Checking the quality of animal glue

A high-quality glue solution after digestion should not change the color of the litmus paper. When immersed in cold water, the glue should swell; a high-quality solution dissolves in hot water.

The glue produced using the correct technology should turn into jelly during cooling. A poor-quality substance with poor adhesion properties does not gel. Also, cooled glue is not capable of gelation if acid (acetic, hydrochloric, nitric) is added to it.

If the glue is kept on fire for too long, violating the production technology, it will also not gel when cooled. The substance will not bond the materials tightly enough.

The higher the cooking temperature of the adhesive, the faster it will be ready for use. For example, at 50 degrees, the solution should be cooked for 12 hours.

The addition of lime to the solution of animal origin is unacceptable, since such an additive reduces the ability to stick objects together. In addition, the mixture quickly deteriorates, molds and rots.

Features and types of fish glue

In recent years, the use of fish glue has decreased somewhat, although it is still popular in a number of industries. This tool is used to fix a variety of surfaces, is environmentally friendly and safe for humans. Fish glue is prepared from fragments of the walls of the swimming bladders of sturgeon fish, catfish, etc. A somewhat less effective and high-quality composition is obtained from the scales of teleost fish, heads, and other wastes of fish production. The collagen content in such raw materials is reduced, therefore the adhesive properties of the composition also decrease.

Sturgeon swimming bubbles

Sturgeon swimming bubbles

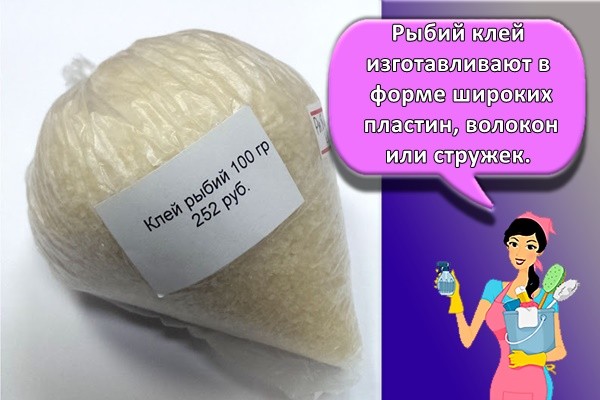

Externally, fish glue consists of fibers, shavings or pressed plates of different sizes, thicknesses and weights. Some types of glue are sold in the form of hard sticks, while others resemble thin sheets of cardboard. In some cases, fish glue is boiled from the broth by evaporating the water and removing the fat that has come out. After hardening, it will resemble a jelly-like mass with increased stickiness. Depending on the composition and manufacturing characteristics, the glue is classified into three groups:

- sturgeon;

- normal (simple);

- carpentry.

Sturgeon (karluk)

This glue is prepared from the swimming bladders of starred sturgeon, sturgeon, beluga, sterlet and other sturgeon. It is translucent, yellowish in color, sold in compressed plates weighing 50 grams, collected in piles. Also on sale there are other types of packaging of the product. Sturgeon glue is produced only where sturgeon fish are widespread (Iran, Russia, countries of North America). Its price is an order of magnitude higher than that of lower grade glues.

Normal

This composition is made from swim bladders, skin, cartilage, fins and bone remains of various fish species (catfish, cod, carp and many others). It costs less than sturgeon, but it is of rather high quality. Conventional fish glue comes in the form of pastes, thick solutions, dry plates and granules.

Joiner

Composition marked "carpentry" is found on the market more often than others. Its price is not high, but the gluing quality is also reduced in comparison with the two previous products. For the mass production of wood glue, any remnants of the fishing industry are used, including scales, heads, entrails.

The substance is well suited for working with wood, is safe and non-toxic. In stores, carpentry glue is most often sold in the form of dry powder or granules, but there are also pressed pieces of yellow or brown color. Any form is subject to self-breeding.Due to the absence of preservatives, mold often forms in the glue when stored in liquid form, therefore, after dilution, it should be used as soon as possible.

Wood glue

Carpenter's (glutin) adhesives containing natural ingredients,

have been used since ancient times. There are several types of natural

glue is bone, skin, fish, casein. They are based on protein

connections.

Bone glue

Produced from animal bone waste, the composition isolated from the horns is considered especially valuable. The glue contains substances such as collagen, gelatin and cysteine. It has good toughness, reliably glues wood surfaces. The mass looks like granules of yellow-brown color, the transparent structure of the substance corresponds to a higher quality.

