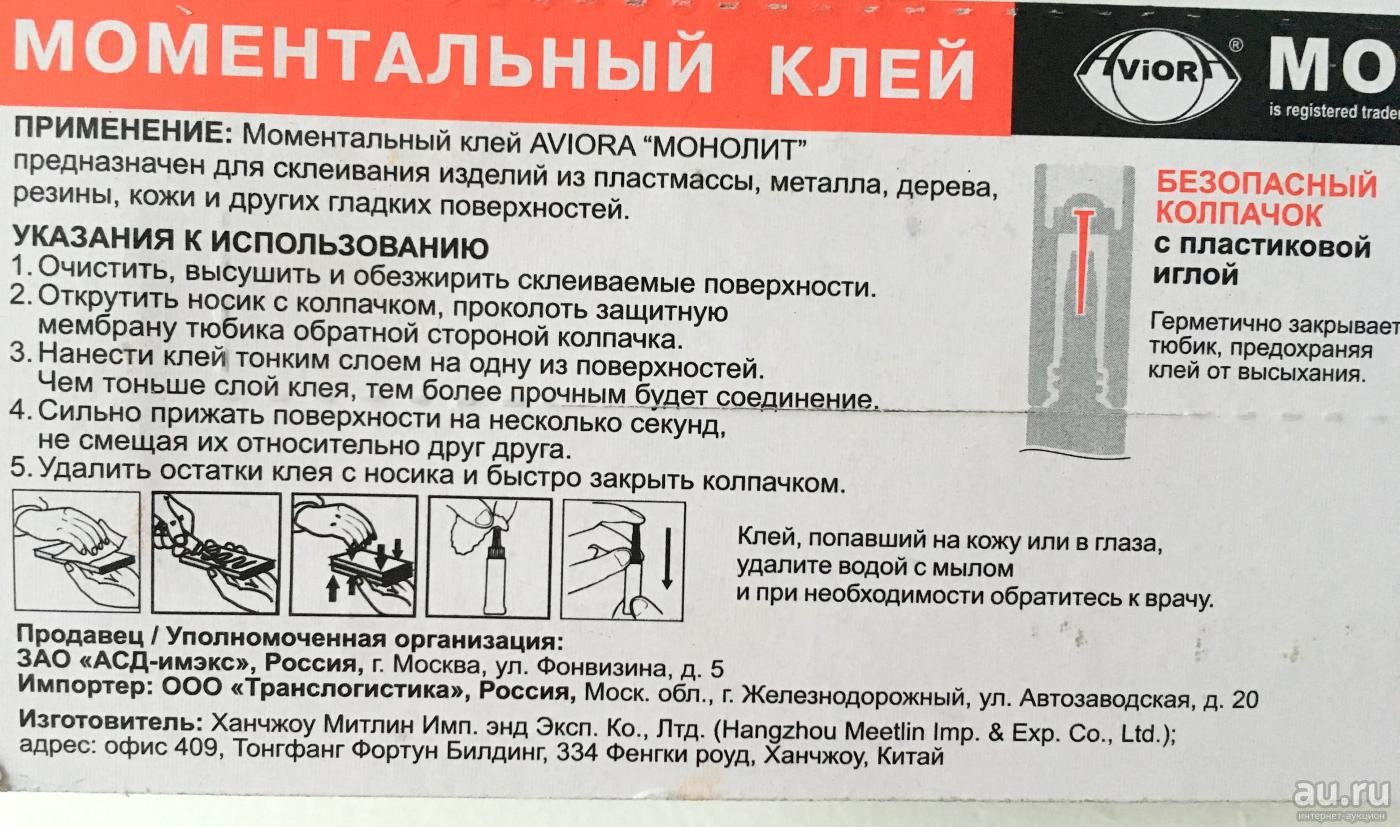

How To Work With Cyanoacrylate Superglue - Procedure

Any gluing of objects with superglue can be done at home, for this you do not need to have special skills

The instructions for working with it are simple, it is important to perform all actions quickly - there is almost no time left to adjust the position of the parts. Only on soft, hygroscopic materials is superglue bonding slower, and it will be possible to correct their position within 30-120 seconds

Before bonding, large gaps and cracks must be filled with concrete dust, dry plaster or soda, and then drop superglue there - the defects will immediately be filled with a dense white acrylic-like mass. The surface should be washed, all dirt and grease should be removed. Acetone or alcohol can be used as a cleaner and grease remover. Further, the procedure for working with superglue is as follows:

- pierce the metal protection on the tube with the upper part of the cap;

- on an absolutely dry base, apply a little superglue, firmly press the second part;

- start gluing from the center to the edges, otherwise air may get inside the seam;

- press the parts for 10-30 seconds;

- leave the product to dry.

