Types, properties, application

There are nine varieties of "Ceresite", which are used when gluing tiles.

CM 9 - for tiles and tiles

The least popular glue from the Ceresit line. Its main disadvantage is considered to be weak protection against temperature extremes and poor resistance to dampness. Also, CM 9 hardens for a long time - within 3-4 days. Experts advise using a compound for gluing facing bricks, decorative stones and tiles.

It is possible to use CM 9 only on even surfaces, since when gluing to deformed surfaces, adhesion is low.

CM 11 Plus - for indoor and outdoor use

If gluing needs to be done outside, it is better to use CM 11 Plus. This adhesive mixture is used for fixing bricks and tiles. It is also added to cement, concrete and lime mortars.

CM 11 has a low level of moisture absorption, which is only 3%. It is thanks to this that the glue can be used for outdoor work. The composition quickly hardens after use - within 30-40 hours.

CM 12 - for porcelain stoneware

People who are going to cover the floor with large tiles can use the special CM 12 glue for porcelain stoneware. This glue is used only for interior work; it is not suitable for exterior work due to its poor resistance to frost.

The main characteristics of the adhesive include:

- high plasticity, due to which the mixture has a thick and viscous consistency;

- resistance to dampness, which allows the use of CM 12 in rooms with high humidity;

- durability and reliable grip even on uneven surfaces.

CM 14

For working with ceramic surfaces, many experts recommend using the CM 14 adhesive mixture. It is considered universal, as it is suitable for interior and exterior decoration. The features of CM 14 include high temperature tolerance, which allows the use of glue for covering warm floors.

CM 14 has the following characteristics:

- thick consistency that reliably holds the tiles on vertical surfaces;

- not susceptible to the effects of dampness and frost;

- environmental friendliness and safety;

- compatibility with other types of glue from the Ceresit line.

CM 16 - for outdoor and indoor use

CM 16 is ideal for wall cladding with tiles, clinker, porcelain stoneware and decorative stone. The composition is elastic and not subject to deformation under the influence of high or low temperatures. CM 16 is not afraid of water and therefore it is used for cladding coverings on balconies, terraces and even in swimming pools. To improve adhesion, such glue is used together with Ceresit 65 or 51.

CM 17

It is an adhesive composition with high elasticity, used for outdoor and indoor use. Experienced builders advise using CM 17 only for working with deformed coatings. Moreover, it is used not only for gluing tiles. It is also suitable for working with chipboard, gypsum, plasterboard and concrete. Resistance to moisture allows you to apply CM 17 to damp surfaces.

CM 115 - for mosaics

For fixing marble, glass and mosaic it is necessary to use "Ceresit" CM 115. The main advantages of this glue include the following:

- the possibility of using on the surface of the insulated floor;

- elasticity;

- frost resistance and moisture resistance;

- preventing the development of mold on treated surfaces.

To improve the properties of the glue, it is mixed with elasticizers before use.

CM 117 - frost-resistant adhesive for facade tiles

For cladding the facade with tiles, CM 117 is suitable, which is resistant to frost and high levels of humidity.This mixture can also be used indoors for gluing tiles in the bathroom.

Easy Fix for wet rooms

Experts recommend buying Easy Fix for laying medium-sized ceramic tiles. Adhesive properties allow this product to be applied to both vertical and horizontal surfaces. Easy Fix is not afraid of frost and high temperatures. Also, the composition is resistant to dampness, which allows you to use it outdoors.

Tips & Tricks

Finally, we have prepared a few tips to help you do your job efficiently.

- Dilute the mixture with clean water strictly according to the instructions that are on each package. It is best to mix the composition with a drill.

- After the first stirring, you need to leave the glue, then mix it again and proceed with the lining. During operation, the glue is mixed several times.

- Work with this mixture should be carried out in a room with low humidity, where there are no drafts.

- If the work will take place outside, the weather should be clear and warm.

- If during outdoor work the weather is too windy, the durability of the diluted composition will be halved. Therefore, it is recommended to dilute the mixture in portions.