Skin glue

Received from tannery waste. The subcutaneous layer (flesh) contains oligopeptides that are sticky. Such a mixture is distinguished by a high degree of adhesion; after drying, it acquires a light shade. Finished products are sold in the form of powder, tiles or flakes.

Isinglass

For the manufacture of fish glue, the remains of fish are used - scales, entrails, head, tail. It has increased adhesion strength and high ductility. The gluing seam is practically invisible, it connects dissimilar surfaces well. However, it does not tolerate moisture well and has a rather high price. Available in the form of granules or flakes.

Casein glue

Produced on the basis of milk protein with the addition of various

components to improve individual properties. It contains caseinate

calcium, inorganic phosphates and nitrates, slaked lime, kerosene and copper

vitriol. It adheres well to surfaces made of wood and other materials.

Differs in high reliability, high temperature resistance

and high humidity. Casein glue is used in the production of environmentally friendly

clean products, it does not have harmful emissions. Can be stored dry up to

12 months under normal conditions. The finished powder consists of gray granules.

Among the shortcomings, one can note the effect of mold on it. except

Moreover, over time, the dried composition darkens and leaves stains on the glued

surface, so it should not be used to connect light

materials. The prepared solution must be used within 2-4 hours,

otherwise, the glue mixture becomes unusable.

Review of popular brands

When choosing a suitable thermally conductive solution, it is recommended that you familiarize yourself with the most popular brands. Products from top manufacturers are valued for their high quality and strong connection of components.

Manufacturers produce several types of thermally conductive adhesives under different brands, including natural and synthetic ones. The latter additionally contain plasticizers, which makes them resistant to moisture and frost. Both types of solutions are used for installation work with metal, ceramic and glass products. The difference between natural and synthetic solutions lies in the quality of the composition and the final cost.

"Radial"

Radial glue solution is suitable for mounting LEDs and heat-dissipating fittings to transistors and processors in situations where it is not possible to apply heat-conducting paste.

When applied, the "Radial" glue provides stable and high-quality heat dissipation without losing its characteristics at a temperature range from -60 to +300 degrees. A distinctive feature of the products of this brand is slow drying, which allows it to retain its plasticity for a long time after being squeezed out of the tube.

"AlSil"

Hot glue "AlSil" is a modern composition for screwless mounting of radiators, cooling systems and other structures where heat removal is required.Often, glue is used on memory cards in laptops and system units.

The composition is supplied in a syringe weighing about 3 g, which makes it convenient to apply to the work surface. The AlSil solution is economical because it can be applied from a syringe in a thin layer.

GD9980

The heat transfer compound GD9980 is used to displace accumulated air between the surface of the microcircuit and the base of the radiator. The heat dissipation property of the glue of this brand is less compared to the products of other manufacturers, but the GD9980 composition is capable of fixing parts on the processor with particular strength, attaching heatsinks to motherboards, RAM slots and video card microcircuits.

Instruments

In order for an angler to make a wobbler, you will need to prepare a number of tools and equipment that will help facilitate and speed up production. To perform the work, you need: a sharpened penknife, a hacksaw for metal or a jigsaw with a fine saw, a screwdriver with a set of wood drills of various small diameters from 0.5 to 3 mm, pliers, a small hammer, a file with small notches, needle files, sandpaper 0.1 and 2 numbers of abrasive coating and tweezers. Of the equipment, a vice will be required, which allows you to securely fix and subsequently comfortably process the workpiece.

Peculiarities

The readiness of bone wood glue can be checked in another way. A stick is raised above the composition, with which the substance was stirred. If the product drips down in drops, the process is not completed, the complete readiness is evidenced by the flowing down of the mass in a single-toned stream.

