Views

The main characteristics by which epoxy glue is classified include the following:

- composition;

- consistency;

- curing method.

In terms of composition, it can be of two types.

- The one-part adhesive uses a liquid resin or a resin with a solvent. The product is packaged in tubes and is ready to use without preparation. It is used for gluing small parts or sealing gaps.

- Most often, epoxy glue is two-component. It is sold in a kit that includes two tubes. One tube contains the resin in a paste form, the other contains a liquid or powder hardener. The contents of the two tubes are mixed and used immediately, since after some time the mixture loses its adhesive properties. Most manufacturers produce just two-component glue. Its application is almost universal.

There are two types of glue consistency.

- Liquid glue is in the form of a gel. It saves time as it does not need to be prepared and is also convenient for application to the surface.

- The plastic mass will have to be prepared. To do this, cut off the required amount from the contents of a cylindrical tube or bar, knead it with your hands and moisten it with water. The plastic mass is great for repairing chips, pits, and other defects.

The curing method divides adhesives into the following types:

- in the first, curing occurs at room temperature;

- the second must be heated before adding the hardener.

Form filler

Resin is good for casting in molds, as shown in the photo. Parts that are obtained using this method can be machined. The rules by which the mixture is prepared in this case are identical to the rules already described above:

- In a similar form, glue is often used, for example, by aircraft modelers;

- To give the product any color, various dyes are added to the resin, as shown in the photo;

- And to make it as plastic as possible - plasticizers.

The following are used as fillers for epoxy resins:

- powders;

- textiles of synthetic origin;

- glass fiber;

- and other substances.

Let's sum up

Epoxy glue is a substance that many have heard of. However, the application features and characteristics of such an adhesive are not known to many. With its help, you can achieve a high-quality and durable connection. However, to prepare the substance, you will need to follow the rules described above.

Epoxy Resin Specifications

Before finding out what temperature the epoxy resin withstands after hardening, it is worth learning about the main technical parameters of this substance. These are the following characteristics:

- the complete polymerization process takes place within 24–36 hours;

- accelerate the resin hardening procedure by increasing the temperature to + 70⁰С;

- in conditions of low temperatures (up to + 15⁰С), the curing time of the resinous substance decreases;

- when hardening, the epoxy does not shrink and does not expand;

- after hardening, the resin can be subjected to any processing: grinding, polishing, drilling, turning, painting, etc.;

- the recommended operating temperature of epoxy resin is set within the range from -50⁰С to + 150⁰С;

- the maximum allowable temperature during operation is up to + 80⁰С;

- the cured material shows excellent resistance to aggressive influences, including alkalis, solvents and high humidity.

Epoxy is often used for decorative purposes

Melting temperature of the substance

According to the technical regulations, it has been established that the temperature at which the epoxy melts is + 155⁰С. But, given the declared technical characteristics, it is difficult to say that the epoxy will melt. Even heat-resistant epoxy glue or ED-20 epoxy, which is usual for household work, after polymerization, even in ultra-high temperatures, will behave as follows:

- crack;

- foam;

- change its structure without turning into a liquid state (crumbling and breaking).

Some resins (depending on the type of hardener used) can catch fire and produce a lot of soot. The combustion process will continue until the moment of heat replenishment (for example, in an open flame). As soon as the fire source is eliminated, the hardened resin will stop burning.

Even when burning, epoxy is much safer than many other artificial substances. For example, foam or expanded polystyrene. Therefore, it makes no sense to talk about what temperature the epoxy glue can withstand until it melts. Almost always, the cured epoxy does not melt, but collapses, turning into a charred, shapeless mass.

Are there fast-setting resins

All epoxies are classified into two major groups. These are structural resins and decorative (or jewelry) resins. Decorative epoxies are characterized by transparency and faster cure times. They are used mainly for design work for the manufacture of souvenir products.

Decorative resins have a faster curing time

Permissible operating temperature of finished products

Technical regulations adopted certain standards for the operation of products and repaired things, when working with which epoxy resin was used. These are the following indicators:

- constant temperature: from -40⁰С to + 120⁰С;

- maximum permissible: from -40⁰С to + 150⁰С.

But some brands of epoxy, according to manufacturers' estimates, have different characteristics. For example, such extreme (maximum permissible) indicators:

- epoxy adhesive grade PEO-490K (LZOS, Lytkarino): + 350⁰С;

- epoxy PEO-13K (LUMEX, Saint Petersburg): + 196⁰С;

- compound PEO-28M (PLANET, Veliky Novgorod): + 130⁰С.

Such epoxy substances are specific. Many professionals attribute them not even to epoxy, but to epoxy-silicon-organic. The additional inclusion of silicon creates an increased resistance of substances to thermal effects.

What temperature and load can withstand

The product, glued with epoxy, easily holds any vibration loads. The bonding point has a high impact resistance and is therefore not damaged even by strong impacts.

This resin is excellent for high and low temperatures. Operating temperatures range from -100 to +150 degrees. In this case, the solution tolerates sudden temperature jumps of more than 50 degrees. This allows the use of epoxy for fixing products that are installed in freezers or fireplaces with critical temperatures.

