Bonding methods

When working with polyurethane adhesives, the following technology is used:

- "Cold" - before applying the glue, it is necessary to degrease the surface, after which the first layer is applied, after ten minutes - the second. After five minutes, the parts to be glued are firmly pressed and held for at least 3 minutes;

- "Wet" - the applied glue is sprayed with water on the surface, after which the materials are joined under a press;

- "Hot" - a press is used in the gluing process. An adhesive is applied to the previously cleaned material, after 30 minutes it is heated to 80 degrees and pressing is carried out.

In the process of hardening, the glue slightly foams, which does not in any way harm the gluing of smooth surfaces due to the very thin applied layer, and when gluing porous and rough surfaces, it even helps to better fill microcavities. Therefore, one-component glue is indispensable for gluing wood, foam, chipboard, etc.

Adhesives manufacturers

A large number of polyurethane-based adhesives are sold in stores. Domestic and foreign manufacturers provide such products to the market. Here are the most popular brands:

- Anles. The range of the company includes about 10 polyurethane adhesives for industrial and household use. The adhesives "ADV", "Vilad", "Polyurethane", PVC Fix and others have earned the respect of users. All of them are used for gluing PVC, rubber-fabric products, polyurethane, thermoplastics, leather, glass, metal.

- "Titanium". Several canned adhesives are produced under this brand for professional and home use. Especially known is the foam glue "Universal" - a one-component composition for external and internal work, quick-drying, with high fire resistance. Another good composition is Bonolit "Formula of heat". This glue is so strong that it is used for masonry blocks, the construction of external and internal walls, as well as partitions. It serves as an alternative to conventional cement mortars.

- Desmokol. It is widely used in shoe factories, reliably holds rubber and polymer materials. Available in small tubes, cans and even 200 liter barrels.

- Kenda Farben. The company presents on the market a very high-quality polyurethane compound SAR 306, which has high thermal stability. It is used for gluing PU, TPE, and various rubber products. The addition of a special hardener increases the adhesion of other difficult-to-bond materials.

- Sika. This Swiss brand produces a whole line of polyurethane-based products. Especially known is the polyurethane sealant Sikaflex, which has high tensile strength, resistance to moisture, chemicals and physical stress.

- Inov. A cold-curing polyurethane binder of this brand from the People's Republic of China is used for laying seamless coatings, the production of rubber plates, rubber crumb, rolls.

- Henkel. Products from the Ceresit line are high quality adhesives for tiles and other materials. The most famous polyurethane adhesive is Ceresit CT 84 - a means for fixing window sills, filling gaps between expanded polystyrene plates, aerated concrete blocks, for fixing thermal insulation. Also on sale is the Moment Crystal glue from Henkel - a transparent polyurethane gel for all types of materials, except for Teflon and polyethylene.

- Polinor. Polynor Stik glue is a one-component composition for fixing extruded polystyrene foam, aerated concrete, panels, mineral wool. It can be used for sealing joints and open areas, for attaching decorative elements.

- Soudal.Soudal brand produces polyurethane adhesive Soudabond Easy - a professional composition in cylinders for fixing mineral wool, cork, gypsum board, glass wool, foam blocks and fiber-cement boards.

- "Lighthouse". Glue "Super NN" of this manufacturer is intended for banner fabric, leather, laminate and parquet, all types of plastic, polyurethane, as well as rigid PVC and ABS. Before use, it is imperative to clean the bases with Cosmofen solvents.

Also polyurethane-based adhesives are produced by the companies "Neomir", "Rastro", "Kleon", Adesiy, Bostik, Duayen and others. The funds have different prices and volumes, but, for the most part, are of good quality. You can get excellent polyurethane glue at any hardware and hardware store.

The best polyurethane adhesives for wood

CHEMOLAN B45

Polish CHEMOLAN B45 wood glue is made on the basis of polyurethane. Unlike similar materials from other manufacturers, this substance is highly resistant to heat and high humidity, static, dynamic loads. CHEMOLAN B45 PUR glue is adapted to various materials: metal, concrete, PVC, foam plastic, roofing material, mineral building boards, asbestos-cement blocks, drywall, etc.