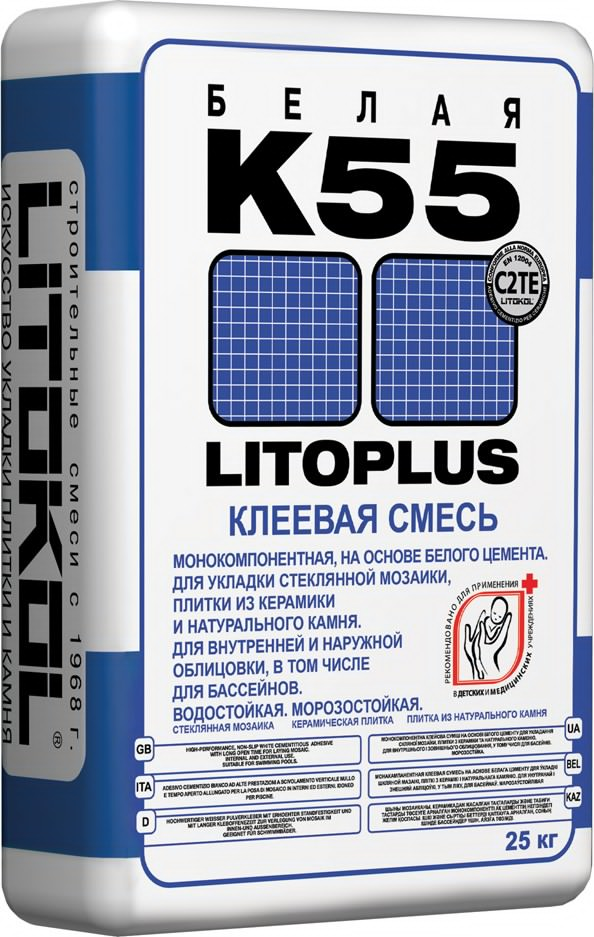

- If you plan to lay the tiles for places with high humidity (baths, saunas, swimming pools), you should choose a mixture of Litokol K55, which is based on a latex additive.

- After finishing work with glue, it is better to immediately soak the tools in water and wash them, otherwise it will be very difficult to do this later.

- It is not difficult to work with the material, however, it is the accuracy that will contribute to the best result.

For more information about Litokol K55 tile adhesive, see below.

Dispersion adhesives from LITOKOL

They are adhesive masses from Litokol, which are made on the basis of dispersion resins. In appearance they resemble a thick white paste.

Ready-made compositions are used to work with various bases and decorative materials. They have a high rate of adhesion and elasticity. Withstand temperature extremes.

LITOACRIL FIX

Ready-made tile adhesive. It sets quickly, so there are no problems when working with vertical surfaces.

Suitable bases:

- Various types of plaster.

- Plasterboard, gypsum boards.

- Concrete screeds. It is used when laying tiles on floors with underfloor heating systems.

Main characteristics:

- The color of the mixture is white.

- The pot life of the solution after mixing is 1 hour.

- The allowed time for adjusting individual tiles is 30 minutes.

- The optimal layer thickness should be checked with the manufacturer.

- Temperature range for laying - from +5 to +35 degrees.

- Temperatures for normal operation of the hardened glue mass are from -30 to +90 degrees.

Grout the joints after 6-8 hours.

LITOACRIL PLUS

Ready-made Litokol glue for tiles. It is used during interior finishing works. Suitable for fixing various decorative materials.

Suitable bases:

- Various types of plaster.

- Plasterboard, gypsum boards.

- Concrete screeds. It is used when laying tiles on floors with underfloor heating systems.

- Walls from foam blocks.

Main characteristics:

- The color of the mixture is white.

- The pot life of the solution after mixing is 1 hour.

- The allowed time for adjusting individual tiles is 30 minutes.

- The optimum layer thickness should be checked with the manufacturer.

- The temperature regime for laying the masonry is from 5 to 35 degrees.

- Temperatures for normal operation of the hardened glue mass are from -30 to +90 degrees.

Has a low index of resistance to alkalis, acids, active chemical compounds.

Choosing Litokol tile adhesive correctly: characteristics, recommendations and consumption calculator

It is important not only to choose the right tile and layout, but also to lay it efficiently. Many do not even think about the choice of glue, and take the first familiar mixture out of habit.

Even if you have already done installation on it, it may not be suitable for new tiles. This article will focus on Litokol tile adhesive: which mixture is best suited for certain laying conditions, its characteristics and features of use.

Litokol tile adhesive is made at a plant in Russia using Italian technology.

Fast navigation through the article

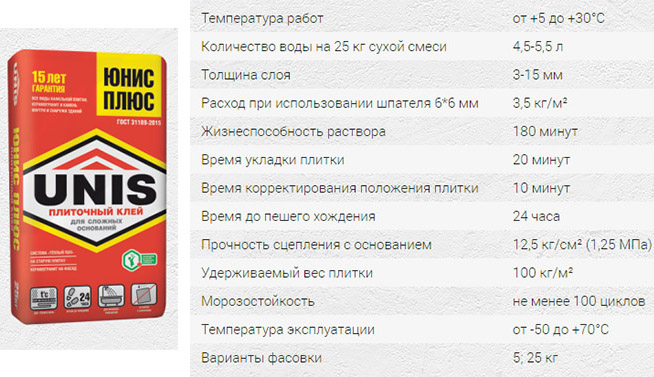

Tile adhesive is divided into 3 main types according to EN 12004 "Ceramic Tile Adhesive":

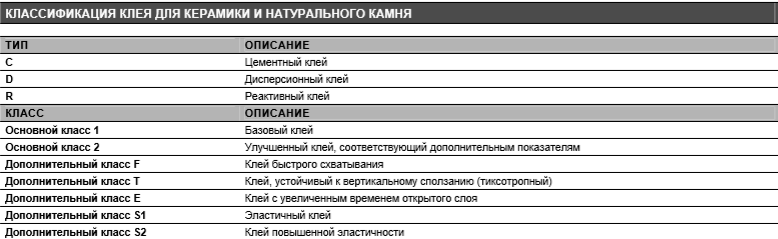

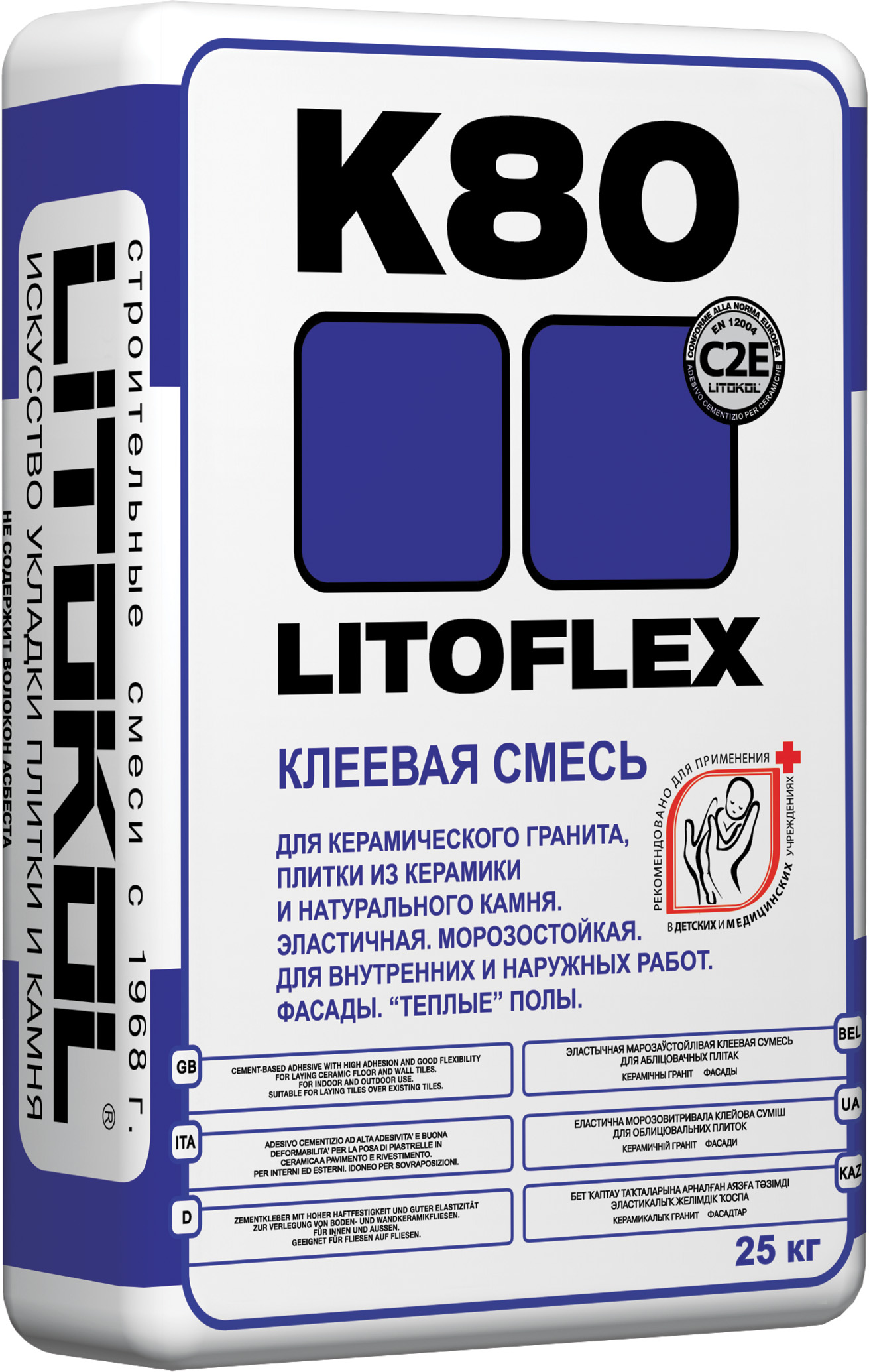

- Cement (type C, for example, Litoflex K 80) - sold as a dry mixture that is diluted with water. Suitable for laying tiles, natural stone, mosaics or glass.

- Dispersion (type D, for example, Litoacril Plus) - ready-made paste on an acrylic base. Used for laying tiles on a prepared substrate or drywall.

- Reactive (type R, eg Litoelastic) is a two-component mixture that must be mixed before use. When mixed, the components react and form a unique adhesive layer. Such glue is used on non-standard substrates: wood, metal, plastic, surfaces with increased operational load.

There is no video topic for this article.

| Video (click to play). |

- Main class 1 - base adhesive;

- Main class 2 - improved glue, corresponding to additional indicators;

- Additional class F - fast setting adhesive;

- Additional class T - resistant to vertical creep (thixotropic);

- Additional class E - with increased open time;

- Additional class S1 - elastic;

- Additional class S2 - superelastic adhesive.

Classification of tile adhesives according to EN 12004.

Standards for each type of glue.

With this online calculator, you can select the glue and find out its consumption. Use it for preliminary calculations, as it shows the general average data. Because of what the consumption of glue depends, it is written in a separate article.

Summary table of mixes by tile size and base:

For laying tiles with a water absorption of more than 3% on standard substrates (concrete or cement), cement glue is well suited.

If the cladding will be done with small faience tiles (less than 25x25 cm) or unglazed cotto terracotta tiles on a standard base, Litokol K47 or PLUSFIX glue will work well. These mixtures are made on the basis of Portland cement, quartz sand and cellulose ethers.

It is better to lay large-format tiles on Litokol X11 - a reinforced adhesive mixture for floor or wall cladding. It has increased adhesion (1.1 N / mm²) and an increased mortar pot life (8 hours). Consumption approx. 1.3 kg / m² per mm of layer thickness.

If there is a warm floor under the tiles, the latex additive LATEXKOL should be added to the glue. It will strengthen the mixture and make it elastic so that it does not crack during thermal expansion.

Precautionary measures

KN-2 mastic belongs to combustible (flammable) materials. Do not smoke or use spark-generating tools when handling this substance. It is forbidden to make a fire during repairs. When the adhesive catches fire, a fire extinguisher, sand, and asbestos cloth are used to extinguish the flame. It is prohibited to use water to extinguish a fire.

You need to work with mastic in a protective suit, respirator or mask, tarpaulin gloves. KH-2 is considered a toxic product. If the substance comes into contact with the skin, it must be carefully wiped off with cotton wool soaked in solvent, and then the area should be washed with warm water and soap. If glue gets into your eyes, wash your face with warm water and consult a doctor.

Repairs should be carried out in a well ventilated area. When working with an adhesive product, it is forbidden to inhale the vapors of this substance. The solvent, which is part of KH-2, completely evaporates after 3 hours. After the adhesive has completely dried, the room in which the repair was carried out must be well ventilated.Further stay in the room where KN-2 glue was used is absolutely safe.

Instructions for use

Each package of Litokol epoxy tile grout comes with detailed instructions, which are recommended to be read before using the material. Here are the main provisions of the instructions, as well as advice from experienced craftsmen who will help you master high-quality sealing of tile joints with epoxy-based grouting.

How to dilute?

To obtain a working mixture, it is necessary to mix the bulk with a liquid hardener. The main thing to know before starting mixing: the mixture should be consumed in 40 minutes. After this period, the epoxy grout hardens and becomes unusable.

In 40 minutes, it is necessary not only to seal the joints, but also to rinse the treated surface with water. Therefore, you need to mix the components of the mixture in small portions. For beginners for the first time, it is enough to dilute 200-250 g of the mixture.

To prepare the grout you will need:

- scales;

- clean plastic container;

- mixing spatula;

- latex gloves.

Dilute the mixture in a proportion of 8 g of liquid hardener for every 100 g of epoxy mass; this proportion should be clarified in the instructions for grouting.

Let's describe this process step by step:

- A corner of the hardener bag is cut off to make a small hole. This will allow the opened packaging to be stored for a long time.

- Place the container on a scale and pour the calculated amount of hardener into it, for example, 20 g.

- Using a spatula, add the calculated amount of epoxy mixture to the same container, for our example - 250 g.

- Remove the container from the balance and mix the contents thoroughly with a spatula until the liquid fraction completely disappears and the mixture becomes homogeneous.

It is not recommended to use mixers with a high speed for stirring, because if the mixture is turned too fast, the mixture heats up and the setting time is shortened.

How to apply?

Before preparing the grout, the surface for its application must be completely prepared. The optimum air temperature for work is + 18-23 ° C, at temperatures below + 12 ° C it is not recommended to use epoxy grout.

It is convenient to rub the seams with a special rubber float. The grout is applied on a trowel with a spatula, then the material is spread over the tile surface with diagonal movements, rubbing into the seams. With the edge of the float, clean the mixture from the tile and rub it into the seams again.

To grout the corners, use a spatula and a special corner with a 45 ° bevel. After using the entire diluted mixture, the treated area is cleaned with a clean rubber float and poured abundantly with cold water, after which it is wiped with a cellulose sponge, rinsing it thoroughly. This helps to create an even and smooth seam surface.

After grouting, a film appears on the surface of the tile from the epoxy mixture, which must be removed the next day, otherwise there will be indelible yellow stains. This is done using a special tool Litonet, which is applied every other day in accordance with the instructions and left for half an hour. After that, the surface is washed with water using a stiff brush or white felt and wiped dry with a cotton cloth.

Only on the fifth day after cleaning, you can start using the treated surface. Prior to that, it must not be covered, splashed with water and other liquids, walk on it, put objects, expose to temperature extremes. Therefore, it is advisable to install floor tiles last.

Which wallpaper glue is better to buy

When choosing an adhesive, it is better to follow the recommendations of the wallpaper manufacturer itself, if he has provided such information. In the absence of recommendations, it is necessary to use specialized adhesive mixtures suitable for the selected type of canvas

It is important to study the composition, it is desirable that the product contains antifungal or antiseptic additives that will protect the surface from pathogenic microorganisms. Buyers themselves advise to breed dry mixes based on the thickness of the wallpaper - the thicker the material, the thicker the solution should be

Experts remind that it is necessary to inspect the container for damage and deformation, be sure to take into account the shelf life and toxicity of the adhesive component in order to avoid unpleasant consequences

With regards to brands, the TOP 2020 rating recommends paying attention to the following funds:

- Econ is the best non-woven base. It has a long shelf life, is suitable for hanging ceiling wallpaper, dissolves easily and is easy to prepare. Plus contains anti-fungal supplements.

- KleoSmart is suitable for all types of vinyl. It is non-toxic, absolutely odorless and has good adhesion properties. Also safe for humans and animals.

- Lacra was named the best among the glue mixtures for paper wallpaper. Contains a powerful antiseptic, has a thick consistency and economical consumption. Plus, its cost is relatively low.

- Norme Color is excellent for fiberglass wallpaper. It is fireproof, sold ready-made, neutral to low temperatures and dries very quickly without leaving stains or smudges.

The rest of the nominees of the rating are also declared as high quality reliable mixtures intended for surface treatment. Each of them underwent thorough testing, which determined their place in the TOP 2020.

How to use it correctly

Before starting work, the cement mixtures must be mixed with a solvent, and in reactive compounds, the base and the hardener must be combined. Dispersion stirring is optional.

The rules of use are the same for almost all adhesives:

- Knead small portions - this is what the masters recommend. Reactive and cement mixtures thicken quickly and become difficult to work with. The density makes it difficult to evenly distribute the mass, so the decorative elements are stacked unevenly.

- You need to apply glue to a small section of the wall with a thin layer. After gluing the decorative elements, the adhesive mixture is applied further. Overcoating large surfaces will cause the adhesive to cure before the tiles are attached. This reduces the quality of adhesion.

- Most of the cement mixtures are produced in packs of 25 and 5 kg. If you plan to decorate large areas, it is cheaper to take in large packs.

Advantages of the material

- High adhesion, which makes it possible to equip coatings even in those places where high traffic and high loads are expected.

- Excellent elasticity. This feature of the material compensates for the stress that occurs between the tile and the substrate. Thanks to this, even in the event of thermal or structural deformations, the tile remains intact.

- Moisture resistance. The glue is not destroyed by water, therefore, the tiles can be laid in rooms where the humidity parameters are high enough. These are not only bathrooms and showers, but also basements, production halls, medical institutions, exhibition and shopping centers, etc.

- Frost resistance. It is due to this property that the adhesive "Litokol K 80" can be used for cladding surfaces outside buildings.

- Extended pot life. Therefore, there is usually enough time to completely use up the solution without waste.

- Fast hardening. After the installation is completed, you can start rubbing the tile joints on the walls after 7-8 hours, and on the floor after a day.

- Low cost - for "Litokol K 80" the price is about 1950-2000 rubles. per bag weighing 25 kg.

The best moisture resistant tile adhesive

It is a special adhesive for installing tiles in bathrooms and stairs. It contains a hydrophobic modifier, which makes it possible to cover even fountains and swimming pools.

Litokol Litoelastic

5.0

★★★★★

editorial estimate

100%

buyers recommend this product

See overview

It is a reactive epoxy-polyurethane adhesive that does not require water to make. You only need to mix two of its components.

The agent is used for external and internal cladding of vertical and horizontal surfaces with natural stone and ceramic tiles.

Advantages:

- High adhesion;

- Frost resistance;

- Not susceptible to cracking;

- No drying shrinkage;

- Resistant to deformation.

Disadvantages:

High price - from 3000 rubles per 4 kg bucket.

Litokol Litoelastic will even glue mosaics and tiles to metal substrates. The glue is super reliable and versatile in its own way, but very expensive.

Knauf flex

4.9

★★★★★

editorial estimate

96%

buyers recommend this product

This adhesive is intended for areas of high stress, as well as for lining swimming pool bowls. The solution remains viable for 3 hours. Open time is 20 minutes, there is 10 minutes for tile adjustment.

Advantages:

- Resistant to serious dynamic loads;

- Compatible with substrates that do not absorb water;

- Water-, frost-, heat-resistant;

- Retains elasticity after hardening;

- Does not get dusty when working;

- The widest operating temperature range (-50 .. + 80 ° С).

Disadvantages:

Increased consumption.

This adhesive is used for vertical and horizontal surfaces without restrictions on the size and weight of the tiles to be laid.

Weber.Vetonit Easy Fix

4.8

★★★★★

editorial estimate

89%

buyers recommend this product

This adhesive has a cementitious base which gives a gray color. You can work with the ready-made solution for about two hours at a temperature of +5 .. + 35 degrees. For 1 sq. m. it takes about 3 kg of dry product.

Time of open use and correction of tiles - no more than 15 minutes. The composition is water-resistant, but it cannot be used for underfloor heating and other high-temperature surfaces.

Advantages:

- Adhesion over 1 MPa;

- Suitable for outdoor work;

- Frost resistance;

- No tile slippage;

- Reliable fastening.

Disadvantages:

Cannot be used with primers containing quartz sand.

This adhesive can be used for laying mosaics, as well as for indoor and outdoor installation of tiles.

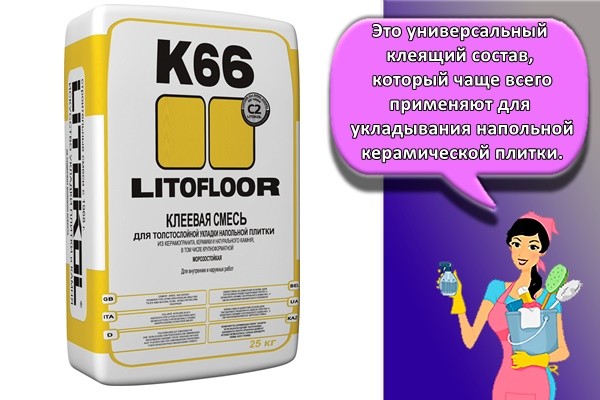

Unis "Pool Hydro"

4.8

★★★★★

editorial estimate

87%

buyers recommend this product

The composition is designed for laying tiles no larger than 60x60 cm in water tanks. It is also suitable for natural stone and mosaics. With it, you can lay tiles according to the "top-down" method.

The glue is frost-resistant and, after drying, can be used at temperatures from -50 to +70 ° C.

You can work with the solution at temperatures from +5 to +30 ° C, and its pot life is 180 minutes.

Advantages:

- Used both indoors and outdoors;

- Applicable for underfloor heating;

- Time for laying and adjusting tiles - 20 minutes;

- Strong adhesion (1.3 MPa);

- Can be used on difficult substrates.

Disadvantages:

Operation in contact with water and negative temperatures is possible only after 28 days.

It is a multipurpose compound used for areas with difficult operating conditions. However, he needs to be given enough time to build strength.

Prospectors "Lux"

4.7

★★★★★

editorial estimate

84%

buyers recommend this product

See overview

The adhesive is intended for ceramic and clinker tiles, porcelain stoneware, as well as artificial and natural stone. It is used in unheated and damp rooms, as well as outdoors.

Suitable for laying tiles in water tanks. No more than 15 minutes are allowed for correction, and the open time is 20 minutes.

Advantages:

- Suitable for underfloor heating (temperature resistance up to +70 ° C);

- Can be laid on old tiles;

- The pot life of the solution is at least 4 hours;

- Frost resistance;

- The plasticity of the solution.

Disadvantages:

The size of the tiles used should not exceed 40x40 cm.

It is convenient to work with this tool - it does not slip and is easy to apply.However, exceeding the recommended layer of 3-5 mm can lead to shrinkage of the tiles.

Scope of application of plastic mixtures

The plasticity of the adhesive is due to the presence of plasticizing additives, polymers, epoxy, rubber and polymer compounds in its composition. As a result of the properties of the glue, it is recommended to use it for the processing of the following substrates:

- concrete with a cellular structure;

- Chipboard;

- cement-bonded particle boards;

- drywall;

- plywood;

- aerated concrete;

- old tile;

- concrete screed;

- wood.

In addition, flexible tile adhesive is often used for lining bathrooms, swimming pools and underfloor heating systems.

This mixture must have not only good elasticity, but also effective adhesion (at least 1 MPa). With this type of glue, you can mount the following finishing materials:

- porcelain stoneware;

- ceramics;

- marble and glass mosaics;

- acid-resistant and clinker tile products.

Elastic mixtures for gluing drywall are versatile. With their help, you can finish with any materials. This glue contains Portland cement, polymer and modified fillers, plasticizers, quartz sand, plasticizing additives and moisture-repelling substances.

Which glue is better to choose

A large assortment of adhesives is offered on the construction market. A person who decides to lay a mosaic sheet on his own cannot always decide on which glue to glue the tile better. Before buying a product, you need to familiarize yourself with the types of compositions, their main characteristics.

Cement glue

Dry mixtures, which are diluted with a solvent to a semi-liquid consistency before laying the tiles. Recommended remedies:

- KNAUF FLIESEN. Knauf is economical, has high binding qualities, provides adhesion when applied in a layer of 0.7 cm. It dries slowly. Suitable for bases with complex configurations.

- Eunice 2000. Fast drying, highly elastic cementitious mixture with good adhesion. Freezes in 3 hours.

- Basin mastplix T-12. Great for uneven substrates: evens out even strong surface differences. Firmly connects the mosaic to the wall or floor.

- CERESIT CM-11. Versatile, quick-setting. Designed for interior decoration. Easy to work with.

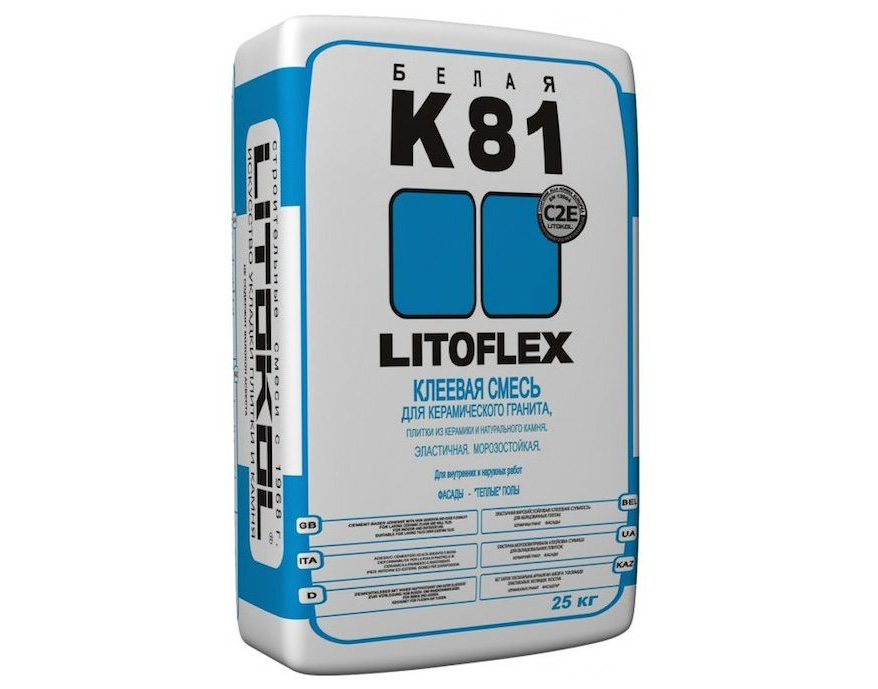

- Litoflex (Litokol Litoflex) K81. Elastic, durable.

Cement adhesives are versatile and inexpensive. But there is a small drawback: mixing the solution with a construction mixer is accompanied by the appearance of dust.

Cement adhesives are versatile and inexpensive. But there is a small drawback: mixing the solution with a construction mixer is accompanied by the appearance of dust.

Ready-made acrylic-based mosaic tile adhesive with additives and resins. It is used immediately after opening the package. The main advantage of dispersion solutions is that they do not lose their properties during long-term storage in a tightly closed container.

Dispersion mixtures are elastic and vibration-resistant. Masters are in demand:

- Litoacril Fix, used for gluing mosaics in living rooms. For decorating bathrooms or kitchens, take Litoacril Plus, which has increased moisture resistance.

- Ultramastic III Mapei from the line of acrylic mixes from the Italian company Mapei. Suitable for tiling with mosaic decor on heated floors and walls in damp rooms.

- Lacrysil glue "Crazy Velcro". Durable, with zero element slippage. After drying, the seams do not soften under the influence of moisture.

Dispersion compositions are more convenient to use, but they are more expensive than cement ones.

Dispersion compositions are more convenient to use, but they are more expensive than cement ones.

Two-component adhesive

Reactive (two-component) composition, consisting of a base and a hardener. Popular brands:

- Litokol LitoElastic. Waterproof, can be used on any basis. Finished seams are flexible and not prone to cracking.

- Reactive mixes from the manufacturer Mapei allow you to glue the mosaic even on substrates with low adhesion. The most popular is Keralastic.

- Ceresit CU-22. Strong reactive mixture. Resistant to chemicals, humidity and temperature changes.

Two-component mixtures harden quickly, so you need to try to lay mosaic elements without errors. If there is little experience in gluing decor, then it is better to choose slow-setting agents for laying the mosaic.

The disadvantage of two-component mixtures is the high cost. It is not profitable to use reactive adhesives for facing large areas.

The disadvantage of two-component mixtures is the high cost. It is not profitable to use reactive adhesives for facing large areas.

Which of the varieties of mixtures will be the best depends on the type of mosaic, surface characteristics and some other factors.

Two-component adhesive - description

Two-component tile adhesive is a high-strength compound, which is represented by a hardener and polyester or epoxy resin. Also, binder additives of synthetic origin, which improve the properties of the glue seam, are necessarily introduced into the mixture. These include plasticizers, modifiers, minerals that optimize the plasticity of the mass.

After combining both components, the polycondensation reaction begins, as a result of which the solution solidifies. Until this moment, they can glue tiles, ceramics, artificial and natural stone, boards, mosaics. Most adhesives are also suitable for other floor coverings - laminate, linoleum, parquet.

The composition is used for external and internal work. No less popular is a waterproofing agent in rooms with high humidity. Most brands are suitable not only for tiling, but also for working on deforming and vibrating substrates. Other surface materials with which the two-component adhesives adhere well:

- concrete, brick, aerated concrete;

- cement screeds;

- plaster;

- drywall, gypsum fiber, plaster;

- metal;

- OSB, plywood, chipboard;

- old tiled wall coverings.

Which to choose?

To decide on the choice of a suitable type of glue, you need to know exactly the scope of its application. Especially, this applies to situations when the tiles need to be laid in the bathroom or bath. The material must have a sufficient level of water resistance.

If the floor surface is not too flat, then you should definitely give preference to glue that can level the surface, for example, epoxy.

When choosing, it is worth considering:

- the specifics of the work, tiles are required to be laid indoors or outdoors;

- the material of the surface on which the tiles need to be glued;

- humidity level and temperature indicator;

- type of tiles.

When purchasing glue, you should not pay special attention to its price, since expensive compositions are not always of high quality and vice versa. It is better to proceed only from your goals and the above factors.

It is better to proceed only from your goals and the above factors.