What mistakes do craftsmen make most often?

Haste and lack of experience lead to the fact that even such a process as soldering polypropylene products is incorrectly performed. Let's describe the most common problems and their features.

Most often, defects on products appear due to the fact that the connecting elements are incorrectly placed during soldering. For example, gaps appear when the structure is not pushed into the fitting until the very end. Due to this, the working pressure decreases, the wall thickness. The problem is especially relevant for those who, immediately after heating, insert the pipe with their own hands into the fitting, without exerting sufficient effort.

At the same time, excessive forces are not allowed during soldering. Otherwise, another problem appears. Excess molten material begins to squeeze out of the gap, along the edges of which the end face and the internal stop of the structure are located.

Such surpluses are also called "grates". After that, the permeability of the working substance through the system decreases. The connecting element begins to experience a more serious load.

- Some people do not always set the temperature correctly. The required temperature is 260 degrees. Deviations that are allowed are minus \ plus ten degrees. This value is optimal for any type of product, regardless of the diameter. The main thing is that the soldering iron does not overheat. Then it will be possible to maintain the required pressure level in the material. In this case, the surface should not cool down too much before all the elements are connected to each other.

- Another common problem is the wrong equipment. Soldering irons need to be selected in terms of power, depending on which pipe diameter you have to process. For example, 500 watts is the best choice for a 50mm design. 1000 watts is needed if a 100 mm pipeline is being processed.

Video 6. Errors in the selection of connecting fittings for soldering + welding time table

Tips for choosing a welding machine

Before purchasing the right equipment, it is recommended that you pay attention to the following few characteristics:

- Manufacturer. What determines the cost of the device, the quality of workmanship.

- The material from which the device is made, the build quality. Soldering cannot be done without taking this factor into account.

- Complete set, additional attachments.

- Power. Depends on what diameter parts are being soldered.

Soldering iron for PVC pipes is a tool with the simplest possible operating principle. The heating element is in the very middle. He is responsible for creating the optimal temperature during soldering.

Video 7. Review of a soldering iron for PVC welding

It is better to perform the procedure not alone, but together with an assistant. Someone has to operate the tool, while the other prepares and puts in place the details.

About power

Equipment with a power of 1.5 to 2 watts is found on the market most often. This may even be a lot for those who use the instrument at home.

Enough and 680 watts to solve this problem. At least for working with products with a diameter of 16-63 millimeters. 850 watts is the optimal solution for ∅ 63-75 mm. Finally, from 1200 watts will be needed for products ∅ by 125 millimeters, so it will be easier to solder.

What about the attachments?

Better to purchase large kits. The best choice is tools with attachments for almost every diameter, a couple of pieces. Many of their soldering irons allow you to install two or more at the same time. But these are professional units, because they are not cheap.

Additional recommendations

For 5 cm and large diameters, the optimal solution is the use of a butt joint.But this advice is in the nature of a recommendation, not a mandatory axiom.

To the surface, whose temperature has been brought to a certain indicator, we bring the socket with which the fitting is equipped. After that, they proceed to work with the pipe itself.

It is important to observe the holding time accurately. Videos will add clarity to the story

The main advantage of this technology is that there is no need to install fittings on straight sections. The main thing is that the cuts of the structures are as even as possible. Special tools will help with this.

They are brought to the heating elements of the soldering iron to each other, on one line, this rule must also be strictly observed. Thanks to these devices, centering is easier to achieve in order to achieve the best result. Each stage is clearly visible in the video.

They are brought to the heating elements of the soldering iron to each other, on one line, this rule must also be strictly observed. Thanks to these devices, centering is easier to achieve in order to achieve the best result. Each stage is clearly visible in the video.

Some soldering irons have special sound signals that indicate the beginning or end of a stage. Thanks to this, the brazing of PVC pipes becomes more efficient.

TOP 5 best adhesives for polypropylene pipes

Adhesives are available to users at hardware and plumbing stores. They differ in strength of bonding, packaging, nature of application and type. Buy and use bonding agents for their intended purpose.

COSMOPLAST 500

One-component adhesive, used in everyday life and industry. Has good grip strength. It is used in the manufacture of plastic windows, due to the ability to fasten parts at different angles. The time of the first adhesion is fixed in the first seconds, and finally dries up in less than a day.

DOW CORNING 7091

This representative, with a layer thickness of more than 5 mm, acquires the properties of a sealant, but up to 5 mm, has a connecting effect. Perfectly connects objects of the same type. It is flexible, resistant to moisture and remains unchanged at high and low temperatures. Refers to one-component type.

