How to apply tile adhesive

The use of glue differs depending on its purpose.

Preparation of the base

The bases, with the exception of heat-resistant glue, are prepared in the same way:

- cleaned of dust, greasy stains, oil paint;

- remove crumbling plaster;

- level the surface with a plaster mixture;

- irregularities up to 10 millimeters are smoothed out with an adhesive on which the tile will lie;

- impregnate porous surfaces with Hercules primer.

Leveling work is performed 72 hours before the start of facing work. The floors are smoothed with a coarse Hercules leveler. The warm floor is pre-heated and cooled. When gluing the cladding to all types of adhesives, except for heat-resistant, the tiles are not wetted.

Before starting laying a stove or fireplace, the base is moistened with water. Clay solid bricks, before glue is applied to them, are immersed in water for 8 minutes, refractory bricks - for 10 seconds. The side parts of the stove, fireplace are cleaned from traces of lime, dust, the seams of the old masonry deepen to 7-8 millimeters. The prepared surface is moistened with water, preventing it from drying out while laying the tiles. Tile tiles are soaked in water for 2-3 minutes before laying, ceramic tiles - for 10 seconds.

Preparation of the solution

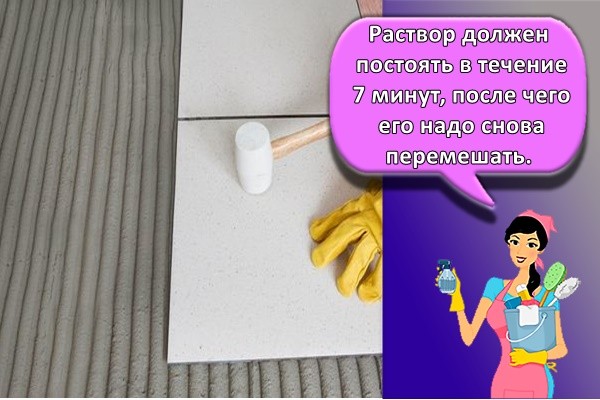

The solution is prepared according to the instructions. The dry mixture is poured into water in the specified proportion and kneaded by hand or with a mechanical mixer until a homogeneous mass is obtained. The solution should stand for 7 minutes, after which it should be mixed again.

Work instructions

A metal notched trowel is used to apply the glue. The thickness of the applied layer depends on the width of the notch. The solution retains its adhesive properties for 10-20 minutes. During this time, you must use it completely. The thickness of the adhesive layer is from 1 to 5 millimeters. The minimum layer is applied when tiling with tiles larger than 40 centimeters, in swimming pools and during outdoor work.

The tiles are laid with a distance of 2-3 millimeters, using signal flags. The veneer can be repaired within 10 minutes. Remove excess glue no later than 30 minutes after starting work. Sealing of seams on wall coverings - after 1-2 days, on floor coverings - after 2-3 days.

When laying the oven, a trowel and jointing are used. The thickness of the joint is 7-10 millimeters. Drying of the oven takes 72 hours, during which it warms up several times. For the first time - no more than an hour, up to a temperature of 100 degrees, in subsequent - with an increase up to 3-5 hours and an increase in temperature up to 300 degrees.

Furnace lining is possible after a month of regular use. The surface is leveled with adhesive using a smooth trowel. The laying scheme is marked. The mortar is applied with a notched trowel, the damp tile is pressed into it and held for 2-3 seconds. Excess glue is removed immediately. The next tile is indented from the first by 4-5 millimeters. Seam sealing - 2 days after the end of the cladding. The first short-term firebox - after 3 days.

Application features

Decorating the stove and fireplace with Hercules tile mortar can only be carried out when the brickwork is completely dry. This requires:

- using a smooth spatula, fill all existing seams and cracks with mortar;

- apply the mixture under the first tile with a notched trowel (the layer thickness will depend on the dimensions and weight of the finishing material);

- apply a wet tile to the mortar and press it in thoroughly;

- remove excess glue on the sides;

- put the subsequent finish in the same way.

After this, the stove or fireplace can be warmed up for the first time. This can be done up to a temperature of 1000 ° C, but only for 1 hour.Further operation, the very next day, can be carried out without any peculiarities.

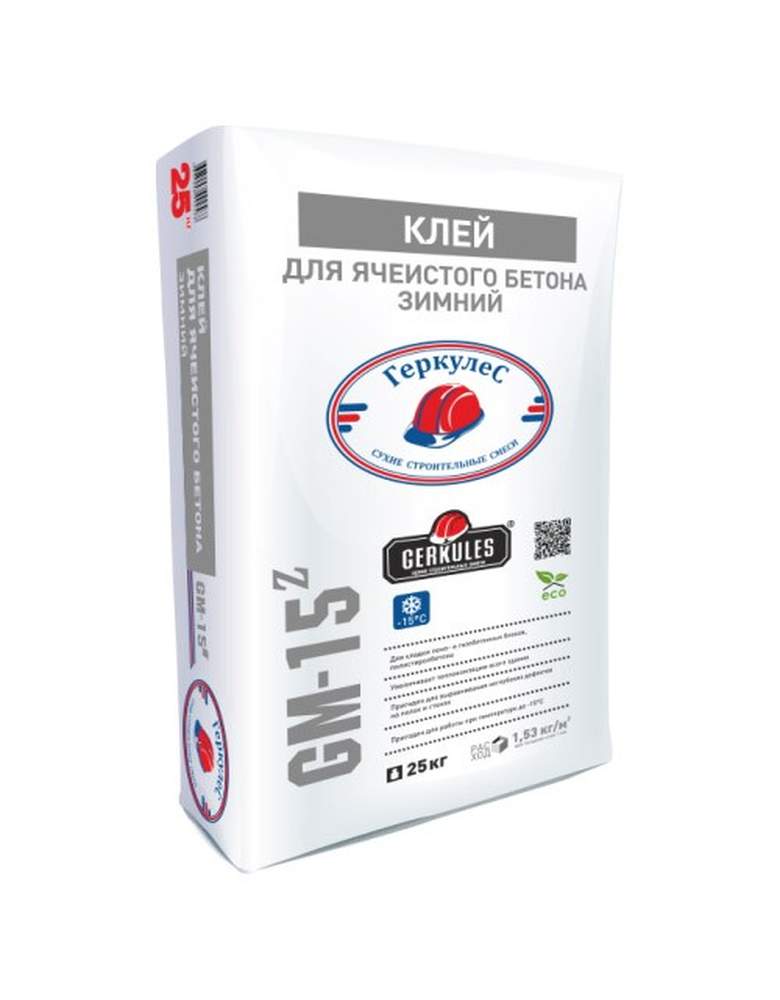

Varieties and specifications

Hercules glue contains:

- cement;

- quartz sand;

- polymer additives.

An astringent suspension is used:

- to cover structural elements of buildings (walls, floors, facades) with protective and decorative building materials;

- smoothing the surfaces of walls and floors;

- brickwork.

The peculiarity of the glue is the ability to use it for interior decoration and exterior facades. Hercules is released in the form of a dry mixture in a paper container. Package weight - 25 kilograms. With a bonding layer thickness of 1 millimeter, 1.5 kilograms of ready-to-use mortar is sufficient for laying 4 square meters of tiles.

The adhesive gives good adhesion to brick, concrete, plastered, wood surfaces. After kneading, plasticity remains for 4 hours. Temperature mode of work performance - + 5 ... + 30 degrees.

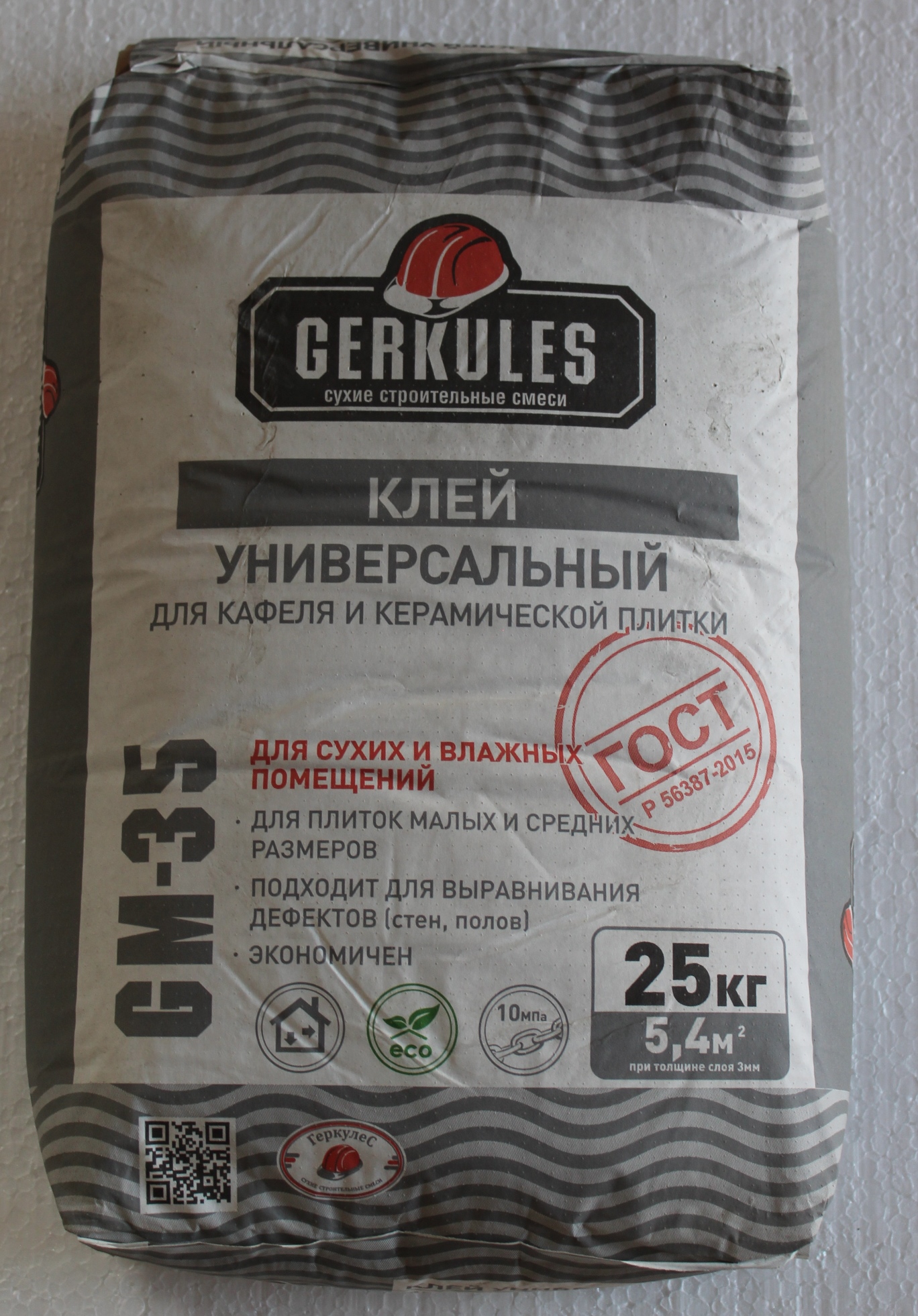

Universal

Construction semifinished product made of cement and sand with polymer inclusions is used mainly for decorating the walls of bathrooms and kitchens with tiles. In addition, the solution is used to correct defects in plastered surfaces, if the difference does not exceed 1 centimeter. High bond strength and moisture resistance allow Hercules to be used on all types of mineral substrates:

- brick;

- aerated concrete;

- concrete;

- plaster.

Applied facing material:

- ceramic;

- tiled;

- porcelain stoneware tiles.

The maximum unit size for a ceramic wall covering is 40x40 centimeters, for a porcelain stoneware floor covering - 30x30 centimeters.

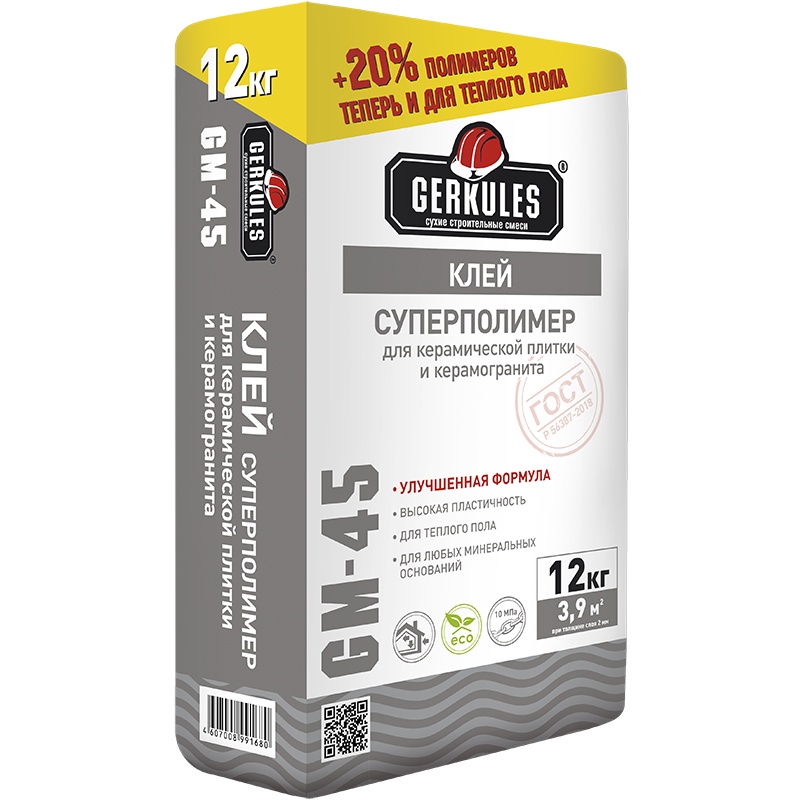

Superpolymer

The adhesive suspension is intended for decorative finishing and protection of buildings inside and outside. Recommended by the manufacturer for brick, concrete, plastered surfaces. The mixture is used when installing underfloor heating with a ceramic, porcelain stoneware coating.

The peculiarity of the glue suspension allows you to lay a porcelain stoneware square with a size of 60x60 centimeters, to correct defects in floors and walls that have differences in height up to 1 centimeter.

Plaster mix

The composition is used for plastering brick, concrete exterior and interior surfaces. The mixture can be applied manually and mechanically.

For tiles

For gluing tiles, the manufacturer recommends Universal Tile Hercules. The adhesive mixture is used for wall and floor cladding.

For porcelain stoneware

The reinforced composition is intended for gluing porcelain stoneware and natural stone tiles:

- marble;

- granite;

- sandstone;

- limestone.

The size of the facing material is from 60 centimeters. The adhesive composition retains its properties under extreme conditions: at temperatures below 0 and high humidity. Application of Hercules glue for porcelain stoneware:

- Living spaces:

- bath;

- kitchen;

- the corridor;

- warm floor.

- Administrative, shopping, entertainment buildings:

- internal;

- outer cladding

On an adhesive basis, you can lay out street paths, a porch.

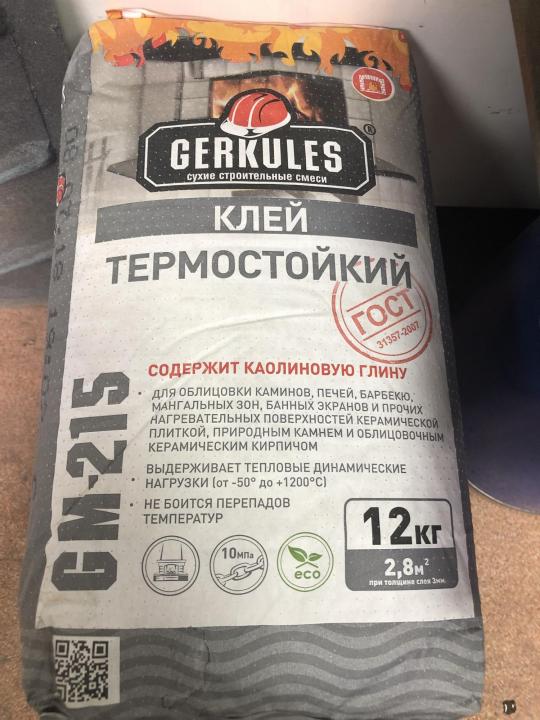

Heat resistant

The adhesive is intended for laying brick stoves, fireplaces and decorating them with ceramic tiles. The properties of the solution are maintained for an hour. For laying 50 bricks, 25 kilograms of mortar will be needed, for facing 1 square meter with a layer thickness of 5 millimeters - 7.5 kilograms.

For mosaic

For laying out mosaic panels from ceramic, glass tiles, a dry mixture of Hercules white is intended. Foundations for cladding:

- cement plaster;

- drywall;

- concrete;

- concrete waterproofing.

Adhesive application: wall, floor coverings, swimming pools.

Preparation of the base

There is a lot of information on how to lay tiles or porcelain stoneware using tile glue. But what is the correct way to use the Hercules superpolymer solution for laying the stove and fireplace? We will talk about this further.To begin with, of course, you need to prepare the base. First of all, you need to moisten the floor with water before laying the first row of bricks. The same must be done with the bricks themselves.

If the brickwork has already existed, it must be cleaned of unnecessary plaster, dirt and dust, grease stains and any other unnecessary defects. The seams between the bricks must be cleaned and abundantly moistened with water. Before proceeding to the use of Hercules universal tile solution, the tile is immersed in water for a few minutes, and the ceramic tile - for a few seconds.

Outcomes

So, for facing the floor and walls, tile is very widely used, which can be of several types. It can be stated that the success of its installation depends more than 50% on the selected adhesive. That is why there is a need for careful selection of glue.

If you clearly understand the range of tasks to be solved, then it will not be difficult to choose tile glue. Moreover, there are enough manufacturers on the construction market offering mixtures for various surfaces for tiles. After analyzing all the moments you have, you will certainly make the right decision.