How to use correctly

It is recommended to glue the coating after preparation of the base. To do this, its surface should be cleaned of the remnants of the old finish. If necessary, it is recommended to level the wall and remove visible damage. After that, the surface should be carefully primed. It should be borne in mind that a completely dried coating is covered with glue.

To carry out the procedure, you should do the following:

- It is recommended to start gluing from the corners. This will help eliminate differences between the rows.

- The glue should be applied in small portions to glue 4 squares.

- It is recommended to apply the solution to the tiles themselves. This will help to achieve a stronger hold.

- The plaster cladding should be applied to the base and pressed by hand. Then, if necessary, correct its position.

What varieties are there

Almost all types of assembly glue are made on a dry basis. It usually has a white tint. Sometimes gray mixtures are found. This variety is considered the most successful. Additional components are often added to the gypsum to improve adhesion. They help to improve the composition of the product. Another type of mixture is glue with quartz. This component helps to reduce the cost of the composition. Well-known manufacturers practically do not use this substance.

The properties of gypsum glue vary depending on the number of additional components. The main function of the substance is considered to help in the installation of various structures. Thanks to its use, it is possible to achieve reliable adhesion of the working composition to the treated surface.

The amount of water indicated in the instructions will help determine the level of adhesion. If 0.3 liters of water is required per 1 kilogram of glue, you should be sure that there is not as much gypsum in the substance as there are other components. This means that the adhesive characteristics of such a substance are not very high. As a result, the material may delaminate at the initial stage.

Terms of use

In order for the flooring to last more than 30 years, it is necessary to strictly follow the installation technology. There are no universal rules, since each type of floor has its own nuances.

On a concrete floor

The entire surface must be stripped down to clean concrete before installation. The final layer is cleaned and sanded, potholes, cracks are putty.

Be sure to seal the joints between the wall and the floor. Small gaps are sealed with concrete mortar, large ones - with sealant or polyurethane foam.

Bonding points are degreased. Glue is applied to the concrete pavement. Linoleum is glued to the oiled area. The surfaces are firmly squeezed together and cured until dry. The complete gluing process takes an average of 24 hours.

On a wooden floor

The composition of the glue must be evenly distributed with a spatula. First, it is applied to a wooden base, and then to linoleum. The surfaces are glued together.

Before gluing the linoleum end-to-end, a tape of glue is applied to the seam. Scotch tape is cut at the seam and the glue is squeezed out into the gap. After 10–20 minutes, the fastening material is removed.

You can also resort to cold welding (a sealant that is designed to secure the edge). It can be colorless or colored.

Dispersive

It is an adhesive in the form of finely ground polymers in a liquid that can be used immediately after opening the package.

The main component of the substance is water. It is combined with various additives such as:

- Acrylic, paint;

- Cellulosic acids;

- Chalk;

- Resin.

The composition has become widespread due to the following technical characteristics:

- High operating temperature - up to +15 degrees Celsius.

- Can be used for heated floors.

- 100% guarantees safety for humans.

- Increased level of adhesion.

- Durability and resistance to heavy loads.

Common types:

| Representative | Composition | Where is applied |

| Bustilat | Latex, chalk, carbomethylcellulose | For gluing felt-based linoleums. |

| Humilax | Rubber, latex | For covering from felt, synthetics. |

| Acrylate | Thermoplastic resin | For surfaces with a homogeneous coating. |

Basic requirements for the adhesive

In some rooms, the floor surface is covered with carpet. This carpet needs to be fixed well so that it does not pile up or deform. You can glue the carpet to the floor using double-sided tape. True, much better adhesion to the surface will be provided by the glue. With the help of such a substance, you can lay the track on steep steps or on slippery surfaces.

> For carpet, choose a glue that will dry for one hour. This time is enough to eliminate errors or remove defects that have appeared. A product that dries and hardens quickly is not suitable for gluing. In a short time, the track will not have time to attach to the floor.

In this case, it will saturate the carpet and penetrate the front surface, leaving stains. The main requirements for carpet glue are: drying speed (not less than an hour), simplicity and ease of use, excellent adhesion to any surface, the coating must remain elastic after hardening.

Varieties

There are several types of glue that can be used to securely fix the carpet to the floor. Each product has its own strengths and weaknesses.

Dispersive

Dispersion types include PVA glue and acrylic-based products similar in composition. PVA has no unpleasant odor, toxic additives. It is easy to use, the substance dries quickly and adheres well to surfaces. The consumption of such a composition is 0.5 kg per 1 square meter of area.

Dispersion glue based on PVA has a significant drawback - a decrease in properties at high humidity. Consumption is 0.3-0.5 kg per 1 square meter of area. Acrylic-based glue is more expensive than PVA. But such a product is more resistant to moisture, provides better adhesion, and is more elastic.

Velcro

Velcro adhesive provides good adhesion to any surface. The application of this composition allows at any time to tear the flooring off the floor, and then reuse it. This substance dries up in 25 minutes. With Velcro, the carpet can be fixed to any surface. The substance is resistant to moisture, but, if necessary, can be washed off with soapy water.

Velcro does not contain toxic additives, does not burn, is not afraid of temperature extremes. The most famous adhesive is KIILTO GRIP.

Two-component

There are special two-component polyurethane-based adhesives on the market. The hardener is not included in the adhesive, it is sold as a kit. The components are mixed before use. The solidification of such a substance occurs within one hour due to chemical reactions that take place between its components. Moisture does not affect adhesion.

Brand advantages and disadvantages

The advantages of the company's products include the following:

- variety of products - they can be applied in different ways;

- no shrinkage after drying;

- moisture resistance;

- no bubbles;

- resistance to high temperatures - some types of products can be used for heated floors;

- resistance to the action of chemical elements;

- elasticity after hardening;

- excellent adhesion to different materials;

- resistance to ultraviolet radiation and weather factors;

- lack of solvents in substances;

- fast solidification - taking into account the composition, this takes from half an hour to 2-4 hours, while it takes a day for absolute drying;

- lack of a pronounced smell;

- different shades of sealants - there are also colorless substances on sale;

- convenient attachments included or easy distribution with a spatula or brush;

- the presence in the assortment of compositions for wood - such substances help to avoid deformation of the material;

- high strength - the removal of adhesive or sealant is carried out exclusively mechanically;

- the possibility of heat and sound insulation of the room;

- economical consumption and durable results;

- ease of application of wallpaper compositions - there is no need to eliminate smudges.

The disadvantages of Bostic adhesives include the following:

- high cost of products in comparison with competitors;

- the risk of allergic reactions - some formulations can cause such symptoms due to the presence of aminosilane in the composition;

- the fire hazard of Vinikola;

- the risk of changing the shade of the material - this is observed in extreme conditions.

Recommendations for selection and use

Experts recommend buying the adhesive with or after the floor covering to ensure that the adhesive will work. It is better to buy glue for linoleum in hardware stores or large supermarkets, where conditions for its storage are created.

When choosing, it is important to pay attention to the type of finishing surface:

- Moisture-proof backing, old material - universal, silicone.

- Concrete is water-soluble.

- Wooden floor - homogeneous compounds, PVA.

- Chipboard - products based on water.

- Floors faced with stone, porcelain stoneware - reaction adhesives, moment.

- Plywood, wood coating - dispersion composition.

- Slab surface - mixes with a low water content.

If the surface under the linoleum is uneven, the situation can be corrected with fiberboard plates, which create a solid base. The material absorbs moisture, so you cannot use water-based glue under it.

In order for the linoleum to adapt to the room temperature and lie down better, it is left on a roll for several days in the room where it is planned to be glued.

Then the linoleum is rolled out and left for several days so that it takes the right size.

If you are planning to temporarily lay linoleum on a concrete floor and later replace it with a more expensive material, liquid nails are a good option. Having glued the material to liquid nails, you can then remove it without damage. For temporary installation on a wooden surface, double-sided adhesive tape is suitable.

Place a cloth under the tube while working with the reactive adhesive.

If glue gets on the floor, wait for it to dry and carefully cut it off with a knife. In any case, even after cutting, a small stain will remain

It is impossible to apply the material in a thick layer. The surface will not stick better from this, but the excess will appear as bumps.

Recommended brands

There are many options for gypsum glue, each of which has certain characteristics.

Plusfix

This glue in powder form is made on the basis of sand and cement. It also contains cellulose. The substance is used to fix small decorative bricks. They can also fix tiles with a maximum size of 25x25 centimeters.

Litokol X11

This tool is made from cement with the addition of sand. The glue allows the use of solid tiles. The composition is well suited for gypsum.

Perlfix

It is a popular formulation that is economical. The undoubted advantage of the substance is its environmental friendliness.

Gypsum

This powder sets easily. During work, it can be easily removed from the surface using ordinary water.

Litoacryl Plus

The tool is produced in the form of a paste, which has an acrylic base. The substance is resistant to water and is considered universal. The product is suitable for finishing vertical surfaces. It does not run off and dries quickly.

Casco Extreme Fix

The agent is released in the form of a liquid emulsion.It is convenient to apply to hard-to-reach places. The adhesive composition quickly sets.

Litoflor K 66

The composition is suitable for work outside and inside. It is permissible to use it at negative temperatures and in conditions of high humidity. The composition is allowed to be used even for uneven textures. In any case, it provides reliable adhesion.

Titebond Multi

It is a versatile adhesive that is used for indoor and outdoor use. The substance solidifies within half an hour. It easily fixes metal, concrete, plaster. Also, using the tool, it is permissible to fix tiles and other materials. The substance is harmless to humans and hardens easily. It is resistant to negative temperatures.

Moment Universal

This is a domestic composition that has a wide range of applications. The product hardens rather quickly - within 15-30 minutes. It is characterized by high strength. The glue is capable of withstanding a load of 40 kilograms per meter.

The composition is economical and highly elastic. It can be used for uneven surfaces. The substance is resistant to moisture and temperature fluctuations. In this case, the product includes toxic substances and has a pungent odor.

Stayer 41334

This is a high-quality German glue that has a wide range of applications. The composition is characterized by excellent strength and hardens in a quarter of an hour. It is characterized by low consumption and an affordable price. At the same time, the composition is considered to be of high quality, but it is afraid of water.

Titanium Ceramic

This is an environmentally friendly composition that has a dispersion structure and does not include organic solvents. The use of the substance provides fast setting - it occurs within 5 seconds. In addition to ceramics, the composition is suitable for gypsum surfaces, wood, stone, PVC. It is allowed to paint the substance after drying. The key disadvantage is the lack of plasticity.

Kraftool KN-901

The composition is highly resistant to temperature fluctuations. It is used for problematic coatings. The substance is characterized by super strong adhesion.

General rules of application

Bostic adhesives can be used in different areas. Each of the varieties has certain characteristics.

Vinicol

To use this type of glue, you should follow these steps:

Apply the composition to both surfaces to be bonded. Let the first coat dry for 10 minutes.

Apply a second coat

It is recommended to dry it for a maximum of a quarter of an hour.

Fold the parts to be glued carefully. It is forbidden to move them

It is important to ensure that no air enters the seam.

Compress elements strongly

For this it is worth using additional tools.

Sealant

To apply a sealant, it is worth doing the following:

Squeeze the contents of the bottle onto the prepared parts of the seam.

It is important to fill the joints evenly, avoiding air getting into them.

Smooth the surface with a damp trowel.

Remove the adhesive tape around the edges of the seam.

Tarbicol

To use Tarbicol adhesives, you should do the following:

- Apply with a roller or notched trowel. One or both surfaces should be treated.

- Lay the boards in strips. Their width should be 1 meter. First you need to glue the first strip and fit the boards with a wooden mallet. After that, the next strip should be laid.

- It is imperative to make a temperature gap. Its size should be 7 millimeters. Then the gap will be covered with a skirting board.

- The glue can be open for 10-20 minutes.

- It is permissible to use parquet in a day.

- Grinding is performed only after a week.

For fiberglass

To use such glue, you should do the following:

Apply adhesive to the wall with a roller

This should be done in an even layer.

Wallpaper should be applied on a sticky base.

It is important to ensure that the adhesive does not penetrate the coating.

You can paint the wallpaper in a day.

Improvised means

Non-standard means that are not intended for this help to fix the gypsum tile. This option is used for short-term use of the coating.

Putty

It is recommended to use a leveling filler to fix the cladding. It should be applied on suitable substrates. These include stone, brick, plasterboard sheets. It is also permissible to use the substance for concrete and plastered surfaces. It is worth mixing the solution in the usual way, and apply 1 centimeter thick using a spatula.

Alabaster

The use of alabaster allows you to point tiles to plaster. It also provides anchoring to concrete or masonry. First, the composition should be mixed with water to get a thick and sticky mass. It is recommended to apply the substance on a primed surface. For this, a latex solution is used.

Main varieties

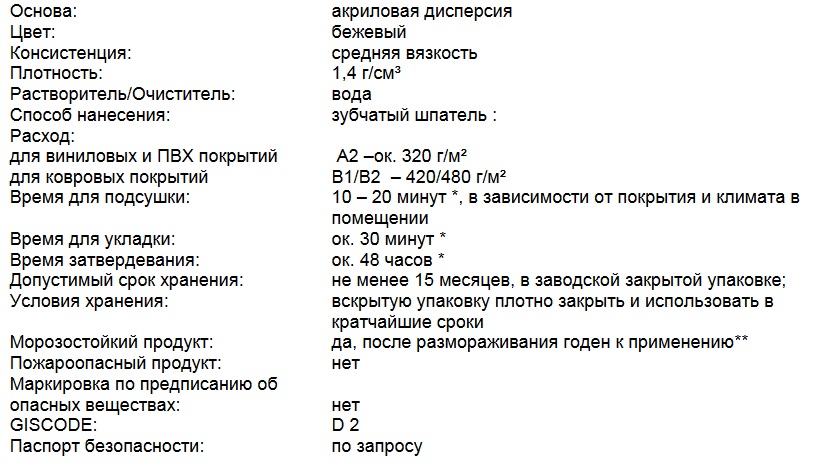

There are two main types of Forbo glue:

- reactionary;

- acrylic.

The first one is a mixture of polyurethane and epoxy mortar. When applied, a reaction takes place, as a result of which a very strong connection of materials is obtained that can withstand heavy loads. It should be noted that the surfaces must be cleaned and degreased before applying the reactive adhesive. Acrylic solutions are based on water. They are practically harmless, do not have an unpleasant odor, and are also very easy to use.

Consider the main Forbo formulations, as well as their technical characteristics:

- 140 - withstands heavy loads at optimal consumption, is used for gluing linoleum, polyvinyl chloride, chipboard, ceramics and laminate;

- 144 - universal, withstands heavy loads, used for gluing cork, parquet and polyvinyl chloride;

- 425 - used for gluing textiles to substrates that absorb moisture, due to special technical characteristics, the work takes no more than 15 minutes;

- 522 - high quality, used for gluing products made of polyvinyl chloride and vinyl;

- 523 - conductive acrylic, does not contain solvents, used for gluing linoleum and carpet;

- 525 - acrylic, has a low consumption, is used for gluing textiles, vinyl and polyvinyl chloride, including on substrates that absorb moisture;

- 528 - Strong, mainly used for gluing linoleum and textiles;

- 541 - acrylic, frost-resistant, used mainly for gluing carpets on both absorbent and non-absorbent substrates;

- 578 - frost-resistant, solvent-free, used for gluing textiles and vinyl;

- 643 - universal, does not contain solvents, can be used not only on the floor, but also on walls and ceilings;

- 628 - strong, moisture resistant, quick-setting, used for gluing PVC products on absorbent substrates;

- 650 is a strong acrylic used for bonding cork, PVC, rubber and carpet surfaces.