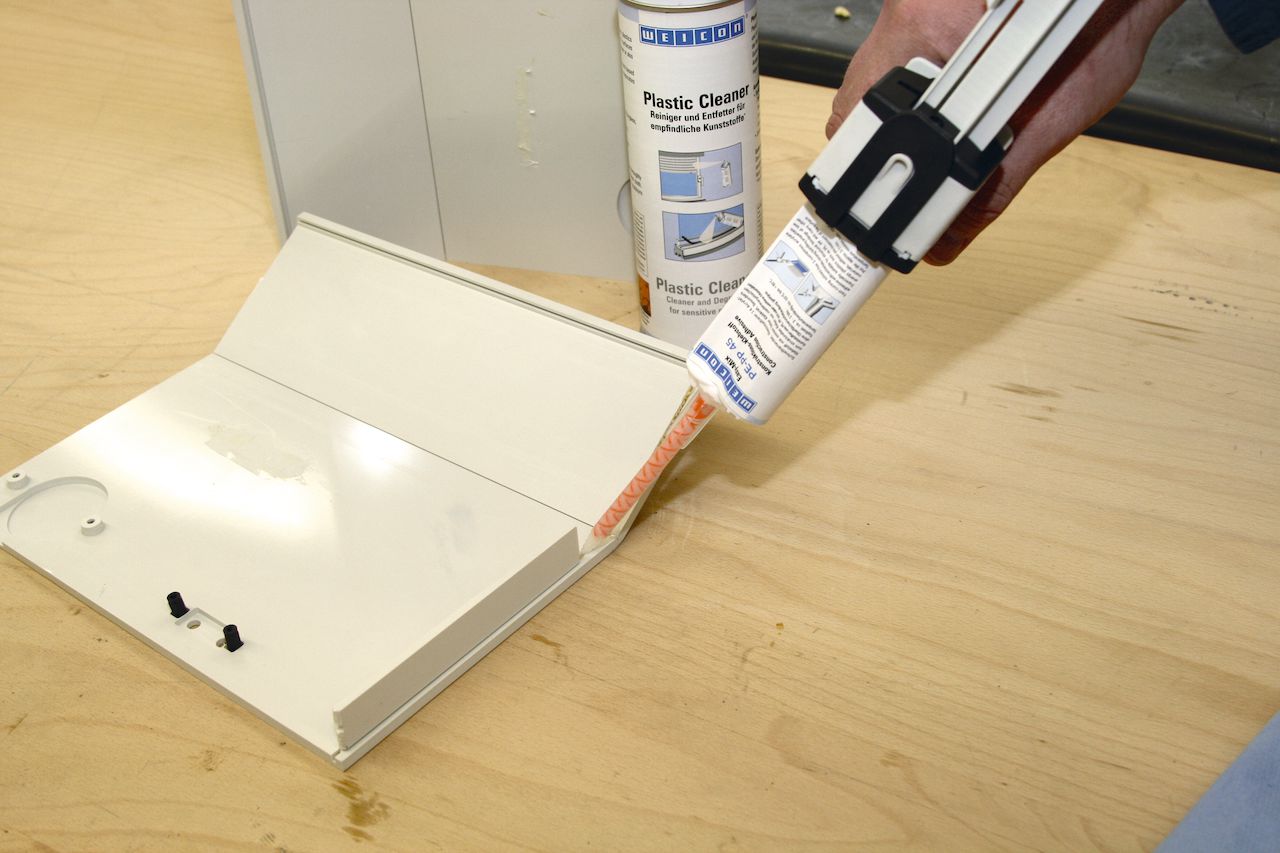

WEICON EASY-MIX PE-PP

A two-component or epoxy adhesive guarantees a perfect bond. The product is capable of polyethylene, PVC, fiberglass and other materials. The main composition includes methyl acryl, which promotes fast adhesion. Dries in 24 hours at + 20 ° C.

HENKEL SUPER MOMENT MAXI

This special adhesive for polypropylene materials easily handles the most difficult tasks. Among the masters, it got the name - glue polypropylene. It sets quickly and firmly bonds metal, cardboard, ceramics, plastic and porcelain. Convenient and soft packaging, with an elongated spout, allows you to apply the product accurately and economically. Superglue, according to experts, sets instantly.

SUPER GLUE POWER

Transparent glue for polypropylene has a gel-like consistency, which is well reflected in the connection of objects of different shapes. Perfectly bonds plastic, leather and wood. The composition includes ethyl cyanoacrylate, due to which drying is many times faster. On white and colored materials, the seam is transparent and almost invisible. The strength is fixed at 175 N. This adhesive for polypropylene pipes does not have a pungent odor.