- Affordable price.

- Excellent adhesion to wood and other wood-based materials.

- Wet surfaces adhere well, no need to pre-dry.

- High mechanical strength of the bond.

- Fast bonding.

- The glued surfaces do not lose flexibility, elasticity, and are resistant to water and temperature extremes.

- Universal application.

- Ease of application.

- Shelf life is only six months.

- When storing this glue at temperatures below + 5 ° C, the composition loses its useful properties.

Bostik Tarbicol PU 1K

The main purpose of polyurethane glue from the French company Bostik France is to lay parquet plates and arrays of boards of various lengths on surfaces made of concrete, cement screed, tiles, metal, plywood, chipboard, fiberboard. Adhesive joints formed with Bostik Tarbicol PU 1K do not lose strength when heated in the "Warm floor" system. The adhesive does not contain solvents or water. Liquid consistency in the form of a cream paste.

- Versatility (works with absorbent / non-absorbent substrates).

- High efficiency.

- Ease of use, easy application.

- Oiled surfaces do not dry out immediately when opened.

- With the help of this glue, craftsmen manage to smooth out small irregularities in the coatings.

- Resistance to high humidity in bathrooms, kitchens.

- Convenient branded PU PACK packaging with clear instructions for use in Russian.

- Frost resistance, the structure of the composition does not change at temperatures up to minus 20 ° C.

- Does not support combustion.

- Relatively high cost.

- In a liquid state, the glue is toxic, contains isocyanates; during operation, contact with open skin and mucous membranes of the eyes is not allowed.

Ceresit R 710

Ceresit R 710 two-component polyurethane adhesive for wood is produced under the well-known HENKEL brand. The bonding agent provides a high quality installation of wood, rubber, vinyl, PVC, ceramic, metal, wood floorboards on various substrates (absorbent / non-absorbent). Most often, this composition is used in buildings with high mechanical loads - industrial workshops, sports halls, garage complexes. The R 710 is used when arranging a raised floor with built-in cable routing channels, when installing plates for fixing metal support structures.

- Versatility of use - Ceresit R 710 is excellent for indoor and outdoor use.

- Does not contain organic components.

- Forms highly durable, reliable connections.

- Convenient packaging of 10 kg.

- No drying time required.

- Quick readiness for mechanical stress - after 8 hours.

- Very expensive glue.

- Protect skin and eyes when working.

- Storage is required under certain conditions - at a temperature not lower than + 10 ° С.

Chimiver Adesiver Elastic

One-component wood glue Chimiver Adesiver Elastic is designed for parquet work. This product does not contain such components as solvents, water, epoxy resins, amines, isocyanates. The final hardening of adhesive joints occurs within three to four days. The seams are resistant to water, fire, temperature extremes, natural aging, and increased wear. Experienced craftsmen use Adesiver Elastic to glue wooden parquet blanks to marble, concrete, ceramic tiles, metal. The glue is applied to surfaces at an ambient temperature of +15 to + 25 ° C (room temperature).

- Adequate price.

- High product efficiency.

- Choice of colors (walnut, oak, etc.).

- Economical consumption.

- Shelf life is at least 9 months.

- Convenient packing in 10 kg buckets made of durable plastic.

Recommended adhesives

For the repair of inflatable boats, experts and experienced fishermen recommend using several brands of glue, each of which has its own advantages:

1. 4508 is an effective water-resistant adhesive with a high degree of strength. Due to its ability to form an elastic seam, it is used to repair rubber fishing equipment: boats, suits, boots. The glue contains a solution of polyurethane resins.

Attention! Combined use of 4508 glue together with Desmodur and Leikonat hardeners increases the wear resistance of the glued joint several times. 2

Polyurethane glue is a professional two-component glue specially designed for gluing PVC, acrylic, polyurethane, rubberized fabrics used to create awnings, banners, boats. Among the advantages of polyurethane glue, experts note resistance to temperature extremes, water, engine oil, gasoline, and mechanical stress. The use of this glue gives a thin elastic seam of high strength that can last more than 10 years.

