How to properly work with adhesive

Due to the use of certain components in the composition of decoupage glue, it cannot be called completely safe. Be sure to adhere to certain rules. Otherwise, there will be no difference between it and conventional PVA. The jar is expensive, so the consumption must be reduced, and this can be done in various ways.

The first thing you should pay attention to is the place of purchase of decoupage glue. It is not worth buying from an unknown manufacturer

It is not necessary to dilute the glue, but it is necessary to check its consistency before use. A good composition will not drain very quickly from the brush. The tools used to glue the surfaces depend on their shape. For normal sizes, a very thin brush is suitable, for others it is something like a roller, and still others can be processed only with the tip of a thin needle.

You need to pay attention to the following nuances when working:

- it is better not to use thick glue - it will set, but will not show effectiveness for a long time;

- drying speed - there are models that dry instantly, in order to fasten the parts with other compounds, it will take an hour and a half;

- smoothing - it is necessary to carefully smooth the surface in order to prevent the formation of wrinkles and bubbles;

- sticking - some options need to be tightly clamped to be effective.

The decoupage glue is equipped with a special cap. There is a thin hole under it where you can insert a brush and take the right amount of composition.

Types of glue and their manufacturers

Initially, two-component formulations were invented. They came with a primer, which was applied in a thin layer, giving backing before applying the adhesive (mainly cyanoacrylate composition). That is, the primer serves as a kind of surface solvent to create a strong joint.

The negative side of using such adhesive masses is toxicity. The primer, when interacting with polymers, releases substances hazardous to the body. It is not safe to use such connections at home.

The new type of glue is made from methacrylate. This is also a two-component mass, but without a harmful primer.

Manufacturers:

Weicon Easy-Mix PE-PP instead of a primer uses very small glass balls, which are distributed over the polyethylene, thereby increasing the wettability, adhesion. There are no toxic compounds, so the product is applicable in a domestic environment. Before applying, it is not necessary to clean the surface, only from strong dirt. The paste is ready to use, dosing and mixing takes place at the same time, there will be no error in the ratio.