There are other means for bonding polypropylene. Before repairing the pipeline, it is necessary to carefully study the composition, recommendations for use, as well as other available capabilities of the product. Thus, it is possible to exclude errors of poor-quality adhesion.

Types of adhesives for polyethylene and polypropylene

Polypropylene is actively used in various industries, for example, in medicine and food production, in the automotive industry, and high-tech industries. They appreciate it for its plasticity and ease of processing, because this material can take any shape.

Polypropylene is sold, as a rule, in the form of granules of different colors, which are later used in industry.This material is used to make packaging for food, disposable syringes, car bumpers, pipes, films, film threads and much more.

There are several types of polypropylene:

- isotactic - the most commonly used in industry,

- atactic - differ in waxy and oily form,

- stereoblock,

- syndiotactic - have a viscous consistency.

In general, all types of polypropylene have the following properties:

- low density,

- strength,

- impact resistance,

- preservation of properties under multiple bends,

- low gas and vapor permeability,

- resistance to alkalis, salt solutions, acids, oils,

- water resistance,

- easily recyclable,

- not afraid of boiling.

Adhesives that can hold together plastic parts can be roughly divided into two groups

- Thermosetting. They are based on epoxy, polyester and thermosetting resins.

- Thermoplastic. Adhesives in this group are classified into rubber-based mixtures and resin-based adhesives.

Thermoplastic polypropylene adhesives soften and dissolve when exposed to temperatures. Thermosetting ones have a slight advantage, since they retain their structure unchanged.

An example of thermosetting adhesives is anaerobic polypropylene adhesive, which takes effect when exposed to an accelerator, hardener or heat.

Anaerobic adhesive for polypropylene

Another classification of mixtures is one- and two-component. One-component ones are presented in a ready-to-use form, you just need to squeeze them out of the tube.

This is, for example, transparent adhesive sealant for Moment polypropylene. Two-component include two components that must be mixed together before use.

One-component adhesive for polypropylene Cosmoplast 500 can be cited as an example; it is actively used in window production for gluing profiles.

As for two-component formulations, epoxy glue with a hardener and epoxy resin is popular here. It has a longer shelf life, since until the two components react, gluing will not occur.

Tool for installing polypropylene pipes

| Photo of the instrument | Name |

|---|---|

|

welding machine, for work at home it is recommended to use units designed for welding PP pipes of small and medium diameter - up to 63 mm. |

|

The pipe cutter is the ideal device for cutting polypropylene. |

|

Shaver - designed to remove the reinforcement layer. |

|

The facing tool is needed for high-quality joining of the pipe |

|

Marker for marking pipes. |

|

Using a spirit level and a pencil, draw the direction of the pipes on the wall. |

|

Roulette is one of the main tools in the construction site. |

| A degreaser is needed to remove impurities from the surfaces of the welding joints. |

The soldering iron can be purchased or rented. There is not always a trimmer or shaver on hand. However, you will need these tools to work with reinforced pipes. So, the shaver is designed to remove the reinforcement. Its knives are parallel to the pipe axis. Thanks to this, the middle layer of communications is removed. The facing tool is used to prepare pipes, remove a layer of reinforcement. Such a tool processes the end face, additionally it creates a chamfer.

A marker and tape measure are used for marking. Moreover, it is necessary to determine not only the places where the products are cut, but also the areas that will be inserted into the nozzles of the welding machine.

Soldering machines for pipe welding

Such devices are arranged quite simply. Main nodes:

- temperature regulation and control unit;

- handle for fixing the device;

- a support that avoids direct contact between the surface on which the welding machine is installed and the heating element.

The kit includes nozzles that differ in diameter, as well as gloves, a small tool.The package contents vary depending on the model of the device. The wider it is, the higher the price.

Types of soldering irons for polypropylene

There are hand and mechanical soldering irons. However, in a domestic environment, the first of the options is used. This is due to the simplicity of the design, ease of use, and small dimensions.

Do-it-yourself soldering of polypropylene pipes is performed using 2 types of devices:

- xiphoid soldering iron;

- cylindrical.

Soldering irons differ in the shape of the heating element. Several holes are provided on the plate of the xiphoid devices, which allows the installation of various attachments, which consist of 2 parts: a mandrel and a sleeve. They are designed to heat the end sections of communications. So, a connecting element is pushed onto the mandrel, the sleeve is designed to heat the end section of the pipe.

Cylindrical devices differ in design from the xiphoid ones, which is due to the presence of a heating element in the form of a cylinder. In this case, crimp-type nozzles are used. They are put on a metal cylinder, firmly fixed. A mandrel and a sleeve are provided on both sides of such nozzles. The soldering principle is the same as in the case of the xiphoid counterpart.

