How to choose cold welding?

Today on the market, cold welding is presented in a wide range, but there are also popular compositions that combine quality and inexpensive cost.

The key point when choosing a cold weld is the purpose of the bonding.

If the repair of an already finished coating is required, then you should select stable compounds that contain PVC. The high content of glue, PVC, makes it possible to give strength to damaged areas. This glue will be harder than those brands that have a solvent in their composition.

This will work even if the flooring has been cut unevenly.

Important! If the joint has a walking gap, then type A glue cannot be used.

If optimal conditions are made for gluing and new sheets of linoleum are taken, then those options are used for gluing, they include a huge amount of solvent. Cold glue, which includes a huge amount of solvent, has high elasticity and, when dried, is practically invisible on the surface. True, the drying force will be lower, however, if the loads are not high, this is not a problem. But the expense in both cases will be the same.

Cold welding for linoleum consumption

Consumption of material for joints will depend on the thickness of the flooring and the type of mixture used. The thicker the web and the gap between adjacent elements, the more glue will be used to fill it. Cold welding is sold in the form of tubes of 60-100 milliliters.

Titanium

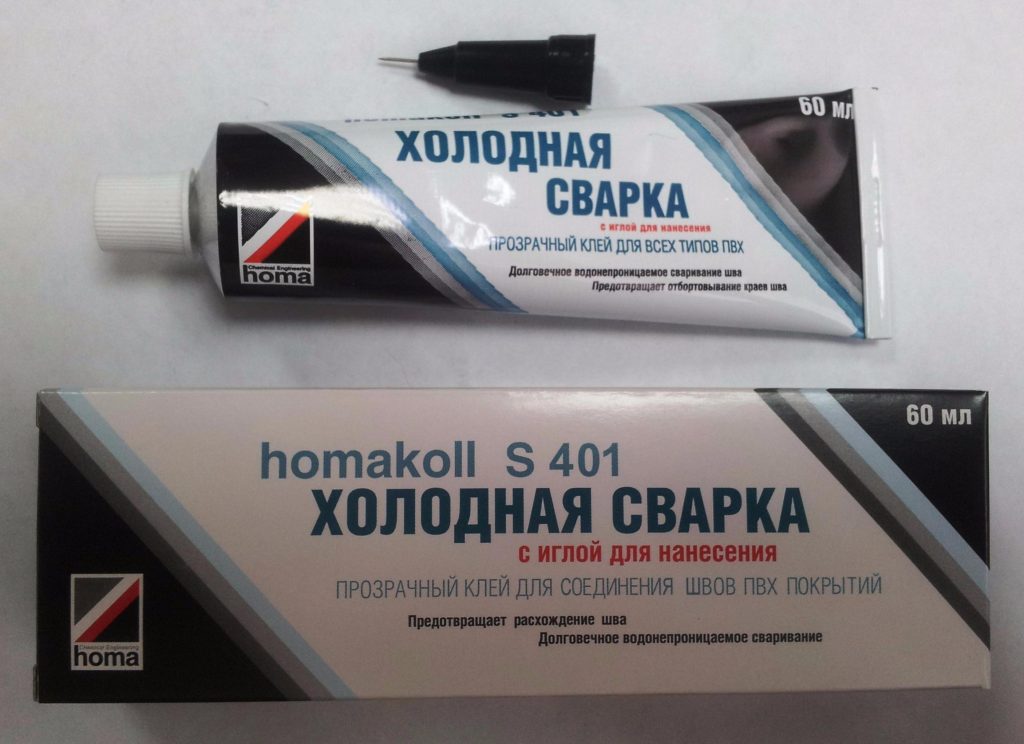

Such glue is sold in the form of a tube, which contains 100 milliliters of the composition. This clear or white mixture consists of a solvent and a base. For ease of application, a rod is inserted into the tube. The mixture hardens within 5 minutes from the moment of application, 100 milliliters is enough for 40-45 running meters of the seam. In addition to the usual composition, t-type titanium can be found on sale, which is used to fill gaps within 3-4 millimeters. You can see how to work with this glue in the video clip.

Axton

This Polish-made product is produced in tubes of 60 milliliters and is used to fill gaps within 3 millimeters. The consumption of the mixture is a fairly high tube for 5 meters of the seam. The mortar quickly compresses and shrinks, so it is applied in large doses.

Tarket

Tarket is a domestic product. A tube with a capacity of 50 milliliters is equipped with a thin metal needle. The composition is suitable for all types of linoleum, it can even be used to fill joints in the presence of uneven cuts of the coating. The consumption of the mixture ranges from 10 to 20 running meters with the capacity of the tube. This product has received numerous positive reviews from consumers.

