Peculiarities

This product has won its great popularity due to its excellent characteristics and high durability. This glue is produced in Germany by Rema Tip Top. This product has been known on the Ukrainian market for several decades and has earned only the most positive reviews during this time. Type Top offers a wide range of substances that are used in various fields, from heavy production to the food industry.

The sc 2000 mortar is most often used for connecting and repairing conveyor belts by vulcanization, and is also good for lining rollers and drums. This substance is suitable for creating a protective coating that is excellent for increasing wear resistance and reducing the chance of corrosion on industrial equipment. Such connections are much better than mechanical ones, as they create an even distribution of stress over the entire plane of the parts. All this contributes to an increase in the duration of the equipment life.

glue type top

The mix Type Top sc 2000 contains only two components. It is excellent for use in mechanisms that are constantly subjected to significant stress. Most often it is used for rubber-to-metal, rubber-to-rubber, fabric-to-fabric, concrete-to-rubber and rubber-to-fabric connections.

Additional properties

It is important to take into account that the application of glue can be carried out on a plastered surface and a cement screed, after the formation of each of which 28 days have passed. As for concrete foundations, you can start work on such surfaces 90 days after the completion of work.

In order not to encounter problems during operation, you should not start manipulating the finishing of deforming bases. This adhesive is also incompatible with products whose water absorption is less than 1%. If there is a need to lay tiles in rooms with high humidity, as for showers and bathrooms, the Ceresit CM 11 adhesive mixture, the technical characteristics of which are presented in the article, can be used only if the humidity rises periodically, as well as the presence of intensive ventilation. It is important to properly prepare bases that have large gaps and potholes. The craftsman should repair and level the surface using plaster or mineral filler.

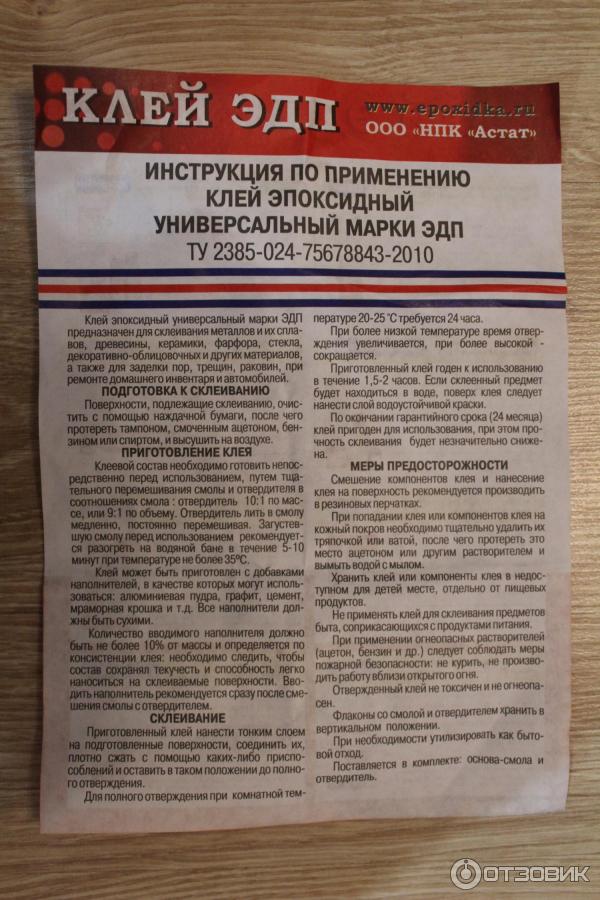

Composition and properties

The ratio of epoxy and polyamide resins in the composition of VK-9 is 1: 2, in mass units - 60:40. Visually - a gray, viscous mass. Additional components - organosilicon compounds and mineral inclusions:

- asbestos;

- boron nitride;

- titanium dioxide.

The compositional composition hardens at a temperature of +20 degrees. Heating the components during mixing until they boil leads to crystallization and loss of adhesive properties. The mixture retains the property of gluing surfaces for 2.5 hours. The seam obtained after hardening is highly resistant, does not allow water to pass through, does not react to acids, alkalis, heating, and does not shrink.

The maximum tensile strength after hardening at +20 degrees is achieved during the day:

- setting after 2 hours;

- strength at a pressure of 10-12 technical atmospheres (atm) - after 5-7 hours;

- in 150-160 technical atmospheres (atm) - after 18-20 hours.

The in-plane shear strength varies from 140 atm at +20 degrees, to 45 atm at +125 degrees. The adhesive bond retains its working qualities at temperatures up to +125 degrees. At +200 degrees, functionality - 500 hours, at +250 degrees - 5 hours. Each of the components of the glue has advantages, the combination of which gives, in general, the desired properties.

Epoxy resin

Epoxy resin in VK 9 is a brown, transparent, viscous liquid.

Characteristics of the substance:

- gives a strong bond with metal surfaces;

- resistant to aggressive chemical influences;

- uniform solidification, without shells and cracks;

- does not collapse under the influence of temperature;

- does not let water through;

- during the hardening reaction, phenols and formaldehydes evaporate.

In its pure form, the epoxy joint is not flexible enough: it cannot withstand vibration.

Polyamide resin

Polyamide and epoxy resins mix well.

Polyamide polymer:

- elastic;

- slightly absorbs water;

- does not emit toxic fumes;

- possesses high density after solidification;

- resistance to compression.

The synthetic compound belongs to surfactants, superior in adhesion property to epoxy resin.

Special recommendations to consider when working

Colored sealant is sold in tubes designed for use with a gun. Before starting work, you need to cut off the edge of the plug, screw on the applicator.

Mandatory preparatory work: the base is cleaned of dirt, residual glue, dried; the edges of the seams are covered with adhesive. Such preparation will ensure adhesion and cleanliness of the cladding.

Joint filling must be carried out in full. No later than the expiration of 8 minutes, the seam is smoothed with appropriate tools soaked in water. The adhesive tape is removed immediately after smoothing. If contamination remains, then they are removed until the mass dries. Removal is carried out with an alcohol solution. If the grout is dry, the removal of contaminants is possible only mechanically, since the mass cannot be dissolved by chemicals. In this case, you must be careful not to damage the cladding.

When the product hardens, acetic acid is released, therefore, work should be carried out in IZ products. If the substance comes into contact with the open skin or eyes, immediately rinse with running water.

The use of glue "Ceresit CM 11" in tandem with an elasticizer

"Ceresit CM 11 plus", the technical characteristics of which will become known to you after you have read the article, can be used when arranging heated screeds, on parapets, plinths, entrance lobbies, external staircases, terraces, balconies, as well as operated roofs, however in this case, the glue must be used in conjunction with the CC 83 modifier. The mentioned additive is used when there is a need to apply the described glue on deformable bases, namely gypsum plasterboards, particle boards, and OSB. The combination of adhesive and elasticizer allows the composition to be used in indoor and outdoor pools and tanks. Experts recommend using this technology on ceramic claddings for both internal and external work. This can even include glazed products. This solution is also suitable for paint coatings, which are characterized by a high degree of strength and excellent adhesion properties. If you are faced with the task of using an adhesive composition on anhydrite or gypsum bases, as well as cellular lightweight concrete, the age of which starts from 1 month, then the recommended addition to the composition in the form of an elasticizer is an indispensable solution.

Additional tips and tricks

There are frequent cases when, due to improper storage, the polymer composition has thickened. To dilute the glue, you need to add alcohol or another substance on the same basis to the material. A similar tool is recommended to be used to remove polymer solution from clothing, shoes and other surfaces. This procedure should be carried out immediately, without waiting for the resin to dry.

Despite the fact that Dragon belongs to the universal polymer adhesives, when working with floor coverings, it is recommended to use highly specialized products that contain acrylic components. Such solutions provide high-quality adhesion of parquet, laminate or fiber to a concrete or other base.

Dragon has proven itself well when installing insulation such as mineral wool or foam. It is also suitable for gluing tiles to walls or floors. However, it is recommended to use polymer adhesives in powder form to fix the wallpaper. A product based on modified starch, which does not form lumps during dilution, is considered optimal for such cases.

p> Share link:

Main characteristics

- Universal construction adhesive KS is multifunctional, made on a silicate base or thermoplastic resin. Resin-based products are called PVA, and silicate-based compositions are characterized by increased heat resistance and, even after freezing and thawing, can be used for their intended purpose.

- Before applying the glue, it is necessary to prepare the surface by cleaning it from dirt and remnants of the old coating. The porous material must be primed. Minor defects are eliminated with KS glue-paste. Some mixes can be applied directly to old coatings.

- The composition is prepared by mixing, applied in a thin layer on one of the surfaces to be glued. The material should be placed on the paste within 10 minutes. The same amount is given to correct the situation. After leveling, the material is pressed firmly and left to harden. It takes about 72 hours to fully solidify.

When using adhesives, it is recommended to use special goggles and protective clothing, and to ventilate the room well during and after work. Avoid contact with skin, respiratory tract, esophagus, eyes. In case of contact with skin, rinse with soapy water and seek medical advice.

The formulations are stored in large Euro tanks or in small plastic buckets with a tightly closed lid at room temperature. To prevent adhesives from losing their properties during storage, they must be protected from moisture and ultraviolet radiation.

Five cycles of freezing and thawing are allowed, provided that the package is kept closed. The shelf life is about 18 months, subject to the storage rules.

Spheres of application of glue

KS are used for gluing non-concrete, wood, brick surfaces of materials such as glass, wood, ceramics. With its help, parquet boards, block parquet, chipboard, cardboard, linoleum products are glued.

Since the adhesives are resistant to high temperatures, they are indispensable for laying stoves and fireplaces. It copes well with sealing small cracks, does not cause swelling of wood and cardboard substrates.

Tile adhesive is approved for use in any premises: from attics and kitchens to basements and production halls. It is used for finishing entrances, staircases, covered areas.

It can be used as a masonry compound, as well as a putty for decorative finishing of stoves and fireplaces, provided there is no contact with fire. Also, adhesives are used for masonry work in the creation of partitions and walls from glass blocks.

The author of the article is Kristina Sekushina

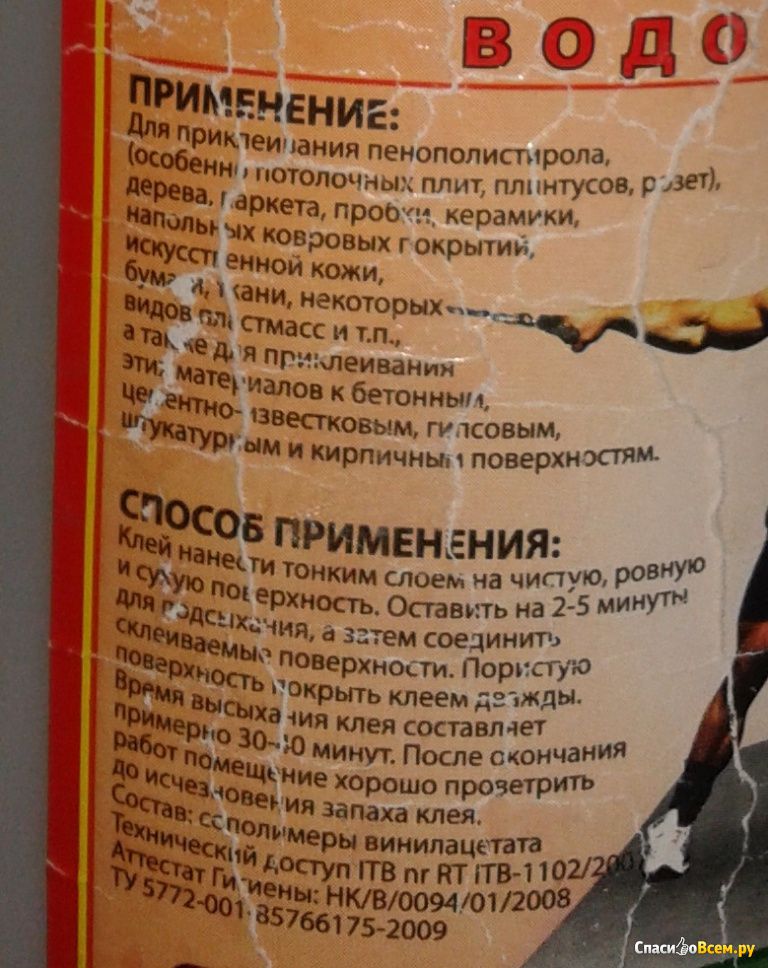

Scope and application features

Universal glue is suitable for wallpaper, bonding plastic and wood products, bonding metal and glass parts.

Such funds are not very liquid, they do not spread much, so that even small parts can be perfectly glued and repaired.

- The so-called contact adhesive has a wide range of applications. It can be used when laying parquet, carpet or linoleum. This tool is often used to securely fix plastic panels, soundproof materials.

- If you plan to work with floor coverings, then it is better to choose a building universal adhesive. As a rule, it should contain acrylic polymers. This product is perfect for laminate, parquet and even coconut fiber coverings. A day after the work, it will already be possible to walk on such a floor.

- Also, universal glue can be used during the installation of insulation systems. It works well with materials such as styrofoam or rock wool. For such work, a universal assembly tool is usually chosen. It can be used while laying tiles. And not only indoors, but also for outdoor work.

- For gluing any kind of wallpaper, it is best to choose a universal powder in the form of a powder, which you need to dilute yourself according to the instructions. Often, such a product contains modified starch. Thanks to this, the product dissolves easily in water without forming lumps. The universal product is suitable for paper and fabric canvases, as well as for vinyl wallpaper.

- For minor repairs, you can choose the usual universal remedy in a small tube.

Properties

Ceresit CS 25 silicone grout has properties that provide a high-quality coating:

- One-component acid-hardening compound.

- Flexibility of the joint after complete drying, which prevents cracking during shrinkage of the building.

- Resistant to moisture.

- Resists direct sunlight.

- It is used for work inside and outside the building.

- The strengthened antifungal formula prevents the spread, mold growth, the spread of bacteria.

- Does not contain toxic compounds, so the use is safe for the body and the environment as a whole.

- Increased adhesion to enamel, glass, porcelain surfaces.

- No adhesion to rubber, bitumen, tar, Teflon, oil surfaces.

- When dry, acetic acid is released, which makes it impossible to use the product for contact with food, sealing up aquariums, etc.

- The colors of the sealant are identical to those of the cement grout.

- Over time, the color does not fade, remains the original until the end of the operational period.

- It can be used as an adhesive.

All properties, characteristics will appear in the declared form with proper storage, transportation, use of the goods. The tool is not used for purposes not provided for in the technical description.

Manufacturer and form of release of glue

Glue brand 88 is produced by several well-known manufacturers. The most common are products with the names "Moment", "Clayberg", "Rogneda" and "Expert". The quality of the product may vary - imported options have improved parameters, but are offered at a higher cost.

The substance is produced from a mixture of polychloroprene materials. The composition contains the following components:

- phenol-formaldehyde resin;

- nephras;

- ethyl acetate;

- rubber.

The consistency of the finished solution is homogeneous and viscous. The color ranges from gray to light brown. In some cases, precipitation occurs, which is a natural process. Regardless of the manufacturer, the products have unique adhesive properties and are used in various conditions.

Instructions for use

In order for the gluing work to be successful, and the result turned out, you must adhere to the instructions for use:

Preparation of the planes to be glued. When working with Type Top, the temperature should be within 10-25 degrees, do not allow direct sunlight. The surfaces must be thoroughly cleaned from dirt, dust, oil formations, rust, degreased (detergent Type Top).

Dirt from fabrics, rubbers is removed by dry cleaning methods.

Preparation of adhesive solution. The mass is prepared by mixing the glue with the hardener.The hardener should be 4 percent by weight of the adhesive.

The finished mass should be consumed within 2 hours.

- Glue application. The application takes place in several stages: the first layer is applied evenly, then it takes half an hour, and the mass is applied again. The second layer dries up to a state of low adhesion.

- Gluing. When the planes overlap, make sure that the air has completely escaped. After connection, a strong pressure is carried out, fixation.

We recommend a video on the topic:

Manufacturer

The main domestic manufacturer is the Mikhnevsky plant. The company's products are certified, and the adhesive composition fully complies with the requirements of GOST. It is used for fastening parts of very different weights, so that in fact the scope of its application is wider than the installation of electrical structures. But in practice, there are few options that can withstand contact with electrical wires, so in this area of construction work it is simply irreplaceable.

Glue is produced in 2 types of packaging:

- a tube with a volume of 0.1 cubic meters. dm;

- a can with a volume of up to 0.25 cubic meters. dm.

The container is airtight, what you should pay attention to when buying. The plant guarantees the declared technical characteristics only if the packaging is not damaged

Precautionary measures

The components included in Dragon have a negative impact on human health. When working with polymer materials (especially in cases where interior decoration is being carried out), it is recommended to wear a respirator and gloves. With prolonged inhalation of the vapors that the glue creates, dysfunction of the central nervous system or kidneys is possible. Also, poisoning of the body, characterized by attacks of nausea and headache, is not excluded.

When working with polymeric materials, contact of the adhesive with the skin should be avoided. This product rarely causes allergic reactions. But such cases cannot be ruled out. If the glue gets on the mucous membranes, the latter must be immediately rinsed with plenty of water. After completing installation or repair work, the rollers should be cleaned with solvent or acetone. Hands can be washed with regular soap under running water.

Main characteristics

Wallpaper glue CMC is protected from the formation of mold, mildew, which will not show through on the wallpaper. If the composition includes sodium tetraborate, then you should not worry about the appearance of insects. Due to these characteristics, the powder is often added to putty mixtures, concrete mortars.

This product is produced at Russian and foreign enterprises.

Main technical characteristics:

- moisture content of the composition up to 12%;

- dissolves in water by 96-100%;

- infusion, swelling of components, activation of properties - 2-3 hours;

- ready-made it is used within a week.

The amount of added water depends on the density of the wallpaper: for thin material - 8 liters of water per pound of powder; for dense canvases - 7 liters of water per pound of powder.

In order for the glue to fully activate its properties, warm water is taken for dilution, the mass is left to swell overnight.

Manufacturers of glue KMTS

In construction stores, in the markets, there are Russian, imported TMs for sale. The price of the former is much lower, but the technical characteristics are not inferior.

Famous manufacturers:

- Pennant 75B is produced in Russia. The finished solution has a high viscosity, water-retaining qualities. Suitable for all types, types of wallpaper on all surfaces, including metal. No toxic substances, safe. Packing in bags.

- Carbocel produces a universal CMC product for all types of canvases. It is an environmentally friendly product with high solubility values. Highly effective filler-free product. Available in packages of 0.3 kg, 0.5 kg, 15 kg.

- Omega produces an adhesive based on carboxymethyl cellulose with the addition of antifungal components.Suitable for various wallpapers in structure, width. The solution is prepared within three hours, as a result, a homogeneous mass without lumps is formed. Shelf-life Unlimited.

- Polycell CMC-7 is a white fine-grained powder, readily soluble in water at any temperature. It is used in construction as a thickener for putties, increases the plasticization of mortars, adhesion strength.

- Malva produces glue designed for fixing multilayer wallpaper (foam), paper canvases, fabric backing. Fastening is carried out on painted, concrete, plastered, wooden surfaces.

Review of popular brands

There are eleven popular manufacturers of rubber mixtures, whose products are most often used.

Rubber cement

It is a high quality compound made from natural rubber mixed with solvents. Rubber Cement is most commonly used to bond elastic products. After drying, the glue layer resembles rubber in its consistency.

4508

People who are interested in waterproofing products should pay attention to 4508. It is used in the manufacture of products made of rubber

4508 does not lose its properties in contact with water and therefore can be used when repairing wetsuits or rubber boats for fishing. Among the disadvantages of the funds are the fact that it quickly ignites if it is near a fire.

88 CA

It is a versatile adhesive that is used for bonding metal, wood, glass, concrete, fabric and plastic surfaces. 88 CA is resistant to temperature changes, so it can be used at temperatures ranging from minus fifty to plus sixty degrees. Store 88 CA in dark rooms, protected from children.

Loctite

It is a one-component adhesive mixture that only begins to cure at room temperature. Therefore, experts recommend using Loctite only indoors. Suitable for gluing wood, metal, plastic and rubber surfaces. The advantage of Loctite is that it hardens in 10-15 seconds after use.

"Gum"

Fans of elastic products should turn their attention to "Gummy". It is used in the repair and manufacture of products from durable fabric or rubber.

Also "Gummi" is suitable for gluing cardboard, paper, wood and natural leather. Among the advantages of the glue are resistance to low temperatures and high humidity.

"Radical"

People who are going to repair a wetsuit should use Radical. It is ideal for restoring water supplies as it is highly resistant to moisture.

"Mark A"

Such a tool is used during the manufacture of rubber or leather shoes, bicycle tubes and tires. "Grade A" contains components that exhibit increased adhesion to glass, leather, wood, rubber, paper and foam rubber. Resistant to low temperature and high humidity values. Thanks to this, it is used both indoors and outdoors.

88n

It is a yellowish homogeneous mass in which there are no foreign inclusions or lumps. 88n is recommended for bonding materials such as plastic, leather, rubber, wood, ceramics, glass, porcelain and paper. The mixture hardens within ten hours after application. When stored for a long time, a little sediment may appear in the liquid, but it does not affect the properties of the glue in any way.

GOST 2199-78

According to GOST, adhesives made from natural or synthetic rubber can be used in several fields of activity. They are used in the manufacture of leather furniture or footwear. Also, glue is often used to make rubber products that are often in contact with water.

Plasti Dip

Such a product is made on the basis of an aqueous emulsion containing bitumen-type polymers. Plasti Dip is used for bonding thin rubber materials, paper or wood. The composition is durable and shock-absorbing.

Rubber cement

Rubber cement is often used to restore rubber products. It is often used to repair punctured inflatable boats, bicycle tubes or mattresses. The advantages of Rubber cement include fast solidification, reliability and resistance to moisture.

Characteristics of glue k 414

The k flex glue k 414 is specially designed for fixing insulation made by K-FLEX. It resists aging and does not react to weathering. All surfaces treated with this adhesive are provided with additional properties.

The mass has a one-component composition based on polychloroprene rubber. The glue is resistant to all external influences. Available in different volumes: 220 ml, 500 ml, 800 ml, 2.6 liters. The container is yellow. After use, it closes tightly until the next need. The composition is applied at a temperature in the range of 5-30 degrees.

There are no aromatic additives. Has excellent adhesion to metal. Does not adhere to surfaces containing paint, asphalt, bitumen or oil deposits. It can be used at temperature extremes, for complex structures (tees, sliding parts, elbow, etc.).

When thickening, glue to 414 is diluted with a cleaner of the same TM.

Main characteristics:

- drying is achieved after 10 minutes;

- open time up to 20 minutes;

- working temperature within -40 - +105 degrees;

- with a closed container and a temperature regime of 15-25 degrees, the mass is stored for a year with the preservation of its original properties.