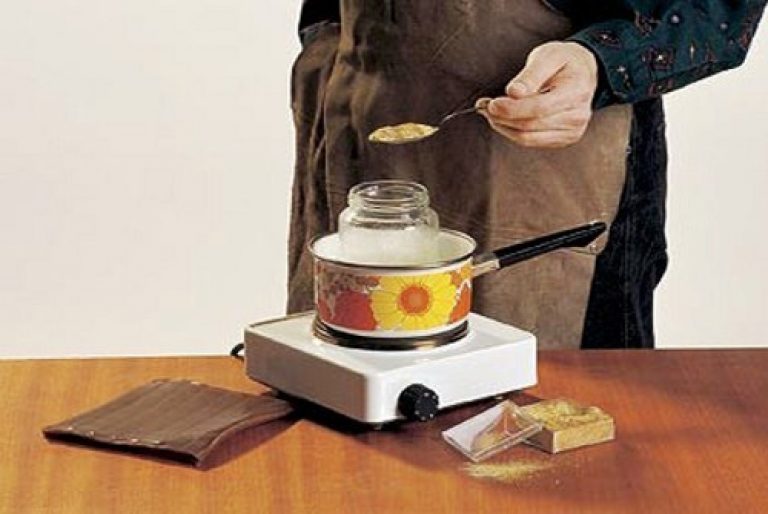

For cooking natural glue, a special device is used - a glue. It consists of two vessels of different sizes, one of which is inserted into the other. A large container is filled with water, and a second container holds the resulting glue. In the next step, a small vessel is placed in a large tank, put on fire. The optimal manufacturing material for glue is copper.

Characteristic

PVA

The manufacture of PVA glue begins with the selection of the following components:

- Gelatin - 5 g;

- flour - 100 g;

- water - 1 l;

- glycerin - 4 g;

- alcohol - 20 ml.

Previously, a day before the manufacture of PVA, gelatin is poured with water. Swollen gelatin, flour and distilled water are mixed, boiled in a steam bath and until a dense, uniform texture is formed. Then add glycerin and ethyl alcohol to the mixture, stir and bring again to a thick, uniform texture. Allow the resulting adhesive mixture to cool and use it as directed.

DIY glue making

Joiner

Carpenter's glue is ideally suited for permanent bonding of materials, mainly from wood, for example, cardboard, plywood. To make the glue, you will need a tile, which you need to grind and soak the crushed small pieces in cold water so that it completely covers them. The resulting mixture must be kept until a soft jelly mass is formed. As a rule, it takes 10-12 hours to transform. Then the mixture in a container must be put on a steam bath and continuously stirring to bring to a uniform liquid texture. Allow the resulting mixture to cool, then use it as directed. If a light glue is required, a little hot water is added to it. For strong adhesion of leather products in 500 ml of the composition, add 1 teaspoon of glycerin. This is such a difficult technology for making glue.

Tiled

It is best to glue front, decorative tiles with tile adhesive. It is made from water, sand, cement and PVA. Since sand, in fact, acts as a putty, it is recommended to take sand with a boundary diameter of 2 mm. The proportion of cement and sand is 1: 3. For example, 1 bucket of cement requires 3 buckets of sand.To prepare the mixture, cement and sand are thoroughly mixed, and then a solution of water with PVA is added. For 1 bucket of tile glue, you will need 500 g of PVA. The volume of PVA can increase when tiles are glued in places of high humidity. The resulting mixture is mixed until a uniform, thick texture is obtained and is suitable for use. The glue should be used immediately, without waiting for it to harden. The hardened mortar should not be diluted with water and applied during the gluing process.

Casein

There are many similarities between carpentry and casein adhesives, but the latter is more resistant to moisture. In the manufacture of casein glue, casein powder, water, and borax are used. Water is added to the casein powder, and then infused for about 3 hours. Hot water is also added to the borax in a ratio of 1: 7. The resulting solution is mixed with casein, boiled in a steam bath and stirred continuously. After 40 minutes. after removing from the steam bath, the glue is usable.

You can make casein powder yourself. Why sour low-fat milk is expressed through thick gauze. Casein with gauze is washed in water, boiled, wrung out and dried until firm.

To make a mixture of homemade casein, you need borax, water and casein powder in a ratio of 1: 4: 10. When combining ingredients, water should be added gradually. It is advisable to use the finished composition immediately, since after about 3 hours it hardens and loses its stickiness.

Water resistant

Quite often in the household, you need glue that is not afraid of damp and is waterproof, for example, for a rubber boat. We offer several methods for making adhesives:

- Low-fat cottage cheese and slaked lime are mixed until a thick, uniform mass is obtained. Then the glue is ready for use. It is applied to surfaces that should be clamped and dried well;

- 100 g of high-quality wood glue is cooked over low heat until a liquid texture is obtained. Then 35 g of drying oil is added and the mixture is well stirred. Please note that it can only be used preheated.

Making glue at home is a simple and affordable process! Of course, homemade glue is not used to glue the frame or repair punctures in the wheels of a car, but it is not replaceable in everyday life.

What glue is right

Despite the wide variety of adhesives for MDF, their main purpose is tight and reliable gluing and adhesion of panels to the wall. All of its types are divided into groups:

- universal compounds;

- special;

- polyurethane foam;

- liquid Nails.