Selection criteria for welding machines

Power. To work with communications with a diameter of no more than 75 mm, you should purchase a device with a capacity of up to 1000 watts. Its capabilities are sufficient to ensure a high quality seam. However, in everyday life, the soldering method is more often used to fix pipes with a diameter of up to 50 mm. In this case, units with a capacity of up to 700 W can be used. Moreover, it must be remembered that the starting currents when turned on are much higher, therefore, a power reserve (20-30%) must be provided.

Heating element type: plate, cylinder. In everyday life, the first of the options is used, it is easier to work with it

This is important if there is no experience in this type of installation work.

Number, type and size of nozzles. Determine what products need to be soldered

The diameter of the communications is taken into account. In the simplest models, it is possible to simultaneously solder 2-3 pipes and even more, the same number of fittings. In this case, there are 2-3 holes on the heating element.

Manufacturer.

On the construction market, you can find equipment manufactured in different countries: Russia, China, Turkey, Czech Republic. The last option is more expensive, such devices are of high build quality and reliability. Welding machines may have an error in temperature measurement. As a result, the actual indicator often does not match the target.

Preparation and bonding of pipes

Technology for gluing PVC pipes.

Any glue intended for polypropylene pipes is based on polyvinyl chloride, which dissolves in methyl ethyl ketone, tetrahydrofuran, cyclohexanone. In addition, various additives are added to the two-component adhesives to improve the adhesion performance and control the viscosity of the mixture and the setting time. As the glue hardens, the solvents evaporate and the chains of polymer molecules intertwine.

For installation, it is recommended to purchase proven brands (expensive glue is not always of high quality). If you follow the instructions supplied with the adhesives, the quality of the result is guaranteed even without welding.

Regardless of whether the parts are soldered or glued, preparation is necessary.

The work should be carried out indoors at a temperature from + 5 ° C to + 35 ° C. Of the tools you will need:

- glue gun;

- a brush made of natural bristles.

The device of scissors for plastic pipes.

- Using scissors (pipe cutters), you need to cut pipe pieces of the required length. Then sand the edges of the cuts with emery paper to remove any burrs that prevent the formation of an airtight joint.

