Views

The Moment Stolyar glue is presented in the modern markets in the form of 5 series.

They differ in the composition of the basic substances, color, conditions of use, setting period and complete hardening.

- "Moment Carpenter Glue Express" is a versatile moisture resistant material suitable for working with wood of any species. It can be used to glue plywood, fiberboard and chipboard bases, veneer boards. The time of complete setting is influenced by the air temperature and moisture content of the wood.

2. "Moment Carpenter Super PVA" is suitable for working not only with wood, but also with chipboard, fiberboard and laminate. It can be spotted among other varieties by its bright red can. He, unlike the previous variety, has a transparent structure. After drying, it is almost invisible on the surface. But it is suitable for work in dry and moderately damp rooms, as it belongs to class D2.

3. "Moment Carpenter super PVA D3 waterproof" is a versatile material that differs from other varieties in the optimal degree of frost resistance. He is not afraid of repeated freezing and thawing. It can bond not only wooden but also laminated substrates. You need to choose this variety for work in rooms with high humidity levels.

4. "Moment Universal PVA Joiner" has a water-dispersion basis and is also suitable for working with any recommended materials. It has a shortened full-cure period, transparent consistency, does not leave streaks, cloudy spots or colored reflections on the surface. In order for the glue to create the most dense, reliable and durable adhesion, you need to ensure a tight fixation of the surfaces for 20 minutes.

5. "Moment Carpenter instant grip" is an acrylic water-dispersion composition, suitable for working with any species of wood, sets in 10 seconds, therefore, requires certain application skills. It is very simple and easy to apply and does not leave any marks on the surface. You can use it to fasten wood to metal, PVC to plastic. It is able to withstand 5 short-term freezing cycles without damage.

How to make yourself

If you want to use a natural adhesive, it is better to make it yourself. For this, they use products that are available in the house, or that are easy to buy in the store.

From starch flour

Ordinary paste is boiled from potato or corn starch. In this case, it is better to cook it just before work. Having poured starch into a bowl, dilute it first with cold water until thick. Then they begin to pour in warm water, stirring occasionally. When the paste cools down, then use it.

Joiner

To prepare the glue, the powder is diluted with warm water 1: 2. Then put on low heat and heat up to 65 degrees. Diluted with water to the desired consistency and kept in a water bath. The composition of the finished product must be uniform.

PVA

To get a liter of glue, you will need:

- white flour - 100 grams;

- ethyl alcohol - 20 grams;

- gelatin and glycerin - 5-10 grams;

- color pigment as desired.

First, dilute gelatin in warm water in 50 or 100 milliliters of water. The substance swells for a day. Now the gelatin is diluted with water and heated in a water bath, bringing to a boil. Flour is gradually poured there. The mass is cooked for an hour with thorough stirring. It remains to add alcohol and glycerin. Remove from heat after 30 minutes.

Advice

Each original package of Moment glue contains individual instructions for use. But there are universal tips and tricks for working with contact rubber adhesive:

- When buying a Moment, you need to be interested in product certificates and expiration dates.

- Knowing the amount of work to be done, select the appropriate packaging for the adhesive composition (for use without residue). Remains of glue in unsealed packaging quickly thicken (dry out), it is difficult to apply them evenly in subsequent applications.

- Before gluing the materials, their surfaces are cleaned of traces of dirt, dust, remaining particles from any mechanical treatment.

- For better adhesion and an increase in the contact area, the parts are pre-treated with fine sandpaper, and then degreased with acetone or gasoline.

- When applying the Moment, use a brush; if thick glue is used, use a spatula.

- To ensure a snug fit, the products to be glued are pressed and placed under a press.

- When working with formulations, it is necessary to ensure high-quality ventilation of the room.

- Avoid contact between the Moment and the skin - burns may remain.

For DIYers, another useful practical tip:

Domestic use of a large number of rubber products and rubberized materials involves their periodic repair or restoration. With the right rubber glue, the moment any repair, without deviating from the manufacturer's instructions, can be done efficiently at home.

How to make PVA glue at home

If they do not want to spend money on packaging from the store, people try to figure out how to make PVA glue on their own. Of course, there are no particular difficulties in this, but the ingredients will need to be selected exactly:

- 4 g glycerin;

- 1 liter of distilled water;

- 100 g wheat flour;

- 20 ml of ethyl alcohol;

- 5 g of gelatin.