At the end of the work, you need to wipe the nozzle of the tube from the superglue, screw it tightly. Opening if the lid is stuck, the bottle will be problematic, so it must be cleaned thoroughly.

Applications

Stationery glue is widely used:

In needlework and children's creativity. Applications, paper and cardboard crafts in kindergartens cannot do without its use.

- For work on fabric, leather, fine suede in applied art, office composition is also used. I use it to process the edges and cuts of thin fabrics so that they do not crumble.

- In the kitchen, to remove burnt-on residues from pots or pans. A solution of water and glue is poured into the contaminated dishes in a 2: 1 ratio. Bring to a boil and leave to cool. The burnt grease is then easily scrubbed off with a soft dishwashing sponge.

- In horticulture, trunks, cuts of trees and shrubs are treated with silicate composition. It creates a smooth film and protects wood from small pests, mold and mildew.

Silicate glue and office glue have another name: liquid glass. This composition is used in construction and installation work: for hydro and thermal insulation, as an adhesive material for fixing building structures, for making tiles.

Polyurethane sealants

Polyurethane sealants are an elastic, adhesive, sealing compound on a polyurethane base that retains its elasticity for a long time. This sealant can be used for gluing and sealing almost any material: metal, wood, stone, lacquered sheet, plastic, ceramics, concrete.

Polyurethane sealants have good adhesion and guarantee strong adhesion of surfaces, which is not destroyed even during strong earthquakes up to 5 points.

• Resistant to corrosion.

• Hardens on reaction with moisture.

• Can be painted, easily varnished.

• Have quick adhesion.

Due to the fact that polyurethane sealants contain harmful corrosive substances, it should be remembered that when working with them, they should not be allowed to come into contact with open skin areas.

They are sold in standard original packaging with a weight of 310 ml, also in cardboard boxes or in a 600 ml aluminum bag.

Specifications

If liquid glass is foamed, it practically ceases to conduct heat. This is actively used by producing heat-saving materials. They produce heat insulators based on sodium silicates. Similar products are used in industrial devices. To fill the silicate solution, squeezed sugar cane, reeds or sawdust from trees are often taken. Sometimes slag from iron, chromium or quartz sand is used. Thermal insulation properties are very high, they are equated to temperature ranges up to 1300 degrees, and withstand a quick change from minus to plus.

The metallurgical industry also uses silicate glue, it is mixed with the sputtering composition of the electrodes used in welding. Ferrous metallurgy always needs sodium silicate.

The foundry and chemical industries consume the lion's share of liquid glass in their production.

The mechanical engineering industry connects various parts, often using liquid glass.

By the way, the silicate mixture is used in the production of washing powders. In the textile and paper industries, silicate is used to give products a shine and hardness.

In its pure form, it is used mainly in various works related to repairs. They protect the lower facades of structures from the influence of ground and atmospheric waters. Basins, walls, floors and basement ceilings are treated with glue.

Let's summarize

A widely used, high-strength agent with high bonding properties - all this is a silicate glue. It was originally conceived for gluing paper and cardboard products. Later they began to add it to concrete and cement solutions to give the solutions great bonding properties. By mixing glue in the mixture, they also achieve greater thermal stability and waterproofing. Mold, rot and various fungi do not take on surfaces treated with glue solution.

The most significant disadvantage is high alkalinity. It is this property that can lead to injury when using it. But, despite this minus, glue is often used in a wide variety of areas of construction and decoration.

