The main characteristics of glue for cork and its varieties

All cork products have excellent sound-insulating heat-shielding properties. Thanks to these factors, excellent appearance and quick installation, cork products are conquering large groups of admirers.

If you plan to glue the cork on the walls, it is not recommended to use acrylic glue.

If you plan to glue the cork on the walls, it is not recommended to use acrylic glue.

It is worth remembering that cork is an expensive material, therefore, it should be designed for a long service, which the glue should provide.

There are not so many professional cork adhesives. Experts identify 2 types of the most common adhesives: acrylic adhesives and contact solution.

Professional builders do not recommend using acrylic glue to connect the cork to the wall material, since it destroys the surface structure of the material and impairs its properties.

Professional builders do not recommend using acrylic glue to connect the cork to the wall material, since it destroys the surface structure of the material and impairs its properties.

Contact solutions are commonly used adhesives. In order to firmly and permanently connect the wall with the cork, this glue must be applied to two surfaces in the same proportion, and then pressed.

The main advantages of a contact adhesive solution include the following factors:

- good resistance to humid environments;

- excellent strength indicators;

- resistance to sudden temperature changes;

- protection against exposure to chemical elements (acids, alkalis).

Contact adhesive is applied directly to the cork and to the surface

The installation requirements for the cork adhesive are the same as for all other bonding agents.

There are recommendations for use at a temperature of 15-20C and a relative humidity of not more than 70%.

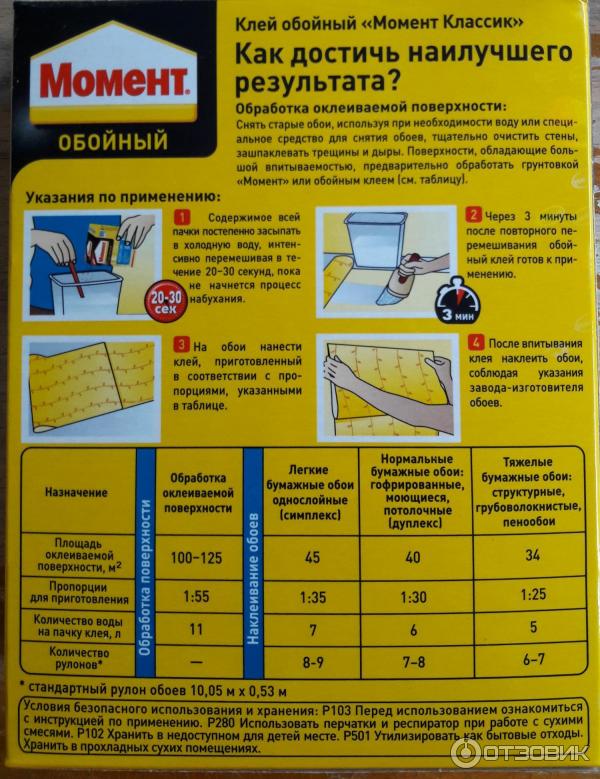

In most cases, in order to glue the cork panel, you need to press it against the wall for 20-30 seconds. This period will be sufficient to create a reliable connection.

All contact adhesive solutions can be divided into 2 types:

- water-based substances;

- solutions using a solvent.

Both types of compositions are widely used when walls are glued with cork.

Water-based adhesive solutions

Adhesives of foreign production are of the highest quality

Almost all water-based solutions created for gluing cork and other wall materials are produced abroad. This factor automatically indicates a considerable cost of substances.

The reliability and ease of application of these formulations can only be admired. Correct performance of the recommended assembly steps guarantees high product quality.

Having applied such an adhesive to a panel or wall in a thin layer, it is advisable to hold the surfaces to be glued for as long as possible to ensure a reliable connection and release of water from the composition.

Using such a composition, cork panels can be used in absolutely any room.

Using such a composition, cork panels can be used in absolutely any room.

It is worth noting that people do not always tilt their choice to the side of aqueous solutions, since their price can be several times higher than their counterparts. It should be remembered that such a factor as the environmental friendliness of the material is very important.

Solvent adhesives

Such mixtures are suitable for all surfaces.

Such mixtures are suitable for all surfaces.

The solvent-based adhesive has a wide range of applications. The material covered with such a solution adheres perfectly to almost any surface. To be able to exploit

glued cork wall panels for their intended purpose, no need to wait for a long period, the material sets immediately. The solvent is known to have a characteristic unpleasant odor.

Despite the dignity of compositions of this type, represented by instant adhesion and excellent pricing policy, solvent-based glue in the composition has obvious drawbacks:

- toxicity;

- the ability to use at temperatures up to 20C;

- flammability of the substance. For more information on how to glue the cork to walls and ceilings, see this video:

Types and characteristics of cork materials

Now in hardware stores, various types of cork coatings are sold on walls and floors. As for wall materials, they come in two types: wallpaper and panels. Wallpaper can be paper-based or roll cork.

The first ones play a decorative role, they are covered with varnish or wax composition on top. Due to their low weight, they can be glued not only to the walls, but also to the ceiling. The effect of heat and sound insulation due to their small thickness should not be expected from them. Some wallpapers need to be planted on an adhesive composition, with others it is enough to simply rip off the inner backing and fix them like a self-adhesive film.

Rolled cork cloth is also used as wallpaper, but it costs an order of magnitude more. It is thick, durable and comes in rolls that cannot be bent. This material is 100% natural, sometimes it is even sold unprocessed, and after gluing it requires additional decorative finishing. Most often, such a canvas is used for pasting the kitchen, hallway.

Other cork finishing materials:

- Panels. Top covered with varnish, wax, ideal for wet rooms.

- Plates. They have a different shape than panels (usually wider and shorter), they serve as insulating material from noise and cold.

- Tile. It happens one-layer, two-layer. The first option is simple tiles made from one layer of material. The second type of tile has a brightly colored bottom and veneered top layer. The colored fragments in the two-layer tile show through a little.

For the floor, a cork backing is used, which is usually laid under parquet, laminate. It reduces heat loss, reduces noise levels, and neutralizes base defects. Such substrates can also be glued to walls under any finishing material in order to warm the room, soundproof, and improve the adhesion of the wallpaper to the surface.

Terms of use and tips

When using bearing glue, some rules must be followed:

- Despite the fact that some structures are used on uncleaned surfaces, nevertheless, if possible, it is necessary to clean and degrease. This will have a positive effect on the bonding result.

- Stronger bonding will occur on rough surfaces.

- Do not allow material to get on the balls of the bearing, as this will damage the part.

- The glue should be distributed evenly over the entire joining plane of the element. Some compounds can be applied to one of the connected planes.

- The company "Loktayt" for the application of its compositions provides for manual use, semi-automatic and automatic method.

- For a better distribution of the mixture on the planes, it is necessary to rotate them relative to each other with the composition applied to them.

- If re-bonding occurs, then previous applications must be removed from the surface.

We advise you to watch the video review:

Shoe glue requirements

Many shoe troubles can be fixed at home. Up to 80% of pairs are now produced using special adhesives, and shoe glue is almost always used for repairs instead of threads and nails. This is due to the high quality of modern adhesives, which have an excellent level of adhesion to various materials and can easily withstand serious loads.

You need to choose glue for shoe repair depending on the specific task. For example, if you need to glue the insoles, use ordinary shoe glue.For the sole, they buy a reinforced composition, if it bursts, sealing is carried out with special means, then gluing. It is best to buy a professional glue of a well-known brand. In the absence of experience in such acquisitions, you need to make sure that the product has the following properties:

- reliability, long service life;

- water resistance;

- frost resistance;

- high degree of adhesion;

- lack of rigidity, elasticity;

- no harm to leather shoes or products from other materials.

Most good adhesives are suitable for leather, leatherette, eco-leather, as well as rubber, polyurethane, synthetics, felt, fabric

Nevertheless, some compounds for polyurethane soles are not suitable, they roll off, which you need to pay attention to when buying. Usually, it is recommended to purchase compositions based on artificial rubber for summer shoes, and adhesives with higher frost resistance for winter shoes.

For repairs for a short time, you can take an inexpensive tool, for long-term wear, it is better to spend money on better quality glue.

Universal types of floor adhesives

There are several universal adhesives for installing cork coverings. Water-based acrylic adhesive is used in rooms with low traffic, where heavy furniture is not installed.

Such varieties are distinguished by technological features:

- only the glued surface is lubricated;

- the basis is acrylic, diluted in water;

- glues tiles only in small rooms;

- low cost.

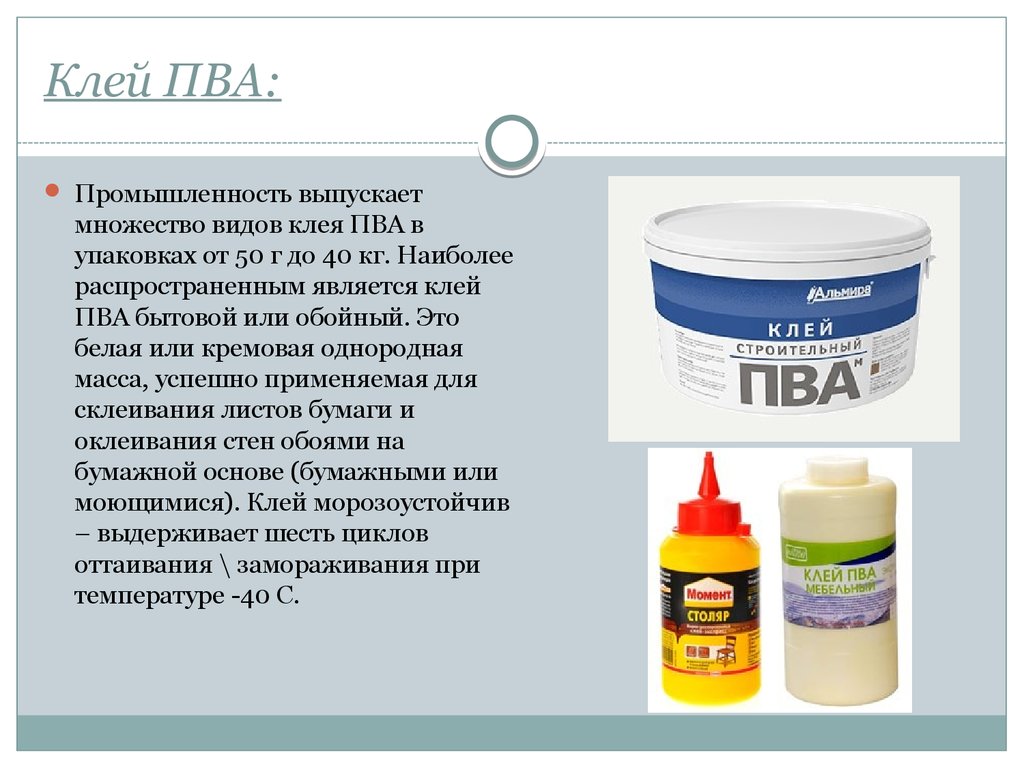

Perfectly adheres to PVA cork. But working with such a substance requires accuracy and increased care.

For gluing the cork with waterproof PVA, the agent is applied to the surface of the tile and base. Wait until it dries up. Then put the tiles in the right place and press down with force. After a minute, the pressure can be removed, the glue will set, the tile is glued.

PVA glue for cork

PVA glue for cork

How penofol and isofol are obtained

Lightweight and thin insulation used in construction, the automotive industry and produced in rolls is divided into several types. All types of penofol are made from polyethylene foam, with one or both sides subject to foil. A composition with a protected special coating is applied to the self-adhesive material.

Isofol is obtained from soft elastic polyethylene, which sticks to different surfaces, is well cut, and serves for a long time. Foil-clad material has excellent insulating and reflective properties, is easy to attach, and has low thermal conductivity.

What glue is used for furniture edge

Most often used as furniture edges:

- melamine - made of decorative paper impregnated with melanin, has a self-adhesive layer;

- PVC edging - flexible tape of different profiles;

- ABS plastic is an environmentally friendly, impact-resistant border (chlorine free).

In order to repair an edge made of polyvinyl chloride or ABS at home, use PVC glue or popular compounds marked "for PVC" - "Moment", "88-Lux" and others. They are convenient to use, quickly and easily fix the edge, inexpensive and safe.

If the repair is carried out by professionals, then they use hot melt adhesives, which become elastic after heating, and when cooled down, they quickly harden. This property is obtained from the thermoplastics included in their composition of ethylene-vinyl acetate. To use such glue for the edge, special equipment is required, therefore the composition is used in production, where the function is put on stream or is performed at home using a special glue gun. Kleiberit products are well known among professionals.

Properties and applications

Since the application of glue does not cause the product to lose its attractiveness, it can be used in a wide variety of cases. It is great for cardboard, paper, polymers, foil, textiles, foam, and:

- sisal;

- foam;

- beads;

- fittings;

- thread, yarn;

- wool;

- foamiran;

- ribbons, lace;

- floristic decor;

- polyethylene;

- photographs;

- napkins.

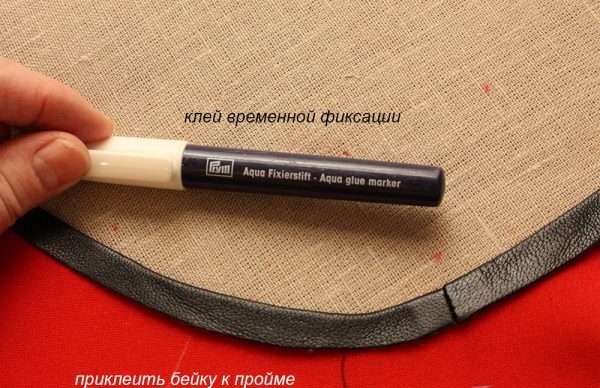

Most often, temporary glue is used for fabric in order to create patterns, fix patterns, sew in zippers, and process the crumbling edge of matter. The use of glue reduces time costs, reduces the number of defective products, while the result is beautiful and neat.

Needlewomen working in the patchwork technique appreciate temporary adhesives for the ability to attach yarns and threads to fabrics with further sewing. Then the product is washed and the glue dissolves. It is very convenient to attach stencils to glue for a short time, and then easily remove them.

Other areas of application of the product:

- minor repairs at home;

- design work, interior decoration;

- decoration of furniture, windows, curtains, curtains, doors;

- decoration of rooms for the holiday;

- creation of complex decor and applications on fabric;

- artistic activity;

- furniture production, assembly of individual units and fastening of small elements;

- some operations in electronics, mechanical engineering, light industry;

- production of advertising materials;

- creation of wall newspapers, posters, thematic stands and exhibitions.

Adhesives are often sold in the form of sprays, although there are other types. The aerosol form is very convenient to use, because it is enough just to spray the adhesive on the product. You can peel off the parts several times, which is very convenient when fitting. Most temporary adhesives are freeze-resistant, water-resistant, colorless and odorless. Some formulations require subsequent mechanical removal or washing, others evaporate over time.

How to glue cork coverings on the wall: instructions

If this is the first time you are gluing eco-friendly cork material on your own, then carefully study the recommendations.

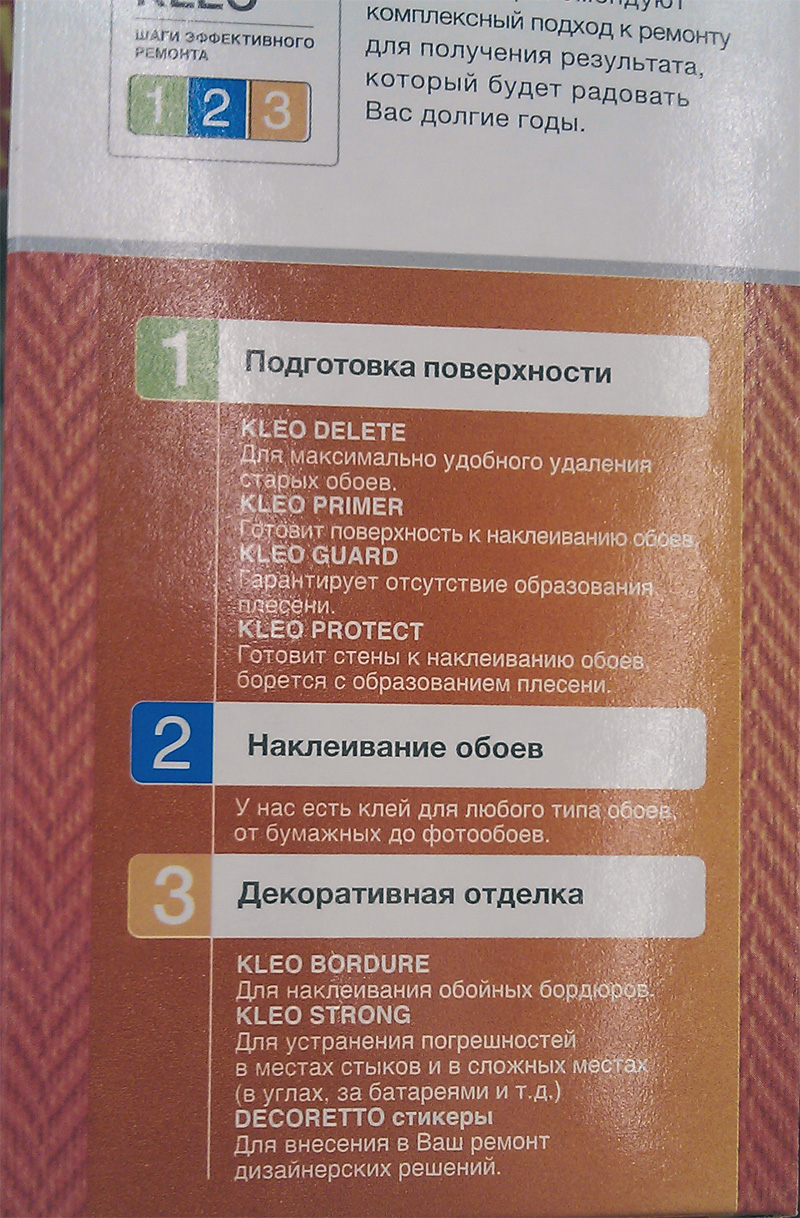

- Preparation of the base. In order for the finish to keep up with the base, it must be properly prepared. The walls are cleaned of old cladding, if there are cracks, they must be filled with cement mortar and leveled to the building level. For better adhesion, the plane is primed and dried.

- Layout of walls and material. If the panels are laid not from the ceiling to the floor, but on a part of the horizontal plane, it is necessary to draw the cladding boundaries using a plumb line.

- Pruning. Panels or rolls will not bend. Therefore, in the corners or on the projections, the canvas is cut off with a mounting blade for docking.

- Distribution of the adhesive mass. The adhesive mortar is applied in a thin layer to the wall and facing cloth with a roller, flat brush or spatula.

- Installation. To form a viscous film on the surface of the solution, leave at room temperature for 15–20 minutes. After that, the element is applied to the base, focusing on the markings, and pressed against the wall.

- To ensure that the cork panels adhere evenly, the top is rolled with a plastic or rubber roller.

We recommend a video on the topic:

The details of the pressed veneer cannot be glued again, therefore, apply the tiles strictly along the marking lines, otherwise it will not be possible to correct.

- After installation, leave to dry for 48 hours. The room is regularly ventilated.

- If decorative elements are located in a damp room, they are covered with a water-repellent and fungicidal composition.

Popular brands

Among the adhesives that can be used to connect cork products, there are more often those belonging to imported manufacturers. You cannot find them in all stores, and the range of such adhesives is small.

"Moment Cork"

- laying of wall, floor coverings, cork moldings, roll and sheet backing;

- gluing cork to leather, rubber, wood, various metals and alloys, rigid PVC, felt.

Do not use glue for joining polyethylene, polypropylene, styrofoam, as well as plasticized PVC. The product does not contain toxins, harmful solvents.If it hits various surfaces, you just need to wait until it dries, roll it into a ball and remove it.

Bostik Quelyd Kork

This adhesive is also used for cork in rolls and tiles. It is intended for thin coatings (up to 5 mm thick) when glued to cement, wood, plaster substrates only indoors. The adhesive composition is not suitable for work in rooms with high humidity - kitchens, bathrooms.

The main characteristics of the composition:

- provides high strength of the seam, which is not affected by mechanical damaging factors;

- makes it possible to adjust the position of the sheet, tiles within a few minutes;

- has good adhesion to various base materials;

- has a color close to the cork shade;

- does not contain solvents, is not flammable;

- frost-resistant.

This glue is made on the basis of vinyl polymers. You can work with it at temperatures from +10 degrees, humidity up to 60%. Time to initial hardening is 10 minutes.

Decol Vern

Contact adhesive of this brand is made on a polychloroprene base, includes synthetic resins. It is ideal for all cork coverings, including floor and technical cork, and is also recommended by most cork wallpaper manufacturers. The product emits an unpleasant odor during use, but gradually disappears as it dries.

Decol Vern glue is toxic, you need to work with it only with the use of personal protective equipment and in a ventilated area. The composition is flammable, easily flammable. The glue sets quickly, making it possible to correct the position of the parts within a minimum time. The requirements for good adhesion are:

- indoor humidity - less than 65%;

- air temperature - from 0 degrees;

- base moisture - 2.5-3%.

Wakol D 3540

The glue of this brand is produced in Germany, belongs to water-dispersion compositions, has a latex-acrylic base. It is used for gluing any type of cork up to 6 mm thick on concrete, brick, wood, including porous substrates. The tool is intended exclusively for internal work, since it does not have frost resistance. The composition is environmentally friendly, not harmful to humans, as it does not contain solvents.

There are some peculiarities in the application of Wakol D 3540 glue:

- the base must be dry, porous, strong, without falling off pieces and residues of organic compounds;

- concrete and cement-sand coatings should first be primed with a primer of the same brand;

- before applying, the glue must stand at room temperature, and it must also be thoroughly mixed;

- on absorbent substrates, the drying time of the layer is 30-45 minutes, on non-absorbent - 60-90;

- working time with glue is 2-3 hours;

- glue consumption is 250 g / sq. m;

- you can start laying the cork when the adhesive layer changes color from white to transparent;

- on complex substrates, it is advisable to apply glue to the coating itself, leave it for a day, and then lay it in the usual way;

- you can walk on the cork material immediately after gluing it, and applying varnish, oil is permissible only after a day;

- you can work with glue at temperatures from +18 degrees, humidity up to 70%.

Before working with the composition, you need to make sure that the base meets the following requirements: humidity - less than 4%, temperature - more than +15 degrees.

Cork house

Contact adhesive for cork coverings Cork House is intended for gluing technical cork up to 10 mm thick to a variety of materials - concrete, fiberboard, chipboard, wood, brick, etc.

It is important to apply the product to both substrates - with a velor roller on the cork, with a notched trowel - on the wall, floor. Apply the coating 20 minutes after applying the adhesive

It is important to press the stopper correctly and thoroughly right away; tearing off and reapplying is unacceptable. Complete drying takes place after 2 days.

Self-production

It should be noted right away that it is recommended to use factory-made fluids to achieve maximum effect. But if the wallpaper itself began to flake off or have been in use for many years, you can make a DIY wallpaper remover.

Based on laundry soap

The easiest option is to rub the used sponge with laundry soap when soaking. If time permits, then you can prepare a solution. To do this, grind a bar of soap with a knife or grater (old remnants will do as well), then pour water on the shavings 2-3 fingers higher. The mixture is stirred and left overnight. Stir regularly to speed up dissolution. If it is too thick, add water.

After diluting grated laundry soap in warm water, it is advisable to strain the solution

After diluting grated laundry soap in warm water, it is advisable to strain the solution

Dish detergent based

In this case, production is faster. The proportions depend on the density of the product. If a thick gel is used, then you need to take 1 part of it and add 50 parts of water. For thinner formulations, less water will be required. There is no exact ratio, everything is done by eye. During stirring, you should act carefully so that no foam forms. If this happens, you will have to wait until it settles. You can work with foam, but then there will be a lot of dirt.

It is not so important which brand of detergent to use, the main thing is that it is liquid

Vinegar based

For these purposes, the most common acetic acid solution is suitable. Pour it into a clean container and add hot water in a 1: 8 ratio. The mixture must be left for 15 minutes, after which it can be used.

During the preparation of such a product, harmful fumes are released, so the composition should not be interfered with and it is better to set it aside.

The vinegar mixture may have a pungent odor, but it is harmless by itself.

The vinegar mixture may have a pungent odor, but it is harmless by itself.

Fabric softener based

This product practically does not foam, so it can be applied with a spray bottle. The conditioner is poured into a bottle and the same amount of water is added. If the package says it needs to be diluted before use, it is best to add more water. After that, it is necessary to turn the container over several times, but do not shake it, otherwise a small amount of foam will form.

Air conditioners from different manufacturers differ in consistency, so the amount of water for operation with a spray gun is selected empirically

Air conditioners from different manufacturers differ in consistency, so the amount of water for operation with a spray gun is selected empirically

Powder based

10 liters of water are poured into a clean container, after which 1 kg of washing powder is poured. He himself will not dissolve, so the product is thoroughly mixed. Then you should wait until the foam subsides and the composition is ready.

To prepare the solution, it is better to use a powder for automatic machines, since it foams less

To prepare the solution, it is better to use a powder for automatic machines, since it foams less