The process of cooking the adhesive is as follows:

- Soak gelatin in plain water, as indicated in the instructions on the package, and leave for a day.

- Combine all components in a separate container, with the exception of glycerin and alcohol, and send to a water bath until completely melted and turned into a homogeneous and thick mass. In this case, do not forget to stir the mixture.

- Add the remaining ingredients to the resulting composition, mix thoroughly and remove from the water bath.

- Wait until the mixture cools down and immediately start using it or place it in a container and close it tightly with a lid.

Also, consumers are interested in how to make PVA glue colored and whether it is possible at all. Oddly enough, such an experience can be safely carried out without any special skills.

The following ingredients are capable of coloring the adhesive:

- watercolor paints;

- gouache;

- nail polish;

- iodine;

- brilliant green;

- pencil lead;

- marker / felt-tip pen (draw a thicker stain on the paper and drip glue there).

The number of these components is allowed to be chosen independently - depending on the desired color saturation. Having connected the PVA and the coloring element, the mass must be thoroughly mixed with a wooden spatula or a toothpick, if its volume is minimal.

Areas of application of superglue

Usually adhesives based on cyanoacrylate are used where it is necessary to quickly glue and quickly dry products, for example, when installing windows for fixing seals, when attaching radio components, instrument assemblies, optics, microcircuits. In everyday life, many radio amateurs use their own glue based on superglue and soda: when mixing the components, the mixture instantly turns into a solid "plastic" and firmly connects the wires, parts. With the same mixture, you can repair cracks, chips, pits with your own hands.

The areas of use for superglue are varied:

- repair of footwear, leather goods;

- manufacturing of structures in dentistry, orthopedics;

- creation of jewelry;

- advertising production;

- construction;

- sewerage plumbing;

- gluing rubber products;

- instrumentation;

- sealing of various units;

- cold welding of polymers, elastomers.

There is even a medical superglue - an analogue of BF-6.It is used for sealing wounds, quickly stopping bleeding, impregnating dressings. Some super glues, when applied to paper, cardboard, and other compositions containing cellulose, enter into an exothermic reaction. Therefore, on these surfaces, you must first try superglue on an inconspicuous area and only then apply it for work.

Pros and cons of adhesives

Titan glue has a number of advantages and disadvantages, which should be familiarized with in advance. The main benefits include the following:

- Convenience and ease of use. Many experienced builders praise the product for its ease of use. The adhesive is produced and sold in a small sealed package. To apply liquid to a surface, simply remove the cap and apply a little pressure on the dispenser.

- Heat resistance. The advantages of Titan glue include its resistance to temperature extremes. The adhesive copes with both low and high temperatures.

- Resistant to moisture. The product can be used outdoors and in damp rooms, since at high humidity the applied liquid does not lose its quality characteristics.

- Harmlessness. In the manufacture of the adhesive mixture, microelements that can harm human health are not used.

- UV resistant. Unlike Moment superglue, Titan can be used outdoors. Even in direct sunlight, the adhesive layer will not break down.

- Transparency. The cured mixture is completely transparent, and therefore if it crawls out of the gluing, it will not be visible.

- Coupling speed. The applied liquid hardens and reliably adheres to the treated surface within 30-40 seconds.

- Resistant to corrosion. The adhesive composition prevents the development of rust and therefore is often used for gluing metal products.

- Strength. The tool belongs to the group of high-strength adhesive mixtures that can withstand loads from 40 to 90 kg / cm2.

Among the disadvantages are:

- Difficulty flushing. If the glue accidentally gets on your skin or furniture, it won't be easy to get rid of. To wash it off, you will have to use solvents.

- Bad smell. An unpleasant, pungent odor is generated when working with adhesive.

Description and benefits

The adhesive based on polyurethane has a special curing principle. The liquid begins to harden after prolonged contact with moisture or after applying a hardener. After hardening, the surface to which the glue is applied is covered with a thin transparent film.