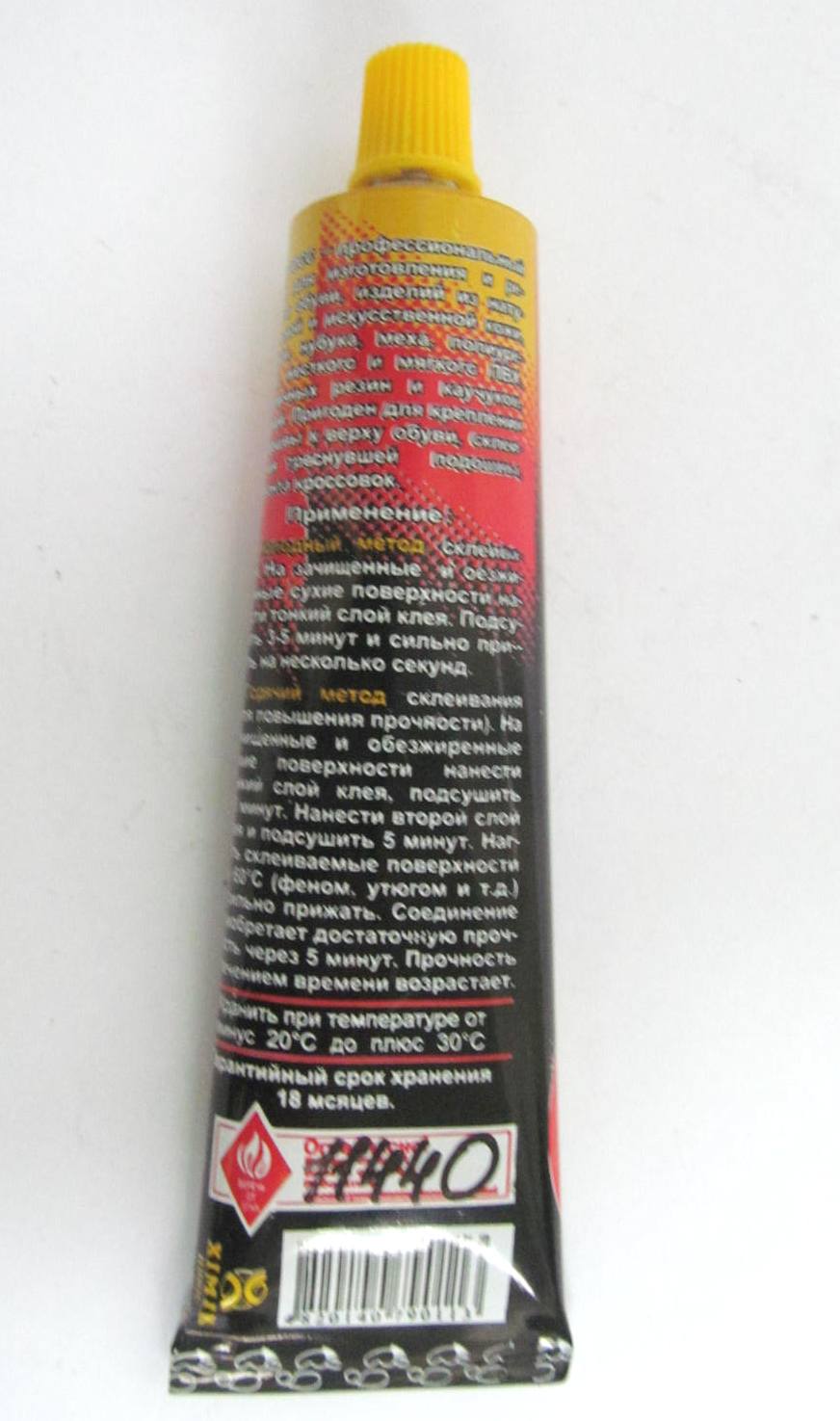

BF-2 has a viscous texture of a red-brown hue. Possesses moisture resistant, inert, universal properties. The composition includes toxic aldehydes, phenol.

V-Strong GELIAHAO 302 is a two-component product based on acrylate. Provides increased seam strength. The consistency is transparent, hardening occurs in 4 minutes, so there is enough time for correcting.

Which glue to choose?

For gluing synthetic fabrics, a special waterproof glue "Dubok" is suitable. He is a versatile model that performs well in any task. Before use, both surfaces to be joined are treated with acetone using a cotton swab. Then glue is applied to the fabric and allowed to dry for a few minutes, after which a second layer is applied, the products are connected and placed under the press for several hours.

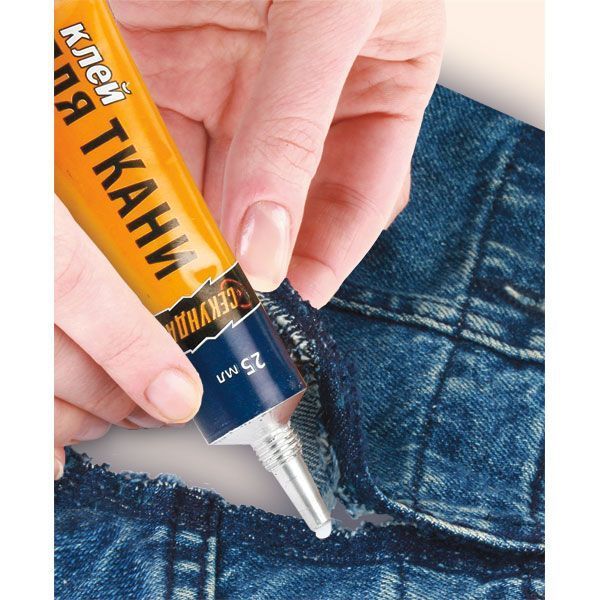

Secunda fabric glue is also versatile and suitable for most problems that arise. It is not afraid of washing, ironing and wear. The specificity of working with him is almost instant solidification, so that any operations need to be carried out as quickly as possible.