2. Polyurethane glue is a professional two-component glue specially designed for gluing PVC, acrylic, polyurethane, rubberized fabrics used to create awnings, banners, boats. Among the advantages of polyurethane glue, experts note resistance to temperature extremes, water, engine oil, gasoline, and mechanical stress. The use of this glue gives a thin elastic seam of high strength that can last for more than 10 years.

3. "Radical" is a universal one-component adhesive capable of reliably gluing polyvinyl chloride, rubber, neoprene and other materials due to the presence of chloroprene rubber and organic resins in the composition.

Glue "Radical" can be used at subzero temperatures. Inflatable boats made of PVC, glued with this glue, can be operated in fresh and salt water, as well as in the temperature range from -60 ° to + 80 ° C, they perfectly withstand mechanical stress and pressure.

4. "Gummi" is a strong one-component adhesive designed for gluing inflatable rubber and rubber-fabric products. The main component of the glue is natural rubber. The seams glued with "Gummy" are water resistant and elastic.

5. 88 N - glue made of rubber used for cold gluing rubber products. The use of 88 NP glue makes it possible to operate an inflatable boat in fresh and salt water, as well as at temperatures from -50 ° to + 70 ° C. The seams obtained as a result of the use of glue are water-resistant, vibration-resistant, mold and mildew resistant.

Attention! According to experts, the best glue for eliminating defects in the hull of an inflatable PVC boat is glue 4508. In its absence, polyurethane glue and Gummi glue showed themselves better than others.

Application and safety rules

If you work with wood with a moisture content of less than 8%, sprinkle both surfaces with water, allow the liquid to be absorbed, and only then proceed to gluing. Before this, other preparation measures must be taken: they remove dirt, debris, dust, fats and other pollutants. They also clean the bases from cement, plaster, paint. For degreasing, wipe with alcohol, solvent.

The glue is applied in a thin layer over the entire surface. This is especially convenient if the adhesive is aerosolized. Thick pastes, viscous solutions are applied and spread with a spatula. Two-component adhesives are first mixed according to the instructions, then similar actions are performed. The rules for working with polyurethane are as follows:

- the amount of glue should be small, otherwise the expanded layer will turn out to be too thick;

- complex bases are covered on both sides to be glued, others on only one;

- porous surfaces are treated with glue in 2 layers, the second is applied 2-3 minutes after the first;

- aerosol adhesives are sprayed in uniform strips every 10 cm, stepping back 8 cm from the edge;

- after application, the agent is allowed to dry for 5-10 minutes and only then the parts are fixed with strong pressure on them (if possible, the product is rolled with a roller);

- the elements of the product after a tight fit are fixed with a clamp, leave it for 1.5 hours;

- after the polyurethane has dried, the crawled foam residues are carefully scraped off with a chisel;

- you can use the product in a day.

The composition of polyurethane adhesives contains organic solvents, so they are harmful to the body. When working, ensure good ventilation and wear a respirator. If the glue comes into contact with the skin, it must be urgently washed with soap and water, otherwise irritation may occur. Only rubber gloves should be used to glue objects.

What is polyurethane adhesive

This type of adhesives quickly gained popularity after their appearance on the market. Polyurethane adhesive is a composition based on polyurethanes, polymers with high film-forming ability. After hardening, the mixture is resistant to aggressive chemicals and the external environment. The adhesive mixture, subject to the technology, glues together almost any material: metal, glass, ceramics, PVC, wood, rubber. The composition is practically odorless, viscous viscous consistency. The color of the glue in the finished state depends on the components (it can be amber, white, gray).

Composition

The basic components of polyurethane adhesives are aliphatic or aromatic isocyanates and hydroxyl-containing oligomers, oligoesters. To initiate hardening in two-component compositions, water, alcohols, aqueous solutions of alkali metals and organic acids are used. Rarely do modern adhesives use solvents to balance and adjust components. Surfactants (surfactants) are added to the polyurethane glue for better wetting of materials when gluing. Some adhesives additionally contain synthetic resins.

Specifications

In modern construction and renovation work, polyurethane adhesive mixture is considered one of the ideal compositions for work. Most brands are safe for human health, easy to use (applies to one-component types), easily withstand extreme loads, have anti-corrosion properties and retain their strength for many years. As with any chemical mixtures, the main thing is adherence to the application technology. General specifications for polyurethane adhesives:

- Durability.While maintaining stable temperatures and the stipulated mechanical loads, the dried composition retains its bonding properties for up to 30 years (depending on the manufacturer's composition).

- Strength. Polyurethane compounds have high elasticity, which allows them to withstand thermal expansion of materials (temperature differences up to 40 degrees Celsius) or physical movements within acceptable limits without rupture.

- Moisture resistance. The hardened adhesive mixture does not pass or absorb moisture (if the installation is observed, it completely seals the seams). The same feature does not allow the development of mold, pathogenic fungi and organisms.

- Drying time. Once applied to the substrate, the one-component adhesive retains its properties for up to 60 minutes, and the two-component adhesive - up to 2 hours.

- Strength curing period. Depending on the composition and the materials to be glued, the final state is reached after 2-3 hours (for example, when repairing shoes) and up to 48 hours when laying ceramic tiles, parquet, gluing wooden parts.

- Fully cured mixture and parts can be used at temperatures up to 150 degrees Celsius and above. The lower limit is –60 degrees, which is ideal for use in all regions of Russia.

Application

Polyurethane adhesive is used in all areas of construction, production and repair. Such distribution was achieved due to excellent characteristics while adhering to gluing technology, minimal toxicity of most brands, ease of use for non-professionals. At the same time, 1-component and 2-component glue practically does not differ in efficiency. Where are polyurethane adhesives used:

- production and installation of metal-plastic windows, composite materials;

- production of sandwich panels;

- in mechanical engineering for fixing the elements of the skin and hull;

- installation of ceramic and tiles in residential or technical premises;

- laying parquet boards and laminate;

- gluing mosaics (marble, onyx, slate);

- bonding foam insulation, foam, fiberboard, chipboard, MDF;

- household use: repair of shoes, minor breakdowns of plastic, glass, wood, etc.

How to choose the right

The choice of glue depends on many factors. Before buying an adhesive, you need to carefully study its technical characteristics and instructions for use.

Room size

When buying glue, take into account the area of the room. Usually one package weighing 500 grams is enough for 1 square meter of floor. The consumption of the adhesive product is indicated on the label or in the instructions.

Base

When buying a product, you need to consider the type of surface on which the carpet will be laid. Wood floors or floors that are too porous will absorb a lot of glue, so they will consume more glue. It is recommended to prime the substrate with a primer before gluing the carpet. Such a procedure will increase the adhesive characteristics and reduce the consumption of the substance.

Operating conditions

If you need a compound that will firmly fix the carpet on the floor, then a two-component product is chosen. This glue will provide a secure bond. It will be possible not only to walk on the carpet, but also to move furniture. It will be difficult to dismantle such a coating.

If you plan to remove the carpet over time, then buy Velcro glue. At home, it is better to lay the carpet on a water-dispersible adhesive. Such glue does not emit toxic substances, but it reliably connects materials.

Floor covering base

When choosing an adhesive, you need to pay attention to the base of the carpet. Carpet can be jute, textile, latex, polypropylene or rubber backing

The instructions for use indicate with which base the adhesive can be combined.

Carpets with rubber or polypropylene backing can be applied with two-component adhesive.For a textile base, it is better to buy a water-dispersible product.

Convenience

It is easier to install the carpet with Velcro. Water-dispersive product, no less convenient to use. Two-component glue is mixed before use, moreover, this composition dries quickly.

