Permanently bonded epoxy adhesive

Technicians and hobbyists alike agree that epoxy is the most popular product. Even taking into account the fact that a modern manufacturer of building materials offers more resistant and powerful mixtures, epoxy firmly holds its place of honor. Wherever there is a need for gluing solid materials, the first glue in demand and popularity is used.

The main ingredient in the glue, epoxy resin, was discovered in 1938. Already at the beginning of 1940, production was put on stream. The first official name for this type of glue is "Araldite 1". The invention of such a tool opened up a new glue for the masses for universal use in industry and for household work.

The developments of recent decades in this industry have given very good results, new unique gluing techniques and materials have been discovered, as well as old ones have been improved. In recent years, numerous varieties of epoxy compositions have been developed that allow the action of in a wide temperature range. Such openings allow to obtain connections with the highest strength and long service life.

What is "Dismakol" glue

By its composition, it is a selected composition of polyurethane resins and modifiers that provide key consumer qualities, for example (see photo):

- Transparent inconspicuous glue seam;

- Complete hygroscopicity - the seam glued with this glue practically does not get wet;

- Convenience in work and ideal value for money.

Glue "Dismakol"

"Dismakol" can be used if the instructions are followed in decorative and applied and repair work, it provides strong adhesion of glass, plastics and metal.

Observe safety precautions when handling adhesive. Shoe glue "Dismakol" contains solvents and other combustible materials, so it cannot be used and stored near electric heaters, open flame

When working with "Dismakol", it is required to provide high-quality ventilation of the room or ventilation of the working area (equipping the workplace - photo).

Shoe workshop

How to use epoxy glue correctly

Surfaces intended for a strong connection are pre-cleaned and degreased. Moreover, glossy and smooth materials are subject to processing without fail. To improve future adhesion, such surfaces are treated with fine sandpaper to create the required roughness. After finishing the preliminary preparation, a thin layer of epoxy is applied to the working areas (its height should be 1–1.5 mm).

Any excess glue that appears must be immediately removed with a dry cloth. The glued surfaces must be fixed (for strength, you can wrap it with a rope or press down with clamps). After a day, additional devices are removed, and the product is left until the glue is completely polymerized. If you wish, you can place the product in the oven and keep it there for 1–2 hours at a temperature not higher than + 80⁰С.

Observe precautions when handling resin

Adhesive application recommendations

Is it possible to dilute PVA glue with water, we figured it out. Remember that when working with PVA glue, regardless of the type, adhere to some rules:

- for applying glue to thin wallpaper, one layer of the product is enough, and for dense materials - two;

- for spot application of PVA, a special nozzle is used, and if it is not there, they use improvised means - a syringe without a needle or an ordinary pipette;

- a sponge or roller is used to treat a large surface;

- glue is applied, starting from the center and gradually moving to the edges;

- glued objects, if possible, are held under pressure for greater reliability.

Having studied the information provided in the article, you received an answer to the frequently asked question: "how to dilute PVA glue?"

Taking into account the recommendations given, the use of glue will be a rational solution for you if you need to connect any parts together.

Additional tips and tricks

KN-2 rubber mastic is produced as a ready-to-use dark mass. The surface to which the glue is applied is first thoroughly cleaned of dirt and leveled. True, minor defects can not be eliminated. The elastic mass will penetrate into any crevices and level the base on its own. To save glue, it is better to treat the surface with a primer before applying the substance.

This adhesive is based on a high rubber content. Due to this feature, KN-2 can be used for gluing rubber products. Typically, this mastic is used to securely fix linoleum or rubber-based carpet to the floor. You should always remember that the KN-2 glue contains a solvent. It is advisable to wait 15 minutes after applying the mass to the surface. During this time, the toxic vapors of the solvent will have time to evaporate. After application to the surface, the glue hardens after 7 hours. True, for the mass to dry completely, you need to wait 24-72 hours.

A rubber-based product of the KN-2 brand is used simultaneously for gluing materials and providing waterproofing. When hardened, this substance becomes similar to rubber. The adhesive can be used as a cushioning material.

All cracks and places where the adhesive penetrates are protected from moisture penetration. The viscous mass penetrates into any pores. After drying, it hardens and does not change its properties either under the influence of moisture or as a result of a sharp increase or decrease in temperature.

It is a universal product for gluing various materials and protecting the premises from water penetration. The mastic can be used at any stage of construction and repair work. Toxic substances evaporate a few hours after the application of KN-2. True, this glue is undesirable to use in the kitchen or for gluing kitchen items.

p> Share link:

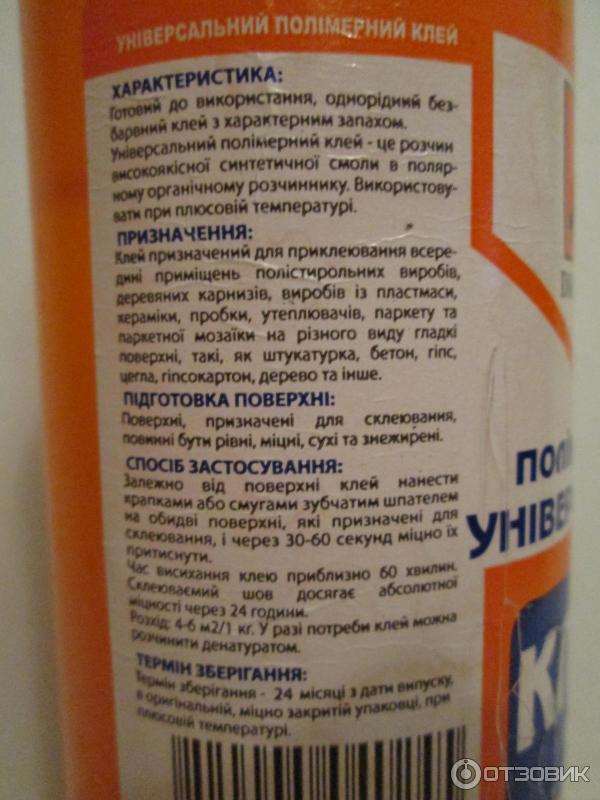

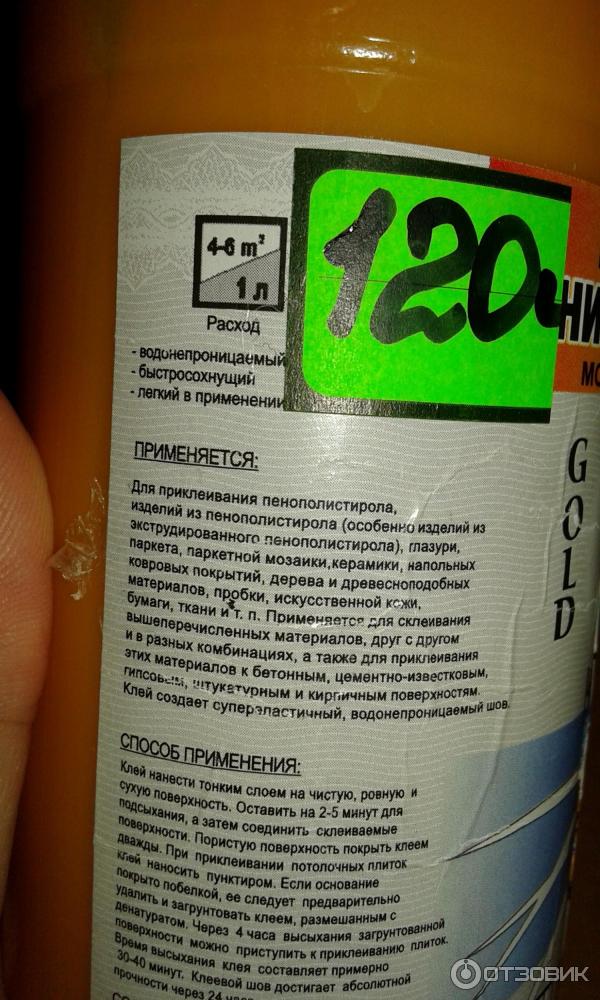

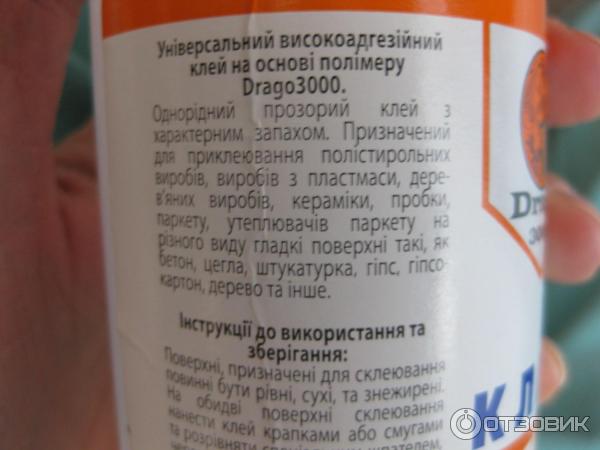

Purpose

Glue "Dragon" has a polymer base. It is designed for renovation work, not for the installation of building structures. It is used for gluing plastics, ceramics, wood, leather, vinyl, asbestos, parquet, metal, rubber, fabrics.

Has good adhesion to brick, plaster, plaster. Polystyrene elements, cornices, tiles, carpet are glued to these materials with the help of Dragon glue.

Use "Dragon" glue for facing fountains and swimming pools. It can be used for minor shoe repairs. You can glue souvenirs and various trinkets. After all, the universal polymer glue "Dragon" hardens rather quickly. The seam turns out to be strong, not afraid of moisture.

Polymer glue

Infected by the great popularity of polymeric glue. The stench add to its versatility, simplicity in the stasis and the quality of gluing. Polymeric warehouses glue on such objects that were previously screwed on with screws or were nailed down with flowers.

Polymer-based adhesive can be of three types:

- Water consumption sums. Before them PVA and Bustilat are introduced.

- Razchinyayutsya organic speech. Price of nitroclays, gum, perchlorovinilov.

- The group can include polyurethane, epoxy and urea-formaldehyde.

The first and the third group of adhesives are victorious at budivnistvі. Water-dissolving for internal robots, for out-of-the-box vitamins.

In order for the surfaces to be glued together, it is necessary to correctly apply the materials and follow the instructions. It is necessary to show the hour, the temperature and the required grip.

How to dilute correctly if it thickens

About 90% of PVA adhesives sold on the market can be diluted with water. However, carrying out this procedure, it is necessary to follow a number of rules and maintain the recommended proportions. Otherwise, the composition will lose its original properties. It is recommended to use a warm liquid for dilution. Hot and cold water will change the technical characteristics of the adhesive solution, as a result of which the created connection will not be reliable.

After dilution, it is recommended to leave the glue solution for half an hour. During this time, the composition will have time to restore its original properties. PVA applied after dilution does not provide a strong bond. If the thickened adhesive is used to improve the performance of the primer, the compound can be used immediately after mixing with water. In this case, a 1: 2 ratio should be used. That is, add 2 parts of water to one part of the glue. As a result, after mixing, you should get a fluid white liquid that can be mixed with a primer.

> Do not use alcohol or acetone to dilute thickened office glue. Both liquids, when in contact with plastic and other materials, corrode the surface. In addition, office glue is often used by children, and the addition of alcohol or acetone can harm the child.

Share link:

Epoxy adhesive: application

The combination of ease of use and universal properties of epoxy has found wide application in industry and many sectors of the national economy.

Application:

- Construction. The tool allows you to connect three-layer panels, reinforced concrete structures of bridges, connect concrete to metal, glue tiles, fill cracks in concrete.

- Shipbuilding. With the help of epoxy, highly loaded assemblies are installed in the mount, ships are assembled from metal and fiberglass, a water barrier is created to maintain the humidity level, and the hulls of boats and yachts with fiberglass reinforcement are processed.

- Aircraft engineering. It is used in the manufacture of batteries, creating glue-welded joints when assembling an aircraft, fixing both external and internal thermal protection.

- Mechanical engineering. The material allows the production of technological equipment and abrasive tools, fixing plastic parts and brake pads to metal surfaces, carrying out repair work on the car body, gas tank, skins, gearboxes and brake boxes, gluing small and medium parts.

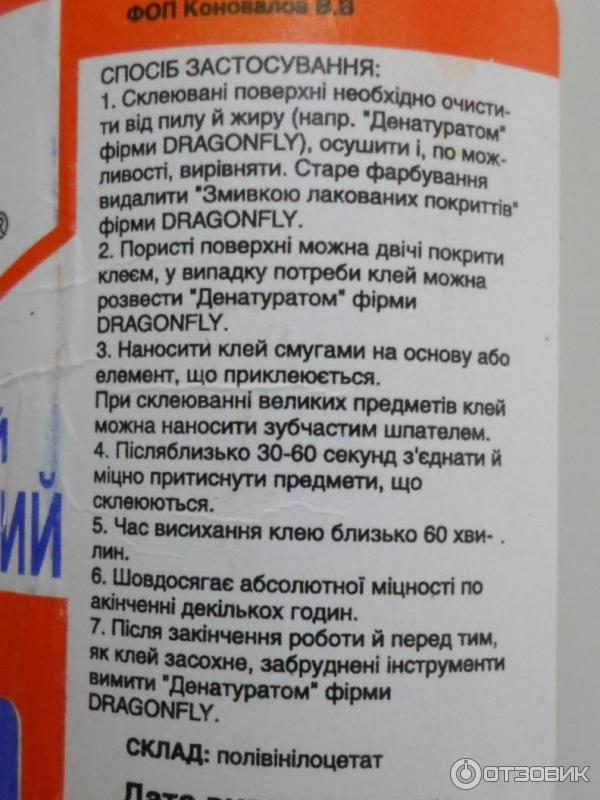

Instructions for correct operation

Any product should be used according to the manufacturer's recommendations, and this is especially true for repair and finishing materials.

How to use the "Dragon" correctly:

- prepare the surface first. Remove from it all soluble and insoluble remnants of the past material (plaster, paint, varnish, if possible). Try to level the material if there are irregularities;

- degrease the surface and dry thoroughly - there should be no moisture on it. Glue "Dragon" is designed to protect against external moisture and wet spots from the inside will not allow it to "grab" the surface;

- Apply glue well to the surfaces you want to bond. Consider the structure and texture of the material - porous, rough or too smooth surfaces may require reapplication of glue or several;

- press the pieces together for 20 seconds, preferably with force and as tight as possible - this will allow the substance to begin the initial gluing. If your material is not titanium, this time will be enough for it to initially bond, universal polymer glue sets quickly;

- leave the glued parts for one hour in a dry place at room temperature, preferably not lifting or moving objects.

Watch the video how it can be used for bricks:

You can use the ready-made gluing after this minimum time, but it will be great if you wait about a day - during this time, the Dragon glue will finally hold the elements together and your use of the repaired item will be absolutely comfortable.

The universal polymer product of the Dragon firm will easily deal with problems that may seem insurmountable to you. You should not hire expensive workers or borrow repair supplies trying to learn how to handle them - repairs with polymer glue are in no way inferior to ordinary ones, and in some places they even surpass them.

Glue is a substance that is always needed in the household. It can be useful both during repairs and after unsuccessful handling of any household item. And parents of schoolchildren need to buy a supply of glue immediately after the child has gone to first grade. But which one to choose? The well-known PVA glue adheres well to paper. And what is the glue for?

How it is used

Nefras

To start using it, mix it thoroughly. To change the viscosity, the glue is diluted with nefras

It is important to remember that adhesive 4508 is applied, only on degreased surfaces.

The glue is spread in two parts at once. You need to do 2-3 layers. The interval between coats should be 20 to 30 minutes.

When the last layer is made, after 5-10 minutes you need to press both sides with force to eliminate wrinkles or bubbles. In order for the glue to have a stable, resistant attitude to natural phenomena, the instruction recommends the use of hardeners. The ratio is 1: 5%.

The glue seam becomes reliable, which has a positive effect in the repair of rubber boat motors. When the agent is used in the manufacture or repair of rubber products, which are necessary for operation in high temperature zones (+30 and above), subsequent vulcanization is necessary.

Users love this adhesive because the products do not need to be preheated before gluing.

What glue is preferable in boat repair

Rubber boat

In the reviews it is called boat glue. It is the most effective adhesive 4508 for repairing boats and structures made from rubber raw materials than other brands of rubber adhesives. The most reliable product due to its high strength.

Because during the repair, you may encounter:

- with holes;

- violation of surfaces and seams;

- malfunction of elements for the steering wheel or oars;

- flaws in the bottom;

- defect and damage to tapes.

Rubber glue 4508 with natural rubber ingredients, where urethanes, various specific additives are added, it is possible to eliminate any malfunctions in the boat mechanisms.

How did this glue gain popularity?

- Good resistance to stress and pressure.

- It is made with high technical indicators of water resistance.

For a good gluing, boat owners advise all areas to be cleaned with fine-grained sandpaper. And then apply the degreasing method. You can use the "Galosha". Then, according to the instructions, apply a thin layer to the contacts of the elements.

If you decide to glue the seams in the product, then dry it thoroughly so that not a drop of moisture remains.

Sika Structural Bonding

Sikapower glue

We suggest considering another type of sikapower glue. There are several types of them. Sikapower glue 4508 seals the joints and makes it possible to paint the products with paint later.

Adhesive 4588 is applied hot. The glue seam is spot welded. Sikapower 4591 is used with different types of joining in products: spot welding, riveting, etc.

These types of glue have:

- Excellent adhesion (even to oiled metal products).

- Resistant to galvanic baths.

- By gluing and sealing car bodies (without processing)

- Anti-vibration filling. Rust protection.

- A high degree of flexibility.

Adhesive thickness for constructions is 0.3 - 4 mm.

Users in their reviews give a lot of tips for using 4508 glue, here is one of them. The technical characteristics of the glue will double at times if you use hardeners in the form of Leukonate or Dismodur together with glue 4508.

Where is epoxy adhesive used?

The preparation of epoxy allows you to obtain a substance with a unique properties that has a wide range of uses. This material, depending on the characteristics of cooking, can be both hard and hard, and soft, plastic. Resin is used for a wide variety of needs:

- Construction. Epoxy has excellent waterproofing performance, which implies its use in the installation of various structures in order to provide additional protection.

- Electrical, aviation and mechanical engineering. The substance is used as a heavy-duty adhesive solution that guarantees high adhesion rates.

- Furniture manufacturing. Epoxy is used as a decorative element.

- Creativity and design. Knowing the correct proportions of epoxy resin and hardener, home craftsmen get a thick, transparent solution, with which they create items of unique beauty. For example, souvenirs, jewelry, various decor and household items.

Epoxy resin is used in conjunction with a hardener

If the epoxy is properly diluted, then after the polymerization (curing) process, a strong alloy is obtained. It is very simple in further (finishing) processing and can be easily ground and polished. Moreover, the solidified polymer mass does not pose any health hazard.

How to prepare an adhesive base

Epoxy resin shows all its declared qualities only when a hardener is added to it. The catalyst starts the polymerization process, as a result of which the epoxy solidifies. Moreover, the end result directly depends on the ratio of the hardener and epoxy resin used during the work.

How to dilute epoxy

To add to the epoxy resin, a special additive is used - a hardener. Usually this composition comes with a resinous substance. But sometimes situations arise when it is required to dilute too thick a mass of hardener + epoxy. You need to know how to act correctly in this case.

Dilution ratio with hardener

To get a high-quality composition for future work, you should know how to dilute epoxy glue, the proportions of which and the amount of hardener added will depend on several factors. For example, from the peculiarities of the production of components - each manufacturer himself sets the exact ratio of resin (glue) and hardener-catalyst.

To obtain a quality material, it is necessary to observe the mixing proportions

Mixing of the components should take place at a constant temperature of + 22-25⁰С, not higher. Experts also advise to carry out preliminary control kneading in order to independently establish the required proportions. Keep in mind that when a hardener is added to it, the resin begins to generate heat violently, therefore, the catalyst is added very carefully, in small portions.

In some cases, the addition of a special plasticizer is required. This substance will minimize the brittleness and brittleness of the cured composition. The plasticizer is added to the rest of the components in the amount of no more than 5-10% of the amount of resin.

How to apply

- The universal adhesive is applied to the ceiling tiles in a thin, broken line. He is allowed to dry for a couple of minutes, and the tiles are pressed against the ceiling. The adhesive composition dries up in 1 hour, and the seam becomes strong in a day.

- Glue-mastic should be applied to the tile with a spatula, pointwise: in the center and 3 points on each side.After application, attach the tile to the ceiling and adjust its position within 3 seconds. The glue sets in 20 seconds and dries completely in 12 hours.

- Liquid nails can be applied over the entire surface of the tile in a thick layer. Due to this feature, such glue is chosen for working with ceilings that have severe defects.

The main types of PVA glue

The main types of PVA glue compositions, subdivided into types by purpose, include:

- stationery - for gluing paper and cardboard bases;

- wallpaper or household - for gluing paper materials to wood and cemented surfaces;

- construction - for fiberglass, paper and vinyl compounds. Serves as an additive for priming compounds, which helps to increase the technological properties and adhesion of materials applied in the future: putty, plaster, dry construction mixture;

- super M - irreplaceable when gluing products made of vapor-proof materials, ceramic and porcelain products, fabrics, glass, leather. In addition, it is used for the installation of a variety of floor coverings;

- Extra - used for gluing wood, plywood, construction nets, wallpaper (cork, vinyl, paper, fiberglass), serpyanka. Used as an additive to increase strength;

- Universal - useful when gluing paper and paper-laminated decorative plastics on wood, glass and metal surfaces.

Manufacturers

Most modern manufacturers of building mixtures produce a line of polymer adhesives. The products of different companies differ in technical characteristics and quality.

When studying the characteristics of a particular product, it should be remembered that high-quality polymer glue should have the following qualities:

- high rates of elasticity;

- good electrical and thermal conductivity;

- fire resistance;

- a high degree of adhesion (adhesion) and the ability to firmly bond various surfaces to each other.

Before choosing the appropriate type of polymer-based solution, it is recommended that you familiarize yourself with the most famous manufacturers and study the reviews on their products.

Dragon

The Polish company Dragon specializes in the production of construction chemicals and adhesive mixtures. This company has been supplying high quality products to the construction market since 1972.

The universal polymer-based Dragon glue is very popular in the Russian market. This composition can be used for both interior and exterior decoration. The mixture is resistant to water and temperature extremes. The time for complete setting of the bonded surfaces is thirty minutes.

Customer reviews of this product are in most cases extremely positive.

Consumers highlight the following advantages of Dragon glue:

- short drying time;

- high quality;

- effective bonding of a wide variety of materials;

- affordable price.

Hercules-Siberia

The Hercules-Siberia company specializes in the production of dry mixes for construction work. In the production of products, the most modern foreign technologies and high-quality raw materials are used.

The company produces two modifications of polymer-based glue:

- universal;

- superpolymer.

Both types of mixtures are available in dry form. The maximum volume of a bag with a free-flowing mixture is 25 kg. The universal compound can be used not only for bonding various surfaces, but also for eliminating minor irregularities in walls and floors. Superpolymer modification is excellent for cladding various surfaces of tiles. It can be used for heated floors.

Axton

Products manufactured under the Axton trademark are manufactured for the Leroy Merlin chain of stores. Axton polymer-based adhesive mix has the highest performance characteristics.Such mixtures are used in the manufacture of metal structures, finishing and installation work, as well as for sealing joints.

Bostik

The Bostik company is one of the world leaders in the production of adhesive mixtures. The company produces compounds intended for both domestic needs and the field of professional construction. All Bostik products comply with international quality standards.

The polymer adhesive Polylex from the manufacturer Bostik is distinguished by a high degree of adhesion. The mixture can be used to bond materials such as ceramic tiles, paper, various types of fabrics, wood-laminated board, linoleum, plastic.

Properties of polymer glue "Dragon"

Find out more information from the video:

First of all, polymer glue must combine elasticity and strength, adhere to any surface that the composition provides. Its technical data should give you confidence that the material being glued will not slide to the side or fall off at all.

Elasticity is needed for uniform interaction with the entire glued area (for example, a tree with all its irregularities or roughness).

Another important quality is moisture resistance. The glue that has just set, of course, it is advisable to protect it from water in all its types and forms, but if such a nuisance still happened, then it's okay - the Dragon glue is designed for use outside the ideal experimental conditions

It may not glue titanium, but it can easily cope with simple wood, as well as with a lot of other materials - leather, vinyl, rubber, plastic and plastic, some types of metal, and even with building coatings like gypsum, plaster and brick. A moisture-resistant coating is important for all of the above materials - this way the repair you make will last longer.

It is also worth highlighting the unique resistance to fire and frost.

Such glue abilities may seem useless, but do not forget about all the complexities of winter repairs, when even the equipment starts to "play up" because of the temperature, not to mention the building materials.

How to properly apply diluted glue to the surface

So, having figured out how to dilute the thick PVA glue, working with it does not imply difficulties. It's simple enough. The presence of instructions will simplify the task, since the insert contains brief information about what this or that type of product is used for gluing and how to use it correctly. Since the use of glue for wood and paper is somewhat different, some people have a problem with gluing wood surfaces. To prevent unpleasant moments from happening to you, remember a simple rule: apply glue to the side of the product that absorbs the composition more slowly, that is, with a less porous structure.