Compounds for MDF sticker

Compounds, or polymer resin contains "Moment", "Titanium" and other additives, thanks to which the glue is used on wood, stone, metal surfaces.

Special series

Chemists have developed this series for gluing not only on ordinary surfaces, but also on concrete. It can be used by both professional builders and amateurs who decide to make repairs on their own. As a supplement to the glue, a gun is used, working with which greatly simplifies the gluing of MDF.

Construction foam

Despite the fact that building foam is most often used for sealing, its use when installing panels is quite possible. Construction foam is produced in two types - for outdoor and indoor use. When fixing MDF panels, it is permissible to use both types of clamp. After drying, the polyurethane foam remains soft. Flexibility avoids deformation of MDF. This is especially true if their composition is based on chipboard materials.

Liquid Nails

The glue is universal, has high adhesion, resistance to corrosion, installation of various building materials, especially those containing wood, is possible.Due to its ease of use, the option of using liquid nails is very popular. Using a gun, glue application is convenient.

Liquid nails based on organic acids have an unpleasant odor, so personal protective equipment should be used. The glue is durable, but when moisture gets in, the seams can undo. This should be taken into account when renovating premises where the humidity is higher than normal.

Universal construction

Multifunctional glue is applicable not only for gluing MDF, but also for other types of repair work. It is characterized by heat resistance (from -30 ⁰С to + 60 ⁰С), quickly sets, and is resistant to moisture.

How to replace fish glue

Fish glue belongs to the category of animal adhesives with an organic base. In addition to this adhesive composition, there are a large number of materials on a similar basis. Parchment, (fish), glove glue. In a few words, the named adhesives can be characterized by the material of their manufacture as follows.

Glove glue is a composition made from scraps of leather that was used to sew gloves.

Parchment glue - a composition of parchment, all the same leather, but different manufacture.

More detailed information on the names of such materials can be found on the pages of the encyclopedic reference - Wikipedia.

As a conclusion of the answer to the question - what can replace fish glue, we answer. Any kind of other glue that meets the requirements of its application.

Fish glue recipe

Prepare fish glue with your own hands if you do not have the opportunity to purchase it already in a liquid, ready-to-work form. Due to the high enough cost or lack of free sale, it is quite easy. But only if:

You have enough free time (the process of making the glue cannot be called fast).

You have the necessary material for making a composition of a certain grade and quality (Karluk, simple or wood glue).

You (and others) do not have an allergic reaction to a specific fishy smell.

There is no way to use a ready-made substitute for fish glue.

If all the above conditions are met, you can start preparing (cooking) glue from fish. We note: exactly to cook, not to manufacture! For the manufacture of fish glue, specific equipment is used (vacuum chambers, etc.). As an example, take a compound called fish glue for carpentry. Due to the availability of raw materials (if desired, you can find and buy dry plates).

Stages of actions:

Grind the plates to the size of gelatin granules.

We place the material in a container and fill it with cold water.

Leave to swell warm for 5 to 6 hours.

We rub the resulting mass with our hands to a porridge of a similar state.

We move the container with the solution to a water bath.

With constant stirring, we achieve complete melting

It is very important not to overheat the solution over 80 degrees.

We add antiseptic compounds to the glue to prevent putrefactive formations.

We filter through cheesecloth.

Pour into a molding container with plastic wrap laid on the bottom and sides .. The resulting glue is ready to use.

The resulting glue is ready to use.

The amount not needed can be dried and stored in a tightly closed container for later use as needed.

Characteristics of the glue

Using PVC, you can create decorations, toy figures, decorative food items, panels, souvenirs, flower, fruit compositions, ceramic floristry.

Polymer clay is similar to plasticine. Plasticizers give elasticity to the mass. It differs in the way it hardens. Some types require heat treatment (when "baked" to a temperature of 130 degrees, plasticizers volatilize, the material hardens). Others freeze on their own.

The material to be heated is preferred.The mass, hardening itself, dries quickly (there is no way to correct the deficiency), cracks when dry.

This clay has several names, but they all denote the same material: polymer clay, curable plasticine, plastic.

There are two ways to color and decorate crafts:

- During sculpting, add dyes, set sparkles, and other decorative elements.

- After "baking", paint the hardened parts with paints, glue decorations, fasten together.