What you need to know when using epoxy adhesive

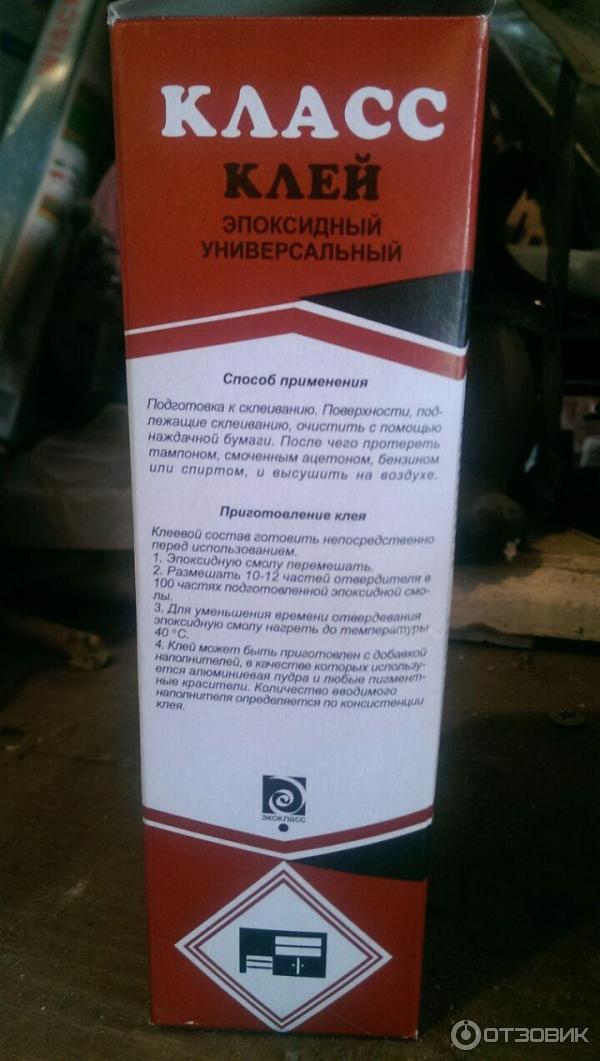

The question of how to use epoxy glue is of interest to many. You should know that epoxy shows its declared qualities only after polymerization, the catalyst of which is a special hardener. The whole process of work is as follows:

- Work surfaces are prepared (degreased, cleaned and polished).

- An adhesive substance is being prepared.

- The glue is applied to the surface of the material and fixed.

- After the end of polymerization, the product is ready for further use.

How to prepare glue for work

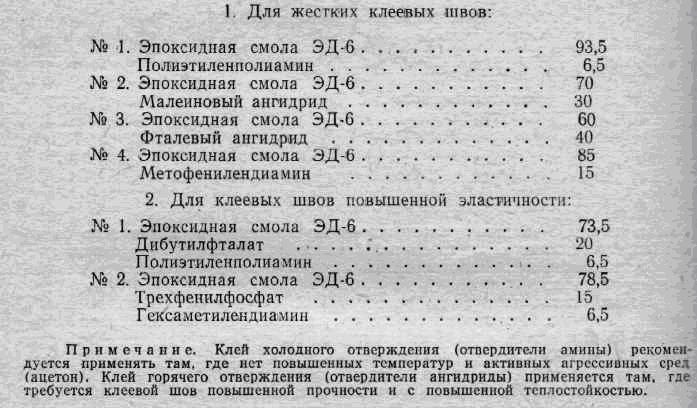

In order for the repair to come out of high quality, you should know how to glue it with epoxy glue.Of course, all the nuances of how to mix the hardener to the adhesive are prescribed in the attached instructions. In the classic version, 1 part of the curing agent-catalyst is taken for 10 parts of resin. Moreover, a hardener is gradually added to the resin, and not vice versa.

When a hardener is added to it, the resin begins to harden (this process is irreversible). Therefore, the finished substance should be used immediately, it cannot be stored for a long time, otherwise the glue will deteriorate. Experts advise not to prepare too much of the composition, but only the amount required for current repairs.

Mass breeding rules

Knead the adhesive mass very carefully, keep in mind that the epoxy, when the hardener is added to it, begins to generate heat. Stir the substances. A spatula or stick made of wood is very thorough and long. But sometimes the resin is too thick. For these purposes, you can use a special solvent for epoxy or slightly heat the mass with steam at a temperature of + 55-60⁰С.

The resin must be prepared for use before use.

Other weak solvents will also help to dilute a substance that is too thick. For example:

- acetone;

- nail polish remover;

- alcohols;

- xylene.

Other organic substances can also be used. However, make sure that the volume of solvent used does not exceed 4–5% of the total resin weight. Otherwise, the composition of the adhesive will lose its qualities.

Drying time

The polymerization period is different and depends on many factors. For example, the type of glue used. So, cold welding will completely harden after 10-25 minutes. But for liquid substances it takes several hours, and completely such mixtures harden after 1-1.5 days.

You do not need to work with epoxy glue in the cold, at sub-zero temperatures. Optimum time for surface setting: + 10–30⁰С.

Consumption rates

The consumption of the adhesive substance directly depends on the thickness of the applied layer. On average, this figure is 1.1 kg of glue per square meter of surface when applying a layer of 1 mm. But the consumption increases when working with various porous surfaces (wood, concrete, etc.).

