How to choose glue

When choosing an adhesive, you should pay attention to the characteristics of the composition and its purpose for hot or cold adhesive bonding. The setting time usually depends not only on the method, but also on the ambient temperature.

So, a high air temperature (over 40 ° C) reduces the adhesion time to one minute, while at room temperature the process takes at least 4 minutes

The setting time usually depends not only on the method, but also on the ambient temperature. Thus, a high air temperature (over 40 ° C) reduces the adhesion time to one minute, while at room temperature the process takes at least 4 minutes.

With the hot method, the glue dries up within half an hour, and hardening lasts two and a half hours, the full cycle of the polymerization process takes at least a day.

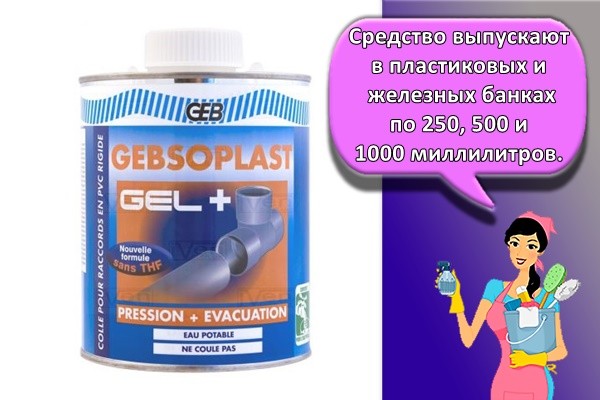

Different types of adhesives are required for compositions with different degrees of hardness (soft, hard and corrugated), while manufacturers distinguish products for soft substrates, that is, for water-pressure pipes and corrugated pipes, and hard ones, which are represented by various fittings and siphons.