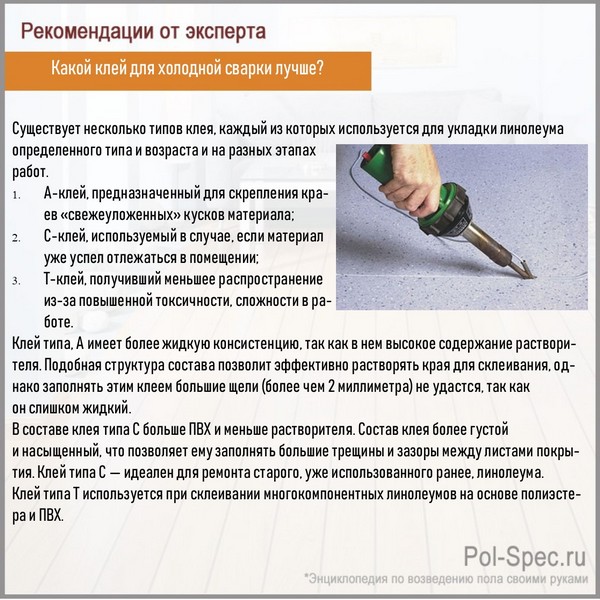

Types and characteristics of glue

How to glue linoleum to the floor? There are two main types of adhesives on the market - dispersion and reactive. The choice depends on the characteristics of the coating and the surface on which it is laid.

Dispersion adhesives

All products of this type are aqueous emulsions of polymer resins with the addition of various fillers, mineral particles. The benefits are clear. Funds:

- do not have an unpleasant odor;

- elastic;

- thanks to the water base, they are non-toxic, environmentally friendly;

- have excellent adhesion to the substrate.

The products are suitable for gluing linoleum to concrete floors. After hardening, they are not affected by moisture, they perfectly seal joints and seams. The price is low: for example, the popular Homakoll glue costs 200-250 rubles / kilogram. Consumption per 1 sq.m is minimal, while many adhesives are frost-resistant.

Dispersion funds are divided into several groups:

- acrylate with acrylic resins are suitable for fastening to wood, concrete, a base made of mineral materials of semi-commercial and commercial linoleum;

- polyvinyl acetate, bustilates with the addition of latex, chalk are suitable for gluing thick felt-based PVC coating to fiberboard, chipboard, concrete;

- compositions like "Gumilax" based on rubber and latex resins are suitable for homogeneous material or foamed household covering on a natural basis;

- electrically conductive adhesives with a dispersion of conductive powder are used when laying antistatic linoleum;

- rubber mastics with bitumen resin are used for flooring on the ground floors, in damp rooms. The rest are only suitable for rooms with humidity up to 55-60%.

Many dispersion adhesives cannot be operated at low temperatures, therefore, for a balcony, summer kitchen or other similar premises, it is better to purchase a composition marked with frost resistance. It will not crumble even when it freezes. When buying, it is imperative to clarify the indication of GOST, check the certificates of conformity and the date of issue. Expired adhesives partially lose their properties.

Reaction compositions

How to glue the coating securely in difficult areas? For this purpose, reaction adhesives are used, for example, universal and for carpet. They are called "cold welding" and are used for welding seams and joints.

The components of the composition react with the material. After polymerization, a tough, moisture-resistant layer is formed between the base and the floor covering, which is resistant to tearing and shearing. The adhesion strength is very high, the joint can withstand shock loads and vibration.

There are one-component and two-component adhesives, the latter must be mixed before use.

Scope of use of reaction adhesives:

- offices and other commercial premises;

- rooms with high traffic - living rooms, hallways, kitchens;

- bathrooms;

- balconies;

- stairs, common corridors.

All adhesives can be divided into two groups depending on the composition:

- Polyurethane. Suitable for any type of linoleum, for all known substrates. They are often used in residential premises, since the unpleasant odor is weak and quickly disappears. The cost is high - from 400-500 rubles per kilogram.

- Epoxy. Consist of epoxy resin and hardener (two-component). Their strength is even higher, but the composition contains toxic components (solvents). Typically, these adhesives are used for outdoor use. Price - from 600 rubles per kilogram.

Most reactive adhesives have a significant drop in adhesion when used on dirty floors. Therefore, it should be thoroughly washed before work. Substrates made of mineral materials need a layer of primer - this will reduce glue consumption and improve adhesion

The disadvantages of adhesives include their rapid flammability - installation must be done with great care

How to use cold welding

Construction adhesive that can reliably bond the floor covering is a toxic substance that is hazardous to health to work with. Also, if used incorrectly, cold welding can corrode linoleum sheets, which will make the joint sloppy. You need to work with glue according to the instructions and following the following tips:

- You need to glue the flooring sheets in a special construction respirator and goggles that protect your eyes. Leave the windows and doors in the room open. Provide good air circulation.

- Choose the composition of the adhesive carefully. Some types of joints and certain grades of linoleum require the use of welds with different percentages of glue and solvent.

- Do not leave the tube open for a long time, otherwise the glue will dry out. It is not enough to put a cap on the spout - it is better to insert a needle into it according to the size of the hole or an awl.

- After gluing the seams, you should not try to speed up the drying process with hot welding or a simple hair dryer. So the adhesive will decrease in volume, the joining will turn out to be unreliable.

- While gluing, press the joints to the floor with an impromptu press. This way you can avoid the appearance of air bubbles, which eventually destroy the seam.

- After applying the adhesive, wipe the top of the flooring with a felt cloth to remove excess PVC with solvent. For the same purpose, masking tape is glued over the joints. Even with such protection, it is better to wipe the linoleum with felt.