Starch use

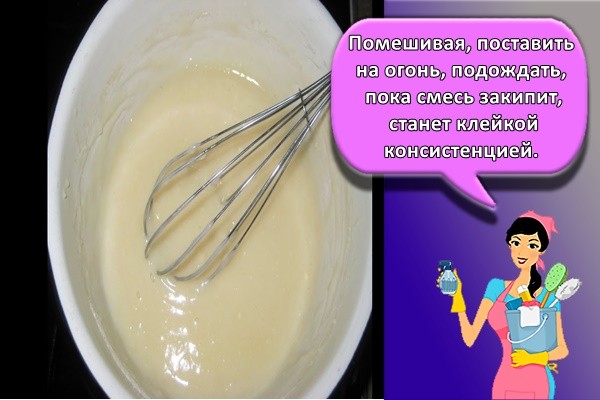

For starch glue, prepare half a liter of water and 3 tablespoons of cornstarch. As a container, it is better to use galvanized or enameled dishes, which are put on fire together with water until it boils. The starch should be dissolved separately, and then, as in the case of flour, poured into the liquid.

When the glue boils, it can be removed from the heat. The main advantage of this composition is that it turns out to be more transparent and does not leave traces. It should be used without a trace, because after a while it will lose its ability. In order to improve the quality of the glue, it is recommended to add about 100 g of PVA glue to it. But if you also add wood glue, then the mixture will cope with priming the surfaces before gluing the wallpaper.

Varieties of glue

The most popular today is PVA glue in the form of an emulsion of water and polyvinyl acetate. Plasticizers and other components are added to the ingredients in the process. The smell of the mixture is almost not pronounced, but it is used for gluing different materials. PVA glue can be divided into:

- clerical;

- household glue;

- universal composition;

- Super glue;

- dispersion of PVA.

As for the household composition, it is intended for gluing paper products, it can also be used as wallpaper glue. This mixture is white or beige and can be frozen and thawed 6 times. With office glue, everything is clear, but the universal composition allows you to connect not only paper and cardboard, but also wood, glass, and leather products. Superglue is a frost-resistant compound. As for the dispersion, it is an aqueous solution of polymers stabilized by a protective colloid.

How to get the right taste and consistency

The pastry glue should have a neutral taste and smell so as not to interrupt the main course. Too thick or liquid fixative, composition with lumps will not give a reliable connection, spoil the appearance of the product.

Little things that affect taste and texture:

- Sometimes the icing sugar sticks together to form one large lump. Take the time to crush it as small as possible. Otherwise, the mastic will tear when rolling.

- Do not apply the confectionery composition to the soaked crust, only to the dry one. The glue can dissolve due to the large amount of sugar.

- If you are using buttercream, let it cool well in the refrigerator before applying the mastic.

- Decorate the cake shortly before serving, otherwise the figurines will get wet and no longer hold their shape.

- If some of the items dry up while decorating the cake, place them in the microwave for a few seconds. This will return them to their previous state.

The mastic can be stored in the freezer for up to two months, and in the refrigerator for no more than two weeks.

The main components of edible glue

The food fixative is made from edible ingredients. When used in moderation, it does not harm a person in any way.

The main components of the edible glue are:

- Water.

- The preservative is citric acid.

- Food additive E 466 - used as a thickener to give the product a viscous structure. It is usually used in the manufacture of yoghurts, curd products, and cheeses.

- Potassium sorbate is a harmless additive E 202. Increases the shelf life of products by inhibiting the growth of mold, fungi and yeast.

Sugar glue is produced in the form of a powder for preparation and a ready-made jelly mixture. The minimum price starts from 50-70 rubles per 100 grams.

Popular brands of confectionery fixative:

- Magic Colors. Manufactured in Israel. It has a very secure hold, it is used for gluing massive objects. The grip force allows you to hold even marzipan figures. Suitable for masking defects on the surface of the product. Sold ready-made. It is a thick, viscous substance.

- Rainbow edible glue. The choice of professional pastry chefs. It is held together by complex designs, multi-layered desserts. The glue is tasteless and odorless. It can be eaten by allergy sufferers, vegans, as it does not contain animal ingredients. Country of origin - Great Britain.

- CMC (food carboxymethyl cellulose). The powder is tasteless and odorless. Stir it in water before use. It is used for the preparation of mastic.

- The full name is Essentials Edible Glue. Created on a plant basis. Suitable for making and fixing large, heavy parts.

Cooking food glue at home

Products for making an edible fixative at home:

- egg whites;

- sugar;

- flour or starch;

- lemon acid.