Safety engineering

Epoxy adhesives become completely safe for humans only after complete curing. When working with a liquid substance, certain safety rules must be observed:

- work in a room that can be thoroughly ventilated after the end of the process;

- use personal protective equipment: respirator, gloves, glasses;

- wear work clothes made of dense material, there is a long sleeve;

- everything that came into contact with the liquid mixture (sticks, dishes), after finishing work, throw it away, and ventilate the room well.

Gloves should be used for work

Stamps

It is best to stop the choice on these 4 types of glue with quality characteristics:

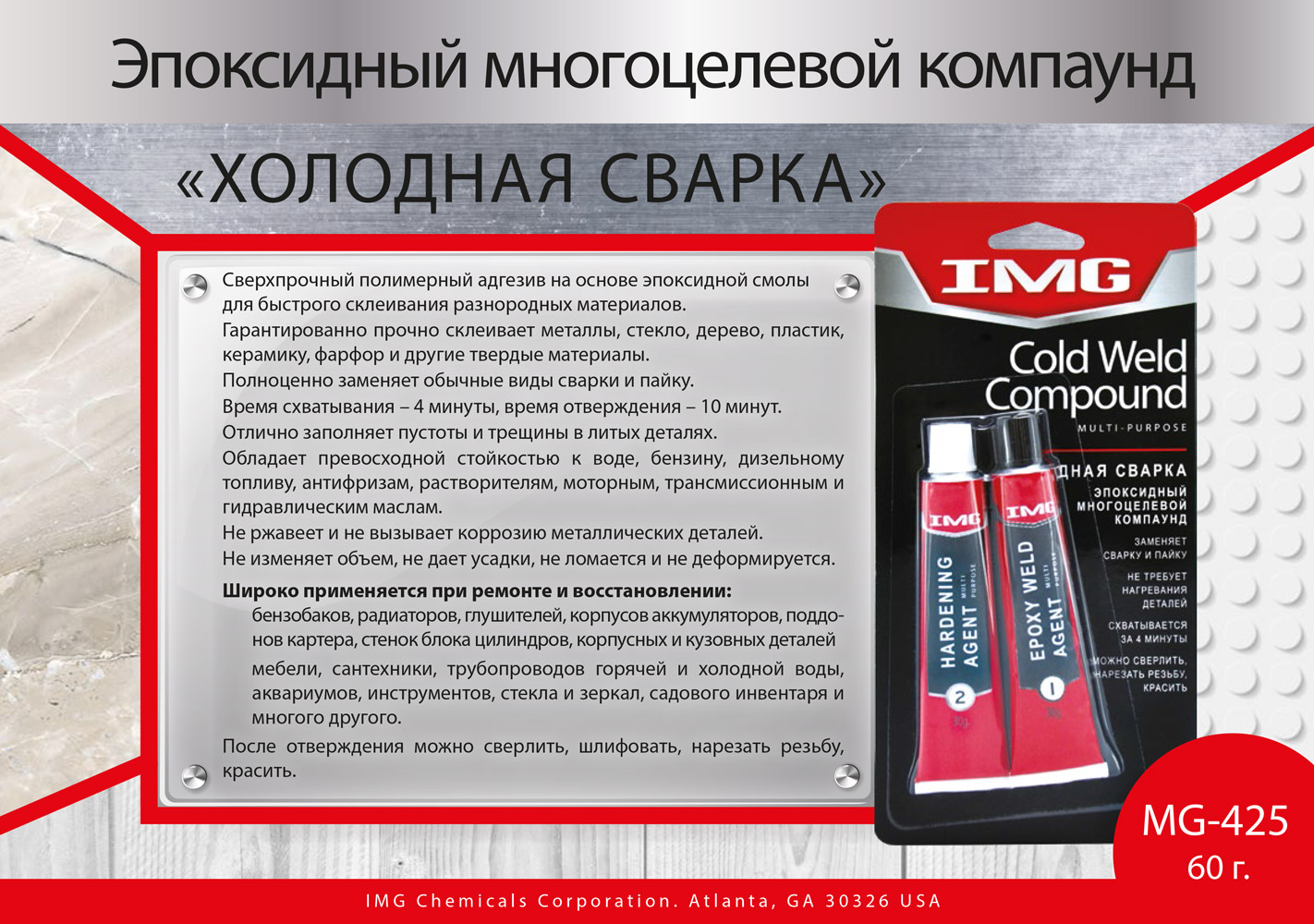

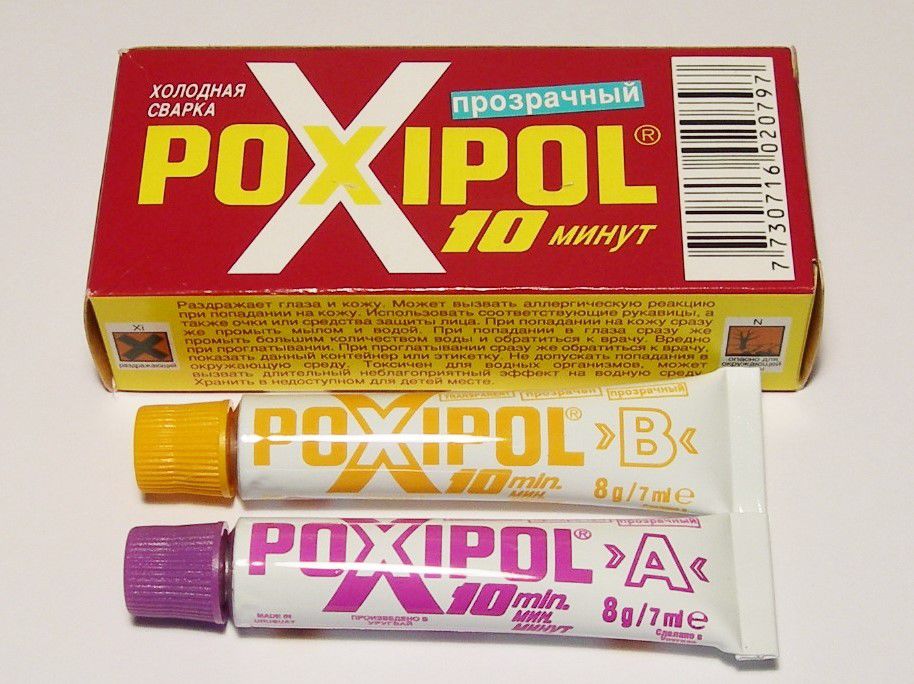

"Cold welding".

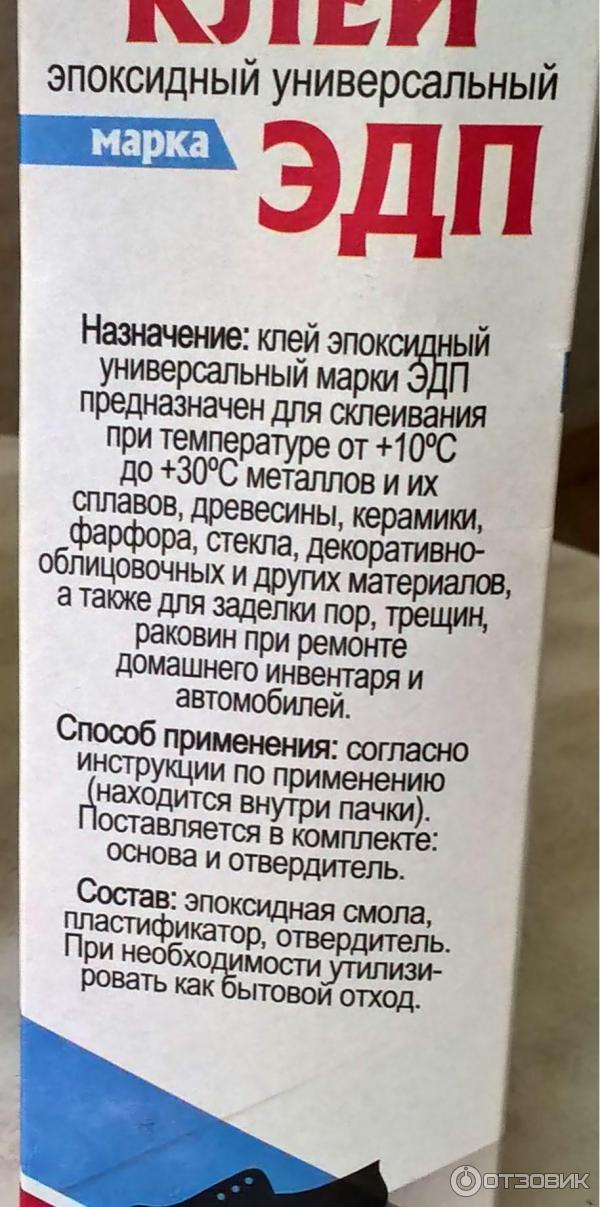

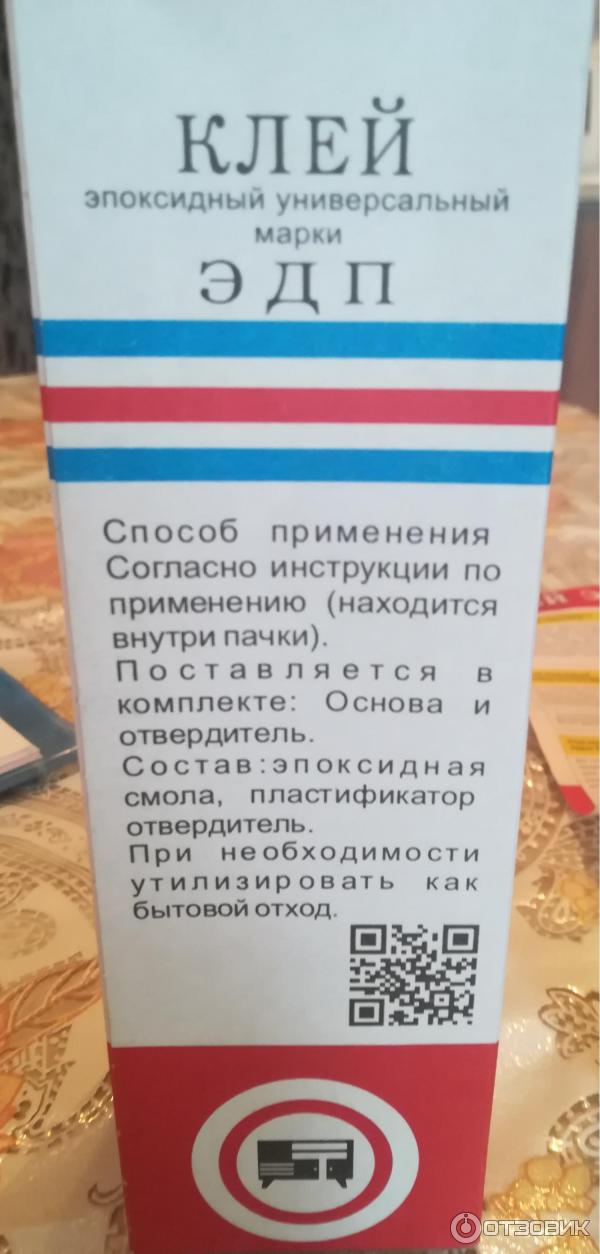

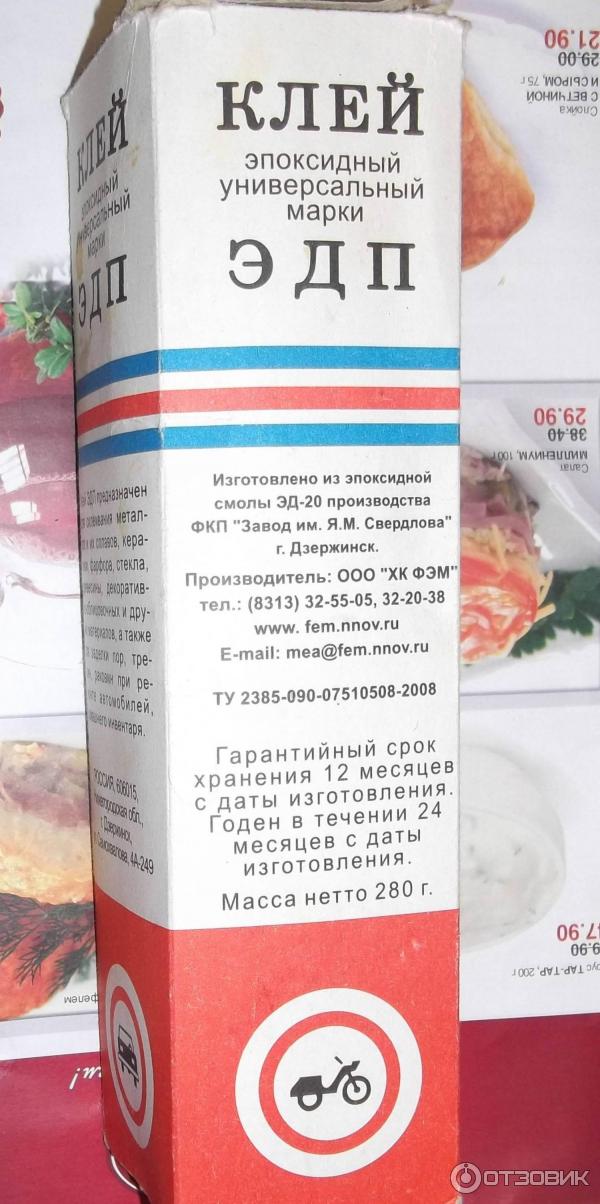

EDP.

"Contact".

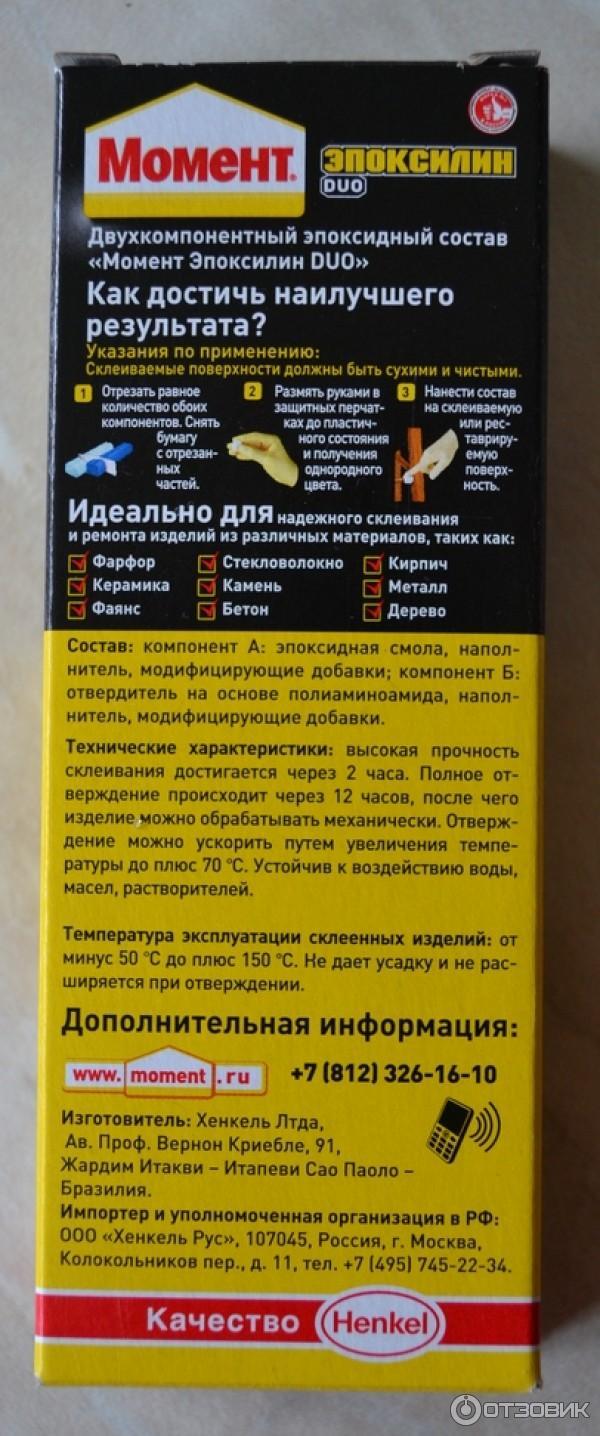

Glue "Moment" Epoxylin.

It is possible to determine which manufacturer will be better only by experience and taking into account the main purpose and characteristics of the varieties.

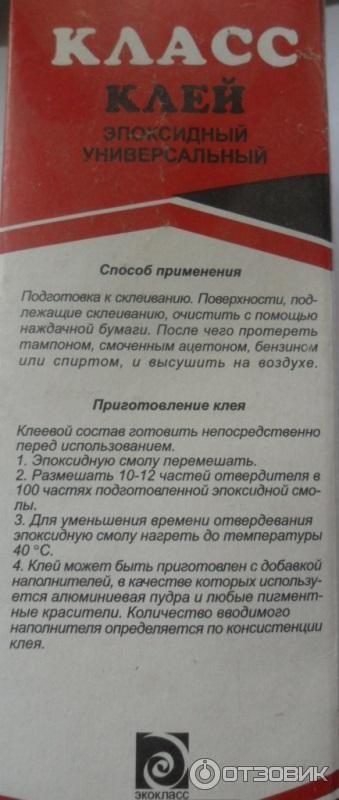

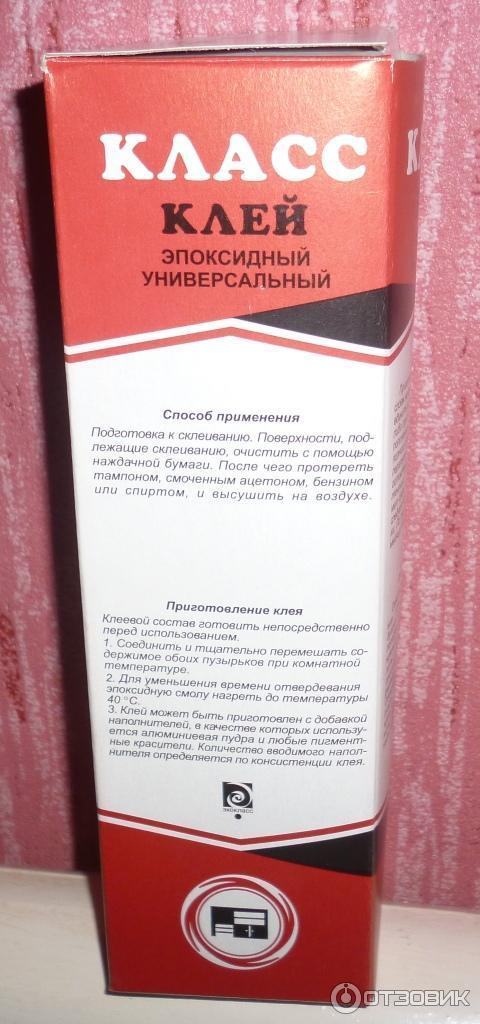

Cold welding is produced by such manufacturers as Akapol, Russian Astat, Anles brand, Runway trademark. The epoxy composition of EDP is suitable for working with various materials, produced by domestic manufacturers NPK Astat LLC, Himalyans GK LLC, Anles JSC, Ecoclass LLC, Khimkontakt. The epoxy solution "Moment" from the manufacturer Henkel is very popular, and the domestic manufacturer, CJSC Petrokhim, has also proven itself quite well. "Contact" allows you to work even with wet surfaces.

On the video: Epoxy resin, tricks of use.

Useful tips for storing and using the adhesive

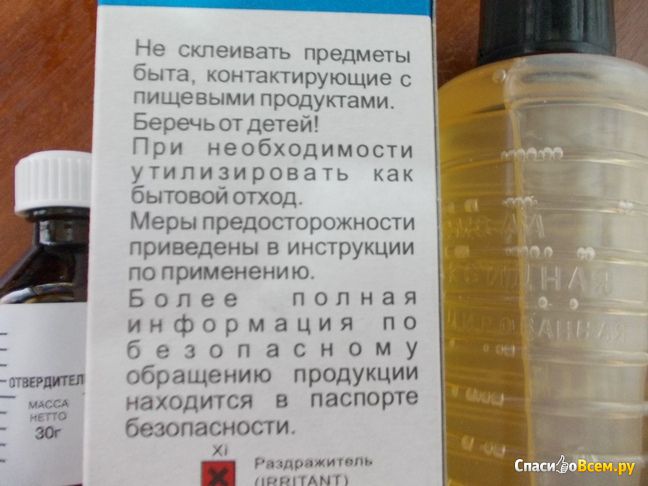

- Do not use glue to repair items that come in contact with food.

- If glue comes into contact with your skin, you should quickly wash the damaged area with soap and water.If irritation develops, seek medical attention.

- If the resin or glue is poorly squeezed out of the tube, then you need to warm it up - put it on a battery or place it in hot water.

- To extend the shelf life of the glue, it is necessary to evacuate the air from the package and put the tube in the refrigerator.

For home use

The modern industry produces several brands of glue for home use.

The most popular formulations are:

- Epoxy glue "Moment" - sold in all hardware stores, has an affordable price for a wide consumer. The glue is packaged in small tubes containing plastic mass weighing 50 grams, or in large packages designed for reusable use. The glue can be used for several months after opening, provided that it is stored at temperatures up to +25 ° C.

- Clay-plasticine "Contact" - is used for gluing surfaces in contact with moisture - pipe joints, shelves in the bathroom. The glue hardening time is one to two minutes.

- Glue "Cold welding" - designed for instant connection of metal products. Does not damage the edges of metal parts, adheres to alloys that cannot be welded.

- EDP epoxy adhesive is designed for bonding various surfaces - from metal to glass and porcelain. According to consumer reviews, it is considered optimal in terms of price-quality combination. It is used for repairing car parts, repairing cracks in plumbing and other purposes.

Epoxy adhesive: composition and properties

Epoxy adhesive epoxy is a synthetic thermosetting product. The product is a combination of the main element of epoxy resin and additional substances such as solvents, hardeners, plasticizers and fillers.

Solvents for epoxy adhesive:

- xylene;

- acetone;

- alcohols.

To obtain the highest quality adhesive material, it is necessary to take no more than 3-5% solvent in relation to the volume of dry resin. Since the solution is difficult to remove from the adhesive joint, the amount of solvent should not be exceeded.

It is important to consider that alcohols accelerate the hardening of epoxy glue.

Epoxy fillers:

- powdery components: aluminum oxide, carbon black, vanadium, beryllium and zinc oxide, aluminum or nickel powder;

- carbon and glass fibers;

- fabrics made of synthetic or glass fibers.

Esters of phthalic and phosphoric acid act as plasticizers. Experts recommend using oligomeric and polymeric plasticizers, using oligoamides and oligosulfides, since their use affects the physical and mechanical properties of the epoxy material, allowing them to regulate and improve the quality of adhesion.

With the successful connection of the necessary components, an adhesive mass should be obtained, which will have the following qualities:

- frost resistance - the glue can withstand temperatures up to -20 ° С;

- heat resistance - usually up to +250 ° С, depending on the filler;

- plasticity - the already solidified composition is elastic, therefore, with a slight displacement of the parts, the seam does not break;

- glue tolerates atmospheric, gasoline and oil exposure well;

- the product is resistant to cracks and shrinkage;

- under the influence of detergents and household chemicals, the glue does not decompose;

- water-repellent effect - the structure of the glue provides the details with high-quality waterproofing;

- good interaction with various surface structures.

Disadvantages:

the glue is not suitable for working with polyethylene, teflon and silicone;

in the work you need to be extremely careful, since the composition hardens very quickly and if flaws are detected, it will be incredibly difficult and costly to fix them;

it is important to observe safety measures in working with the material, since if it gets into the eyes or on the skin, it will be very problematic to wash the glue.

The main features of the substance

Fast curing epoxy adhesives cure quickly after adding a hardener to the base composition. The hardened mass has the following qualities:

- frost resistance (the mass can easily withstand temperatures up to -20⁰С);

- heat resistance (temperature limit at which the glue keeps gluing: up to + 250⁰С);

- good ductility and elasticity, which provides a high level of bond strength;

- resistance to aggressive media (acids, alkalis, oils, petroleum products, household chemicals);

- low shrinkage;

- water-repellent properties and high waterproofing performance;

- excellent interaction with almost all materials.

But you should be aware of some of the disadvantages of such glue. For example, not all surfaces lend themselves to gluing - epoxy cannot connect Teflon, silicone and polyethylene. Take into account the accelerated polymerization time, therefore, if there are blemishes during gluing, it will be very difficult to remove them later.

Adhesive does not work with all materials

Where is used

Due to its high technical qualities, versatility, epoxy glue is actively used in various branches of modern industry. Namely:

- in construction, to connect reinforced concrete structures, panels, cracks and potholes in concrete are filled with glue, with its help, tiles are laid;

- shipbuilding uses an adhesive substance for the installation and assembly of ship parts made of fiberglass, plastic and metal, the substance is also used to improve the waterproofing qualities of materials;

- aviation (design), used for gluing various parts, manufacturing and installing batteries, additional fixation for thermal protection;

- mechanical engineering uses epoxy glue for mounting accessories, fastening brake pads and various parts when assembling machines, for carrying out various repairs.

Varieties of glue

Experts distinguish two large groups of epoxy adhesive. It:

- Liquid. Packaged in tubes. This form of release is convenient and easy to use.

- Plastic bars. Its consistency is similar to plasticine or dough. Also available in tube packaging. After squeezing out, the mass is slightly moistened with water and softened by hand.

Various modified formulations can also be found on the market. The temperature regime of polymerization of such modifications ranges from + 60–120⁰С. These adhesives are used for bonding various materials that are resistant to solvents, petrochemicals and oils.

In household, home use, several brands of epoxy glue are common. They are recognizable and familiar to almost everyone:

- universal glue Moment;

- Contact designed for sealing pipes, repairing plumbing;

- cold welding glue is used for gluing metal products.

Is epoxy glue harmful to health

When working with an epoxy-based adhesive, you should be aware that it is a health hazard. When working with her, it becomes mandatory to use personal protective equipment: gloves, a respirator mask and glasses. If the glue mass enters the stomach, a person runs the risk of serious poisoning, and contact with the skin leads to the development of allergic reactions.

Adhesive consistency and differences

By structure, two types of epoxy glue can be distinguished:

- Liquid glue is a gel squeezed out of a tube. Very simple and easy to use. You just need to squeeze the gel out of the tube and apply it to the surfaces to be glued. During operation, time is saved on mixing and preparation of the solution.

- Plastic mass - similar in consistency to dough or plasticine, sold in tubes. The necessary part of the plastic is cut off from the common piece and moistened with water. After that, you need to knead the product with your hands for a few seconds and apply to the parts to be glued.

There are also modified compositions of epoxy glue, their hardening temperature ranges from +60 to +120 degrees Celsius. This material is used for bonding metals and non-metals that are resistant to oils, fuels and other organic solvents.

Hot-hardening agents with temperatures from +140 to +300 degrees are considered especially strong. Such compositions are heat resistant and have high electrical insulating characteristics.

In addition to epoxy compounds used in manufacturing and industry, there are a number of universal epoxies used in everyday life:

- Moment is one of the most recognizable modern brands. Sold in any hardware store at a very affordable price. Packaging of goods is convenient for any craftsman: tubes with epoxy gel, plastic masses of 50 grams or reusable large-volume packages. The shelf life of such a product after opening the package is only a few months in a dry place with a temperature of no more than +25.

- "Contact" is ideal for gluing products that will subsequently be exposed to moisture. It is used for sealing joints in plumbing, pipe joints, gluing light shelves and decorative elements in the bathroom. The glue hardens in 2-3 minutes.

- "Cold welding" - suitable for joining metal elements, copes with the task for a few seconds. The mating level of the surfaces is identical to the effect after classic welding. After hardening, the edges of the metal product remain even, which is an additional advantage.

- EDP universal glue - used for fixing various surfaces, from glass and porcelain to metal. Experts say that this particular composition is optimal in terms of quality and composition.

Existing varieties

The central component of the glue is epoxy resin. The material is a synthetic oligomer, which is used without additional substances. Epoxy resin is an indispensable component of paints and varnishes and finishing materials. The consistency of the resin depends on the material it is part of.

By composition

The epoxy adhesives market is represented by two groups:

- one-component;

- two-component.

The one-part epoxy adhesive is ready to glue after opening the storage container. The composition, in addition to epoxy resin, contains organic solvents that prevent polymerization. The one-component composition is used for gluing small parts, sealing plumbing joints and connecting pipes. Another area of domestic use is needlework. Do not store the glue open, since it dries quickly, which is the disadvantage of one-component epoxy glue

Among the advantages of the material, it is important to note:

- reusable use;

- ease of application;

- affordable price;

- ease of storage;

- non-toxicity;

- strength after polymerization.

Solidification of a one-component composition occurs at room temperature, so no heating devices are required. The two-component formulation is supplied in two separate tubes. One tube contains epoxy resin and the other contains a curing agent. The hardener is available in liquid or powder form. The advantages of the composition are:

- gluing two different materials;

- strength and elasticity of the connection;

- ease of application;

- no harmful secretions.

A two-part epoxy adhesive for fixing metal, wood, plastic and glass parts. Materials are combined in any sequence, which does not affect the adhesion strength

The connection retains elasticity, which is important under vibration loads. Apply the adhesive with a small spatula or stick

Mixing of the two components is required before application to the damaged area.A correct calculation of the amount of hardener added to the base composition is required. If there is an excess of hardener, then the "vitality" of the solution will be low, polymerization occurs quickly, which complicates the gluing. Lack of hardener prevents the build-up of strength, which will lead to an unreliable connection of parts.

By consistency

Adhesives differ not only in composition, but also in consistency. Depending on the viscosity of the glue, there are:

- gels;

- liquids;

- plastic masses.

The gel is less fluid than liquid, so it is easier to apply on areas with more damage. Adhesives with gel formulations are consumed more economically than liquid formulations. Deep lesions require intense fluidity of the composition to envelop the fracture site. Liquid adhesives are easier to apply and self-cover the area to be treated. The polymerization time of liquid adhesives is longer than that of gel-like ones. Plastic masses of epoxy adhesives are a substance similar to plasticine. The components are supplied in separate packages or in one. If it is one package, then the curing agent is on top of the epoxy component.

To start polymerization, the hardener and epoxy are thoroughly kneaded by hand. The components are mixed until smooth. Thereafter, there is fifteen minutes for the glue to be applied to the damaged area. Another name for two-component elastic compounds is cold welding. The flexible adhesive is suitable for gluing wood, metal and plastic surfaces. The disadvantage of this method is the protruding mass of glue after polymerization.