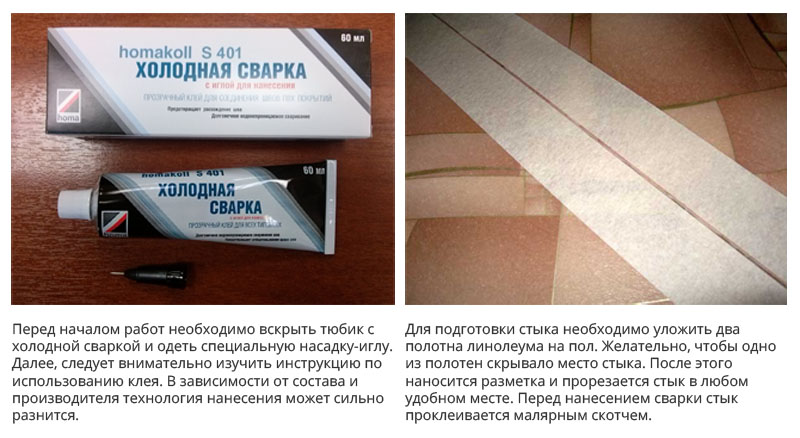

Instructions for use

How to glue a linoleum joint with cold welding? To carry out all the work correctly, you must strictly follow the instructions. It is described step by step below.

Seam formation

After purchasing the coating, its approximate fit, you need to form an optimal seam. To do this, lay both pieces as they will lie on the floor. In this case, the overlap should be 5 cm. Next, you will need a strong metal ruler and a pencil. Fasten both edges of the coating together with double-sided tape so that they do not move during cutting. Then markings are applied strictly in the middle, tightly pressing the coating with a ruler. Then they cut along the markings with a sharp knife to get even edges.

Cleaning the base and seam

Before gluing, you need to thoroughly clean the floor from dirt, remove the remnant of the old coating, and vacuum. Before work, all parts must be dried. Also, as a preparation, the edges of the linoleum should be protected from damage. Cold welding contains aggressive components that can corrode the material. Glossy linoleum is particularly affected. To avoid such troubles, you need to buy a wide masking tape and paste over the edges of both canvases with it, leaving a few millimeters for the glue.

Cold welding

Before work, you need to prepare a clean cloth or cotton swabs to remove excess and glue drips. There are two ways to apply the product:

- First. Using a tube nozzle, squeeze the adhesive onto both edges at once. At the junction, the linoleum will become liquid, the edges will melt.

- Second. Lubricate only one edge, apply it to the floor. Then glue the second edge and place it tightly next to the first. Smooth, smooth the seam.

After a few hours, you can walk on the floor without fear, the exact drying time is indicated in the instructions for the glue. When the linoleum is dry, you need to remove the masking tape.

Removing excess glue

Often, excess composition flows out. Do not touch them while the edges are being welded, as this can cause the floor covering to peel off and break the seam. Dried cold welding is removed in 2 steps. Since the fresh seam is elastic, a crater may remain under strong tension and shearing. It is better to first cut off the excess protruding on the surface, and after a day, bring the matter to an end. You can do all the work yourself, without the help of masters. Installation of a welded seam is a painstaking business, but quite real!

What is cool linoleum welding

For fastening this material, a special glue is very often used, it is called cold welding.

This tool has good characteristics for gluing different materials.

The glue is "cool welding», The adhesive qualities are significantly higher than that of other adhesives, and due to this, professionals prefer to use it in their work.

With this glue, linoleum is glued and repaired.

A big plus of cold welding is the maximum connection of one surface to the second. Thanks to this, a large number of loads are easy to carry. The use of this glue is not considered difficult, and it practically does not stand out from simple gluing, but the result will be high. For skirting boards and other decorative elements made of polyvinyl chloride, use the same glue.

This composition is not afraid of moisture, freezing temperatures and other bad factors.This means that gluing linoleum does not require any special conditions, and also the properties of the glue do not change during use.

What it is?

Linoleum is an artificial material that is produced on the basis of various chemical compounds. The joining of sheets forms a small gap, which is not aesthetic and beautiful. To obtain a one-piece seam, the cold welding method is used.

This approach involves the use of a special glue that connects the sheets of linoleum into a single whole. When exposed to a substance, a chemical reaction occurs that makes the material liquid. In this short time, the joints have time to grab and form a strong connection. Cold welding is a relatively simple connection method that can be performed even without experience and a special soldering tool (soldering iron, etc.).

The properties of the glue are such that they allow you to work with joints of different widths. The resulting joint also has plasticity and practically does not differ in characteristics from the properties of linoleum.

Best adhesives for PVC materials

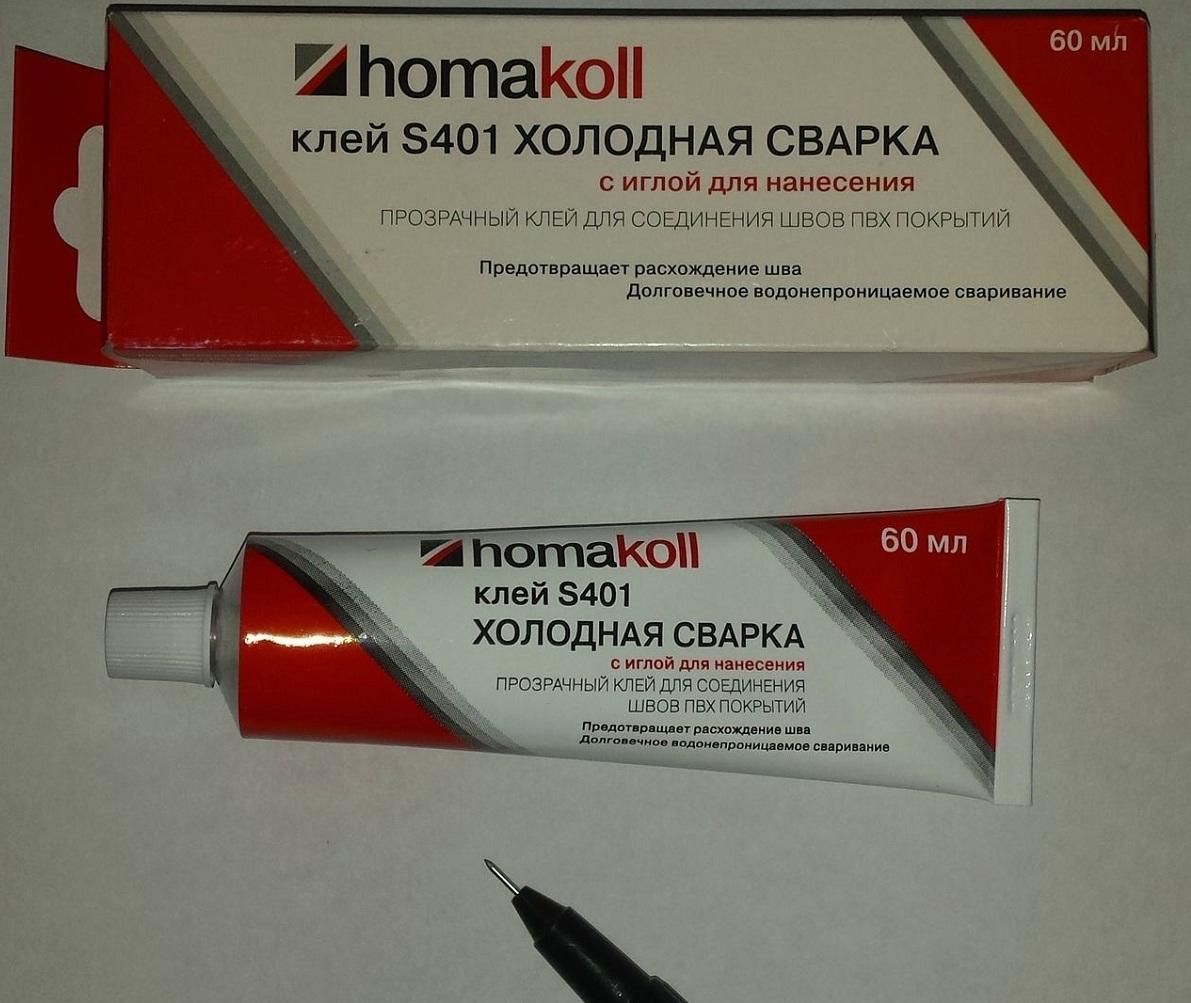

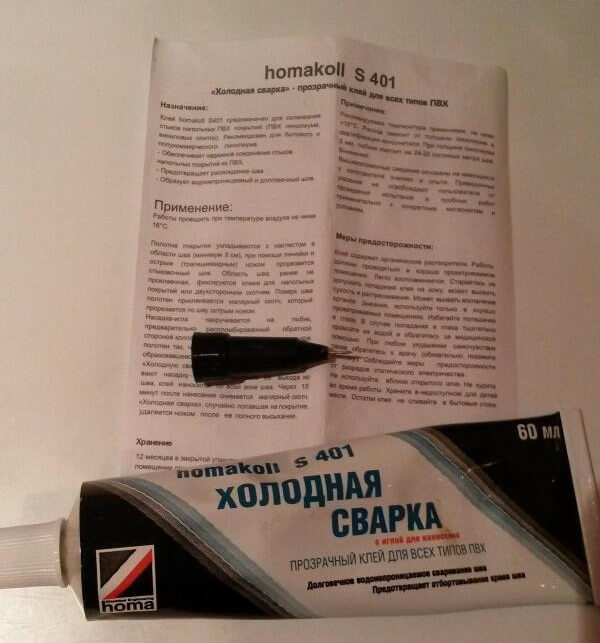

Homakoll

Gluing the seams and gluing the back side to the base is carried out with different compounds. Why this is implemented is clear from the above - in this case, you need to glue the PVC material to a wooden, composite or concrete base.

Some of the best options are the following basics:

- Homakoll is a French adhesive based on a polymer dispersion, which in practice firmly bonds the linoleum surface to any base (requires drying on the base in order to exclude waves), provides an excellent quality of gluing the seams.

- BauGut is a similar material for gluing made in Germany, but made on an acrylic base with fillers, therefore it has a more loyal price. Provides sufficiently strong joints of joints that do not peel off during the entire service life in rooms with a low load.

-

Axton - a very good composition with appropriate reviews for gluing PVC sheets to the base, does not give waves when drying, polymer;

- Tarkett - the advantage of this composition is the fact that the manufacturer produces glued floor coverings, respectively, guarantees the quality of installation with its materials. Tarkett offers a polymer-based backing and seam bonding compound that provides a tight, permanent bond.

- Tytan - also about welding seams, but the principle is slightly different. The composition is a solvent and is more suitable for installation without a gap, otherwise the consumption will be quite large and not economical.

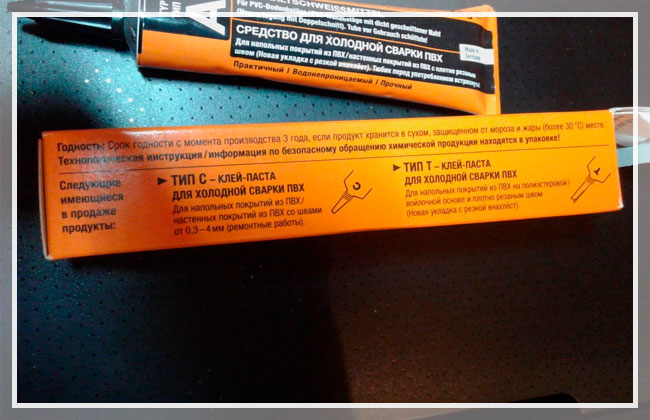

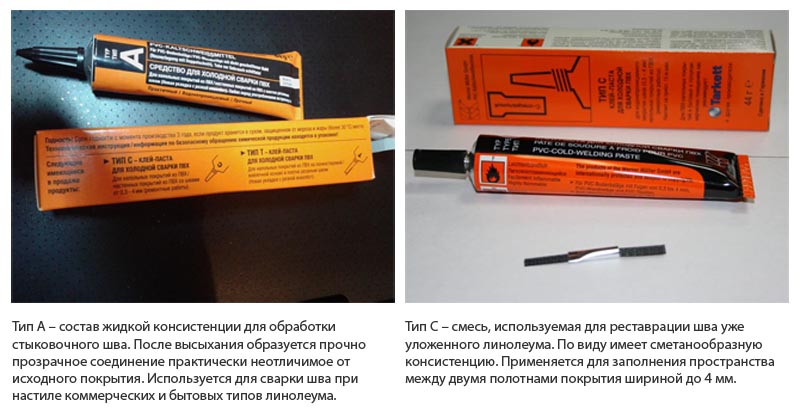

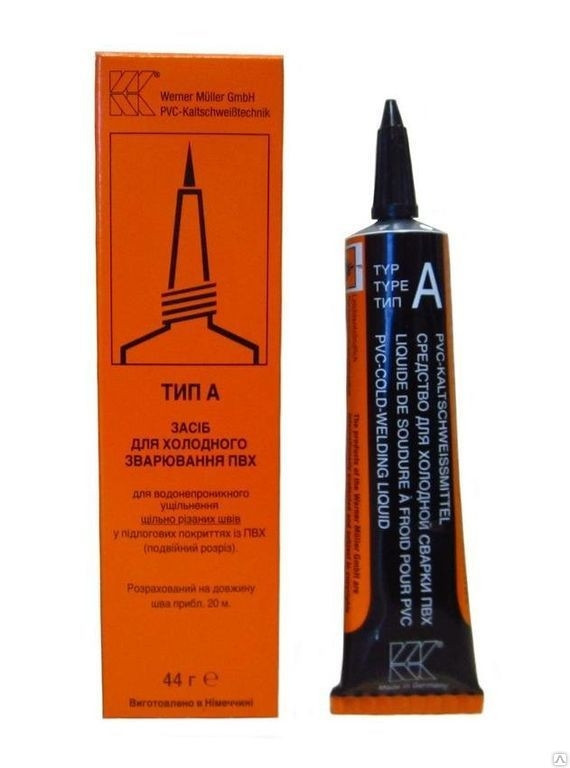

- Werner Muller is the progenitor of technology. This brand offers two types of glue, for gluing without a gap between the sheets (type A) and with a gap type C. With a gap, type C provides a tight seam with an indent of up to 4 mm. A similar composition is produced by Tarkett. Type C is considered a versatile option for do-it-yourself styling when perfect cuts cannot be guaranteed.

Adhesive selection

It is necessary to select a product not only depending on the type of coating. Be sure to take into account the type of base. Some adhesives are universal, others cannot be glued to wood (plywood, board). If you need to save money when connecting the flooring with a wooden floor, you can buy PVA.

It is more difficult with a concrete screed - you will have to acquire a professional composition. Having met a popular brand on the counter, you must carefully read the instructions. It always indicates what the glue is suitable for. Next, a calculator will come in handy to calculate the consumption of materials and, accordingly, the cost of repairs and choose a tool that is affordable.

Manufacturers overview

The market for cold welding for linoleum is very diverse, as many manufacturers produce it. This is due to the fact that this glue is universal and suitable for almost all PVC products.Among the whole variety of models, several main brands of these products should be distinguished:

- WernerMuller. The German brand under which all types of cold welding are produced. The quality of the material meets all international standards. Experts note that the substance forms a high-quality and durable seam. The average consumption of glue is about 44 g per 20-25 running meters.

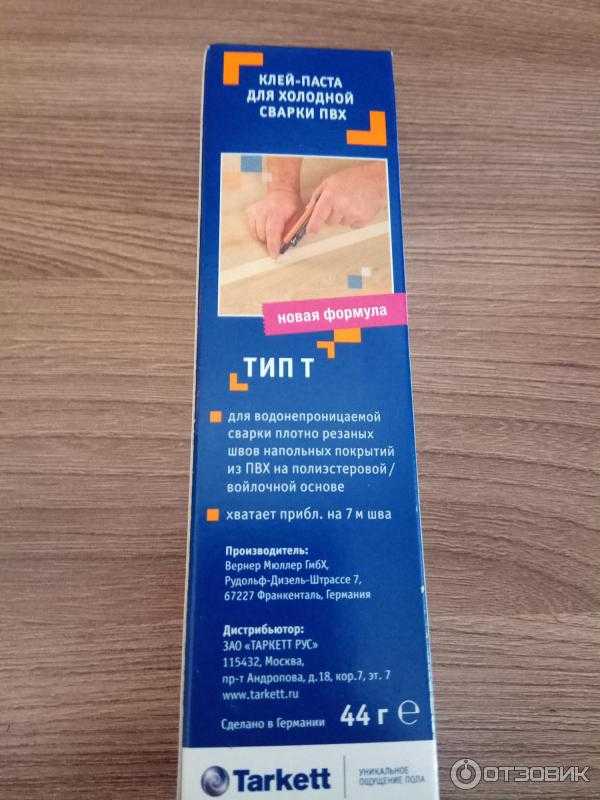

- Tarkett. Another German brand, which, according to reviews, even slightly surpasses the previously reviewed products. The adhesive is versatile and creates an almost invisible seam.

- "Homakol". Domestic glue, which is used mainly for gluing PVC plates and commercial linoleum. Material consumption is approximately equal to the previously indicated indicators.

- Rico. The glue of this brand does not contain tetrahydrofuran, which is toxic to humans. Instead, special compounds of polyurethane foam or artificial rubber are used here. Adhesion using these substances does not differ much from the options where classic glue is used. At the same time, the cost of production is somewhat lower and there is no strong toxic evaporation.

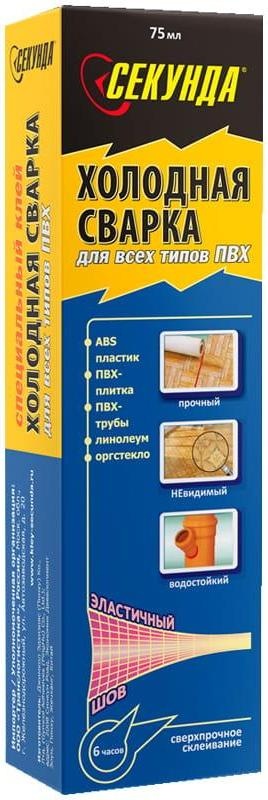

- "Second" and Sintex. Relatively cheap solutions of Russian and Spanish production. The consumption of this material already reaches 45 g per 50 running meters of the seam.

When and why is it needed?

Linoleum is a practical, convenient and easy-to-install material. It is usually made of polyvinyl chloride, but there are other types of material. The coating can be of any color, which allows it to be matched to any interior style.

Semi-commercial linoleum structure

The material has several classifications, the main of which divides all its types into two types - household and commercial. The first has a small thickness and is used to decorate the floors in the apartment. The second one is more durable and reliable, thick enough and fits already in industrial plants, in offices with high traffic, shopping centers, etc. Some categories of commercial linoleum are applicable for installation and at home.

Types of linoleum

Linoleum

Different sizes of rolls allow them to cover the floors in rooms of different sizes - from tiny bathrooms to spacious halls. Especially chic - if the material is laid without noticeable joints. Then it turns out to achieve a monolithic and even coating without the notorious sills at the joints of the canvases, without the heads of the nails noticeable to the eye. It is in this case that you need to know how to properly glue individual linoleum canvases together.

What are the sizes of linoleum

Also, gluing of the material may be necessary if, during careless use, the coating was torn. This can happen as a result of a cut with sharp objects or by carelessly dragging heavy furniture over it.

In this case, the skill of gluing the material can also come in handy.

In the photo - repair with a pencil

Damaged linoleum

The best glue for welding linoleum

A high-quality adhesive is capable of tightly connecting a seam of any complexity. Good cold welding for linoleum should be characterized by a short drying time, high bonding density without the need for additional tools. High quality adhesive can be purchased from the following manufacturers:

- Axton;

- Linocol;

- Sintex;

- Tarkett;

- Homokoll;

- Forbo.