With its help, you can glue not only fabrics, but also repair shoes, leather, glue ceramics and porcelain, glue foam rubber and other soft materials. The line also includes specific models that are used in extremely severe cases. They will cost several times more, but they will also cope with the task as efficiently as possible.

The price of fabric glue is on average 60-80 rubles for a disposable tube. When making a wholesale purchase, you can bring down the specified value to the mark of 50 rubles. It is better to buy in specialized stores in order to protect yourself from fakes.

Review of the best manufacturers and brands

The choice of the manufacturer should be taken very seriously. Now the market for decoupage glue is not yet so wide, it is not subject to compulsory licensing. Therefore, there is a high probability of meeting a fake. Do not hesitate to ask for certificates confirming the quality and instructions for use.

Mod podge plaid

Mod Podge PLAID is a glue developed by an American manufacturer. It is used for outdoor work around the house. Best glues slate, wood, concrete and metal. It is not only an adhesive, but also acts as a sealant and adhesive for surface coating. He is one of the strongest rosters on the list. Suitable for decorating bulky items with large pieces of material. Its peculiarity is that it dries for at least 15 minutes, you need to hold it all this time to ensure better grip.

Decola

Decola is a versatile and effective glue created in Russia. It is designed to work with wood, glass or metal. The tool cannot be called completely devoid of flaws, sometimes there are reviews on the network that it cannot cope with heavy layers. But the minimum price, ease of use make it possible for novice needlewomen to use it.

La Doratura

La Doratura is an adhesive that can bond even heavy surfaces. It is intended for outdoor work, as well as decoupage. Copes with metal, wood parts.

Art potce

Art Potce is a popular tool often used by Russian needlewomen. It combines the advantages of conventional glue and varnish. Perfectly copes with surfaces of ceramics, metal, wood, cardboard and natural stone. They can also process the surface of products, as it leaves a bright shine. But the strong strength of the glue cannot be noted - products covered with it are better placed as a decoration at home, and not actively exploited.

Glitter art potch

Glitter art potch is a unique tool that not only holds parts of the product together, but also helps to decorate it. Leaves holographic particles like tiny sparkles.

Kerzen potch

Kerzen Potch is used for working with paper napkins and fabrics. But the main area of its use is wax products. Due to the fact that the wax particles contained in the composition do not melt the picture when burned in the wax. The composition reliably glues the parts together, does not peel off the surface of the candle or other material. It dries in 1-2 minutes without leaving an unpleasant odor, yellow spots or smudges.

Porcelain glue

Porcelain glue is used to decorate glass, ceramic and porcelain products. It is used to decorate dining room inventory, sets. The peculiarity of porcelain glue is that it must be dried in a special hot oven for at least 90 minutes. But then you can use plates, jugs, glasses without fear for your health, and it is also easy to wash them in the usual dishwasher mode.

"Mordan"

"Mordan" is an Italian-made glue. Its distinctive feature is its ability to work with water-repellent surfaces. Glass and ceramics are covered with gold leaf or gold leaf with its help. The cost of glue is quite high, but only it is used to decorate expensive surfaces (others can damage expensive materials).

Mod podge

Used for working with metal, concrete, wood and slate. Although it is intended for outdoor work, needlewomen around the world actively use it for decoupage. It is especially effective, it dries for 15 minutes.

Types and types of adhesive

It is best to select glue for clothes, furniture among proven compounds that will definitely not spoil the material, although it is necessary to clarify the suitability for a particular fabric in each individual case.

Rubber compounds

If you need to carry out high-quality repair of clothes, glue the internal elements of the suit, carry out other work with fabric without traces and stains, it is better to use rubber glue. Such agents are solutions of synthetic or natural rubber with vulcanizing agents. You need to purchase non-toxic compounds in small packages that are designed for rubber and fabric. They are applied in a thin layer, and after some drying, the processed parts are pressed against each other.

PVC glue

This is a solution of perchlorovinyl resin in organic solvents with the addition of plasticizers. The glue is characterized by high temperature resistance (up to +100 degrees), moderate frost resistance (up to -20 degrees), resistant to the action of water, oil, gasoline. It is applied in 2 layers: the second - 10 minutes after the first. The product will be ready for use in 2 days.

Fabric adhesive "liquid thread"

Compositions of the "liquid thread" type are widely used in needlework, especially when combining different materials. They are well suited for gluing rhinestones, fringes, appliqués, patches, attaching spiderweb fabric, coconut thread, felt, felt. The adhesives are distinguished by the accuracy of application and uniformity of the layer, high adhesion to the surface, and transparency. The products dry in seconds, do not damage the fabric, even beginners can use them.

Nitrocellulose composition

Adhesive based nitrocellulose, solvents and plasticizers are most commonly used in shoe factories. In addition to leather, they can be used to bond strong types of fabric - bologna, banner, membrane, etc. After gluing, it is required to press down the products with a load until the glue regains its final strength.

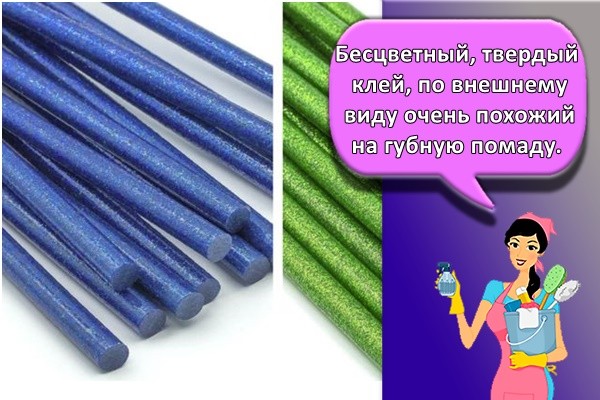

Hot glue

Such agents can be commercially available in powder form and in the form of glue sticks. In the first case, dilution is required until the finished composition is obtained, in the second, the glue must be melted with a special gun. Hot melt adhesives provide a high degree of adhesion, absence of stains, environmental friendliness, reliability of the seam.

Polyvinyl acetate adhesive

PVA can be used for permanent and temporary fixation of products, because if desired, it can be washed off the fabric after washing. Conventional polyvinyl acetate adhesives do not tolerate moisture, but nowadays there are modern moisture-resistant compounds on the market and even two-component products that can withstand direct contact with water. In most cases, PVA is still used in decoupage, creating children's fabric crafts, gluing appliques.

Aerosol adhesive

Aerosol adhesives differ only in the form of release - the composition is poured into small cans. Such means are conveniently sprayed onto the surface to be treated, they can be applied to any area. Also, fabric spray glue is used for fixing patterns, sewing in zippers, laying basting, and processing the edges of fabric. The shelf life of the glue in an aerosol is long, because the solution does not come into contact with air.

What is important to consider when choosing a silicone adhesive

The silicone craft glue can be in the form of hot gun sticks or liquid formulation. Regardless of the consistency, adhesion substances of this type have a high degree of adhesion.

- There should not be many air bubbles in the liquid or gel adhesive. They can form as a result of improper storage of the substance (for example: at sub-zero temperatures).Excessive air can lead to the formation of a porous joint after hardening.

- The structure of the glue should not be too liquid. Otherwise, the glue will harden for a long time and smudges may form.

- For use with children, it is best to choose liquid silicones. They do not require heating and are therefore safer to use.

- Colour. The most versatile is clear craft glue. But for the more sophisticated needlewomen, there is a large selection of thermo rod colors for pistols. There are even glitter cores.

- Some adhesives have a strong chemical odor. When working with such compounds, make sure that there is forced ventilation in the room.

- If, in addition to adhesion, sealing is required for the manufacture of crafts, aquarium or sanitary silicone can be used. The adhesive forms a hydrophobic seam. For other purposes, a universal composition is suitable.

Review of suitable brands

There are six common manufacturers engaged in the production of high-quality neoprene glue.

Aquasure

Universal adhesive mixture used for working with rubber materials. Aquasure is used for more than just rebuilding wetsuits. It is also used to glue other water sports equipment.

Among the features of Aquasure, it is distinguished that it does not lose elasticity even after hardening. This allows you to use such a composition for gluing surfaces in places of bends. The volume of one tube of glue is thirty grams, thanks to which it is possible to process a considerable area at a time.

Picasso

This is another well-known manufacturer that specializes in the production of high-quality adhesive mixtures for gluing rubberized materials.

Many experts consider Picasso products to be the ideal choice for bonding neoprene materials. Such an adhesive composition is characterized by resistance to high humidity and reliability. If the suit is glued together with Picasso adhesive, the seam will not come apart for 3-4 years.

Bostic

It is a high quality adhesive based on starch, dispersion and PVA. Some people think that it is used only for gluing neoprene, but this is far from the case.

Bostic is versatile as it can be fixed on many different surfaces. It adheres well to concrete, brick, wood and plastic surfaces. It can also be used to fix tissue materials.

Stormopren

It is a two-component adhesive commonly used to repair dry suits. Many watersports refurbishers find Stormopren to be the best glue for bonding neoprene. The composition of the product contains components, thanks to which it is possible to reliably fix the rubber coatings. The adhesive reliably adheres latex, leather surfaces, as well as fabrics and rubber. However, it is not recommended to use Stormopren for gluing building materials, since the composition will not provide reliable fixation.

Sargan

People who are looking for funds to repair wetsuits should turn their attention to the products that are manufactured by Sargan. It is a versatile adhesive often used to repair leather goods and water equipment.

Also suitable for gluing leatherette coatings.

The product is sold in tubes, the volume of which is fifty milliliters. However, in stores you can find more voluminous tubes of 100-150 milliliters.

Technisub

If you need to quickly bond neoprene products, you can use Technisub. The main feature of this composition is that it sticks quickly. The applied liquid begins to set within one minute after application.In this case, the glue completely solidifies after 20-25 hours. The advantages of Technisub include its ease of use. To glue the parts, you just need to degrease the surface to be treated and apply glue to it.

Adhesive for home textiles

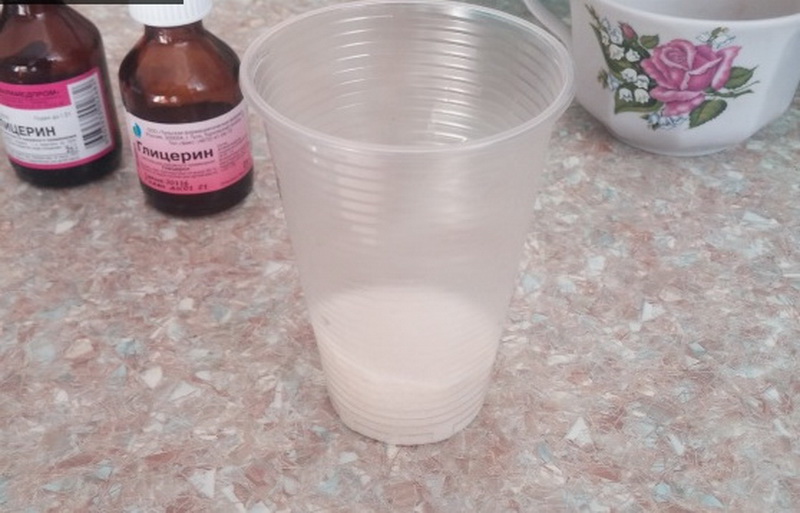

In order to prepare an excellent glue for textiles at home, which is no different from store options, you will need to take the following components:

- liter of filtered water;

- 5 grams of gelatin;

- 5 grams of pharmacy glycerin;

- up to 100 grams of solid flour;

- 2 teaspoons of ethyl alcohol.

All of these components are to be mixed in the following sequence: gelatin soaked until swelling is placed in a container in a water bath and mixed with flour. The resulting mixture is kept under the influence of temperature until it boils. Continuous stirring will be required. After the mixed components have boiled, alcohol and glycerin are added to them.

Watch the video how to make glue yourself:

After cooling, the home textile glue is ready to use.