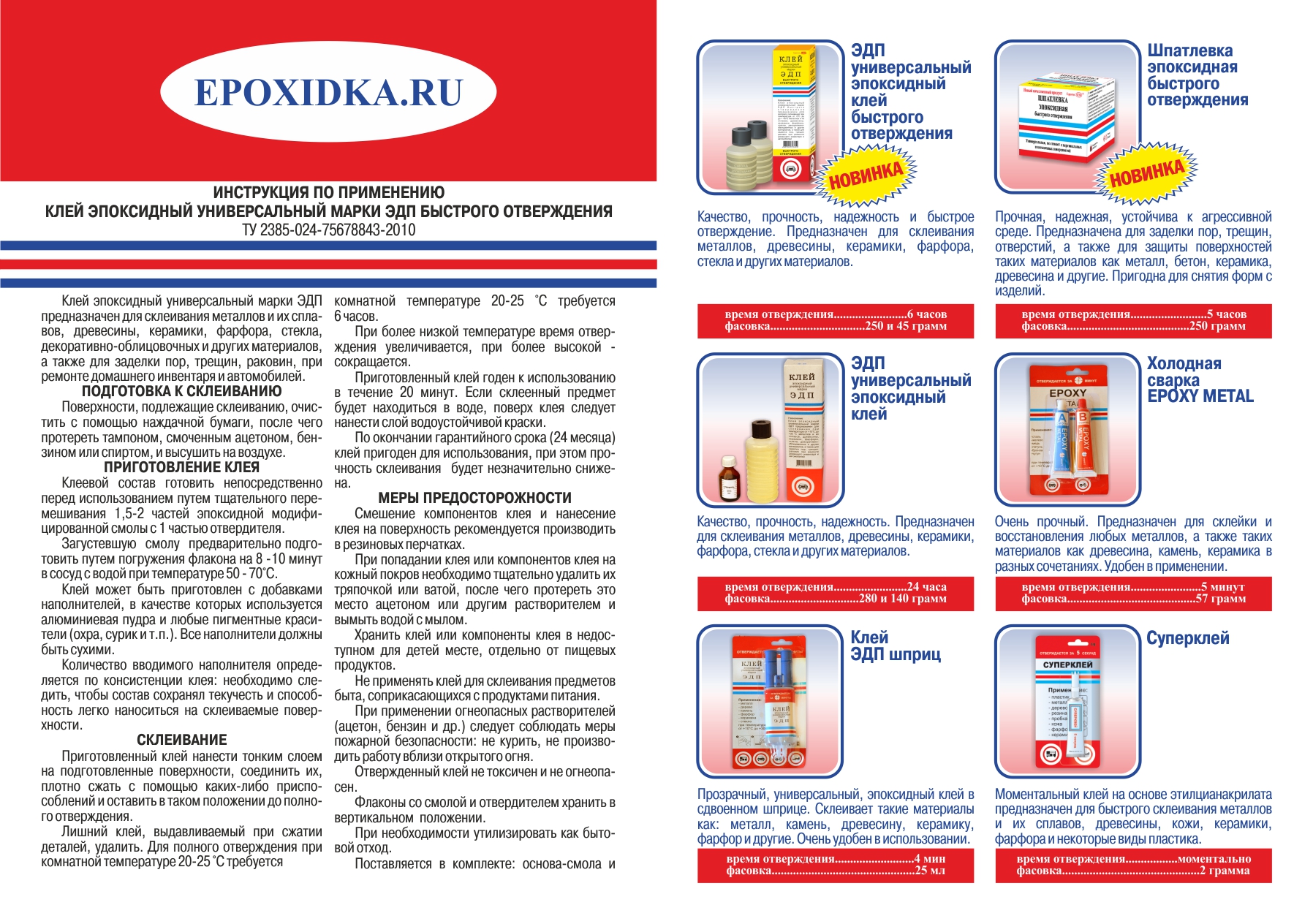

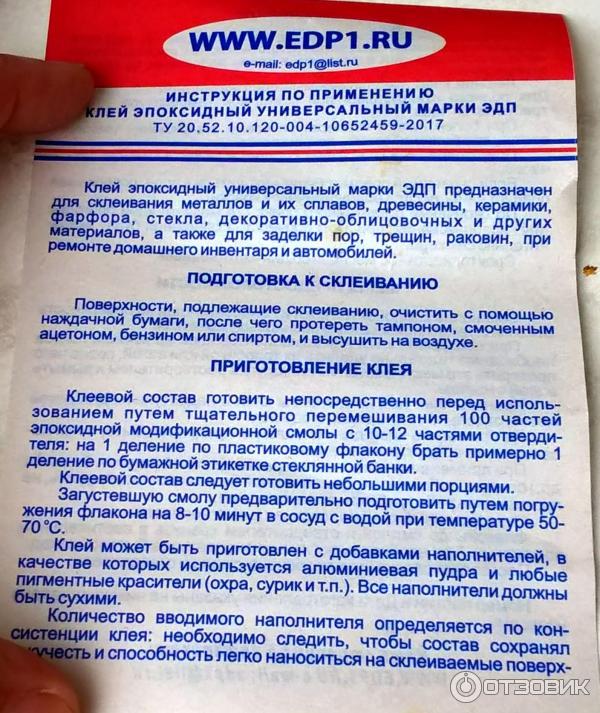

How to use epoxy glue: instructions

The gluing process takes place in 3 stages:

- cleaning surfaces;

- preparation of glue mixture;

- gluing surfaces.

First of all, a thorough preparation of the parts with which to work is carried out, since the finished glue will need to be applied immediately before it hardens. The surfaces are cleaned with ordinary sandpaper, then degreased with a special solution and after complete drying, you can go directly to the glue hardener.

Steps for preparing epoxy glue:

- Squeeze the resin out of the tube into a container.

- Add hardener as directed. Typically, 1 part solvent contains 10 parts resin. An overdose of hardener is allowed 1: 5.

- Mix the glue ingredients by hand.

- Apply the glue composition to the surface of the part and press firmly against the other, fixing the position for 10-15 minutes. The exact time of action of the hardener must be found in the instructions, since some manufacturers may make minor changes to the composition. In a few hours, the product will be completely ready for use.

Additional tips and tricks

To obtain the finished composition, disposable dishes are required, which cannot be cleaned after using the glue. Mixing the components is required with a metal or glass rod. The use of wooden sticks is impractical due to the high porosity.

Polyamide resin is poured into epoxy, constantly stirring for uniformity of the composition. To speed up the polymerization, the parts to be bonded must be heated. At +50 degrees, final hardening will occur within one hour. In a room where the temperature is + 15 ... + 18 degrees, bonding will end in 1.5-2 days.

p> Share link:

Instructions for use

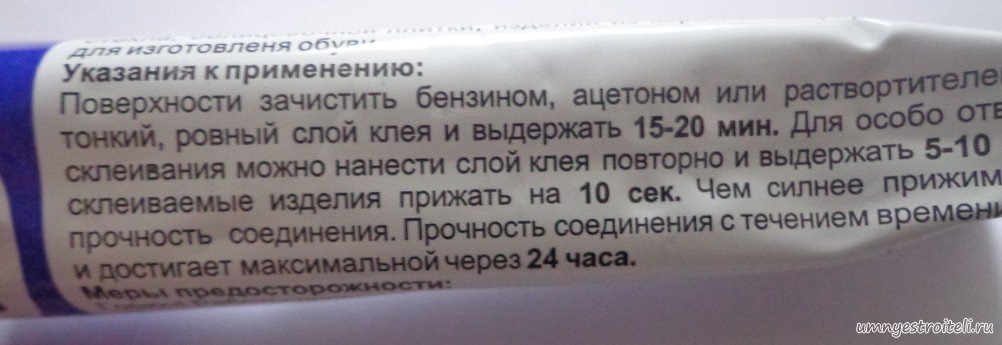

In order to rationally use the substance and prevent dangerous situations, it is necessary to follow the step-by-step instructions for use. It includes the following actions:

- The surface to be treated is thoroughly cleaned of accumulated dirt, dust and grease. When gluing hard surfaces, additional surface treatment with sandpaper is performed to eliminate defects.

- If the glue is used for industrial purposes, the solution is kneaded and a roller, brush or brush is prepared for work.

- The substance is evenly applied to the surface in a thin layer. The parts to be engaged are applied to each other and compressed.

- During operation in construction and the need for priming the surface, a tightening solution of cement and liquid glass is applied in equal proportions.

Using silicate glue to prepare waterproof plaster, it is mixed with sand and cement. A similar method is suitable for the construction of chimneys, fireplaces and similar products.

Share link: