General rules and principles of use

The strength of the tile bond to the oven surface depends on:

- cleaning surfaces from dust and dirt;

- alignment of existing defects;

- thorough mixing of adhesive components;

- tight connection of surfaces after applying KS glue;

- waiting for the product to dry completely.

When laying stoves and fireplaces, the paste should be applied to both surfaces. After 3 hours, the parts will connect, and fully attach after 72 hours. Usually 600-800 grams of glue are spent on 1 square meter of surfaces. Installation of linoleum is carried out by first applying a thin layer, and after 10 minutes - a layer 10 millimeters thick. Smooth out the coating with a roller, removing excess funds.

If the cladding is made outside the house, then the air temperature for work is chosen at least 5 degrees Celsius. The adhesive should be applied correctly on the surface with a spatula. In this case, the thickness of the applied composition should be in the range of 4-8 millimeters. It is best to have an intermittent bead of adhesive on the tile. Then air jams will not form.

If the surface is made of mineral wool, then the surface should be primed with a thin layer of KS glue paste. During work and during the drying period of the glue, it is necessary that there is no exposure to direct sunlight, precipitation.

When working with KS glue, you should not forget about protecting your hands. The alkali in the paste can corrode the skin if it gets on it. If the substance has damaged the skin or mucous membranes, wash your hands under running water and soap. It is advised to wear a working coat, gloves, glasses before repairing. Dangerous if glue gets in your eyes. Here you need to quickly react and rinse the mucous membranes of the eyes with clean water.

Characteristics of VS-10t glue

It is a mixture of two resinous types - phenol-formaldehyde and ethylal. The solvent for the resins is a mixture of ethanol and ethyl acetate with small additions of urotropine, quinoline and tetraethoxylane.

The absence of water in the composition makes such an adhesive bond invulnerable to moisture and even in conditions of direct contact with water. When solidified, the organic solvent simply evaporates, and the resin polymerizes, forming extremely strong seams, insensitive to both moisture and temperature

The last property is especially important: the BC-10t adhesive for brake pads must tolerate heat by default. Produced in sealed packaging

The appearance of the glue

Its physical and chemical characteristics are regulated by GOST 22345-77.

Appearance - according to the requirements of GOST 22345-77, it is a homogeneous liquid, transparent, having a color from light yellow to brown.

Viscosity according to VZH-1s is 50–80. Viscosity according to VZ-246 - 35–70.

The dry residue is 20-25%.

Tensile strength varies with temperature:

with a shift of the adhesive joint of steel grade 30HGSA at 20 C - not less than 195 kgf / sq. cm;

at 200C - not less than 75 kgf / sq cm;

at 300 C - 45 kgf / sq. cm.

In general, the operating temperature range is from -60 to +300 C.

The glue is resistant to the action of many aggressive media - acetone, alcohol-gasoline mixtures, sea water, mold fungi, so it can be used not only for repairing brake pads.

The bond strength is maintained for 200 hours at a temperature of 200 C and 5 hours at 300 C.

According to GOST 22345-77, the glue has a fairly good fluidity and can be used at low pressures.

The product has few analogues. The direct analogue is BC350 T glue. Its packaging is the same.

Pads

Instructions for use

Despite the universal properties of this product and its ease of use, it is necessary to use Dragon glue strictly following the manufacturer's instructions. Before starting work, the composition must be mixed with denatured alcohol. The latter is recommended to be taken from the same manufacturer that released Dragon. It is necessary to mix both compositions until a homogeneous solution is obtained.

Prepare the surface before applying the glue. To do this, you need to remove from the processed materials:

- plaster;

- paint;

- varnish and other particles.

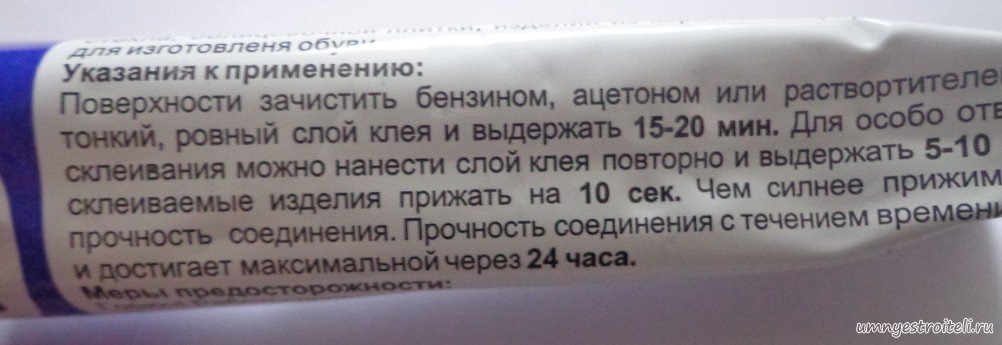

If possible, it is recommended to level the surface, removing all defects and roughness. Also, before starting work, materials should be degreased. To do this, use gasoline or pure alcohol. Finally, you need to dry the surface. Due to moisture, the glue dries longer, and the connection is less strong. Then Dragon can be applied to the prepared surface. If rough or uneven substrates are processed with this composition, then the procedure will have to be repeated one or more times.

General requirements

The composition of the shoe glue is very specific.

This is due to the fact that when gluing boots and shoes, it is important to fulfill a number of prerequisites

- Connection strength - when walking, and even more so when running, the load on different parts of the boot is very different and is constantly changing. Accordingly, the strength of the seam should be very good.

- On the other hand, the seam must remain flexible, otherwise it will constitute an extreme inconvenience or even make the product impossible to use.

- Repairs should not be visible. So the adhesive must be either colorless or exactly the same color as the boot.

- The seam must be waterproof as the shoes are exposed to moisture.

Only some types of products satisfy all these requirements: SAR-306 polyurethane glue, for example, Sar-30 E and the like.

The main features of the substance

Fast curing epoxy adhesives cure quickly after adding a hardener to the base composition. The hardened mass has the following qualities:

- frost resistance (the mass can easily withstand temperatures up to -20⁰С);

- heat resistance (temperature limit at which the glue keeps gluing: up to + 250⁰С);

- good ductility and elasticity, which provides a high level of bond strength;

- resistance to aggressive media (acids, alkalis, oils, petroleum products, household chemicals);

- low shrinkage;

- water-repellent properties and high waterproofing performance;

- excellent interaction with almost all materials.

But you should be aware of some of the disadvantages of such glue. For example, not all surfaces lend themselves to gluing - epoxy cannot connect Teflon, silicone and polyethylene. Take into account the accelerated polymerization time, therefore, if there are blemishes during gluing, it will be very difficult to remove them later.

Adhesive does not work with all materials

Where is used

Due to its high technical qualities, versatility, epoxy glue is actively used in various branches of modern industry. Namely:

- in construction, to connect reinforced concrete structures, panels, cracks and potholes in concrete are filled with glue, with its help, tiles are laid;

- shipbuilding uses an adhesive substance for the installation and assembly of ship parts made of fiberglass, plastic and metal, the substance is also used to improve the waterproofing qualities of materials;

- aviation (design), used for gluing various parts, manufacturing and installing batteries, additional fixation for thermal protection;

- mechanical engineering uses epoxy glue for mounting accessories, fastening brake pads and various parts when assembling machines, for carrying out various repairs.

Varieties of glue

Experts distinguish two large groups of epoxy adhesive. It:

- Liquid. Packaged in tubes. This form of release is convenient and easy to use.

- Plastic bars. Its consistency is similar to plasticine or dough. Also available in tube packaging. After squeezing out, the mass is slightly moistened with water and softened by hand.

Various modified formulations can also be found on the market. The temperature regime of polymerization of such modifications ranges from + 60–120⁰С.These adhesives are used for bonding various materials that are resistant to solvents, petrochemicals and oils.

In household, home use, several brands of epoxy glue are common. They are recognizable and familiar to almost everyone:

- universal glue Moment;

- Contact designed for sealing pipes, repairing plumbing;

- cold welding glue is used for gluing metal products.

Is epoxy glue harmful to health

When working with an epoxy-based adhesive, you should be aware that it is a health hazard. When working with her, it becomes mandatory to use personal protective equipment: gloves, a respirator mask and glasses. If the glue mass enters the stomach, a person runs the risk of serious poisoning, and contact with the skin leads to the development of allergic reactions.

Review of effective brands

Such formulations are most often used.

"Eltitans"

Eltitans universal adhesive does not contain methanol, does not lose its adhesive properties at subzero temperatures, it is used for cladding walls and facades, installing ceiling tiles. When gluing "Eltitance" forms a strong layer, does not turn yellow, but it takes about 40 minutes for the composition to solidify. The thickened substance is diluted with ethyl alcohol.

"Titanium"

In the 90s, Titan transparent glue was released to join the expanded polystyrene tiles with plastic, glass, and metal coatings. When applied to a surface, the composition forms a layer 3-4 mm thick. It dries in 60 minutes, but it takes another 23 hours for the joint to become strong.

"Master"

Inexpensive colorless glue for fixing ceiling panels and skirting boards takes a long time to cure, not everyone can tolerate its specific smell, but it is applied to the surface pointwise, which significantly reduces consumption.