Polyurethane sealants

Polyurethane sealants are an elastic, adhesive, sealing compound on a polyurethane base that retains its elasticity for a long time. This sealant can be used for gluing and sealing almost any material: metal, wood, stone, lacquered sheet, plastic, ceramics, concrete.

Polyurethane sealants have good adhesion and guarantee strong adhesion of surfaces, which is not destroyed even during strong earthquakes up to 5 points.

• Resistant to corrosion.

• Hardens on reaction with moisture.

• Give in to coloring, easily varnished.

• Have quick adhesion.

Due to the fact that polyurethane sealants contain harmful corrosive substances, it should be remembered that when working with them, they should not be allowed to come into contact with open skin areas.

They are sold in standard original packaging with a weight of 310 ml, also in cardboard boxes or in a 600 ml aluminum bag.

Areas of use

One-component polyurethane glue appeared on the building materials market about fifteen years ago, but since then it has been very popular not only among builders, it is constantly used in other industries as well. Thus, manufacturers save on production costs due to the lack of formaldehyde and phenolic resins. Their absence makes it possible not to use additional exhaust equipment, and also reduces the cost of maintenance and wastewater treatment from production.

One-component adhesive is widely used:

- in mechanical engineering for fixing panels of vans;

- in the manufacture and installation of windows;

- when designing sandwich panels;

- when installing tiles in bathrooms, baths, saunas;

- for covering the floor with parquet board and laminate;

- for household purposes, etc.

Types and examples of one-component and two-component adhesives

Let's take a look at the most popular and well-proven polyurethane adhesives.

1.Sar 306 is a one-component polyurethane adhesive designed for bonding rubber, leather, PVC. Its main advantages are resistance to high temperatures and quick setting. When used in conjunction with a hardener, it improves adhesion to difficult-to-bond materials.

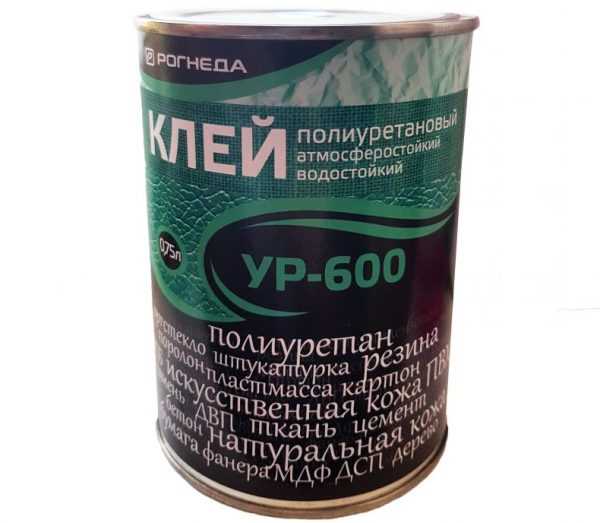

2.UR-600 is a universal waterproof polyurethane glue that is actively used in construction, production and everyday life. It is one-component and is sold ready-to-use. It is used for bonding rubber, PVC, leather, polyurethane, cardboard, plastics, fabrics, plexiglass. This versatility allows it to be used when working with wood (including MDF, fiberboard and chipboard), tiles, shoes, foam, parquet and other materials.

The adhesive forms a transparent, durable, elastic and waterproof seam. The absence of toxic solvents makes it safe for humans. Frost-resistant, not afraid of alkalis, gasoline.

Cost - from 270 rubles.

3.Soudal - this glue comes in the form of an aerosol and is very convenient to use. The adhesive reliably holds foam panels and gypsum plasterboards together both outside and inside.

Its advantages also include quick drying - about 60 minutes, economical consumption, high adhesion to concrete, brick, wood, plaster, plastic and other materials, as well as additional sound and thermal insulation. The resulting glue line can be painted.

The cost of packaging is from 350 rubles.

4. Moment "Kristall" - domestic universal polyurethane glue.Used for bonding plexiglass, rubber, metal, wood, leather, fabric, porcelain and other materials. This makes it very convenient to use at home. The resulting glue line is not afraid of moisture, alkalis and acids.

The advantages of the composition include the transparency of the seam and the absence of stains, the restoration of properties after freezing, the reliability of the glue seam even with a small contact area of materials.

The composition is flammable, so all work with it must be carried out away from sources of fire and using protective clothing.

Cost - from 60 rubles per package.

5. Desmokol - high-quality glue in the form of a solution of polyurethane rubber in organic solvents. Provides a very strong and reliable elastic seam, resistant to moisture and temperatures. Used in the automotive, footwear and furniture industries. Bonds plastics, leather, rubber, metal and glass.

The composition quickly hardens, and you can use the sealed object after 1-2 hours.

Cost - from 58 rubles.

VIDEO INSTRUCTION

Properties and characteristics

The composition of polyurethane glue, in addition to its main component, polyurethane, includes fillers that affect the drying rate, the consistency of the mass, and increase the adhesion to various planes.

The main difference is the ability to increase the volume of the layer when it dries. This ability allows you to penetrate into all the gaps, slots without shifting the adhesion elements.

The seam is resistant to sudden temperature changes within 40 degrees. It does not lend itself to oily liquids, gasoline. Resists water, vibration. Pungent odors, solvents are absent in the composition. Therefore, you can use the product without harm to health and the environment.

Also, the glue includes antiseptics that resist the formation, reproduction of fungus, mold. The operating temperature range is from -60 to 120 degrees.

The applied layer of glue has high viscosity, fast setting. Due to the presence of isocyanates in the composition, when interacting with air moisture, a chemical interaction occurs, in which molecular bonds appear. They provide the strength of the connection.

When a hardener is added to the mixture, the drying time of the film is reduced, the water-repellent properties and the strength of the layer increase.

As for the consumption, it directly depends on the type of material to be glued, ranging from 150 grams per square meter to 500.

Polyurethane based adhesive is available in several shades, from beige to dark brown.

How to use?

With the help of polymer glue, you can independently lay a rubber coating on a site of any size and type: wood, concrete or asphalt.

To do this, you need to prepare tools: a spatula, notched and painting, a building level, a roller, a sponge or brush for applying, a rubber hammer, chalk, a broom or a vacuum cleaner.

Any method of installing rubber plates involves a preparatory stage. The surface under the tiles is pre-cleaned and leveled, irregularities and defects are eliminated, small debris is removed with a vacuum cleaner.

The workflow algorithm looks like this:

- the base must be primed with a mixture of polyurethane glue and turpentine in equal proportions;

- separate the perimeter of the site with a rope;

- apply glue and level it with a spatula;

- it is better to lay no more than 4 tiles at a time;

- you need to start work from the center of the site, gradually moving to the edges;

- installation consists of laying out the plates with their pressing, avoiding significant gaps;

- there should be no air under the coating, the glued material must be tapped with a hammer to exclude "waves";

- at the end, a border is installed along the edges of the treated area;

- if excess adhesive remains on the rubber, it should be removed immediately.

When installing tiles, the approximate consumption of glue is about 300 g per 1 sq. m. It should also be borne in mind that air humidity during installation should not increase more than 70%, and the temperature of the air and materials should be within 10-20 degrees. A double layer of polyurethane glue will have to be applied if the installation takes place next to open natural and artificial reservoirs.

For information on polyurethane glue "Gambit M", see below.

Safety measures at work

When using one-component glue, you must not forget about safety measures, starting with rubber gloves and ending with a respirator.

If the adhesive comes into contact with the skin, wash it off as soon as possible with warm soapy water. And if it gets on the mucous membrane of the eye, then it is imperative to consult an ophthalmologist for subsequent rinsing.

A respirator will come in handy if there is no ventilation system in the room, since the glue emits a pungent and unsafe odor for the body.

Before using the glue, carefully read the instructions for use from the manufacturer.

Let's sum up

Due to the fact that polyurethane adhesives are durable, withstand high temperatures, have excellent adhesion to most types of materials, they are popular in any area of production, and are also indispensable in everyday life. In addition to the above, these adhesives are moisture resistant, and therefore are in constant demand in the construction market.

Application rules

When applying one-component or two-component tile adhesive, the work surface must be prepared in advance. It is cleaned from dust and dirt, debris and various substances - it can be old plaster, cement, paint. To guarantee a good adhesion of surfaces, it is necessary to degrease. This will help completely remove any traces of grease, oil, or other chemicals that have been used before. For cleaning, you can choose regular alcohol or thinner.

Glue application rules:

- The polyurethane adhesive should be applied in a thin layer, preferably evenly over the entire surface. To do this, you can use either a plastic construction spatula or other convenient tools at hand.

2. It is necessary to apply polyurethane in combination with a solvent on two glued surfaces, this is also stated by the manufacturer in the instructions on the package. If you need to glue the porous material, then you need two layers of polyurethane glue, which are applied at intervals of 2-5 minutes.

3.When using aerosol foam glue, it must be applied in uniform strips along the entire perimeter of the plane, at least 8 cm away from the edge, 10-25 cm of exposure is observed between the stripes.

4.After application, the adhesive composition must be left to dry on the surface for 5-10 minutes, after which the materials must be joined, providing strong pressure on them.

5. To speed up the drying process, to increase the moisture resistance of the glue line, you need to wait for its initial drying after 20-90 minutes, according to the instructions. Then use a hair dryer and heat the joint for a few minutes, then connect the glue surface and leave it under a press for 5 minutes.

Why polyurethane?

Highest moisture resistance. Due to its characteristics, polyurethane adhesive provides a strong moisture-resistant bond. It is indispensable for the creation of outdoor and garden furniture for outdoor use all year round.

Strong bonding of dissimilar surfaces. The glue creates a strong and rigid bond when gluing dissimilar materials: metal, ceramics, plastic and, of course, all types of wood. It sets and hardens when interacting with water, therefore it is indispensable for gluing damp wood or treated with additional agents, for example, antiseptics.

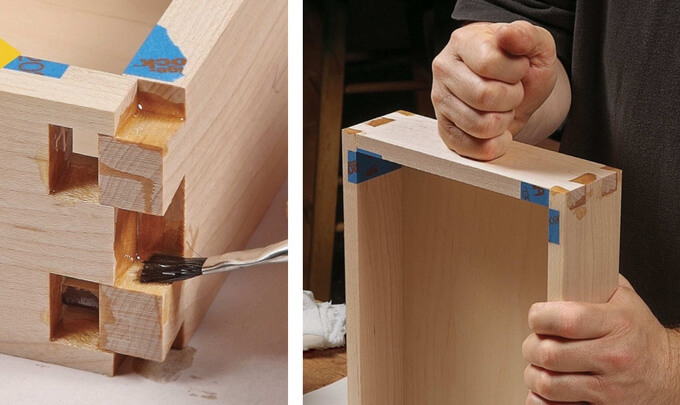

Optimal working hours.One of the main advantages of polyurethane-based glue is the long open time. Unlike PVA, when working with polyurethane, you can take your time. You will have 20-25 minutes to gently apply the glue, precisely fit the parts and install the clamps.

This is especially important when gluing products with a large number of parts. The connection is fixed with clamps for 60 minutes.

During this time, the glue line completely hardens. The final set of strength occurs after 24 hours, therefore, during this time, it is better not to subject the product to additional loads.

Convenience of work. The characteristics of the polyurethane adhesive provide good sliding of lubricated parts, which plays into the hands when assembling tight joints. Unlike PVA and other types of wood glue, polyurethane does not oversaturate the wood with moisture, due to which it is optimal for them to glue the veneer without the risk of warping and other defects.

The perfect parquet solution. The use of polyurethane glue when laying the parquet provides a strong fixation of the wood to the base of the floor and prevents the parquet blocks from swelling from oversaturation with moisture. The latter is especially important when laying parquet from exotic wood species.

This is interesting: Wood glue - varieties of compositions and selection rules