Read on Stellanews: How to remove fungus in a cellar

Type A

Werner muller

Cold welding is suitable for welding new PVC flooring. The consumption of the active substance is 44 grams per 20 meters of the joint. The composition can be used for gluing overlapping sheets. The net weight of the liquid inside the tube is 44 g. The price is 475 rubles.

Main pluses:

- Set quickly.

- Can connect uneven joints.

Minuses:

- Not able to glue the old coating.

Tytan 100 ml

Universal adhesive for cold welding of PVC products.The average consumption of the substance is 100 ml per 45-50 m of the seam. Working time after exposure to air is 10-15 minutes. Drying time - 30 minutes. Full polymerization occurs in a day at 20 ° C. Price - 240 rubles.

Main pluses:

- Versatility. The substance is suitable for working with any PVC products.

- Low price with good quality.

Minuses:

- Small working hours.

Type C

Werner Müller type C

The main purpose of cold welding is loose-cut joints. The compound can glue any PVC coating.

The maximum allowable gap between the sheets to be joined is 3-4 mm.

The cost of one tube is 534 rubles. Volume - 30 ml. The time before hardening after application is 10-15 minutes.

Main pluses:

- Can be bought directly from the manufacturer.

- Fast solidification.

- It softens the leaf well.

Minuses:

- None.

Tarkett Werner Muller type C

A colorless substance can bond loose cut joints in PVC coatings. It has a thick consistency, due to which it fills the seam well, excluding the appearance of air bubbles. Consumption - 42 g per 15 meters. Differs in increased frost resistance. Grabs in 30-35 minutes. Full polymerization - 24 hours after application. Price - 610 rubles.

Main pluses:

- Can be bought directly from the manufacturer.

- Able to quickly glue uneven seams.

- Leaves no residue on top of the coating.

Minuses:

- High toxicity of vapors.

Type T

Tarkett Werner Muller type T

Main pluses:

- The strength of the seam being created.

- Ability to work at temperatures up to 16 ° C.

Minuses:

- Large consumption - 42 grams per 7 meters.

Tarkett cold welding agent Type T

The product can glue the seams of linoleum based on felt, polyester and PVC. The weight of the active ingredient is 45 grams. Consumption - 45 g per 7 meters. Operation at low temperatures (up to 12 ° C) in the open air is possible. The set includes a special T-shaped leveling nozzle.

Main pluses:

- Versatility.

- High-quality bonding of many types of materials.

Minuses:

- High consumption.

- Too thick consistency.

Technology first

Manufacturers delight us with figurative names of technologies. This also happens with Cold Welding technology, also known as Fast Steel, Liquid Nails and others. This is a shaped flow of technology that ensures a strong connection of surfaces when gluing.

Cold welding

If we talk directly about the welding of the same pipes, then we are talking about the deforming effect on the metal, as a result of which new interatomic bonds are established.

There is nothing of the kind in the adhesives offered on the market. The technology is partly repeated by a two-component epoxy resin, which is supplied with a metal powder hardener.

Indeed, the connection turns out to be very strong, and it is this method of gluing that can be found in a number of manufacturers, but not in all.

In relation to linoleum, the principle of gluing is realized most closely to welding. When gluing together, if not interatomic, then molecular bonds are established. Moreover, different brands have it implemented in different ways. The principle consists in joining PVC materials using PVC glue, which is epoxy resin with a hardener.

As a result, for example, if linoleum is glued joint to joint, the distance between the edges fills a material similar to the coating - PVC, which at the molecular level is bound to two separate parts of the material. As a result, such a connection will be inseparable and can be operated indefinitely until the coating itself wears out.

The principle of gluing, PVC with PVC glue, to ensure molecular bonds, is implemented in all the best products for this purpose. We will talk about them.

Dispersion adhesive

Such glue consists of acrylic or cellulose glycolic acid with an admixture of special additives - chalk, latex, and water acts as a solvent. They do not contain hazardous volatile toxic substances, have no strong odor and are suitable for indoor use.

Dispersion glue is mainly presented in 3 varieties:

- Bustilat is a widely used universal adhesive based on chalk, latex and carboxymethyl cellulose. Recommended for linoleum with felt (fleecy) base. It is believed that after using this glue, non-removable stains appear on the PVC coating.

- Acrylic adhesive is made from thermoplastic resins, has a high degree of viscosity and is ideal for domestic heterogeneous and homogeneous floor coverings (fibrous, jute or with a two-layer synthetic base).

- Gumilax is a latex and rubber glue for laying natural linoleums and artificial coatings on a fabric or felt basis.

The main and only disadvantage of dispersion mixtures is complete or partial loss of properties at low temperatures (less than 15 ° C) and high humidity (more than 60%). The frozen and then thawed composition does not recover and loses its elasticity. However, there are also frost-resistant water-dispersion adhesive for linoleum, like Homakol 268 or Forbo 418 (Forbo 418).

Forbo 418 dispersion adhesive for linoleum.

Laying linoleum

After the measurements have been taken, the canvas is cut off at the edges, leaving allowances for fitting. If the wall is flat, they begin to glue the PVC covering close or overlapping, so that later it can be cut.

In the photo: do-it-yourself laying and trimming of linoleum.

When laying linoleum from two strips, they do it perpendicular to the window so that the seam is lost in the direction of the light. Then the floor covering will appear monolithic. Linoleum should be properly docked so that the pattern on one piece matches the image on the other. The second canvas begins to roll out from the overlapping joint to the previously spread one, this subsequently allows you to make an even and neat cut.

Types of welding

Linoleum glue comes in several varieties. On the market, you can find several options for the mixture with different composition and method of use. There are the following types:

- Type A. Sold in liquid form because it contains a lot of solvent. The glue perfectly dissolves the material and binds it. But it is not recommended to use the mixture if there is a gap of more than 2 mm between the parts that are joined. In this case, it will not work to make a strong and stable connection, it will quickly break. But type A allows you to make the seams almost invisible and very neat. The connection is capable of withstanding heavy loads.

This option is suitable for new coverage. The ends are very flat, and the docking is tight.

- Type C. Thick glue, contains a lot of filler. The composition contains a mastic made of waterproof binders, and this allows you to make the connection elastic. This type is suitable for gaps up to 4 mm. Type C is often used both for making docking and for repairing small defects on an old product.

- Type T. It is rarely used. The reason is that it is suitable for multi-piece linoleums made of polyester or PVC. Type T is more suitable for semi-commercial material.

Types of gluing

Now they use two options for gluing:

Cold welding for linoleum.

This is when each part of the coating is laid out in size in its place and glued. Then they press and glue, in all seriousness, to the previous next line in the same way. And so they carry out until they cover the entire floor surface.

In these cases, colorless glue is used, this makes it possible to make the seams invisible.

Hot welding.

Of course, this is not traditional metal welding, but something similar. This method is used as a rule on an industrial scale. During hot welding, heat treatment takes place, the edges of linoleum, it goes at a temperature of four hundred degrees. During processing, a cord is sewn into the middle of the sheet, and due to this, the materials are bonded.As soon as the cord is inserted, the seam is equalized so that it cannot be seen.

Cold welding types

Cold welding for linoleum is done in various types, which stand out for their qualities and method of application.

And so there are three main types:

Cool welding for linoleum type A - has a liquid consistency and contains a solvent in its composition, in a huge amount, it is needed to process the edges.

This glue is not used for gaps larger than 2 millimeters.

The main feature of this material is the creation of a beautiful and invisible connection.

Also, with the help of this glue, a strong and reliable connection is created, but it is not recommended to use it for repairs.

Cool welding for linoleum type C is an adhesive for cold welding of linoleum, it has a huge amount of PVC material, in other words, it contains less solvent.

Due to the fact that the adhesive composition is rich and juicy, it will easily unite gaps larger than 2 millimeters.

Cold welding is used to seal and repair cracks in old pavements. The size of the slots should not be more than four millimeters.

When the glue dries, it leaves a tight, durable seam.

Cool welding for linoleum type T. This type is made for professional use.

This composition is excellent for using linoleums, which are multicomponent and which are made on the basis of PVC and polyester.

After applying the glue, the seam comes out secure and elastic.

A characteristic feature of the following grades is considered to be a low melting point, however, in this version, large indicators are not required, which are found in cold welding for metal.

Criterias of choice

When choosing adhesive for fixing the floor coverage should be considered a number of criteria.

Sub floor type

First of all, you should focus on the type of subfloor. Depending on this, one or another composition is chosen.

Absorbent

This category includes a cement or concrete base. Also, the absorbent coatings include chipboard, fiberboard, OSB, plywood flooring or solid wood. For such substrates, it is recommended to choose a water-soluble composition.

In this case, it is worth considering some features. Board materials are capable of deforming from excess moisture. Therefore, thick compositions with a minimum of water are suitable for them. Any glue will work for concrete.

Non-absorbent

This category includes floors that are tiled with natural stone, tiles or porcelain stoneware. In this case, water-soluble formulations will have no effect, since there is no space for moisture to escape. In such a situation, reaction adhesives are suitable.

When using them, it is important to observe safety rules - to use protective gloves and a mask. Ventilation of the room is of no small importance.

Linoleum can be based on different components. There are homogeneous and heterogeneous compositions. Often the coating is made of PVC. The choice of glue is based on the manufacturer's recommendations. Gummilac is suitable for a foamed coating. It provides excellent adhesion and helps to avoid damage to the coating. For commercial linoleum with a complex composition, you will need a special substance.

Compared composition - Econ and Economy glue

Axton glue

One of the disadvantages of these materials is the high price.

For this reason, we pay attention to the glue for the joints of Econ linoleum, the features and practical experience of gluing can be seen in the video. This is another domestic development that provides high quality seam gluing - Cold welding

The advantage is, of course, the low price. Econ is made on the basis of polymer materials and really provides a tight seam.

An even more profitable option is the glue for the Economy linoleum joints, in this case we are talking about an acrylic base, which can be used without threats of damage in any room except the hallway and living room.Rather, in these rooms, the seams, if glued with Econom, can theoretically come off, but in practice, when using acrylic for gluing, this usually does not happen.