"Moment"

It sets quickly, provides a very strong connection between the surface and the tile, there is no smell of the universal Moment glue. It contains thickeners, and the product does not spread, a very strong seam is obtained.

"Format"

The tool used for fixing ceramics, wood, polystyrene tiles does not burn, does not contain harmful substances. When applying Format glue to a cleaned coating:

- No traces remain.

- The seam does not flake off.

- The composition quickly sets and dries.

The surfaces to be joined are pressed for half a minute. Glue is used even at -10 and temperatures exceeding 30 ° C.

"Bustilat"

A substance of artificial origin has high adhesion, is indispensable in the decoration of walls, ceilings, and holds various materials together. "Bustilat", which is produced by several Russian companies, in addition to latex, contains chalk, preservatives, carboxyl methyl cellulose. When a viscous mass is applied to concrete, wood, plaster, a strong elastic seam is formed. Finally, the product dries up in a day, does not turn yellow, and remains transparent.

Safety measures

When working with a line of epoxy adhesives, you should not only carefully adhere to the attached instructions, but also observe safety measures. Given the harmfulness of the substance, it is imperative to adhere to these rules. They are as follows:

- Do not allow the resin to come into contact with unprotected skin on the hand. In addition to serious allergic reactions, the contact of glue on the skin, given the speed of polymerization, brings painful sensations. If the resin comes into contact with the skin, wash it off immediately with soapy water.

- For protection from dust and harmful toxic fumes, use a respirator mask with a charcoal filter.

- All work with glue is carried out in a well-ventilated area.

- Use rubber gloves when mixing resin with hardener.

- Do not mix resinous substances in a container that will later be used for food or food storage.

- If the paste or glue is difficult to squeeze out of the tube, the tube can be slightly warmed up under hot running water. Do not use a water bath, microwave oven or ovens for this purpose, otherwise the resin will boil and become unusable.

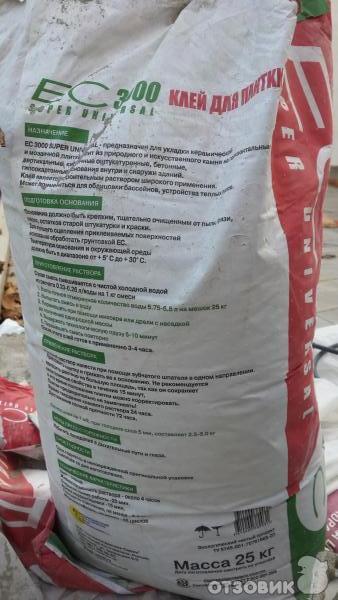

Preparation of the solution

To properly prepare the adhesive, you should accurately measure the amount of water. For 25 kg of glue powder, you will need from 5.75 to 6.75 liters of water, depending on the desired density. The product is poured into water, which is poured into a large container, mixed using a drill with a nozzle, a construction mixer. The glue is ready, as soon as the mass becomes homogeneous, it will not contain lumps. After readiness, it takes another 10 minutes to infuse the product and swell the particles. Within 4 hours, the mass must be used.

Working with glue

The product is applied with a special notched trowel. You should not immediately apply glue to large areas of walls or floors - you need to glue the tiles in 15 minutes, so you should measure your capabilities. Boards must be dry before gluing, they are not wetted. The procedure is as follows:

- attach the tile to the base;

- press it well with your hands;

- you can change the position within 20 minutes;

- immediately after joining adjacent tiles, the tile joint should be cleaned

- the final filling of the joints is done after the completion of work with the tiles, and you need to wait for complete drying (16-24 hours);

- if the floor is pasted over with material, it can be put into operation only in a day, but gentle loads must be observed for another 3 days.

Safety engineering

There is cement in the powder, therefore, when mixed with water, the reaction of the mass will be alkaline. If it comes into contact with open skin areas, irritation occurs, this should not be allowed. If the solution splashes into the eyes, rinse them without delay, then consult a doctor.

General description and purpose

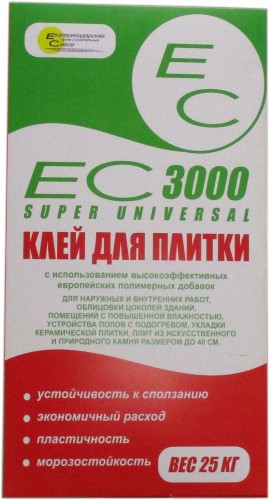

The adhesive is an improved version of the EC 2000 from the range of indoor cladding products. Due to its increased resistance to moisture, the new environmentally friendly modification is suitable for external wall cladding.