You can also use the following recipe: casein powder and filtered water are mixed in a ratio of 1 to 2. The mixture is stirred until a thick gruel is formed. Then you can use it.

About the nuances of the procedure

In order to glue fabric with fabric or other materials, you will need to follow simple instructions:

if textiles are glued together, it is important to conduct a test on small pieces of fabric in order to make sure that the selected composition is reliable;

when gluing fabric with other materials, it is important to first clean and degrease the latter - this will guarantee good adhesion;

some of the compositions can be used only under certain conditions - information about this is contained in the packaging with the selected glue.

Watch the video to find out more:

This article discusses the most common adhesives that allow gluing various types of fabrics both to each other and to other surfaces: wood, cardboard, paper or plastics.

If you prefer a home-made composition to the store options, then it is important to remember that the ready-made mixture, if it has not been fully used, is best stored in a dark, cool room in a well-closed container.

Features of the use of various formulations

The reliability of the performed glue seam depends on what type of textile composition is currently used. Each type of composition has its own characteristics that must be taken into account.

- Nitrocellulose. Suitable for combining leather and fabric. Or for other complex types of matter.

- Styrene butadiene. It is an elastic material that retains its properties even under constant exposure to ultraviolet rays. It successfully resists the effects of water, too high and low temperatures.

- Perchlorovinyl. Works best with leather and vinyl, rubber. It became more widespread among representatives of the shoe industry.

- Hot melt adhesive. The composition is absolutely safe for humans. Colorless material, resistant to water and chemically active substances.

- Nairite with neoprene in the base. Water-resistant composition, with a transparent structure. Allows you to get strong seams, regardless of the type of fabrics that are being processed.

- Polyurethane. Better for high density materials.

- Rubber ylatex. They are combined with foam rubber, leather, fabrics of various types. It can even be used on declicate structures, since they do not harm the surface.

- PVA is a universal glue, including for the direction of needlework.

Waterproof compounds

Varieties and purpose of glue

Many people who are planning to open their own atelier are interested in the question, which glue is best to use for the fabric? This is a very important point, since the quality of work will largely depend on the consumables used, and, accordingly, the image of the company in the eyes of customers. There are several types that are suitable for this purpose:

- - glue on a polyurethane base;

- - glue on a neoprene base;

- - glue based on styrene-butadiene;

- - polyvinyl acetate glue (PVA);

- - heat-resistant glue;

- - nitrocellulose glue;

- - perchlorovinyl glue;

- - polyvinyl chloride glue (PVC);

- - rubber glue;

- - glue for decoupage on fabric.

As you might guess from the above list, different models differ in composition, which determines their basic properties. Such a rich selection of substances opens up enormous opportunities for manufacturers. Transparent fabric glue is produced in almost all countries of the world. Taking into account the constantly growing needs of fashion, the production of accessories for the production of clothing is one of the most profitable and promising areas of business development in the future.

It is necessary to choose glue for leather and fabric taking into account a number of features. First of all, they look at the specifics of the use of clothing. For a coarse robe that will be used in harsh conditions, you need the strongest and most durable model. And for a light summer dress, you will need the same gentle glue that does not change color when solidified and does not leave stains on clothes. Also, if direct contact with the skin is implied, you need to take a brand from environmentally friendly materials in order to avoid allergic reactions, irritations and other troubles.

Varieties and scope of adhesives

The fabric adhesive must meet certain requirements. Unlike hard glued surfaces, fabric is stretched, washed and exposed to detergents. All these factors can reduce the adhesive force of the composition, therefore, when choosing an adhesive, it is necessary to focus on the subsequent operation of the material. It is one thing if you need to glue a decorative element, it is another thing to firmly connect two parts that are being stretched.

What kind of glue is best for joining textile elements depends on the density of the material. If the canvas is thin and translucent, then the composition should be transparent. Moreover, even over time, it should not turn yellow and coarse, otherwise the glue seam will turn out to be hard to the touch and detectable by the eye.

The product must be safe and as environmentally friendly as possible. Otherwise, it will not work for processing clothes. You can choose both silicone glue and rubber-based composition. These funds are considered optimal: they make the seam elastic and connect not only fabric canvases, but also textiles with wood, plastic, etc. It is convenient to attach rhinestones and decorative elements to them.

To understand which glue is worth buying, you need to understand the capabilities of the various components.

Rubber compounds

Of the synthetic adhesives, rubber varieties have gained the greatest popularity. They do not tighten the fabric, do not make it rough, and the seam is tight. The connection is almost invisible, because the glue for the fabric is transparent in most cases.

Several options for rubber compounds:

- NBH "Rubber";

- glue for fabric "Secunda" - transparent;

- Moment "Rubber".

On sale there is a so-called "rubber", that is, rubber glue "Moment", which acts quickly and connects textiles "tightly". It is suitable not only for clothes and shoes, but also for other elastic materials.

The product is applied in a thin layer on both surfaces. Apply and leave under load. Sometimes it is required to allow the composition to be absorbed, and then they are passed with acetone and only then the surfaces are connected.Specific rubber mixes may vary slightly in consistency and application.

PVA compositions

PVA glue is characterized by safety and affordability, although it does not hold all fabrics together, and the strength of the connection leaves much to be desired. But there are different types of mixtures based on polyvinyl acetate.

For gluing fabrics, building PVA is recommended, as well as waterproof glue, which can even be used to connect wood. To choose a suitable composition, it is necessary to decide in what conditions the fabric will be used.

If we are talking about a wall panel or other textile craft, then potent agents are not needed. For applying elements to winter clothes, Super PVA (PVA-M) is suitable as a fabric glue. It ensures reliable adhesion and does not harm the elasticity of the material, even at low temperatures. Both surfaces are treated, the product is left under the load, used in a day.

Hot melt adhesive for fabric

All previous options could not be called directly textile. But thermal compounds are called textile adhesives for a reason. They are common among dressmakers who use hot melt adhesives in any form, but more often they purchase special glue guns for various tasks: applying rhinestones and appliqués, fixing cuffs on trousers, etc.

Pistols are filled with glue sticks (types of sticks: cores for a 11 mm AT-S TK-1101 gun, Rexant and Proskit 61103 hot melt glue stick). A spray can under pressure sprays glue onto large surfaces, and the glue-spray for fabric allows you to connect not only canvases to each other, but also solid parts made of plastic, wood, cardboard. Aerosol adhesive is suitable for various types of fabrics, it bonds the elements firmly and without traces. The advantages of the thermal composition are recognized:

- non-toxicity;

- bond strength;

- speed of action;

- lack of unpleasant odor;

- resistance to alkalis and acids.

Before applying the glue, the surfaces are degreased, then the composition is applied, the parts are pressed and held for about a minute.

How to glue at home

If there is a need to glue polyethylene at home, then you need to use IZ means. The bonding process depends on which base the film is attached to.

Interesting video on the topic:

Between themselves

BF-2 will be glued to each other with polyethylene film. But before work, you need to prepare:

- The surface is thoroughly cleaned from dirt, dust deposits, degreased.

- Apply a layer of adhesive, distribute evenly, connect surfaces.

- Press down for a couple of hours until the mass grasps.

This preparation is suitable for all types of joint compounds.

Adhesives are toxic compounds, work is performed with gloves.

In addition to glue, double-sided tape, soldering the ends between two metal plates, and molten plastic will help to glue the film.

To metal

In order for the polyethylene to tightly, reliably cover the metal surface, the following steps must be taken:

- the metal surface is cleaned, degreased;

- warms up to 120-150 degrees;

- the film is carefully stretched, gradually applied to a metal plane, and rolled.

To concrete

It is not difficult to stick insulation to concrete, the main thing is to follow the rules:

- the concrete surface is cleaned, leveled, primed;

- glue is applied to the side of the insulation, where there is no foil;

- wait a minute until the glue is soaked;

- impose the canvas, press;

- the edges are additionally coated, fixed;

- wait until it dries completely.