Manufacturers

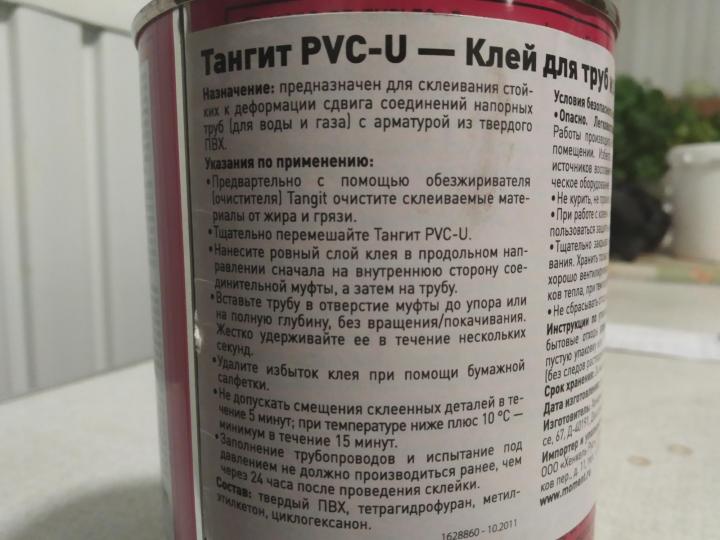

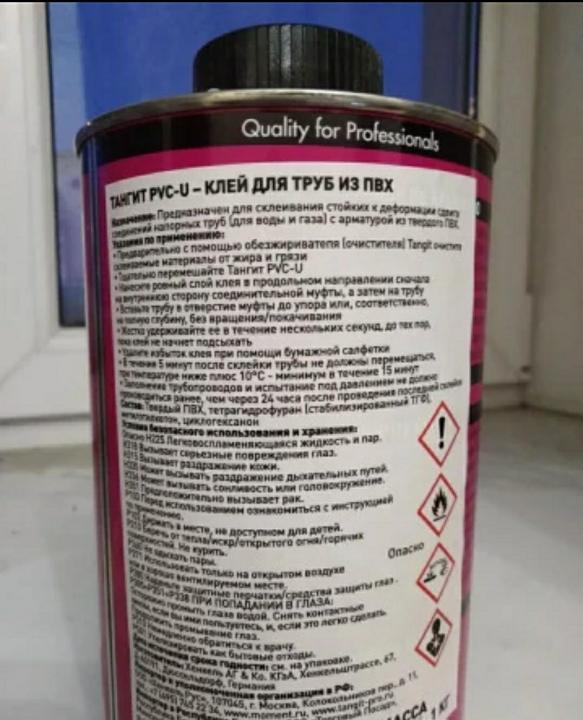

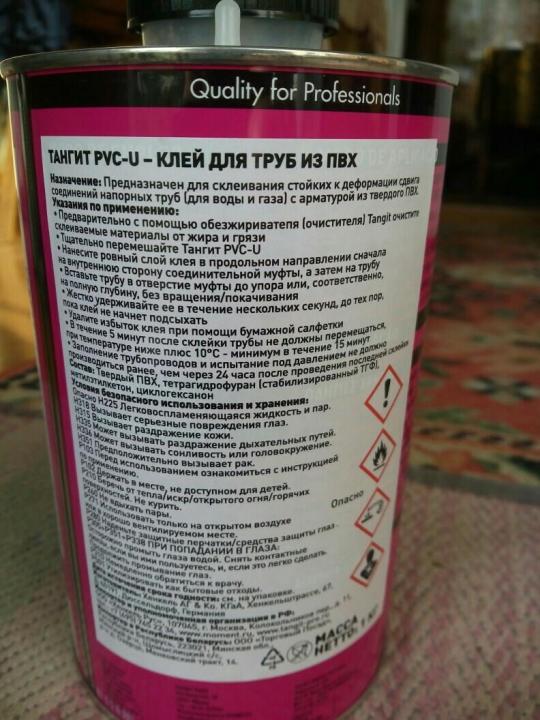

It is better to choose products from trusted manufacturers that have proven themselves in the market. For example, the German company "Tangit", whose products are certified and can be used to connect pipes for drinking water. The glue of this manufacturer is simple and convenient to use, each package is equipped with a brush for application.

The brands "Mars", "Phoenix" and "Vinilit" are also distinguished by the quality of the products, which have an increased stickiness of the composition, which creates a strong bond.

Classification

All PVC fittings can be divided according to the installation method into:

- adhesive (cold welding);

- threaded;

- flanged.

A large group is made up of combined parts that combine two different connection methods. For example, adhesive and flanged, adhesive and threaded. No fittings are used for high-temperature welding of PVC pipes. This connection method is used on large-diameter pipelines in industrial construction. Butt welding is carried out using professional, expensive equipment.

PVC fittings allow you to mount metal shut-off valves in a plastic system, connect a polymer segment of a water supply system with a metal one, and make a transition from one diameter to another.

According to the manufacturing method, PVC fittings are divided into cast and segment fittings. The cast parts have a one-piece body. During their production, the molten polymer is poured into a finished form, where it is cooled and solidified. The resulting part has no connecting seams on the body. Segment assemblies are assembled from blanks, glued during the production process. Cast fittings are more resistant to mechanical pressure.

According to the performance characteristics, PVC materials are divided into:

- pressure head intended for plumbing systems;

- non-pressure - sewerage, storm drains, installation of power grids;

- for rarefied media.

According to their purpose, PVC fittings can be divided into three large groups:

- Connecting. This includes glue, threaded, flanged couplings, which are used to connect straight sections of the pipeline.

- Branching - straight and angle tees, crosses.

- Regulating - shutoff valves, plugs.

For the installation of bends, manufacturers offer corners with a large turning radius. They allow you to avoid sewage congestion, typical for sharp turning points (starting from a right angle).

American clutch

The American coupling is a popular type of plastic combined fittings that allows you to mount both a straight joint and an angle joint.A distinctive feature of the American woman (the connection method was invented by the Americans) is a union nut, which allows you to mount a high-strength detachable connection. It is convenient to use the American coupling in the installation of hard-to-reach areas.

Bonding technology

Initially, it is necessary to mark the pipes. For this, a detailed project of the installation must be prepared. The pipes will be measured and marked for cutting along it.