The process does not require special skills and time-consuming, but you will be completely confident in the quality of the product. The recipe for making the simplest food glue:

- Carefully separate the egg yolks from the whites.

- Beat the whites with a hand mixer until stiff peaks form. When turning the container to the sides, the mass will keep its shape. The dishes in which you cook must be completely dry.

- Add a teaspoon of citric acid and a pinch of powdered sugar.

- Stir all ingredients. With vigorous stirring, the mass will begin to thicken.

- Put the mixture in the refrigerator for 5 hours, covering the dishes with cling film.

Useful video on the topic:

For mastic

This is a plastic sugar mass, from which figurines are made for decorating a cake, covering the cake layers. Elements made of mastic retain their shape for a long time. To fix the decor, you can prepare edible glue:

- Mix half a teaspoon of mastic thickener (CMC) with 4 tbsp. l. water.

- Leave until the powder is completely dissolved. The lumps should become transparent.

- Cover the container and refrigerate for 10-12 hours.

- You should get a thick, viscous mass.

The glue for mastic is kept in the refrigerator for up to a week.

We recommend a video on the topic:

With gelatin

Gelatin in plates is suitable, it dissolves better and does not leave lumps. Agar agar can be used. Cooking method:

- Pour gelatin with water and leave for half an hour to swell.

- To speed up the process, the container can be heated slightly. Do not bring the gelatin water to a boil!

- Pour in the icing sugar and stir to avoid lumps. The mixture will begin to thicken.

- Add colorings - purchased or natural (vegetable or fruit juice).

Interesting video on the topic:

Chewy marshmallow

Homemade food glue recipe:

- Melt regular marshmallows or marshmallows in a water bath.

- Add a quarter teaspoon. icing sugar and tsp. lemon juice.

- Stir well until thickened.

- The resulting mixture can be painted in any color.

As a result, a very plastic and pliable mass is obtained, from which you can form any delicious decor for confectionery products.

Flour-based

You can make a reliable food fixer from flour:

- Heat 2 cups of water.

- Mix half a cup of wheat flour with water to form a thick paste-like mixture.

- Pour the resulting mass into boiling water, bring to a boil and remove from heat.

- Add 3 tablespoons of sugar or powdered sugar to the resulting mixture.

- Stir thoroughly until sugar dissolves and cool.

What to buy glue for plastic models

Models of any complexity are made of plastic - airplanes, ships, cars.High-quality glue for this material should not spread over a smooth surface, so it must be carefully selected.

There are many manufacturers producing adhesives specifically for plastics. So, you can safely use polystyrene compounds from Revell, Italeri, Tamiya, Zvezda. Despite the similarity of properties, they can be divided into three groups:

- Liquid - sold in plastic bottles with a convenient applicator.

- Medium density - presented in glass jars with a brush on the lid.

- Thick - packed in tubes. They freeze the slowest, so they allow you to work slowly.

After being applied to the parts, polystyrene mixtures penetrate inside and harden, forming a strong connection. You can use the glued parts in an hour, but the product will finally set in a day.

Revell adhesives for plastic products are sold in cans with a needle, Tamiya equips cans with a brush, but Zvezda adhesives are delivered to stores without additional tools.

What rules must be followed when working with adhesive for prefabricated models

- it is not worth adding too much mixture to the junction of the parts, you run the risk of staining the hands, the tool and the parts themselves with the resulting surplus,

- if a drop hits the part, do not try to wipe it off, wait for the composition to dry and sand this area,

- liquid glue should not get under the masking tape, otherwise, after completing the work and removing the film, you will find that the plastic has "floated" under it,

- the junction with super glue turns out to be brittle, so it is better not to touch it, you can additionally degrease it,

- follow the instructions for use indicated by the manufacturer on the packaging,

- use the products strictly for their intended purpose and only for those materials for which they are intended,

- when working with toxic compounds, it is recommended to use protective gloves.

conclusions

All of these types of wood glue are environmentally friendly. It is better to carry out construction operations with a flesh option or PVA. These substances have excellent setting parameters and an affordable cost. For restoration and bonding of delicate and thin surfaces, fish glue is suitable.

The main criteria for choosing wood glue:

- The lighter and more transparent the granules or tiles, the better the raw materials used.

- The most expensive and best glue is from fish waste. It meets the highest standards. It is used for restoration work and joining delicate surfaces.

- Bone and flesh composition is used for routine repair work.