EC 3000 glue is used for laying ceramic mosaics, tiles, porcelain stoneware, artificial and natural stone slabs. Cement-based tiles adhere well to horizontal and vertical surfaces. The glue can be used to decorate floors and walls, both at home in the bathroom, in the kitchen, and in non-residential areas: the lobby of an office building, recreational floors, in the pool.

Areas of application of the EC 3000:

- fixing medium and small stone slabs;

- floor insulation;

- leveling surfaces with a slight difference in height;

- sealing of seams between plates.

The adhesive firmly holds stone slabs, moderately absorbing moisture - up to 1%.

Specifications

Polymer glue is a colorless liquid with a uniform texture and characteristic odor. The material is based on high quality synthetic resin diluted with organic compounds.

Due to this composition, Dragon glue has the following characteristics:

- elastic;

- creates a strong seam;

- incombustible;

- moisture resistant;

- suitable for use over a wide temperature range.

Due to its increased elasticity, Dragon is able to adhere materials even to an uneven (rough) surface. This material is used in bathrooms and kitchens. When working with universal polymer glue, it is recommended to heat the created seam. This effect increases the strength of the hitch. During cold weather, the properties of the glue do not change after hardening. However, for the material to dry completely, the ambient temperature must be greater than zero degrees. In this case, the glue creates a reliable bond within 15-20 minutes.

The consumption of glue varies within a fairly wide range.The processing of one square meter may require from 10 to 500 grams of polymer material. This indicator directly depends on the type of surface on which the composition is applied. The maximum amount of glue is consumed when objects with a rough surface are connected.

How to properly install tiles on the ceiling

You can glue panels on a smooth surface using PVA. Acrylic putty masks irregularities, firmly connects thin tiles, does not leave shrinkage. For laying the ceiling covering, different methods are used, the installation technology of which is not difficult.

Styrofoam

Panels made of this material are fixed in the bedroom and living room, in the kitchen and hallway. Both rectangular and square polystyrene foam plates are suitable for finishing the ceiling. Installation begins with surface preparation, then the coating is treated with a primer. After marking, the main work is done. Plates are usually laid parallel, if the walls are too uneven, they are placed diagonally:

- A string is pulled between the corners of the ceiling.

- Having found the central point, fix the panel so that its sides coincide with the lines on the marking.

- The next tile is laid from the formed axes.

- At the joints with the ceiling, polystyrene foam is cut.

After completing the installation of the panels, the skirting boards are glued around the perimeter. If necessary, the finishing material is painted in the selected color.

Whitewash

The slabs adhere tightly to the lime-based coating. To install them, you can treat the surface with a primer, and after drying, connect it to the panels. If the whitewash on the ceiling does not hold well, the falling off pieces are removed, and foam tiles are glued.

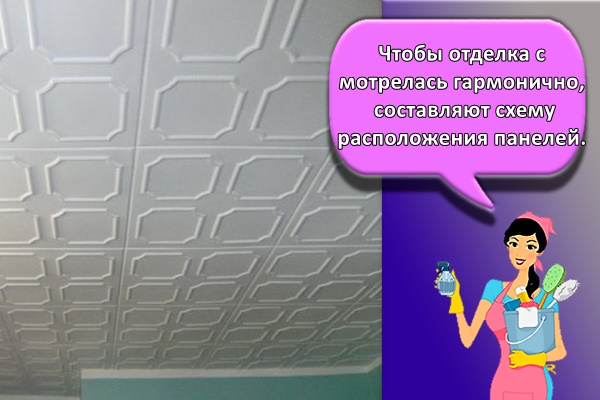

Seamless

To make the finish look harmonious, they make up the layout of the panels. One day before the start of installation, the seamless foam tile is taken out of the box and left on the floor. This helps to avoid deformation during installation. Glue is applied to the back of the product - the center and edges. The liquid composition does not set immediately

The first panel must be aligned along the marking lines and pressed gently. Laying three more tiles without seams results in a square

If there are gaps for masking between the panels, they are covered with acrylic sealant. Elements that are mounted at the very walls are cut under the ruler with a clerical knife.

Laminated

With the help of special machines and presses, tiles are produced that do not collect dust, do not accumulate moisture, and do not turn yellow in the air. Laminated products have all kinds of patterns, colors, differ in relief, and are suitable even for rooms with excessive humidity.

Fix the laminated tiles;

- to chipboard;

- to plywood;

- to the brick;

- to drywall;

- plaster.

There should be no paint or whitewash on the surface on which the panels are glued. The laminated product can be cleaned with a vacuum cleaner, wiped with a damp sponge.

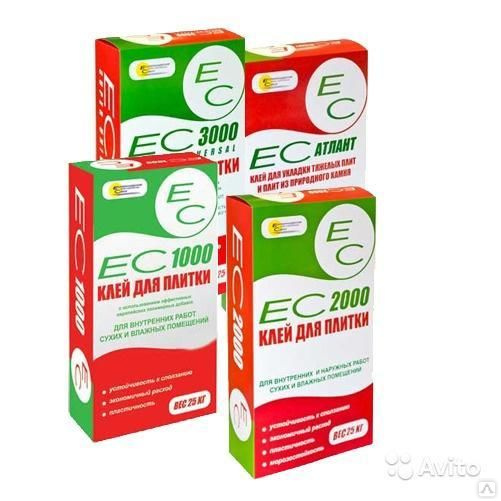

EK glue types

EK 3000 tile adhesive is available in several varieties. If there is no opportunity to purchase targeted funds, they can be replaced with the universal glue described above.

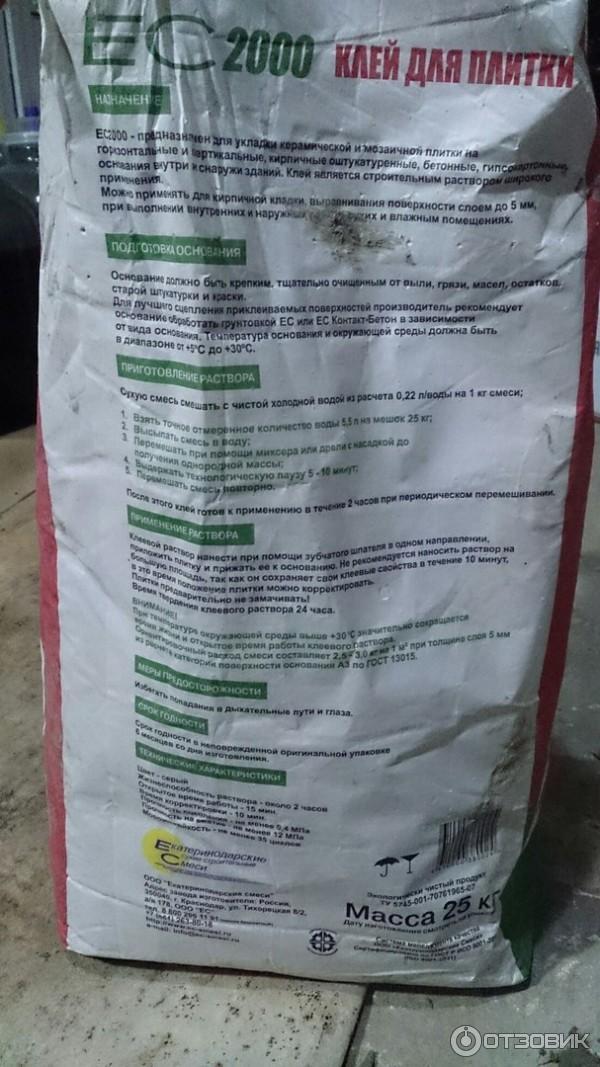

EK 2000 KERAMIK

EK 2000 glue is used directly for bonding medium, small size ceramic tiles on various surfaces. Concrete, brick, mineral materials, plastered surfaces are suitable as a base. The tool is used for external and internal work, with its help you can hide small defects in the base (grooves, cracks). The material has a high adhesion rate (0.7 MPa), but it is lower than that of universal glue. The product is frost-resistant, plastic, the glue powder has small fractions (up to 0.63 mm). The position of the tiles can be adjusted in 10 minutes, the pot life of the ready-made mortar is 3 hours.

EK TITAN 4000

It is a product for porcelain stoneware, heavy slabs.EK 4000 glue is suitable for gluing artificial stone, natural stone, slabs with any water absorption on vertical and horizontal surfaces. The latter can be from any material. Also, the tool can be used to stick plates of expanded polystyrene, mineral wool, it is permissible to fill tile joints with it. The adhesion index is high - 1.2 MPa.

EK 1000 WIDE

EK 1000 glue is a thick-layer composition for laying tiles and blocks. The product can also be used on all surfaces located vertically and horizontally. With its help, blocks, slabs of aerated concrete, aerated concrete, foam concrete, and other porous materials are mounted. On gypsum panels, gypsum concrete, this composition is not used.

EK 6000 MOZAIK

Mosaic adhesive EK 6000 is intended for gluing marble tiles, mosaic tiles, any transparent materials, porcelain stoneware. The type of water absorption of the material is unimportant. This tool can be used to seal the seams and joints of slabs, to be used for the installation of warm floors, to lay tiles on fountains, swimming pools.

EK 5000 Aqua

EK 5000 glue is specially designed for laying tiles in swimming pools, fountains, in water tanks. It is used for gluing materials on balconies, open terraces. A distinctive feature is high moisture resistance, the material is not destroyed by the action of water. The adhesive is interchangeable with the previous EK 6000 brand.

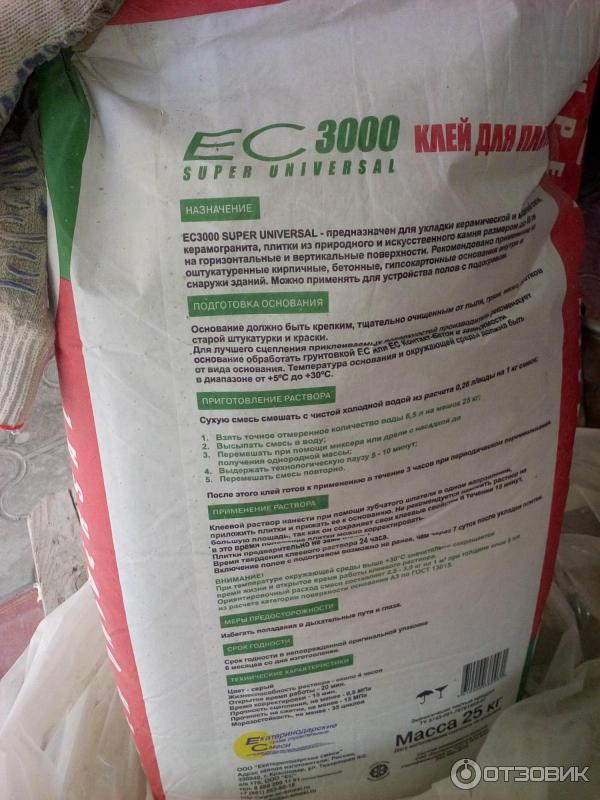

Application of glue

High-strength adhesive EC 3000 belongs to the same "family" of room cladding products as EC 2000 adhesive, but with improved technical characteristics. The operational properties make it possible to use this adhesive composition for external and internal work, it is also suitable for various rooms with high humidity.

Worth knowing! The main purpose of the glue is to lay mosaics, ceramic tiles. The tool is also suitable for natural, artificial stone, porcelain stoneware.

Substrates to which the adhesive shows sufficient adhesion:

- concrete;

- drywall;

- brick;

- plaster;

- aerated concrete.

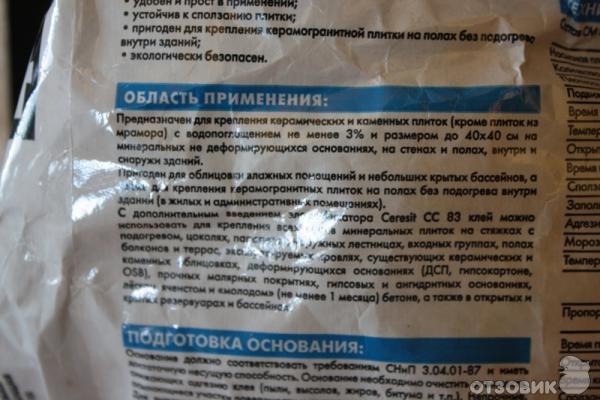

It is possible to apply the product for the subsequent gluing of tiles on both vertical and horizontal surfaces. It is widely used for decoration of bathrooms, floors and walls in the kitchen, plinth cladding, swimming pools. The adhesive is ideal for stone slabs with moderate water absorption (up to 1%), medium and small tiles. It can also be used in the process of installing a warm floor, for filling tile joints, leveling bases with small differences in height.

For what grounds is it suitable

Universal adhesive EC 3000 works well on walls made of durable material. The tool increases the strength, moisture resistance of light substrates. But when working with any surfaces, preliminary leveling with plaster and priming is required.

Concrete

The surface of concrete walls can be smooth or porous. The EC 3000 glue will firmly hold the heavy stone on a dense concrete base. But the rough surface must be leveled before priming. The composition of concrete includes lime, slag, sand, crushed stone. The cladding, laid with EC 3000 adhesive, will hold out on a solid concrete base for many years.

Drywall

Tiles are most often laid on smooth material.

But when working with EC 3000 glue, it is important that there are no cracks and chips on the surface of the base. The cement in the adhesive mix poorly contacts the gypsum

Brick

A brick wall is considered a problem base. The surface must be leveled, otherwise the edges of the tiles will protrude one above the other. Small indentations can be filled with glue

When working with the EC 3000, it will be important to install the tiles on the same level

Plaster

For leveling the walls, gypsum and lime plaster is used. Before laying the tiles, it is imperative to prime the surface in 2 layers in order to improve adhesion to the glue. EC 3000 possesses high adhesiveness, therefore it will better adhere the cladding to the plaster.

Aerated concrete

The tile increases the strength and moisture resistance of the gas block, but its surface also needs to be plastered and primed. Otherwise, over time, the cladding will fall off along with the pieces of the base. For laying tiles on aerated concrete walls, an elastic adhesive is required. EC 3000 spreads easily over the surface and strengthens it thanks to the cement in the composition.

Universal epoxy glue: composition

The main component of the glue is epoxy resin. The substance was discovered at the beginning of the last century, and by 1940 it was put into mass production. Epoxy and nowadays successfully retains its leadership position in the market of building and finishing materials, despite the abundance of other, more powerful mixtures.

The adhesive is widely used in renovation work

The adhesive is widely used in renovation work

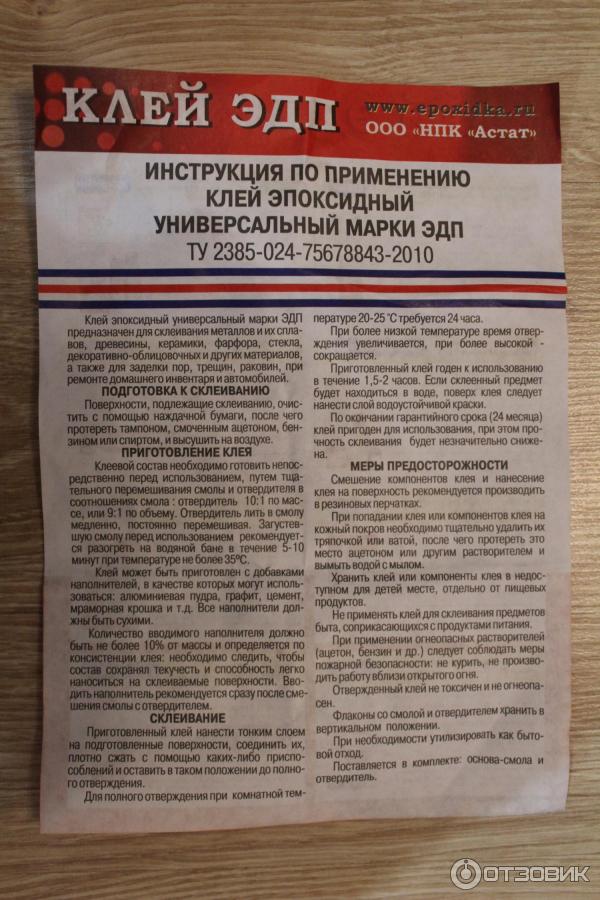

The adhesive substance is a thermosetting synthetic material. EDP glue is a technically verified combination of epoxy resin and other additional components:

- Solvents. Substances used include alcohols, acetones and xylenes. To obtain a durable adhesive, these additives are taken in a proportion of up to 5% of the total resin volume.

- Plasticizers. Phosphoric and phthalic acids are used. To improve the quality of gluing, oligosulfides and ogigoamides (polymer plasticizers) are used.

- Hardeners. A chemical liquid substance that acts as a catalyst for the polymerization process. Two types of accelerators are used: amine and acid.

- Fillers. Powdered additives in the form of zinc, vanadium and aluminum oxide, carbon black, beryllium, carbon fiber glass fibers, nickel or aluminum powders.

What glue is right

There are several types of effective means for fixing ceiling panels that meet these criteria are sold in hardware stores.

Universal polymer

The glue is used in construction and renovation work, it holds almost all materials together. The product is produced in the form of a gel-like mass and has many advantages:

- Dries quickly.

- It is economically consumed.

- Not afraid of moisture.

- Does not lose its effectiveness with a sharp change in temperature.

Universal glue containing polymers is easy to apply, instantly connects surfaces, but many types of products have an unpleasant odor.

Polyvinyl acetate

In the glue, which is based on water, there are polymer particles that harden upon evaporation of the liquid, firmly adheres to each other surfaces. The substance is applied both to the tiles and to the coating with an ordinary brush. Polyvinyl acetate adhesive has a viscous consistency, per sq. meter consumes only 200 g of substance. The composition does not dry out immediately, during this time you can fix the tile, but you will have to press it against the ceiling, otherwise the adhesion will not be strong.

Liquid Nails

For fixing polystyrene, sealing seams and joints, masking cracks, it is more suitable not universal glue such as "Titanium" or "Moment", but liquid nails. They are slaughtered with a special pistol. To connect the tile to a flat surface, lubricate the corners and the center of the panel. If there are a lot of defects on the coating, a lot of liquid nails will be required. Apply a thick layer of glue.

Acrylic putty

A building material with a thick consistency and good viscosity, used in repair and finishing work, is made on the basis of liquid acrylic and water. The putty evens out the surfaces of facades, walls, floors, glues tiles to the ceiling, covers up the seams between skirting boards. The product adheres to wood, brick, concrete, drywall. The advantages of acrylic putty include:

- Strength and good adhesion.

- No shrinkage and no odor.

- UV resistant.

- The presence of thermal insulation properties.

The substance does not burn, does not crumble for a long time, does not turn yellow. After applying the acrylic filler, the surface requires additional sanding.

Specifications and properties of various varieties

There are several brands of KS glue.All of them are used for indoor and outdoor renovation. Each type of product differs in both general and inherent properties only.

"Artel"

The main properties of the Artel brand KS construction adhesive is that it:

- heat and frost resistant;

- environmentally friendly;

- has no smell;

- elastic.

It is not for nothing that the Artel brand of glue is used for gluing block parquet, wooden flooring, ceramic tiles, and linoleum to the floor. Use a beige-brown mass in order to clad the outer and inner walls of houses with natural and artificial stone. Suitable for lining stoves and fireplaces. The optimum air temperature during the period of repairs using a pasty construction agent should vary between 5-35 degrees above zero. The finished composition can be purchased in specialized stores with a volume of 9 kilograms.

"Optimist"

This type of KS glue is more suitable for floor coverings. It holds well linoleum based on jute, fabric and felt, while the glue seam will be strong. Use an adhesive mass for pasting stoves and fireplaces. Seams and cracks can be sealed with glue. By adding the composition to cement mortars, the heat resistance of the building material is increased. The glue line reaches its maximum strength after 3 days. They offer a ready-to-use composition in 18 kg buckets.

KS-3 "Malva"

White moisture-resistant adhesive mass is considered ideal when laying parquet, linoleum of various types on the floor. The paste is easily applied to the surface and sets after 24 hours. Before use, the composition is thoroughly mixed and applied with a spatula to both glued surfaces. Then you need to roll it in with a roller. Excess paste coming out of the seams is immediately removed.

Farvest

KS glue is heat-resistant and suitable for gluing tiles. With the help of an adhesive mass, she is lined with not only the floor, walls, but also stoves, fireplaces. Thanks to high-tech additives to liquid soda glass, the glue is used for surfaces inside the building, as well as outside. Withstands the composition even of natural and artificial stones of a large size.

"Pulse"

The improved adhesive properties of the adhesive allow it to be used widely during renovation and construction. The pasty composition of the composition allows you to quickly and reliably glue surfaces of different structure.

You can stick tiles on surfaces that are slightly heated. The glue begins to harden after 25 minutes. Therefore, it is possible to correct the incorrect masonry after the surfaces are smeared with a building compound. After all, the tool belongs to heat-resistant. It is used for ennobling warm floors.

"Universal"

Construction universal adhesive KS with mineral fillers is necessary when working on wall cladding, both internal and external. With it, you can easily and firmly glue the floor with tiles, linoleum, parquet. The adhesion strength does not depend on whether there are residues of old paint or other coating on the surfaces. The adhesive is resistant to alkaline solutions. Hence the use of funds for the repair of canteens, kitchens in children's institutions, hospitals, and catering establishments.

The coating is firmly glued to fibrous, chipboard, concrete and aerated concrete. Suitable for underfloor heating installation. Cladding is securely held on stoves and fireplaces if you use the universal KS. When laying stoves, sealing cracks, seams, it is an irreplaceable material. It can be added to grout using slab masonry material.

Areas of use

The characteristics of the VS-10t glue make it possible to use the composition in very many cases where not only the strength of the joints is needed, but also the vibration resistance of the resulting joint.

Another important application is the bonding of carbide cutting tool inserts. Bonding load cells of different types

Bonding of load cells of different types.

Vs-10t is used to combine special materials: organofluorine and organosilicon polymers, polyolefins, etc. In this case, according to the instructions, additional preparation of the material is required. For example, polyolefin surfaces are treated with a composition of 75 parts of dichromic potassium and 1500 parts of water.

Organofluorine parts are treated with a solution of metallic sodium in naphthalene and tetrahydrofuran for 20 minutes at 20 C.