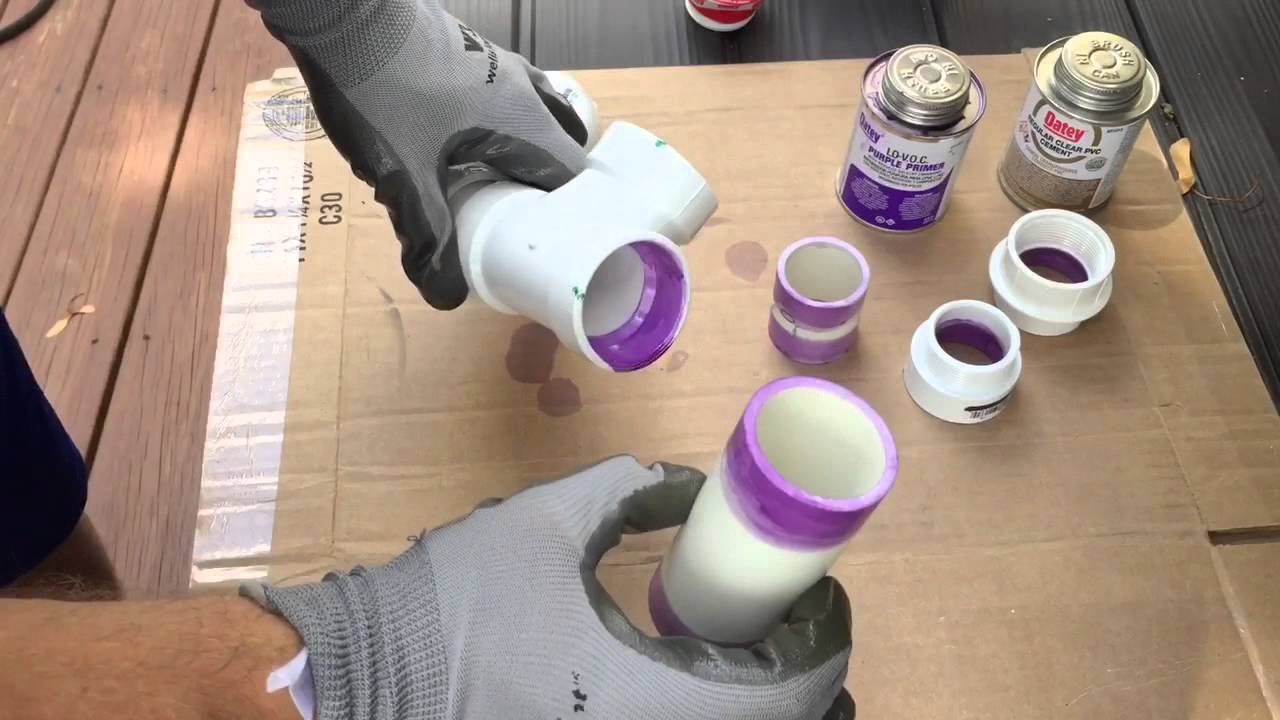

The second stage is cutting and preparing pipe sections of the required length. The pipe cuts must be very even - this is where a quality tool comes in handy. Cut edges must be sanded and degreased with solvent.

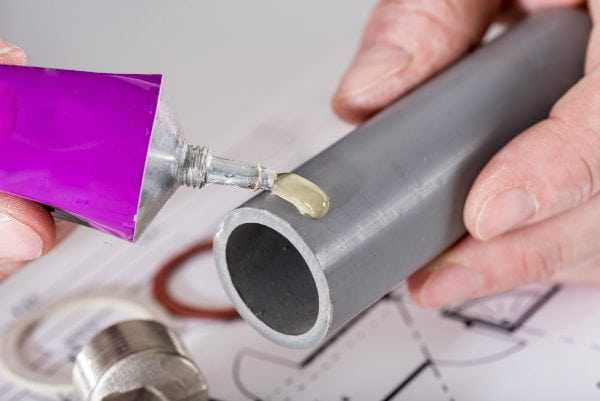

The third stage is to directly glue the parts. The glue gun is extremely convenient to use, since it allows you to accurately distribute the mass of glue over the surface of the part, but if you do not have a gun, you can use a brush. The glue must be applied in such a way that there is not a single free area left at the gluing site.

The fourth stage is the connection of parts. Parts must be pressed together for at least 30 seconds. During this time, the glue will begin to thicken, after which the product can be set aside. It is worth considering that the compressive force of the part must be sufficient - otherwise there is a possibility of leaks in this place.

Glue that has protruded beyond the bonding site must be removed. A regular wet wipe, sponge, or any cotton cloth is fine for this. In order for the connection to acquire the necessary strength and hardness, it will take at least 20 hours. During this time, it is forbidden to move the products, separate them or let water through the pipes.

After that, you need to check the connections. The system must be started up in operating mode, after a thorough examination of all joints for leaks. If leaks are found, the connection must be additionally sealed. When working with glue, the movements should be as clear as possible: the pipe section must be inserted into the fitting in one motion.

Cold welding will allow you to mount a very high quality pipeline. The method is quite effective for both plumbing and sewerage pipelines. It is applicable both in a private and in an apartment building.

For how to use PVC pipe glue, see the next video.

Types of glue for polypropylene

Adhesives for polypropylene, depending on the effect on the bonded parts and components, are divided into:

- Thermosetting: made on the basis of polyester, epoxy or oligomeric resins, hardened under the influence of a special hardener or temperature exposure.

- Thermoplastic: Manufactured using rubber compounds and resins. As the name suggests, when heated, the composition turns into a liquid phase, filling all voids and irregularities. When cooled, it provides a strong and airtight joint or seam. A serious disadvantage is the impossibility of gluing elements used in a high-temperature environment.

Depending on the amount of ingredients, adhesives can be:

- one-component - a ready-made composition with the possibility of direct application from a can or tube;

- multicomponent - a set of resin, hardener and, if necessary, filler. The components are mixed immediately before use in the required amount and used immediately due to their short shelf life.

In terms of consistency, the compositions are liquid, semi-liquid and thick.

Typical products for bonding

- The Moment adhesive sealant is a one-component, elastic, multifunctional compound based on a rubber polymer. Cures at room temperature. To preserve the semi-liquid state, it is packed in tubes.

- Liquid Nails LN 915 glue is a special, waterproof, semi-liquid, light color based on synthetic rubber, produced in cartridges for a gun. Allows a temperature difference from -30 ° C to + 60 ° C.

- Cosmoplast 500 is a liquid, transparent, one-component adhesive composition, widely used in production and in everyday life. Differs in a minimal hardening period.

- Dow Corning 7091 is a one-part adhesive sealant for bonding homogeneous materials, including polypropylene. The joints are durable, resistant to aggressive environments and temperature extremes from -55 to + 180 ° C.

- WEICON Easy-Mix PE-PP is a universal, two-component methyl acrylate-based product with high adhesion properties. Designed for gluing polypropylene, plastic, PVC pipes.

Instructions for use

The durability and quality of adhesion depends on the correct preparation of the surfaces. Instructions for use, written step by step by the manufacturer, on a box or tube. To avoid skin damage, it is recommended to wear gloves. The sequence of execution affects the quality of the further work of the bonded element.

Before applying cold welding, you need to wipe the area of the damaged surface with fine sandpaper or a file. Degrease the area with solvent or acetone. The absence of this procedure can provoke a rupture.

Apply a small layer of glue quickly. The remains of the composition cannot be reused, therefore, calculate the required amount beforehand. After application, a tourniquet or press is needed for strength. After a few hours, the tourniquet or press can be removed, and further work can be carried out.

The remains of the composition cannot be reused, therefore, calculate the required amount beforehand

Indoor or outdoor temperature conditions affect the welding time. The higher it is, the faster the material will dry.

Causes of defects when gluing PVC pipes

Uneven application of the adhesive solution and the formation of roughness on the pipe surface leads to partial non-adhesion.

Solid non-glue occurs only in a situation when the glue layers are completely overdried.

WATCH THE VIDEO

It should be remembered that PVC plastic can be glued for only 2 minutes, and then the glue dries up.

The appearance of a soft layer of glue occurs due to low temperatures outside or due to insufficient time that was allotted for the curing of the glue solution.

The porosity of the glue layer appears when there is air in the layers of the glue solution, which penetrates into such a mixture with gentle shaking of the tube.

The misalignment of the pipe joints appears due to insufficient fixation of the pipe elements to be connected, as well as when they are displaced during the curing of the glue.

If there are residues of dirt on the pipe sections to be glued or if the pipe elements have not been treated with a cleaner, it is not possible to moisten the surfaces of the pipes with an adhesive solution.

As a result, in order to choose the desired adhesive solution for joining pipe elements, one should keep in mind such parameters as the type, thickness and other parameters of the material for thermal insulation.

It is also important to know the area of application of the adhesive solution and the peculiarities of its operation. Buying a specific adhesive solution, you can make reliable thermal insulation indoors.

By purchasing a specific adhesive solution, you can make reliable thermal insulation indoors.

You can also assemble the pipeline system with your hands - when arranging a summer cottage or building a sewer system in a house.

If there are no skills and there is not enough knowledge in this matter, then it is better not to risk it, but to call professional installers at home.

How to properly glue polypropylene pipes

The procedure for gluing a polypropylene water supply system has its own characteristics. First of all, you need to stock up on a pipe cutter, a glue gun and a brush with natural bristles. Let's consider this issue in more detail.

Procedure:

- Cut the tubes with a pipe cutter according to the required dimensions.

- Clean the edges and cuts of the pipes from roughness (you can use fine sandpaper).

- Make a markup: align the structure and mark the gluing points.

- Degrease surfaces that will be coated with adhesive.

- Apply glue. In the case of using the canned version, it is better to use a brush for application. If the glue is packed in a tube, then a special gun will be required.

- Connect the parts of the pipeline strictly according to the marks that were made earlier.

- Remove excess glue.

The reliability and tightness of the connection is checked no earlier than after 24 hours. As a design test, pressurized water is run.

Often, craftsmen repair plumbing using patches in the form of a rubber band or sleeve. They are fixed with a wire or a clamp. Bonding works are carried out in the same sequence, while it is necessary to shut off the water supply. If a collapsible coupling is used for repairs, then it is not necessary to turn off the water.

Currently, a large assortment of means for tightly gluing polypropylene parts is on sale:

Cosmoplast 500. It is a one-component transparent adhesive for domestic and industrial use. The excellent grip quality allows the elements to be held together at a 45-degree angle, so it is popular with PVC window makers. It is characterized by a minimum hardening time: 3 s before the first setting and 16 hours before complete polymerization (if the ambient temperature is 20 degrees).

Dow Corning 7091. This is a one component type of adhesive sealant. When the thickness of the adhesive layer is up to 5 mm, it plays the role of glue, and if the thickness is increased to 2.5 cm, it is a sealant. Recommended for joining materials of a homogeneous type. The procedure for gluing polypropylene with such a tool is similar to working with other adhesives. The resulting compound is characterized by high elasticity, durability, resistance to oil and moisture, to temperature extremes from minus 55 to plus 180 degrees Celsius.

WEICON Easy-Mix PE-PP. It is a universal two-component compound for plastics. The glue perfectly connects polypropylene pipes, PVC, polyethylene, polyamide, fiberglass and other materials can also be glued. The basis of the product is methyl acryl

An important characteristic is called its high adhesion. Fully freezes in a day at room temperature

Of course, this is not a complete list of commercially available adhesives for polypropylene. Before proceeding with the repair of the pipeline, we recommend that you carefully study what this or that tool is capable of. So you will save yourself from possible errors that can cause poor-quality adhesion.

Not so long ago, the problem of how to glue polypropylene sheet or parts from this material was unsolvable. But today manufacturers offer a wide range of adhesives that make bonding the optimal way to join components.

The advantages of using glue include:

- no damage to the material,

- even distribution of stress,

- you can connect different parts,

- some areas are recorded almost instantly.

It should be noted that polypropylene is still a difficult material to bond, so it is important to choose a high-quality adhesive for polypropylene from a trusted manufacturer.

Areas of use

The scope of application of adhesive PVC pipelines depends on their physicochemical characteristics, products are used for the device of communications in the following areas:

- Swimming pool construction. PVC glue pipes are widely used in the construction of water supply and purification systems in swimming pools.Due to the tightness of the joints and the high anti-corrosion characteristics of polyvinyl chloride, such pipes are the most suitable when working with chlorinated water.

- Air conditioning, cooling systems. PVC glue pipes are suitable for the transportation of liquid low-temperature and aggressive substances, such as refrigerant, chlorine and so on in the construction of industrial air conditioning units, chillers, coolers.

- Laying of pressure sewerage. The ordinary consumer is well aware of the sewerage system, which is laid in apartments and country houses. It is assembled in a bell-shaped way, inserting pipes into each other, while sealing is provided by inner rubber rings mounted in the expanded pipes. This type of installation does not withstand the high pressure of the liquid working medium, which cannot be said about the sewer line assembled by gluing. Most often, adhesive PVC sewer pipes are laid in swimming pools and water parks to move significant water volumes at high speed.

- Water purification and preparation systems. Due to the resistance of polyvinyl chloride to solutions with a high percentage of various types and concentrated sulfuric acids, sodium hypochlorite, demineralized and deionized water, PVC pipes are widely used in the workshops of water treatment plants.

- Chemical industry. Bonded PVC pipelines are installed at chemical plants for the transportation of aggressive liquids - mineral acids, alkalis, solutions of salts, oils, fats, gasoline without the presence of benzene.

Rice. 2 Examples of the use of glued PVC pipes

- Agriculture. From the glued PVC pipes, the piping of greenhouses is mounted - drip irrigation systems, pipeline nodes for supplying solutions with fertilizers. In animal husbandry, engineering structures for the delivery of feed and drinking water, and manure removal are assembled from polyvinyl chloride.

- Cold and hot water supply systems. Almost all PVC glue pipes and fittings are designed for use in temperatures up to +60 ° C, therefore they are used to supply cold water. In pipelines with a high-temperature working medium, pipelines made of chlorinated polyvinyl chloride CPVC, which have a higher temperature resistance up to +95 ° C, are used.

- In air supply systems. Since the glued joint provides a high degree of tightness of the pipeline, PVC pipes are often used for the installation of natural or forced ventilation.

Rice. 3 Shaped PVC-parts for gluing

How to prepare and glue plastic piping elements

When gluing or soldering PVC pipe products, prepare them in advance.

The figure shows the stages of gluing pipe elements.

Such work must be carried out in a dry room, the air temperature in which is +5 - +35 degrees Celsius.

To apply the glue solution, you need to use a brush made of natural bristles.

When gluing PVC pipe elements, follow these steps:

cut pipe sections with special pipe cutters. In such a situation, the pipe will have a smooth cut - without the formation of sharp protrusions on the surface of the pipe.

If there is no pipe cutter, then cutting the pipe can be done using a saw with fine teeth;

- then you need to clean the edges of the cut with sandpaper in order to remove the adhering dust that prevents the tubes from being sealed;

- then the entire piping system should be assembled. There is no need to apply glue to the tube. This must be done in order to make notches with a marker on all pipe sections of gluing and to determine the depth of insertion of the pipes into the fittings;

- further, the assembled pipeline system should be disassembled and the preparation of pipe elements for gluing should be started;

- before applying the glue for gluing plastic pipes, open the cleaner and remove grease stains from the surface to be used;

- then, the polyethylene adhesive is mixed;

- further, a thin layer of adhesive solution should be applied with a brush to the fitting sockets, and then to the tube;

- then you need to insert the polypropylene tube into the fitting until it stops. In such a situation, in no case should you touch the tube and other pipe elements connected during gluing - they must be in a stationary state.

In this case, you need to look at the marks that were made with a marker in advance. During the gluing of pipes, do not turn and rotate the pipe absolutely.

At this stage of work, the pipe elements to be glued are held for 15 seconds, and the glue dries;

further, you should remove with a napkin excess glue solution of glue, which protruded along the edges of the pipe connection.

Do not move recently glued tubular products for 5-15 minutes.

Water can be poured into the resulting pipeline only after 24 hours have passed after the end of joining the pipe elements with glue.

Detailed workshop on pipeline installation using the "cold welding" method

When installing PVC pipes, you must follow certain step-by-step instructions:

- Before starting work, you should make sure that the room temperature is in the range of 5 to 30 degrees and there is constant air circulation.

- Prepare the appropriate tools: marker, ruler, pipe cutter, jigsaw, sandpaper, degreasing solvent, natural bristle brush, adhesive itself.

- Prepare your work surface. Parts must be cleaned, washed and degreased. If the pipeline is dirty, then the glue will adhere only the top and form a film, the contact with the pipe will be unreliable and superficial, it will lead to leakage.

- Carry out the markup. Before starting work, prepare a project and a scheme for gluing the pipeline. After that, the details are marked and measured.

- Use pipe cutters or a jigsaw to cut to length to the desired length. Make sure that the cut points are even and smooth. Clean them with sandpaper.

- Glue the elements of the water supply system using a special assembly gun, evenly distributing the adhesive over the surface and leaving no gaps or empty areas. If you don't have a gun, a regular paint brush will work fine.

- Hold the links together with force for about 30 seconds, the mixture will become viscous and dense during this time. Better to leave the links connected together for a day.

- If the glue leaks beyond the surface, it must be cleaned. It is ideal to remove it immediately with a damp cloth or cloth, while it is still fresh.

- Coupling takes place in a day, so until that time the fastened links cannot be touched, otherwise everything can be displaced. As soon as the time period has passed, be sure to check the system and inspect the joints for leaks.

Notes, Tips and General Precautions for Pipe Bonding

This operation is possible only after the simultaneous treatment of the surfaces of the components to be connected with a cleaning agent and the application of glue to them.

Unless otherwise specified, tolerance values should be as follows:

- tightness - no more than 0.2 mm

- clearance tolerance - no more than 0.3 mm.

The following precautions are recommended:

- Use gloves and safety goggles to ensure protection for hands and eyes.

- When using adhesives and cleaning surfaces with cleaning agents, ensure adequate ventilation of the work area to avoid contamination of the air with solvent fumes, which can irritate the respiratory tract and eyes.

Due to the volatility of the solvents in the adhesive and cleaning agent, you should close containers containing these substances immediately after use.

Gaseous solvents form flammable mixtures.In this regard, it is recommended to exclude the presence in the place of work of sources that can cause ignition, including: welding, accumulation of electrostatic charges, as well as smoking

It is imperative that the precautions given on the packaging and prescribed by the manufacturer of the adhesives are followed.

The bonding should be done at an ambient temperature of 5 ° C to 40 ° C to ensure the proper performance of the adhesive and cleaning agent.

The amount of adhesive required to complete the joint depends on a number of factors (external conditions, pipe dimensions, adhesive viscosity, experience of the operating personnel, etc.). Table 3 shows the approximate amount of adhesive that is usually required to join pipes and fittings of different diameters.

| Pipe / fitting diameter d (mm) |

Number of joints per 1 kg of adhesive |

| 16 | 550 |

| 20 | 500 |

| 25 | 450 |

| 32 | 400 |

| 40 | 300 |

| 50 | 200 |

| 63 | 140 |

| 75 | 90 |

| 90 | 60 |

| 110 | 40 |

| 160 | 15 |

| 225 | 6 |

Table 3: PVC / CPVC Pipes and Fittings. Estimated adhesive consumption

- After making all the connections and before using the received components, make sure that there are no solvent residues / vapors inside the pipes. This will avoid possible contamination of the transported fluids.

- Table 4 lists the types of the most common defects that prevent proper bonding.

| Cause | Immediate effect | Consequence |

| Too liquid adhesive (too much thinner) | Improper adhesion | Slippage or leakage at the junction of the pipe and fitting |

| Excessive amount of glue | External and internal gluing behind the joint area | Weakening of the surfaces behind the joint area and the formation of bubbles with microcracks / crack sources on the base material |

| The adhesive is too thick due to solvent evaporation | Improper adhesion Uneven drying |

Slippage or leakage at the junction of the pipe and fitting Possible appearance of surface cracks with crack sources on the base material |

| Insufficient or inadequate adhesive distribution | Improper or loose connection in certain places | Slippage or leakage at the junction of the pipe and fitting |

| Inadequate pipe insertion (incomplete, excessive, axial misalignment) | Improper connection | Transfer of mechanical load from pipe to fitting and / or leakage at the connection |

| Dirty and / or damp surfaces of the components to be connected | Improper connection | Slippage or leakage at the junction of the pipe and fitting |

Plastic pipes for gluing

Unlike metal pipes, polypropylene products can be assembled independently, even without special skills. Experts prefer not to use ordinary plastic for hot water pipes or heating pipes, but use it for sewer communications. But some types of products (in alloys with metal) are quite suitable for both cold and hot water. The advantages of polypropylene pipes are undeniable:

- resistance to changing natural conditions (pressure drop, temperature drop, humidity increase);

- lack of corrosion;

- long service life (over 50 years);

- ease of installation, gluing, repair;

- moderate cost;

- health safety.

Such a pipeline also has disadvantages. The elasticity of the material may decrease when heated, and the coefficient of expansion is high. Under the influence of the sun, some types of plastics age faster, which must be taken into account during installation.

The equipment of a house with a water supply and a sewage system using PVC pipes can be performed with products of different types. Depending on the constituent components and manufacturing technology, the following types of plastic pipes are produced:

- Made of polyvinyl chloride (PVC). The most rigid, gluing them is quite simple. They do not burn, do not react to UV radiation, light.Unfortunately, chlorine is used in the production process, so PVC pipes are not environmentally friendly.

- Polyethylene. Very durable, elastic, easily tolerate even freezing water, do not burst. Inside they are smooth, water does not leave plaque in them, deposits of impurities. Among the minuses, it is necessary to point out that they are not suitable for hot water - they begin to melt. Connected with clamp fittings. A separate type is XLPE pipes, which are used for the underfloor heating system.

- Polybutylene. Suitable for water with temperatures up to +90 degrees, but they are not mounted by gluing. Used in the installation of heating systems.

- Polypropylene. They are used for hot and cold water, for sewerage, heating, very easy to install. They are connected by soldering, they can also be welded.

- Made of metal-plastic. Includes aluminum, is an aluminum alloy with plastic. Due to the three-layer base, they are suitable for water supply, heating, withstand temperatures up to +110 degrees.

Working with a cast iron radiator with a leak

It happens that the heating battery has leaked - the threaded joint has deteriorated, a leak has appeared on the section. For repairs, you will need epoxy glue and a bandage. The material is impregnated with glue, applied to the area of the hole. After setting, you can paint over this area in the base color. This measure is considered temporary, and after turning off the heating, it is better to replace the radiator.

Cold welding of batteries is also used. A special tool is kneaded in hands, applied to the site of injury. It quickly melts, sets and allows the "patch" to exist until the heating is turned off.

You should not try to glue radiators with a strong leak, which led to an emergency. It is better to immediately call a team of specialists who will stop the leak and replace the radiator with a new one.

PVC adhesive pipes - manufacturers

The products presented on the domestic market belong to Russian and European manufacturers, the following brands are most famous:

Agrigazpolymer. The Russian company Agrigazpolymer produces inexpensive PVC pipes for gray glue with a socket with a diameter of 16 to 315 mm, designed for pressures from 6 to 16 atmospheres (atm.). The standard length of products is 3 meters, the cost of the most popular pipes of this length, depending on the wall thickness, is: for a diameter of 25 mm - 43 - 53 rubles, for 110 mm products - 350 - 440 rubles.

Agrigazpolymer provides its products with additional fittings, supplying PVC fittings for gluing in the trade in the form of numerous tees, crosses, couplings, manifolds, adapters, smooth and 90 degree elbows with smooth walls and threaded connections.

Genova Products is a brand owned by an American concern that has 5 enterprises in North America and supplies its pipe products made of PVC and PVC-C materials to Europe, Ukraine, Belarus and Russia. In addition to 3 m pipes with diameters from ½ (12 mm) to 12 (315 mm) inches and Pn from 6 to 25 atm. Genova sells a wide range of fittings, ball valves, hydraulic valves, adhesives and bevellers.

FIP is a trademark of an Italian manufacturer that has been selling its products on the Russian market for over 20 years. The concern is a supplier to the market of Corzan CPVC chloride polyvinyl chloride pipes of light gray color for gluing 5 m long. The products have diameters from 16 to 225 mm and are designed to operate at a pressure of 10 and 16 atm. In addition to pipes, the company sells numerous PVC fittings in the sales network.

Rice. 8 Prices for PVC pipes of the Dyka brand for Pn 16 bar

Dyka is a brand of a Dutch company that manufactures socketless PVC pipes with a length of 5 m for gluing, designed for a pressure range of 6 - 7.5 - 8 - 10 - 12.5 - 16 atm. The outer diameter of the supplied products depends on the nominal pressure Pn and ranges from 12 to 500 mm.

Omniplast - Dutch-made pressure glue pipes with a socket of the Alphacan Omniplast series are designed for a head of 7.5, 10 and 16 atm. The dimensions of the products in the circumference are from 12 to 315 mm inclusive, the operating temperature range is 0 - 60 ° C.

Lareter is a trademark of an Italian manufacturer supplying to the market PVC adhesive pipes fittings with diameters from 16 to 500 mm with nominal pressures from 6 to 25 atmospheres.

Georg Fischer (GF +) is a brand of a Swiss supplier of PVC socket pipes with diameters from 6 to 400 mm inclusive, designed to work with media under pressure from 4 to 25 atm. at temperatures from 0 to 60 ° C.

The company sells on the domestic market a wide range of heat-resistant socketless products CPVC (PVC-C) with the most popular sizes in circumference from 20 to 110 mm with a maximum pressure of 16 atm., Designed for operation in the temperature range from 0 to +80 ° C.

In addition to pipes, the company supplies PVC fittings for gluing to the retail network in the form of elbows, tees, bushings, nipples, couplings, shut-off ball valves, smooth-walled and with threads from 1/2 to 2 inches.

Products with absolutely identical physical parameters are presented on the domestic market by another manufacturer from Holland with the Van de Lande (VDL) brand.

Rice. 9 Cost of PVC-C Corzan

How to choose glue

Before buying an adhesive, you need to decide on the installation method, since this is the initial stage of choosing an adhesive - pipes will be connected with a hot or cold method.

Pay attention to the following information on the packaging:

- Manufacturer. It is desirable that it was a well-known company, it is even better if the same one that produced the pipes purchased for installation.

- Appointment. The most reliable connection is obtained when using specialized compounds for gluing PVC pipes, but universal glue is also suitable for the cold method.

- Type of pipes to be glued. For corrugated and pressure pipes, an adhesive labeled “for soft substrates” is required, for assembling the pipeline using fittings or installing a siphon - “for hard substrates”.

- Setting time. For hot-mount adhesive, three parameters must be specified: drying (no more than 30 minutes), hardening (no more than 2.5 hours) and polymerization (20-24 hours). The composition for cold welding has two parameters: drying at room temperature (3-5 minutes) and at 40 ° C (1-2 minutes).

- Colour. It is convenient to use products with pigmentation - this allows you to control the uniformity of the application of the adhesive layer. Transparent glue is convenient because its excess, left along the seam, is almost invisible.

- Safety and environmental certificate, toxicity instructions. For the installation of cold water supply networks, only environmentally friendly materials can be used.

- Terms and conditions of storage. Expired formulations cannot be used, and if stored improperly, the glue deteriorates before the expiration date ends.

An important point when choosing an adhesive is the presence of instructions. Each adhesive composition has its own nuances of use, and two-component ones also have features for preparing a solution. In addition, the instructions indicate what protective equipment is required during installation.