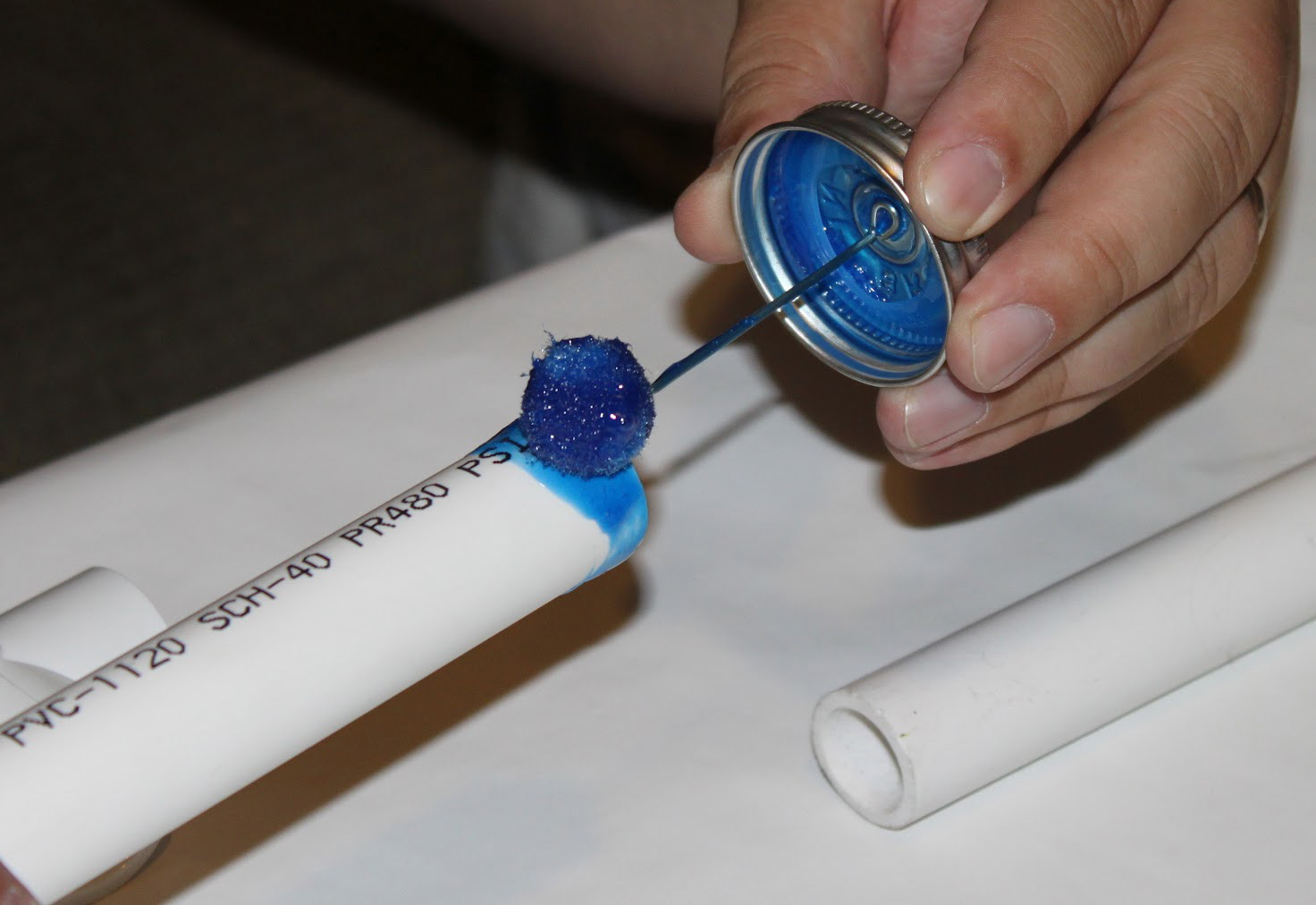

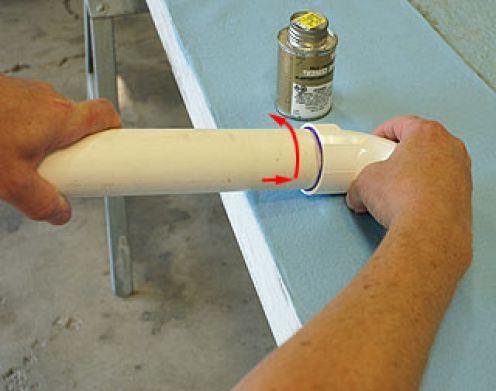

- Further, without using glue, you need to assemble the entire structure in order to try on and mark with a marker all the gluing points and the depth of entry into the pipe fittings. After that, the pipeline must be disassembled and further preparations for gluing must be carried out.

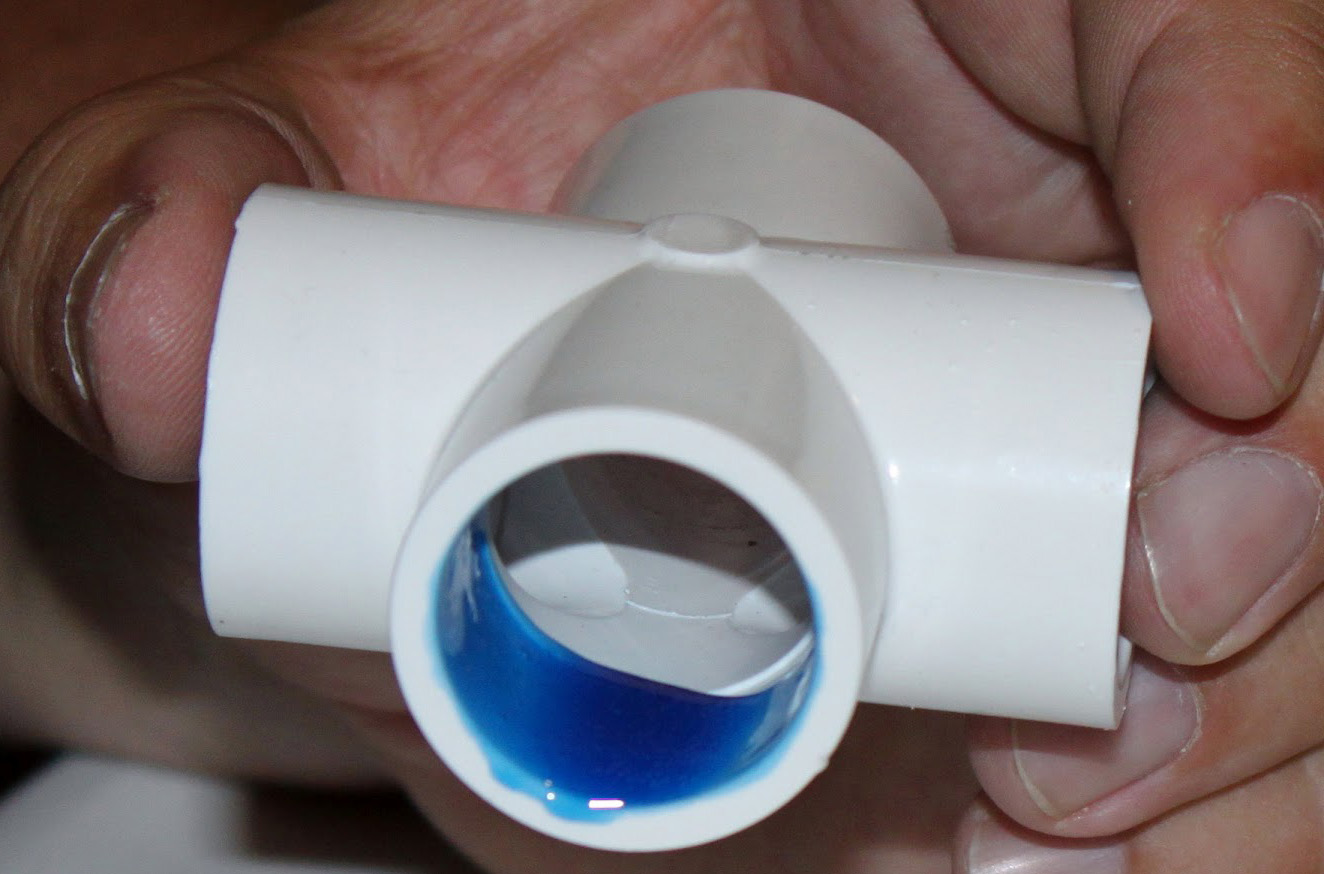

- Stir thoroughly before using the glue. The marked areas must be degreased and the surface cleaned with cleaners. After the surface of the parts is degreased, it is necessary to apply a thin layer of glue with a brush. Then, in the area of the sockets of the connecting fittings and on the pipe, apply the adhesive in an even layer in the longitudinal direction using a gun.

- Insert the plastic pipe all the way into the fitting hole, focusing on the marks made with a marker during the fitting process, without rotating or shaking the parts. You can wait 0.5 minutes longer, firmly holding the parts, wait until the glue dries. If excess glue appears, remove it with a napkin.

- The pipeline can be filled with water and tested under pressure for strength 24 hours after the end of gluing of its constituent elements.

Typical mistakes

Among the errors that occur during welding, we highlight the most frequent ones:

- Insufficient pre-cleaning of parts. This leads to a weakening of the joint.

- Misalignment of pipe and fitting. In 1-2 seconds, this flaw can be corrected, after the joint has solidified, this cannot be done.

- Inconsistency of the material of the welded products. It turns out an unreliable and short-lived connection.

- Violation of work technology, non-observance of temperature and heating time.

You can avoid mistakes if you take into account the recommendations of specialists, comply with the requirements for the performance of work, and do not violate the technology of the welding process.

Such work is quite within the power of a technically competent person who can work with his hands.

If you have not done this before, at the first stage you can invite a plumber and take a closer look at his actions.

Views: 1,050

654

Glue connection of PVC pipes

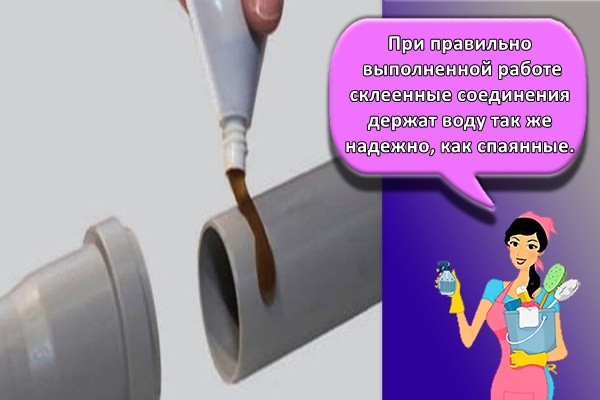

This method of installing a PVC pipeline is also called chemical welding or brazing. The joint formed is one-piece and sealed, while the load on the assembly is evenly distributed over the entire contact surface, as when welding metal elements.

To complete the assembly, the cleaned end of one pipe is inserted with a chamfer (cut) into the socket of the other. The essence of gluing is to soften the surfaces to be joined so that they, without losing their shape, become plastic, and the polyvinyl chloride is split and acquired the ability to enter into a chemical reaction. When the surfaces come into contact, the PVC particles of one pipe bind with identical particles of the other, forming a bond at the molecular level. The glue acts as a catalyst that starts the polymerization process.

However, welding of PVC pipes has its own subtleties, such as various methods of soldering and the nuances of working with adhesives.

Performance characteristics

One of the most popular types of PVC products are glue pipes used for the equipment of household engineering systems and industrial pipelines.

The set of properties of PVC determines the following technical characteristics of the adhesive pipes made from it:

- wall roughness coefficient - 0.6;

- operating temperature range from -15 ° C to + 60 ° C (for a short time up to + 78 ° C);

- ignition temperature - 399 ° C;

- expansion under heat exposure - 5%;

- working pressure - up to 16 bar;

- wall thickness - 1.5-9.6 mm;

- diameter - 32-630 mm;

- form of release - smooth-walled, corrugated;

- the shape of the connecting pipes - straight and bell-shaped;

- connection method - glue;

- color - dark gray, close to black or transparent;

- service life subject to operating conditions - more than 50 years.

What does marking on plastic mean?

- PET low pressure polyethylene or polyethylene terephthalate.It is mainly used for packaging or packaging food. It is produced in the form of a film, bags or transparent containers for liquid and bulk goods, as well as drinks.

- HDPE is a compacted low pressure polyethylene. Used for the release of shrink wrap and packaging bags.

- V (PVC) polyvinyl chloride is a non-food plastic used for the manufacture of strong and durable items such as household buckets, metal-plastic window frames, linoleum.

- LDPE High Pressure Low Density Polyethylene. It is used in the production of bottles for drinks and dairy products, packaging bags, toys, pipes for cold water.

- PP polypropylene. Plastics are chemically inactive, heat-resistant (up to 150 ° C), most widely used in the production of medical products, heat-resistant dishes and household utensils, toys, pipes and fittings for hot water, and much more.

- PS polystyrene. Also food grade plastic, it is used to make disposable dishes, household utensils, kitchen utensils. If it is foamed, it forms an excellent porous heat insulator - polystyrene used in everyday life and in construction work.

- O Other - non-recyclable materials such as those containing metal, paper or other substances). This also includes plastics that do not belong to one of the six groups.

PS - polystyrene

In order to reliably glue the plastic, you need to carefully consider the markings on the product and choose an adhesive designed for polymers of this group. There is another way to determine the type of plastic - a small piece of it must be set on fire. Each type burns with a characteristic smell and type of flame. To apply this method reliably at home, you need to acquire considerable experience.

Some features

- Polypropylene products have a low cost, which is a clear advantage.

- Distinctive characteristics that determine the choice in favor of these products are durability, reliability, ease of installation, including welding;

- Due to the insulating properties, scale does not form inside the pipe, which cannot be said about the metal structure of the pipeline. In addition, structures with polypropylene pipes are much lighter.

- The connection between polypropylene pipes is carried out using a special "soldering iron", which has various nozzles for soldering (welding) the ends of the pipes. Such joints are characterized by high reliability. At the same time, fittings are used to connect the polypropylene pipe and metal parts.

- I must say that the system is quite simply attached to various structural parts. In the process of laying polypropylene pipes, it is necessary to remember one significant aspect: it should only occur at room temperature.

During the installation of the heating system, special attention should be paid to what materials the pipes are made of. Currently, outdated materials subject to corrosive processes are practically not used in modern building structures, however, some manufacturers still offer to purchase them.

Steel pipes are being replaced by high-tech and modern polypropylene pipes.

In order to be convinced of their advantage, you can make a small comparison with other products.

Metal pipes are quite unattractive, prone to corrosion, it is impossible to carry out a hidden installation of the system. Installation is very rarely carried out without the use of welding. Polypropylene pipes, on the other hand, have the most optimal characteristics.

The use of polypropylene pipes in the domestic water supply system. These pipes are distinguished by their durability and ease of installation.

rather quickly, the quality of the connections of such structures is distinguished by reliability.Its wall looks like a sandwich, the inner and outer layers of which are made of plastic. There is also perforated aluminum between these layers of plastic.

Due to this, such a pipe can withstand quite a lot of pressure, since aluminum does not allow the pipe wall to break. Also, polypropylene pipes are resistant to corrosive processes.

Manufacturers currently offer in a huge assortment a wide selection of various fittings that differ in diameter, shape and functionality.

A brazing or welding process provides a place for anchoring the fitting and pipe, although more recently this would have been done with a threaded connection. Thanks to this method of fastening, the greatest resistance against leaks and durability is ensured.

Polypropylene is a very durable material; in the process of crimping at the junction, it can withstand pressure up to 28 atm.

Installation methods

Soldering of adhesive PVC products is carried out in two ways:

- Hot glue - suitable for straight pipes and flared pipes.

- Cold welding - used only for joining socket products.

The hot bonding process is similar to welding metal products:

- the surfaces to be joined are evenly lubricated with an adhesive for hot welding;

- heated to softening (up to 260 ° C) using a special soldering iron, inserting its nozzles into the ends of the pipes, or blowing the pipes with a construction hairdryer;

- insert the end of one pipe with a chamfer into the socket of the other;

- hold the knot motionless for half an hour so that the glue has time to “grab” and dry, this takes about half an hour;

- after 2.5 hours, the plastic will completely cool down, and in a day the polymerization process will be completed - the polyvinyl chloride molecules of the mating surfaces form strong bonds.

The cold welding process is more like the usual gluing of two elements:

- evenly lubricate surfaces with glue,

- insert the lubricated areas into each other,

- hold the knot in a stationary state for about 1-4 minutes for the glue to set;

- the cold weld polymerization process also takes about a day.

Brief instruction

First, fittings and pipes are prepared for welding, which require processing. A layer of foil is necessarily removed when it comes to reinforced products. It is necessary to degrease all the parts that will need to be soldered later.

Video 3. Soldering PVC pipe on the wall with a soldering iron

On the one hand, a connecting element is mounted on the welder's heater, on the other end the pipe itself is fixed. The connecting sleeve is used in a slightly different way.

The main thing is to observe when welding the time that it takes to process certain parts. Rearrangement, fixation and heating with your own hands require compliance with certain time intervals.

Parts will not deform only with smooth execution of each action. The welding machine must be set to the working melting temperature. It is usually 260 degrees. Otherwise, it is impossible to solder.

It is necessary to wait some time after the completion of the process for the structure to cool down. Observe the same requirements when using a coupling.

Video 4 DIY soldering PVC pipeline

How to choose glue

Before buying an adhesive, you need to decide on the installation method, since this is the initial stage of choosing an adhesive - pipes will be connected with a hot or cold method.

Pay attention to the following information on the packaging:

- Manufacturer. It is desirable that it was a well-known company, it is even better if the same one that produced the pipes purchased for installation.

- Appointment. The most reliable connection is obtained when using specialized compounds for gluing PVC pipes, but universal glue is also suitable for the cold method.

- Type of pipes to be glued.For corrugated and pressure pipes, an adhesive labeled “for soft substrates” is required, for assembling the pipeline using fittings or installing a siphon - “for hard substrates”.

- Setting time. For hot-mount adhesive, three parameters must be specified: drying (no more than 30 minutes), hardening (no more than 2.5 hours) and polymerization (20-24 hours). The composition for cold welding has two parameters: drying at room temperature (3-5 minutes) and at 40 ° C (1-2 minutes).

- Colour. It is convenient to use products with pigmentation - this allows you to control the uniformity of the application of the adhesive layer. Transparent glue is convenient because its excess, left along the seam, is almost invisible.

- Safety and environmental certificate, toxicity instructions. For the installation of cold water supply networks, only environmentally friendly materials can be used.

- Terms and conditions of storage. Expired formulations cannot be used, and if stored improperly, the glue deteriorates before the expiration date ends.

An important point when choosing an adhesive is the presence of instructions. Each adhesive composition has its own nuances of use, and two-component ones also have features for preparing a solution. In addition, the instructions indicate what protective equipment is required during installation.

Advantages of polypropylene piping systems

Polypropylene pipes for water supply do not form corrosion and deposits in contact with water.

- The durability and reliability of piping systems is in direct proportion to the properties and quality of the raw material. Polypropylene combines a number of valuable properties, therefore it is perfect for creating pressure heating and water supply systems that will work efficiently.

- Long service life. The surface in direct contact with water does not form corrosion and deposits. Over time, the size of the inner diameter of the pipes does not change.

- The purity of the water is maintained. This material is chemically resistant and non-toxic and therefore has no effect on water quality;

- Resistant to changing conditions. Perfectly withstands pressure and temperature drops over a wide range;

- It has low thermal conductivity; condensate does not form on the surface of the pipeline in operating mode.

- Able to dampen vibrations and noises. Polypropylene fittings and pipes have good sound absorption, so there is a significant reduction in the transmission of noise that occurs during the flow of water through fittings and pipes. As a result, the sound transmission is reduced many times when using such devices (polypropylene). Working with pipes is a pleasure.

- Saving time. You do not need to have special skills to install polypropylene systems. You just need to use a special glue and a gun, the use of welding when using pipes is excluded.

- Cost savings. The value for money is achieved due to the low cost of raw materials and ease of installation. In addition, durability compares very favorably with metal. This also takes into account the costs of the welding processes.

- Unpretentious in service. The polypropylene construction does not require painting as it has a uniform color over the entire surface. There is no need to pre-prepare fittings and pipes, or worry about welding.

A little more about saving. Due to the light weight (9 times lighter than metal), transport and storage costs are significantly reduced, as well as the labor intensity of installation, the time and cost of installation are reduced.