The polyurethane compound is universal, as it is used to join products from different materials. This glue is suitable for bonding ceramics, cardboard, glass, polystyrene, gravel and rubber. The main advantages of the substance include the following:

- bond strength;

- moisture resistance and tightness;

- resistance to low and high temperature indicators;

- resistance to oils, gasoline, acids and other types of aggressive components.

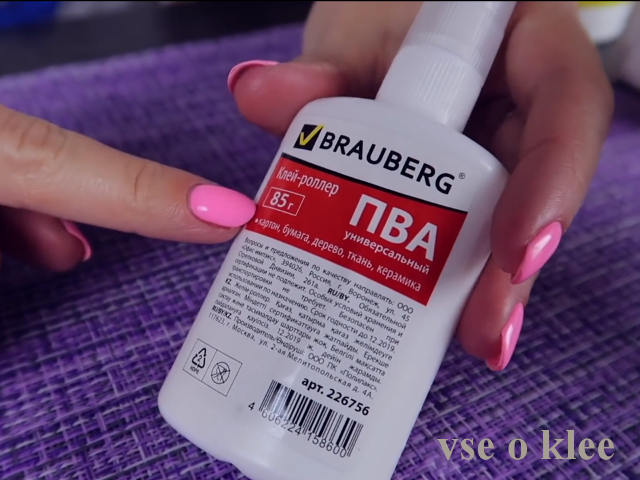

Information about Super PVA

PVA Super glue is a product with unique properties and characteristics. Before you start working with it, you should definitely familiarize yourself with the basic information about this tool. This will make it possible to make sure that the scope of application of PVA Super is really wide, and it copes with the task quickly and efficiently, because manufacturers use the exact formula and the necessary components in its manufacture.

Briefly speaking about a product, you can point to the following features:

- environmental Safety;

- the formation of a thin elastic protective film on the surface after drying;

- increased adhesion.

This list is not exhaustive. We will describe the product in more detail below.

Purpose and application

The difference between office glue PVA and PVA-M (Super PVA) is that the second can be used to work not only with paper, cardboard and small decorative ornaments, but also with leather, fabric, joinery, tiles, porcelain, heavy wallpaper , linoleum.

Since the strength indicator of this tool is large, gluing parts with a large weight to it is always successful and the elements do not detach from each other over time.

Properties of PVA Super

It is important that this PVA glue is frost-resistant, it combines the homogeneity of a pasty mass. The product has a high adhesive capacity, it contains no toxins and organic solvents.

It is sold already in a ready-to-use form. In the bottle, the glue is a snow-white mixture, but when distributed over the surface and dries, the layer becomes transparent and barely noticeable.

Super PVA White House

A very good and cost-effective PVA White House glue is a viscous suspension with a consistency of moderate density. The composition is frost-resistant. It is non-toxic and can be used in a variety of ways. It is allowed to be used in children's crafts, since it does not cause any harm to health.

PVA glue White House Super is liked by consumers for minimal shrinkage during solidification, as well as fast drying and very good adhesion. The main advantages and distinctive features of the mass include the appearance of a transparent seam after drying, which performs a protective function.

To obtain a good result, after using the glue, it is imperative to first degrease the working surface and fully withstand the subsequent clamping time of the parts. Subject to these rules, the connected elements will hold together securely for many years.

Types of PVA glue

Today there is more than one composition of PVA glue. Varieties are classified based on specifications, industry and other factors.

The following types of PVA are found on store shelves:

- Super (PVA-M). It contains additional components, due to which, after the glue dries, the strength is significantly increased. It is recommended to use for household needs, gluing any wallpaper, installing tiles. It is packed in small tubes with a spout and a lid, thanks to which, if desired, they can be made a thin seam in order to glue lagging elements or restore small damaged areas.

- Stationery (PVA-K). It is actively used in everyday life, as a rule, for children's crafts. The product is available in liquid or dry form. In the first case, it is poured into small bottles, in the second, a pencil is formed into a solid PVA glue.

- Universal (PVA-MB). The composition is always ready for joining cardboard, leather, wood and glass products. Ideal for processing carpets, linoleum, serpyanka, etc. The mixture is sold more often in buckets.

- Construction (waterproof PVA emulsion) with polymerizing particles is intended more for compaction of building mixtures, but it can also be used as an independent tool for working with durable and heavy materials. In stores, this glue is found both in small tubes and in cans or buckets.

- Household (wallpaper). This variety provides good adhesion to concrete, brick, drywall and plaster. Also suitable for gluing heavy cloths and work with paper, foam rubber, textiles. The product is sold, as a rule, in large buckets or jars.

What is KN-2 adhesive rubber mastic?

It is an adhesive that is used in everyday life and industrial construction. KN-2 mastic is used for gluing various materials and objects. Sold in tightly sealed metal containers. Inside the tin is a viscous yellowish brown or black mass.The glue is made of synthetic rubber with additives of plasticizers, modifiers, polymers.

The mastic contains a solvent. The composition of KN-2 determines the properties of the product. The additives prevent the development of mold, have a bactericidal and antiseptic effect. The rubber provides the mastic with high adhesion to various surfaces. A certain amount of plasticizers and modifiers ensures good plasticity. The solvent provides the mass with the desired viscosity.

KN-2 product can be used for gluing various types of linoleum, parquet, glass, drywall, rubber, insulation. In some cases, glue is used for waterproofing. The KN-2 product is also used for the installation of bituminous tiles.

The viscous mass is capable of filling any crevices. The rubber composition allows the use of the KN-2 product not only for gluing, but also as a waterproofing material. The substance has high insulating properties, it is resistant to heat and shrinkage deformations. The adhesive provides reliable adhesion to any building material. The KN-2 product can be used in any climatic zone at temperatures from -40 to +100 degrees Celsius. The adhesive has excellent frost-resistant and heat-resistant characteristics.

The glue is convenient and easy to apply to any surface. KN-2 is a cold product. It only needs to be stirred before use. Do not heat the glue. It is advisable to apply the KN-2 brand product in two layers using a brush or spatula. The second layer of adhesive is applied only after the already applied one has completely dried.

The mass finally hardens after 24 hours. On a horizontal surface, the substance is applied by pouring, followed by careful leveling. The recommended application layer is 2 millimeters. Substance consumption with such a layer is 1.5-2 kilograms per square meter of area. After applying the glue to the surface, the solvent contained in the composition evaporates quickly. Complete drying of the substance occurs within 1-3 days. True, KN-2 acquires its final properties only after 10 days.

Too thick mass can be diluted with a solvent (white spirit, gasoline, kerosene). After drying, the glue turns into a layer of dense and elastic rubber. The hardened mass is not exposed to moisture, high or low temperatures.

How is it produced

Many people who are going to use such adhesives are interested in the peculiarities of their production.

A polyurethane-based adhesive is produced from synthesized microelements. Some manufacturers add components to it that contribute to the hardening of the applied adhesive liquid. Most often, synthetic resin is used for this, thanks to which the mixture becomes more viscous and thicker. Composite materials can also be added to the adhesive to improve its adhesive properties. To increase the reactivity, hydroxyl-containing compounds are added to the adhesive composition. When creating moisture-resistant formulations, aminoimides are added.

Product varieties and application technology

There are several varieties of Titan adhesive mixtures, which should be familiarized with in advance. Also, before using them, the instructions for the use of adhesives should be studied.

Assembly adhesive

The most common installation tool is considered to be the universal Titan Wild, which is used for gluing mirrors, linoleum, carpet and much more.

Before using the adhesive mixture, the surface is cleaned of dirt, leveled, degreased and dried. Then glue is applied in a thin layer, after which it is not touched for 1-2 minutes until it dries. In order for the products to be glued together securely, they must be pressed against each other. The joint will harden within 30-35 minutes.

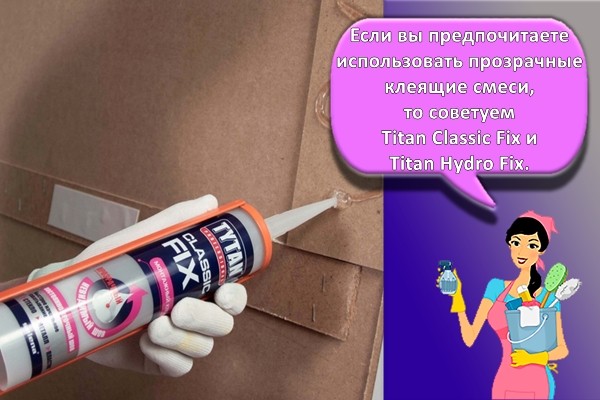

Transparent assembly adhesive

People who prefer to use crystal clear and transparent adhesive mixes often buy Titan Classic Fix and Titan Hydro Fix. Some people use Power Flex, which also remains transparent after drying.

Before applying "Classic Fix", the surface to be treated must first be wiped from dust and cleaned of stubborn dirt. To make the composition more reliably adhered to the coating, it is disinfected with an alcohol solution.

Decor glue

For gluing wallpaper or ceiling tiles, a special two-component composition "Titan Decor" is used. First you need to dilute the glue with water to prepare an adhesive solution. First, a container is prepared in which you need to dissolve "Titan Decor" and mix it with liquid. It is better to use a drill with a mixing attachment for mixing. The composition is mixed for about 60 seconds, after which it is ready to use.

PVA glue for wood D2-D3

When gluing wood, special PVA glue is often used. Its main features include environmental friendliness, safety, moisture resistance, elasticity and low cost.

Many are interested in how to dilute the composition before gluing wood. To prepare the glue solution, PVA is poured into a saucepan and heated to 40-45 degrees. Then it is mixed with water and left to infuse for 10-15 minutes. The prepared composition is applied to the surface in one layer.

Roofing adhesive

For the roof, Tytan Professional is used, which is resistant to ultraviolet radiation and does not deteriorate in high humidity conditions.

Before applying the glue solution, prepare the surface. It is cleaned of paint residues, rust, dirt and other substances that may be on it. Then everything is defatted with ethanol and dried. The glue is applied to the coating in thin strips, after which the surfaces are firmly pressed against each other.

601

This product is made on a rubber basis. Many are interested in what this composition glues. It is used for external or internal work when gluing brick, concrete or wood products. The advantages of the composition include its frost resistance, high strength and level of adhesion to the surface.

604

A multipurpose water-based mixture. "Titan" No. 604 is used for indoor and outdoor use. It adheres reliably to bricks, cement surfaces, wood and paper. Among the advantages of the glue are incombustibility, environmental friendliness, the absence of solvents in the composition and strength.

901

This numbered glue is highly durable, which allows you to glue structures of considerable weight. It is used to secure materials made of wood, paper, brick, concrete and glass. Some people are interested in how long "Titan" No. 901 dries. It completely hardens in 15-20 hours after application.

910

Numbered glue 910 is often used for working with plastic and wood products. This compound is resistant to mold, mildew, dampness and low temperatures. Among the shortcomings, there is a long solidification of the composition, since it dries for 2-3 days.

915

When gluing building materials to porous substrates, use "Titan" No. 915. The product is resistant to temperature extremes and tolerates temperatures above 50-60 degrees. Hardening of the applied adhesive solution lasts 30-40 hours.

930

It is a high quality adhesive made from resins and rubber. Experts advise using it when gluing polystyrene, ceramic plates, wood and concrete.

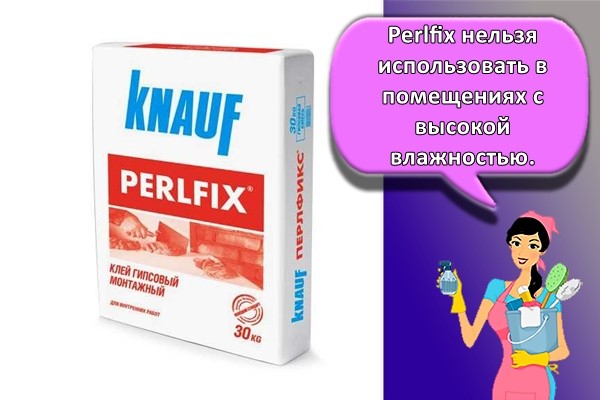

Features and Description

Perlfix is a plaster-based assembly adhesive. It is a product of the international industrial company Knauf. The company was founded in Germany in 1932. The brothers Alfons and Kard Knauf, who lived in northern Bavaria, were fascinated by its qualities when they became acquainted with gypsum. They dreamed of creating ideal building materials using it.

Today Knauf Gips KG is an international company with production facilities all over the world. The production processes are still based on gypsum. The company's technologists are developing unique building materials using it.

Perlfix securely fixes finishing materials. He does not need additional fasteners. The guaranteed service life of the coating glued to it is several decades. Perlfix ready-to-use mortar is used over a wide temperature range. The adhesive is used in houses with medium humidity. The fixation period is one week. The seams must be rubbed. Do this after the glue has completely risen. In sealed packaging, Perlfix retains its qualities for 6 months.

The adhesive mass is non-toxic and hypoallergenic. There are no harmful impurities in the composition. The glue is not harmful to human health. To fix the finishing material well, the adhesive solution is applied in a layer 2 cm thick. The glue is sold as a ready-made dry mixture. He does not need hardeners. It is simply stirred with cold water. A significant plus of using assembly glue from Knauf is simplicity. It is stirred with water, bringing to a pasty state. The finished batch must be used within half an hour.

Perlfix cannot be used in rooms with high humidity. Direct contact with water is not allowed. A coating applied to Perlfix glue will last for many years, provided the work surface is properly prepared. Perlfix has good adhesion to concrete substrates. The increased gypsum content guarantees the strength of the adhesive in compression and bending.

What it is

The history of unique technologies using natural adhesives goes back several millennia. But only in the 19th century, adhesive compositions based on natural rubber began to be used. This can be considered the beginning of the history of modern rubber glue, which necessarily has dissolved rubber in its composition.

Natural rubber

Natural rubber

The rubber material is called for the high-quality connection of the surfaces of elastic products with the receipt (after full curing) of a layer, which in elasticity, characteristics and appearance does not differ from rubber.

Natural rubber has limitations for its use due to the invariable characteristics of resistance to certain external influences and low heat resistance. The problem was solved with the development of the chemical industry. The rubber adhesive can now also be based on synthetic rubber.

With an increase in the types of rubber products and the demand for elastic joints on an industrial scale, the requirements for the properties, characteristics and strength of the seams of the adhesives used are growing. In order to give the adhesive composition a certain ability or change the properties, certain ingredients are added to it. Their composition and quantity is determined by the technical laboratories of manufacturing firms. Consequently, the ingredients, quality and application of the adhesive from different brands can vary significantly. Some brands are produced only for the same type of material, taking into account the peculiarities of its surface, approaching in texture and properties.

The additives can be: various kinds of plasticizers; consistency stabilizers that prevent the transition of components into a gel-like state; resins and polystyrene that increase the strength of the hardened layer; fillers to improve the vulcanization of the type of rubber used and other substances.

To summarize, we answer the question in the title of this section. Rubber glue is a composition of rubber (natural or synthetic), a solvent, a crosslinking agent (substances that prevent polymers from deforming and swelling in a solvent, increase their strength) and special additives.

Views

A group of multicomponent compositions, which are united by a common name - rubber glue - can be conditionally divided into types according to the following criteria:

- Dry residue, according to GOST 2199-78: grade A, grade B.

- By the type of rubber used. Thanks to the invention of synthetic elastomers, it became possible to connect not only rubber products to each other, but also to bond with other materials in various combinations. The seam of such compounds has become resistant to chemical attack, critical temperatures, and ultraviolet light. Common adhesives are made from the following rubbers: natural; chloroprene - high adhesion rate; butadiene-nitrile - waterproof formulations; organosilicon - for joining homogeneous rubber; styrene-butadiene - scotch tape production. Rubbers based on other components have limited or highly specialized use and have not received domestic use.

- By the method of gluing: cold - the process takes place at room temperature, the result is achieved in a day; hot - the bonding process provides for heating (+ 70 ° C - + 160 ° C), the vulcanization time of the composition is reduced to several minutes.

The connection is obtained by hot vulcanization

The connection is obtained by hot vulcanization

Varieties of superglue

Miracle glue was developed in the USA back in the 50s of the last century. Gained worldwide popularity due to the speed and reliability of combining dissimilar substances into a strong indestructible whole.

All superglue varieties contain 97-99% cyanoacrylate and additives that enhance the properties:

- thickeners;

- hardening activators;

- enhancers of elasticity, adhesion and water resistance.

Superglue is suitable for working with rubber, plastic, metal, wood. Any surfaces can be glued.

One-component

Popular types of superglue have one component in the composition, are available in small tubes, blisters. Packaged in a small volume, since in case of leakage, the composition quickly loses its properties, thickens. The setting takes place in a matter of seconds, but the thing should be kept before use for several hours (up to a day) so that the glue is completely hardened.

Two-component

More rare are two-component versions of super glue. The adhesive is activated by mixing the substances from two tubes, which are sold together. Before use, glue and a special activator are connected and applied to the parts. You need to keep within 2 minutes, while the plasticity of the substance remains.

Additional tips and tricks

Experienced craftsmen give advice on working with the popular gluing agent for different materials:

- We must not forget that when two substances come into contact, a rapid heating occurs - a rise in temperature. You should take care of your hands - we put on gloves. Cotton can be impregnated with the composition, they are not suitable. Better to use thin rubber.

- The adhesive composition retains its properties over a wide temperature range from -60 ° to + 80 °. If necessary, you can choose a heat-resistant version that can withstand exposure to +250 °.

- The main thing when gluing is not a thick layer, but a tight pressing of the parts.

- The glue is very economical - a drop is enough for a circle with a diameter of 2-3 centimeters.

- It is not recommended to glue polyethylene, teflon, silicone products. The composition is not suitable for the dishes from which they eat.

- After use, the smudges are carefully removed from the nose of the tube, the cap is screwed on tightly. Massive cheap types of superglue quickly harden; it is usually not possible to reuse the opened product.

- It is better to glue in ventilated areas to remove volatile substances from the air.

- You can replace soda with concrete crumbs, dry plaster, which also increase the adhesion strength.

- Glue frozen on the hands can be removed with Dimexide solution (1 to 3), vegetable oil, soda gruel. The glue will come off on its own if you wash your hands with soap and water several times.

> Superglue is produced by many well-known companies.Expensive options are more reliable, better stored after opening. With the introduction of soda, you can improve the quality of any of them. Baking soda easily reacts with superglue, increasing strength, accelerating adhesion. This is a cheap, easy way to improve the quality of a popular product.

Share link:

Scope and application features

Universal glue is suitable for wallpaper, bonding plastic and wood products, bonding metal and glass parts.

Such funds are not very liquid, they do not spread much, so that even small parts can be perfectly glued and repaired.

- The so-called contact adhesive has a wide range of applications. It can be used when laying parquet, carpet or linoleum. This tool is often used to securely fix plastic panels, soundproof materials.

- If you plan to work with floor coverings, then it is better to choose a building universal adhesive. As a rule, it should contain acrylic polymers. This product is perfect for laminate, parquet and even coconut fiber coverings. A day after the work, it will already be possible to walk on such a floor.

- Also, universal glue can be used during the installation of insulation systems. It works well with materials such as styrofoam or rock wool. For such work, a universal assembly tool is usually chosen. It can be used while laying tiles. And not only indoors, but also for outdoor work.

- For gluing any kind of wallpaper, it is best to choose a universal powder in the form of a powder, which you need to dilute yourself according to the instructions. Often, such a product contains modified starch. Thanks to this, the product dissolves easily in water without forming lumps. The universal product is suitable for paper and fabric canvases, as well as for vinyl wallpaper.

- For minor repairs, you can choose the usual universal remedy in a small tube.

What composition is right

There are three types of adhesive mixtures that are often used when laying cork panels and tiles.

Acrylic solutions

Acrylic adhesive mortars are often used in the construction industry. The main advantages of such compositions include the fact that they reliably hold materials together and are odorless. However, despite all these advantages, many builders do not recommend using acrylic-type mixes when working with cork. They gradually erode the cork and reduce its strength.

Water based

Most of the water-based adhesives are produced by foreign manufacturers and therefore are not cheap. However, for people who want to securely attach the cork, it is better to use just such means.

Mixtures with solvent

The most expensive means are considered, in the manufacture of which special solvents are added. These compounds are distinguished by a high degree of adhesion, due to which they reliably adhere wood-based panels to most surfaces. The main advantage of solvent based adhesives is that they adhere quickly to surfaces.