Additional tips and tricks

In order to correctly repair the awning, you need not only to follow the standard provisions of the instructions, but also to familiarize yourself with the list of additional recommendations. Among them are the following:

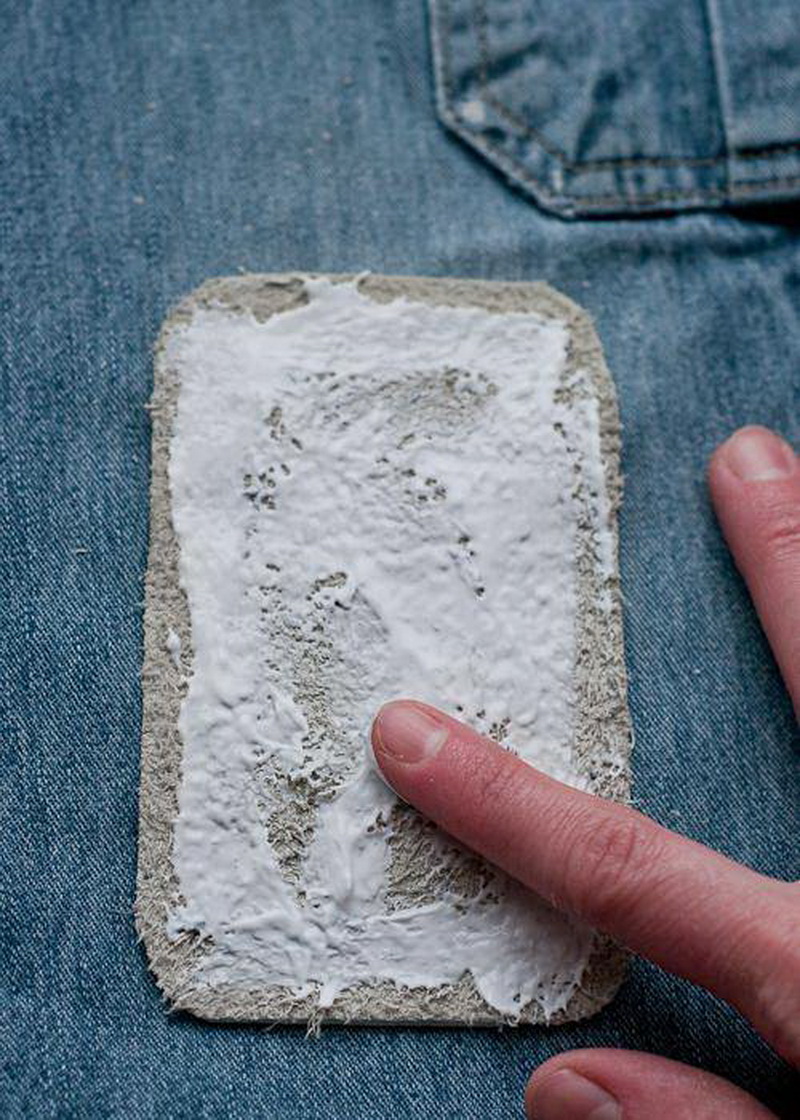

- As a patch, it is better to take a fabric from the same material as the canvas itself.The patch should be durable with no frayed edges.

- Scotch tape is not used in place of the damaged area, as this is not a reliable way to solve the problem. Only certain types of adhesive solutions are able to fix the patch.

- Doubting your own capabilities, you can always contact the workshop, where the integrity of the canvas will be restored. In addition, even very large defects can be repaired in specialized services.

- If the canvas has dispersed along the seam, then after stitching with nylon thread, it is recommended to apply an additional layer of adhesive solution.

- When doing the work, it is imperative to adhere to the instructions for using the adhesive and the basic rules for gluing the patch to the canvas. In particular, it is impossible to carry out repairs without first degreasing the surface, since otherwise the adhesion of materials will deteriorate.

Adhering to simple tips and tricks, it will be possible to carry out high-quality repair work and restore the condition of the canvas. If the wear is so strong that the awning breaks again with minimal external impact, it is easier to replace the fabric.

Share link: