Benefits of latex paints

Getting acquainted with the assortment of building supermarkets, many are surprised to see latex paint - what is it, a natural question arises

Noticing the price tag for imported polymer mixtures, buyers pay attention that it costs more than acrylate, although more affordable than silicone compounds, occupying an intermediate niche

Today, latex paints are water-based emulsions based on polymer particles that can be painted in any color using a color scheme.

Most dyes for interior surfaces have a significant drawback - immunity to "breathable" or unstable surfaces. They collapse at a noticeable temperature amplitude, especially when the metal is heated, the wood dries and soaks. The developers suggested latex paint for walls and ceilings (other substrates) to solve this problem.

The material has good adhesion to the surface of the base, the dried paint does not flake or bubble.

The main positive characteristics of various types of elastic paints and varnishes:

After being applied to the surface of the wall, the water evaporates, and the coloring particles are combined with each other, forming a film.

Each coloring composition has its own disadvantages, but their list is much smaller:

- some varieties are not intended for use at subzero temperatures (this should be written in the instructions or description of the characteristics on the packaging);

- involves an antiseptic primer or impregnation of the surface with fungicides - fungus or mold can grow on the surface of the tree.

On the other hand, not everyone views the last point as a minus. This only confirms the environmental friendliness of latex compounds, which are produced on the basis of synthetic and organic resins.

The latex painted surface retains its original appearance for a long time.

Composition and properties

The glue product contains substances that can firmly bond any surfaces, parts of an object, a mechanism. The properties of Akfix 705 glue are excellent, which helps the product gain popularity among professional builders and ordinary consumers.

"Acfix 705"

Cyanoacrylate based adhesive first appeared in 1958. Cyanoacrylic acid esters are now part of many repair products. Such as Akfix 705 are used in construction, industry. The glue does not contain solvents, therefore, for gluing, a viscous gel must be used together with an activator, which is applied directly to the adhesive. Grasping is instantaneous. This happens as a result of the fact that the components of the activator accelerate the process of carrying out a chemical reaction up to 2-3 seconds. At the same time, the quality of the gel does not change: it remains transparent and durable.

The activator is based on isopropanol and additives to improve the functions of the chemical.

"Acfix 610"

Liquid nails are based on polyurethane. Advantage of glue in it:

- transparency;

- excellent viscosity;

- economical consumption;

- high quality of the connection;

- resistance to moisture, temperature extremes, chemical influences;

- harmlessness.

Gluing surfaces with liquid nails is quick and easy. The glue does not run off, making it possible to connect surfaces vertically or upside down.

Varieties

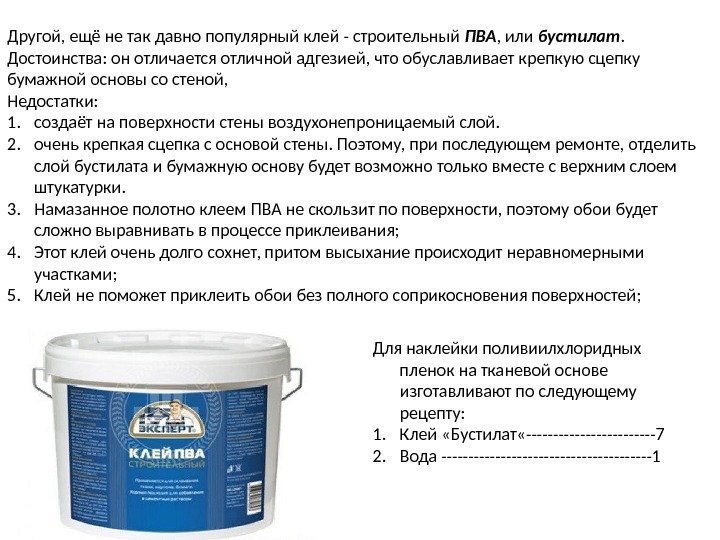

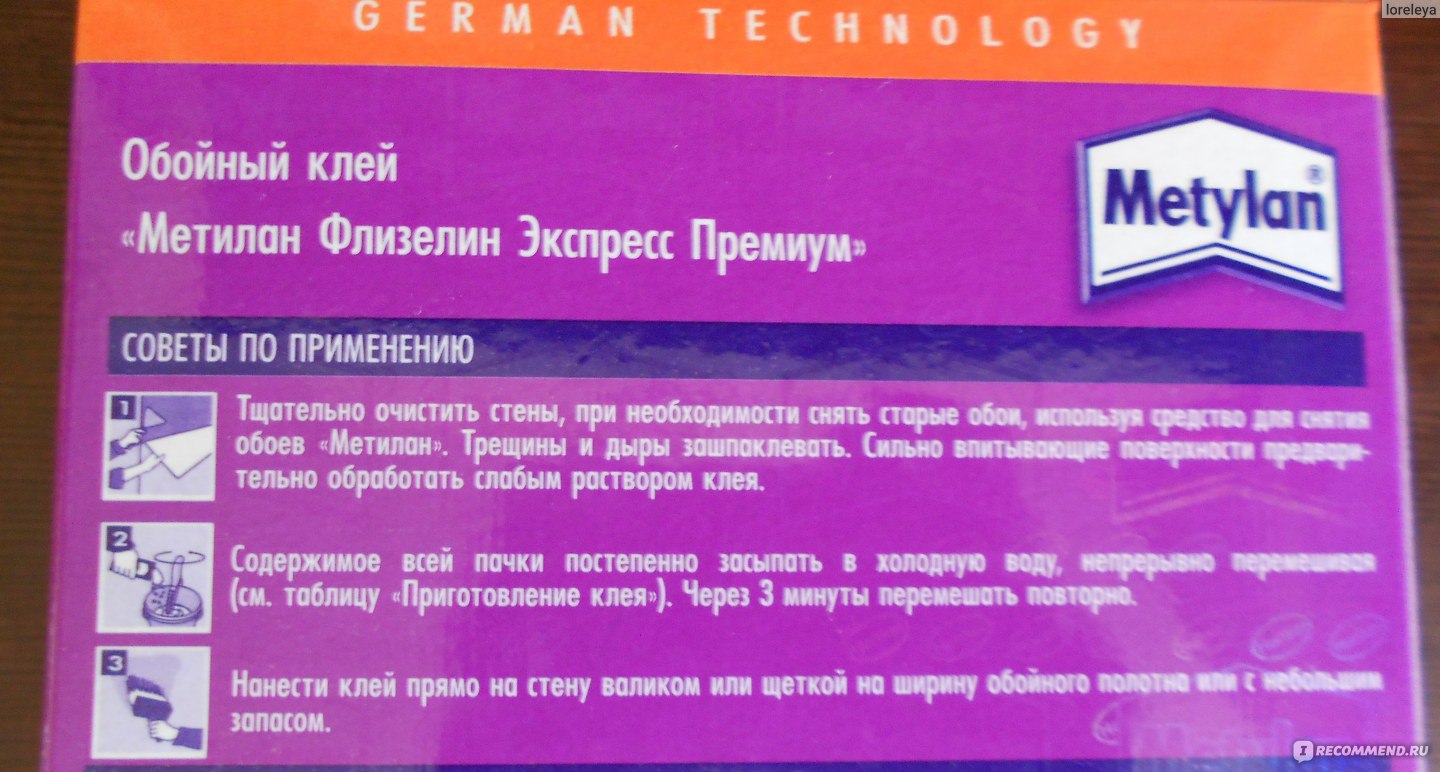

For each type of wallpaper, there is a mixture with a special composition. So it makes sense to look at each one individually to understand exactly which product to use in a particular situation.

Express

This type of glue is suitable for all types of paper wallpapers.One package of such glue is enough for pasting a total area of 35-40 square meters, which is 8 rolls.

Among other manufacturers, paper options are considered rare, so universal glue is often offered. However, the universal glue does not take into account the specifics of the material of such wallpaper, and the Express from "Kelid" was invented to fill this niche.

Super express

Unlike conventional express mixes, super express glue is specially designed for lightweight paper wallpapers and lightweight vinyl sheets. The specificity of the composition allows you to apply a thin layer of glue for good adhesion to the surface, which guarantees the absence of traces on the wallpaper, and also reduces the consumption of the mixture.

Glass fiber

High tack adhesive. Ideal for both fiberglass wallpapers and textile wallpapers.

Also, the mixture is suitable for further surface coloring, because the substances in the composition have no effect on the paint. Wallpaper glued with such a mixture will stick to the wall for a long time.

Special non-woven

Another highly targeted type of glue that is only suitable for non-woven wallpaper. Heavy types of vinyl, and even more so fiberglass will not be able to hold on to such a composition, only paper-based options are also suitable for such a composition. However, fleseline wallpaper will adhere perfectly to the wall, after all, the glue is designed specifically for them.

Special vinyl

Suitable for heavy vinyl-backed wallpapers. It contains PVA glue, which guarantees strength after the mixture has set. Among all adhesives, it is the most expensive, therefore it is recommended to use it only for vinyl wallpaper.

Indicator

In order to improve the quality of wallpapering, professionals can use the indicator composition, which has a pinkish color. After drying, no trace remains on the surface of the wallpaper, but in this way a person can control the layer of the applied composition.

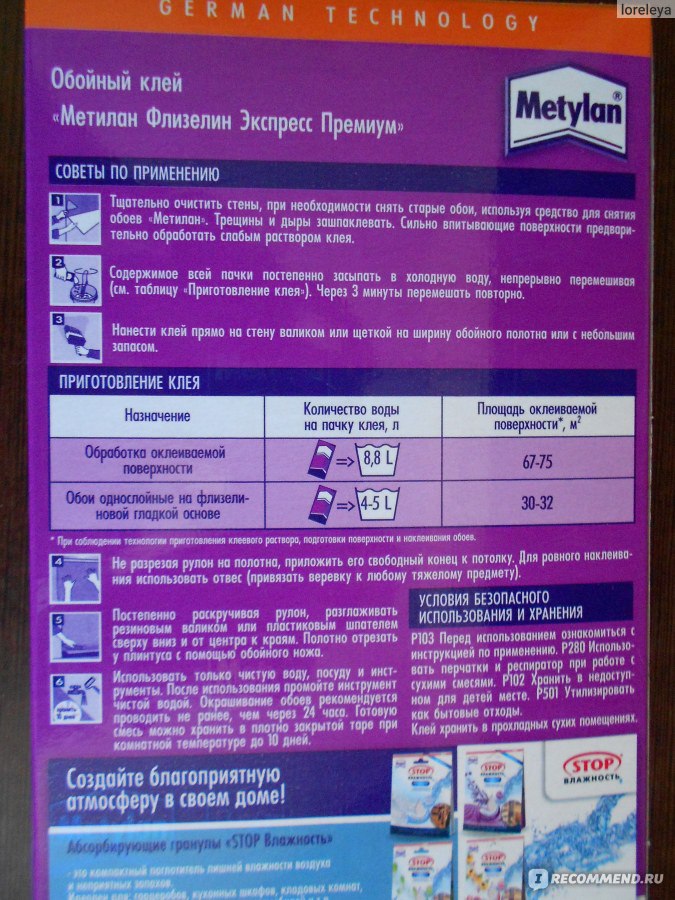

Working solution preparation rules

To prepare vinyl glue for use, you need to carefully dilute the dry powder with plain water. The proportions must correspond to the attached instructions. The air and water temperature should not be lower than +25 degrees. Stir the powder as thoroughly as possible. Only in this case it will be possible to avoid the appearance of lumps. The mixture must be infused for the time indicated in the instructions. Before gluing the canvases, all the necessary preparatory work must be performed.

It is necessary to determine the free space on the clean floor. The canvas is leveled on the surface and greased with glue. It is best to use a clean, dry cloth to press down on the wallpaper. To improve the result, you can walk with a roller several times. All manipulations should be performed slowly and carefully, since there is always a risk of displacing the canvas, which causes folds to form. If the edges of the wallpaper bristle a little, then they must be additionally greased with glue and pressed against the wall. If there are screws or nails on it, then it is better to pull them out before starting pasting or drive them deeper. You need to be as careful as possible in the place where the sockets and switches are located. To make the result look as neat as possible, you need to cut out the necessary holes with scissors. To maximize the correct distribution of all efforts, two people should be involved in the work process. One holds the wallpaper at the top and the other at the bottom. The canvas should go behind the skirting board, which is better to dismantle in advance.

How to choose and calculate consumption

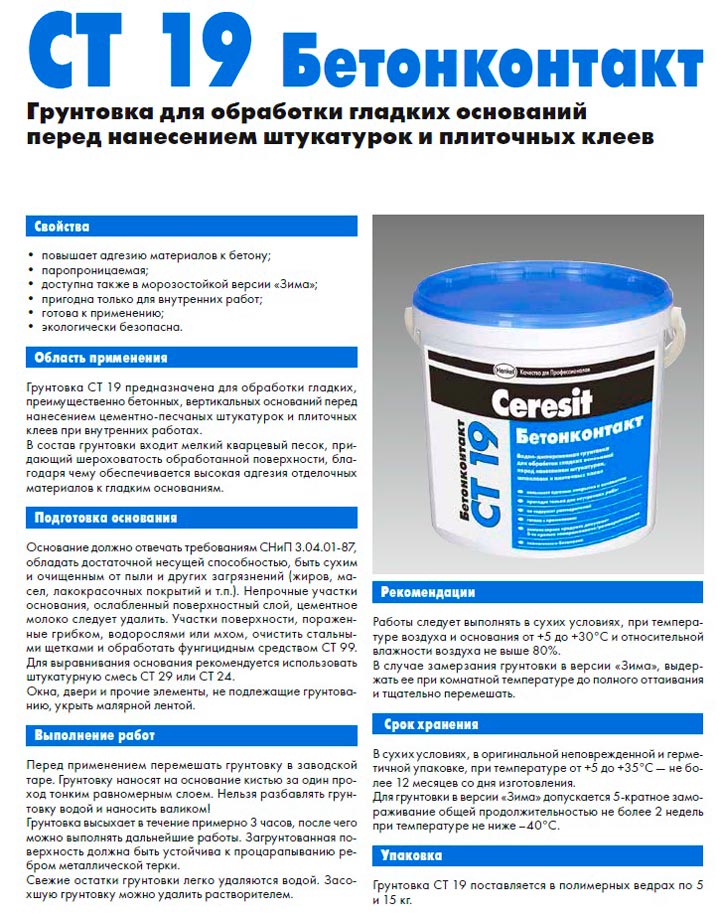

Before using Litokol, you need to familiarize yourself with the specifics of choosing an adhesive for different rooms.

Hallway, corridor or kitchen

In kitchens, corridors and hallways, cladding is often done with terracotta tiles. To attach such material to the bases, it is recommended to use the K47 brand.It is ideal for bonding these slabs to concrete, plaster or brick surfaces.

Bathroom or pool

The pool and bathroom are considered to be humid places. In such places, it is recommended to use waterproof compounds that would not lose their properties at high humidity. Litokol Plus is considered an ideal means for gluing plates, which is resistant not only to moisture, but also to the effects of a chemical environment.

Indoor wall cladding

In order to carry out the cladding of the walls inside the premises, it is necessary to use the brands of glue K66 and K80. These products are ideal for bonding porcelain stoneware to surfaces. Such adhesive mixtures have thixo-stop properties, due to which the tile does not slide down until the mortar has completely solidified.

For outdoor, veranda and exterior walls

On the street, it is better to use special adhesives that are able to withstand temperature changes and high levels of humidity. A suitable outdoor tool is X11, which is suitable for wall cladding.

Stairs and rooms with high loads

Sometimes it is necessary to lay tiles on steps that are subject to increased stress. For facing stairs, you need to use the K77 mixture, which has high elasticity, strength and adhesion. Such a composition is protected from high humidity and temperature extremes.

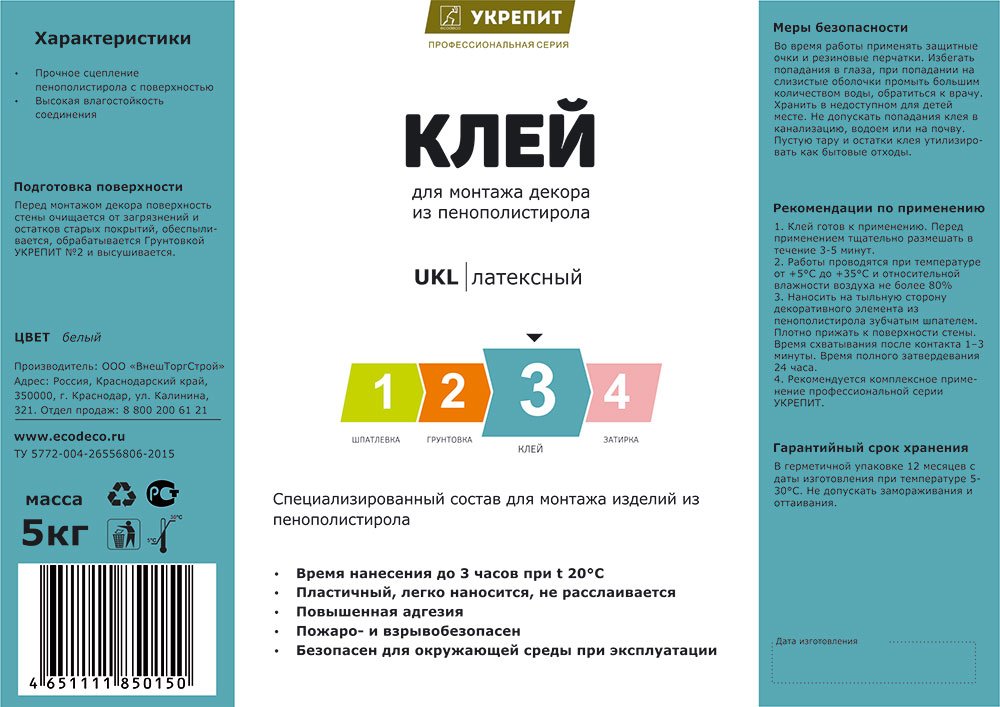

Description and features of latex glue

Latex glue, which is often used for gluing small items and in repairs, is a water-based mixture. The substance contains ammonia and a rubber solution. Some manufacturers use for the manufacture of additional components that increase the tackiness - synthetically obtained resins, inorganic components, ethers.

> There are two types of latex glue. One group contains artificial latex, while the other contains the main component of natural origin. The substance contains a liquid, so the use of glue has an important feature - one of the surfaces must be porous. It is into the pores that liquid excess penetrates, ensuring reliable fixation of parts.

The glue used for gluing surfaces has a certain shelf life. Everything depends on the nature of the rubber. Some varieties retain all qualities for only three months. If the rubber is obtained artificially, the shelf life is up to a year.

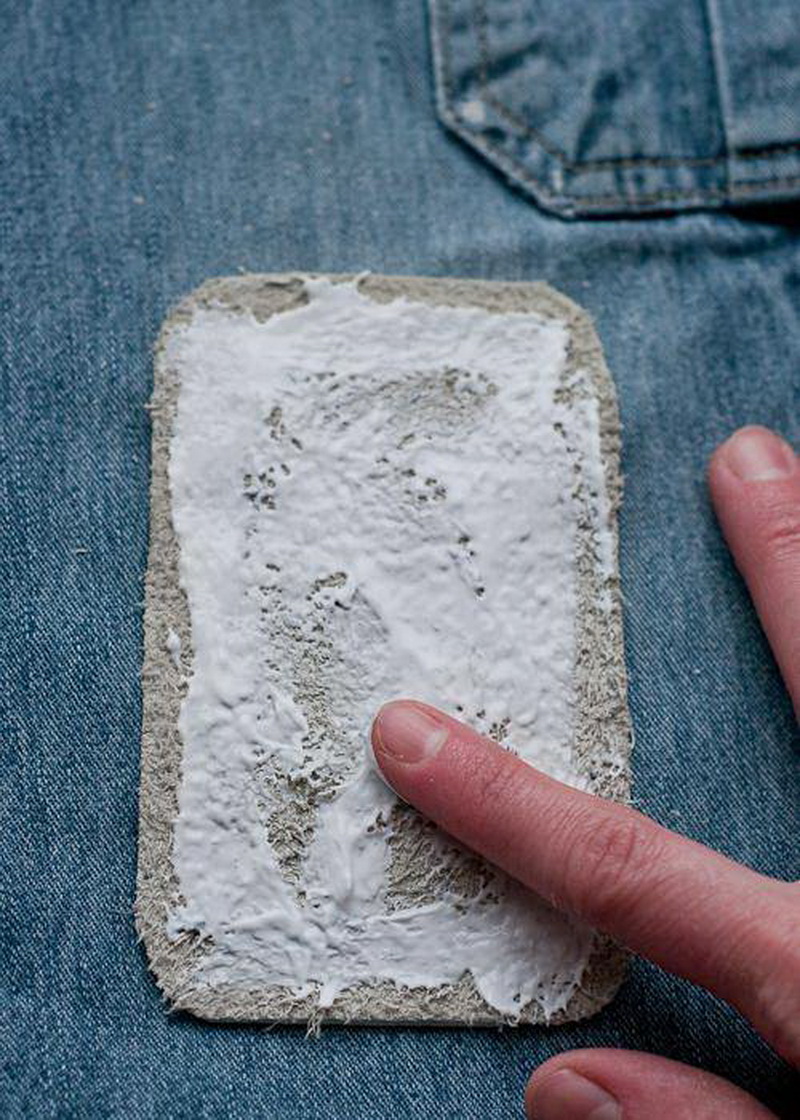

Application features for PVC products

The composition of EVA glue is also suitable for repairing shoes, for the production of which PVC is used. To repair boots, you need to prepare the following set of tools and additional materials:

- several patches of a suitable size, made of waterproof material, to hide the damaged area;

- hairdryer;

- fine-mesh sandpaper;

- acetone for surface degreasing;

- protective gloves;

- wipes for wiping off excess squeezed glue.

Direct repair of PVC shoes is performed by sequential execution of simple steps. Including:

- Sandpaper gently clean the damaged surface and patch. The treated areas will become slightly rough.

- The place where restoration is required is degreased with acetone.

- A small amount of glue is applied to the defect and the patch and left for 15 minutes. Then apply the next layer and wait half an hour.

- The glue is heated with a hair dryer and a patch is applied. Having exactly fixed the patch, it is pressed and held for 5 minutes.

Additional tips and tricks

When planning to purchase EVA glue for repairing shoes or other products, you should consider a number of tips and tricks. The consumption of the adhesive solution will depend on the size of the existing damage, the method of application - manually or with the help of specialized tools and on the roughness of the surface to be treated.It is possible to ensure the optimal consumption of the substance without reducing the quality of setting, possibly experimentally.

During operation, do not expose solutions based on ethylene vinyl acetate to excessive heat, since exposure to high temperatures will negatively affect the physicochemical characteristics. At ambient temperatures ranging from 5 to 35 degrees, the solution can be stored for a year from the date of manufacture.

An important consideration when choosing an EVA adhesive is the material that needs to be repaired. The products are most suitable for working with silicone and rubber products, but there are also varieties for processing polyurethane and PVC items. Correctly selected glue solution will help eliminate defects on various products and extend the possibility of their operation for a long time.

Share link:

Selection criteria for hot melt adhesive

Before choosing an edge glue, you need to pay attention to some features - the thickness of the board, the purpose of the product, the equipment used. Hot melt adhesive must have a number of characteristics:

Hot melt adhesive must have a number of characteristics:

- be insensitive to detergents, alcohol, water, oil;

- do not respond to the action of electrolytes.

The composition is available in the form:

- granules;

- cartridges;

- rods;

- blocks.

Granular hot melt adhesive at normal temperature is a solid in the form of powder, peas, tablets. Heated to a certain temperature, it becomes liquid. In this state, the adhesive is spread over the edge where it hardens. Heating it up again, it is transferred into a fluid state, after which the surfaces to be joined are firmly seized.

The stick-shaped edge adhesive does not need to be completely melted. It is heated at one end, it turns into liquid. The composition is applied to the parts to be glued, heats up again, after which the edge is connected to the end. If necessary, select a hot melt adhesive with a long "open time" between application and hardening. Such hot melt adhesive belongs to low-temperature, today it is widely used both at home and in production.

It is worth paying attention to the temperature at which the glue is applied. The optimum is in the range from 120 ⁰C to 160 ⁰C for PVC and paper, from 150 ⁰C to 200 ⁰C for laminate

In this case, the viscosity should be low. Indicators of all characteristics are available on the factory label of the edgeband adhesive.

How to estimate consumption

On packaging with wallpaper glue, most manufacturers indicate an approximate consumption per 1 sq. In this case, in practice, there are often surpluses or, on the contrary, you have to buy new packaging. In order to correctly calculate the flow rates, a number of nuances should be taken into account, in particular:

- The plastered surface quickly absorbs the glue, and pre-treatment with a primer will reduce the cost of glue above the standard value indicated on the package, by about 5-10 g per 1 sq. m.

- When fully wallpapering the walls, you need to take into account the entire surface area when performing the calculation. If you do not plan to finish the space behind the cabinets or implement various design solutions, not the entire area will be covered with wallpaper and the consumption will be reduced. In this case, you need to subtract the non-glued areas from the total area.

- The consumption of the substance varies depending on the type of wallpaper. In some cases, the glue is applied only to the wallpaper itself, while in other situations the wall is treated. Due to the different absorption properties and the drying rate, the amount of consumed substance changes. For optimum results, use the correct adhesive for each type of coating.

Based on the above nuances, you can start calculating the consumption of the substance. To do this, first determine the area of two perpendicularly located walls in the room, and then multiply the result by half.To calculate the area of the longer wall, multiply the height by the length, and then use a similar formula to determine the area of the short wall. Next, calculate the total area.

To get the most accurate value, you can subtract the dimensions of window and door openings from the total area, but, without special skills, it is better to take into account the entire area, and use the excess wallpaper and glue to glue joints and align the pattern in problem areas.

Having determined the area of the walls, the required number of wallpaper rolls is calculated. For example, if a paper covering is used, then its standard width is 0.53 m, and the length of one roll is about 10.5 m. These indicators are multiplied, and then the total area of the room is divided by the resulting indicator.

As a result, the consumption of wallpaper glue is determined taking into account all the calculated data. Based on the consumption data indicated on the package, it can be concluded in advance whether the content is enough to cover the room.

How to apply correctly

How to prepare the adhesive solution, write in the instructions on the label or package. Usually the slurry is prepared in a plastic bucket. Take water at room temperature (not hot). First, liquid is poured into the bucket. Then a measured amount of powder is poured in a thin stream, with constant stirring. Stir the glue well and leave to swell for 15-20 minutes or 2-3 hours.

Usually, a standard package of CMC weighing 500 grams is diluted in 7-8 liters of water. This solution should be enough for pasting an area equal to 50 square meters. Before gluing the wallpaper, the walls are primed with an adhesive solution based on CMC. For this purpose, take 500 grams of glue per ten liters of water. The liquid mixture is applied to the walls and left to dry for 3-4 hours. The wallpaper itself is smeared with an adhesive mass and left to soak, depending on the thickness of the canvas, for 10-20 minutes. Before pasting the walls, the wallpaper is once again smeared with an adhesive mixture.

Composition and properties

There are two types of glue sticks. They are made on the basis of PVA and PVP. These bases are humectants. The working qualities and application of the formulations differ from each other.

PVA based

The base of the PVA glue stick is polyvinyl acetate. The active ingredient is glycerol. It is a synthetic component, which is a viscous transparent liquid. Glycerol is viscous. It doesn't smell. The moisturizing properties of glycerol are lower than that of glycerin. Various components are added to PVA glue to improve its quality:

- tricresyl phosphate,

- EDOS,

- acetone,

- esters.

These substances improve the adhesion of the adhesive. PVA glue dries faster. The shelf life of PVA pencil glue is 1.5-2 years. After that, the rod dries up, turning into a dense plastic cylinder. In doing so, it separates from the tube. But the fixation time on the surface is also shorter. It takes only 2 minutes for the glue mass of a PVA pencil to dry completely.

PVA glue stick allows exposure to high temperatures. But the lower threshold is limited to 15 degrees Celsius. At lower temperatures, the adhesive hardens quickly. It becomes difficult or impossible to smear it. PVA glue does not dissolve in water. He is not afraid of oil attacks. Atmospheric phenomena are not reflected on it in any way. The only thing he doesn't like is temperature changes.

Output. PVA glue stick has a wider range of applications.

PVP

The base of the PVP glue stick is glycerin. It is a natural substance that effectively protects the glue from drying out. Glycerin absorbs moisture from the environment. He is able to hold it for a long time.

The drying speed of the finished work increases up to 5 minutes. Unlike PVA, PVP pencil connects not only parts of cardboard and paper. It glues photographic paper and fabric. The glue is more resistant to low temperatures than PVA. He is less afraid of her drops. The paper after gluing PVP is not deformed.The adhesive does not change the color of the materials to be glued.

The composition of PVP glue is more complex. It varies from manufacturer to manufacturer. We can only talk about a small list of components that can be included in it in addition to glycerin:

- Water. It serves as a natural solvent. Evaporating, allows the composition to harden.

- Acrylic polymer is the main adhesive component, due to which the substance, when dried, polymerizes.

- Sodium stearate is a substance that makes the glue mass more plastic and facilitates friction.

- Polyethylene glycol - This substance is added to the adhesive to maintain flexibility.

- Polyoxyethylene monooctylphenyl ether is a chemical compound that acts as an emulsifier, providing an emulsion when mixing dissimilar components.

- Polymer of N-vinylpyrrolidone - an ingredient that enhances polymerization.

- Aminomethylpropanol is a buffer that neutralizes acids and contributes to the safe application of the adhesive.

- Sodium hydroxide is an alkali. It is added to maintain the neutral pH balance of the adhesive.

In the composition of the glue stick, the presence of hydrogen peroxide and caprolactam, which impart plasticity to the mass, is possible. If the glue stretches, forming threads, then this is the action of caprolactam.

Varieties of profiles

The edges of the furniture are processed not only with the edge. One of the decorative and protective ways of finishing the cuts are profiles - special overlays that are put on the saw cut or inserted into pre-cut grooves in the chipboard. Profiles change the look of furniture, serve as an additional decorative element, effectively protect the inside of the chipboard from the external environment.

T-shaped

To process the edges with a T-shaped profile, a groove is cut in advance with a mill with a cutter. At the final stage of furniture assembly, the profile is inserted into the prepared hole (hammered with a soft hammer). T-shaped profiles are made with a girth or with simple overlays on the edge. Usually aluminum or PVC is used.

U-shaped

C- or U-shaped profiles do not require cutting into the groove plate, they are simply put on the edge and reinforced with glue

It is important to choose a good adhesive and attach the pad tightly to avoid voids. U-shaped pads are produced from soft and hard materials

Rigid parts are stronger, but assembly on rounded edges is more difficult. The profile will have to be warmed up to give flexibility and fasten with tape until the glue dries.

Tips & Tricks

Finally, we have prepared a few tips to help you do your job efficiently.

- Dilute the mixture with clean water strictly according to the instructions that are on each package. It is best to mix the composition with a drill.

- After the first stirring, you need to leave the glue, then mix it again and proceed with the lining. During operation, the glue is mixed several times.

- Work with this mixture should be carried out in a room with low humidity, where there are no drafts.

- If the work will take place outside, the weather should be clear and warm.

- If during outdoor work the weather is too windy, the durability of the diluted composition will be halved. Therefore, it is recommended to dilute the mixture in portions.

- If you plan to lay the tiles for places with high humidity (baths, saunas, swimming pools), you should choose a mixture of Litokol K55, which is based on a latex additive.

- After finishing work with glue, it is better to immediately soak the tools in water and wash them, otherwise it will be very difficult to do this later.

- It is not difficult to work with the material, however, it is the accuracy that will contribute to the best result.

For more information about Litokol K55 tile adhesive, see below.

How to apply latex composition correctly

This variety, in terms of the method of application, is no different from analogues - it can be slightly diluted before processing over a primer. Experts recommend applying in 2 layers.

The disadvantages of latex emulsions include the need to pre-treat the wall with a primer.

For a more accurate calculation of the required volume, it is important to compare the spreading rate and the area of the treated surface. The second layer can be a little thinner if the quality of the previous one is quite satisfactory.

Elastic polymers are excellently "stretched" over surfaces. Two applications are sufficient to provide aesthetics and color fastness.

On the modern market, colors are presented in a wide range of colors, which allows you to purchase any shade.

Surface treatment sequence:

- Remove dirt and old paint layers.

- Work on minor defects with plaster putty, re-plaster with a finishing mixture (if necessary) after drying.

- Vacuum thoroughly to remove all abrasive particles.

- Treat with antifungal and latex primer.

- After drying, cover with masking tape all parts that do not imply staining.

- Prepare the paint, if it is too thick, dilute it a little with water (the proportion should be indicated on the can, usually 5: 1) and pour it into the kit tray with a painting tool.

- Start painting with a narrow brush in hard-to-reach places, then work with a wide brush or with a medium pressure brush for even distribution.

- After complete drying, reapply paintwork materials.

Latex paint is widely used in living rooms, bedrooms and children's rooms.

For painting ceilings and negative surfaces (inclined towards itself, as in the attic), a thick composition is needed. It is difficult to distribute without experience. It is recommended that you contact a ceiling paint specialist. It is not recommended to work with thick latex with a roller - the quality of distribution of the emulsion decreases.

Better to give preference to the option with a lower degree of gloss. Semi-matt paint is the best option.