Types, properties, application

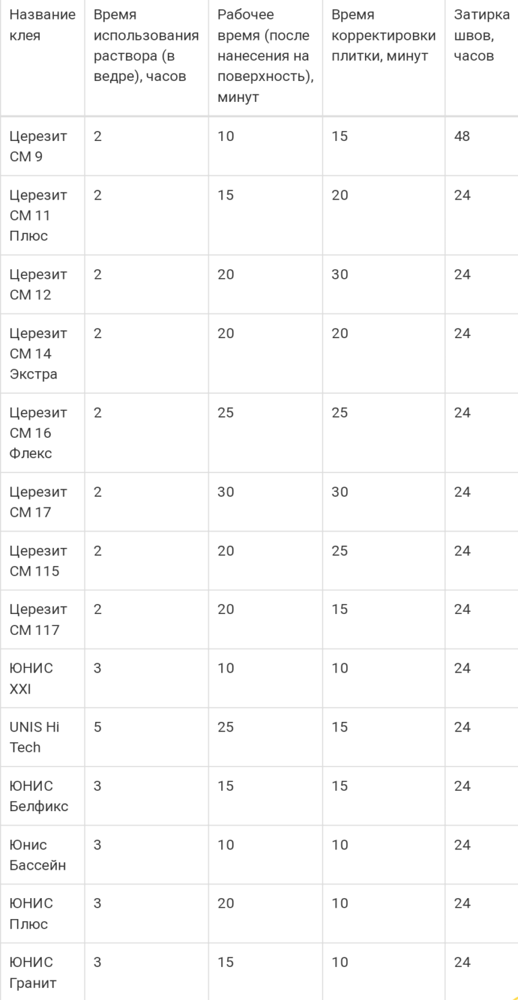

There are nine varieties of "Ceresite", which are used when gluing tiles.

CM 9 - for tiles and tiles

The least popular glue from the Ceresit line. Its main disadvantage is considered to be weak protection against temperature extremes and poor resistance to dampness. Also, CM 9 hardens for a long time - within 3-4 days. Experts advise using a compound for gluing facing bricks, decorative stones and tiles.

It is possible to use CM 9 only on even surfaces, since when gluing to deformed surfaces, adhesion is low.

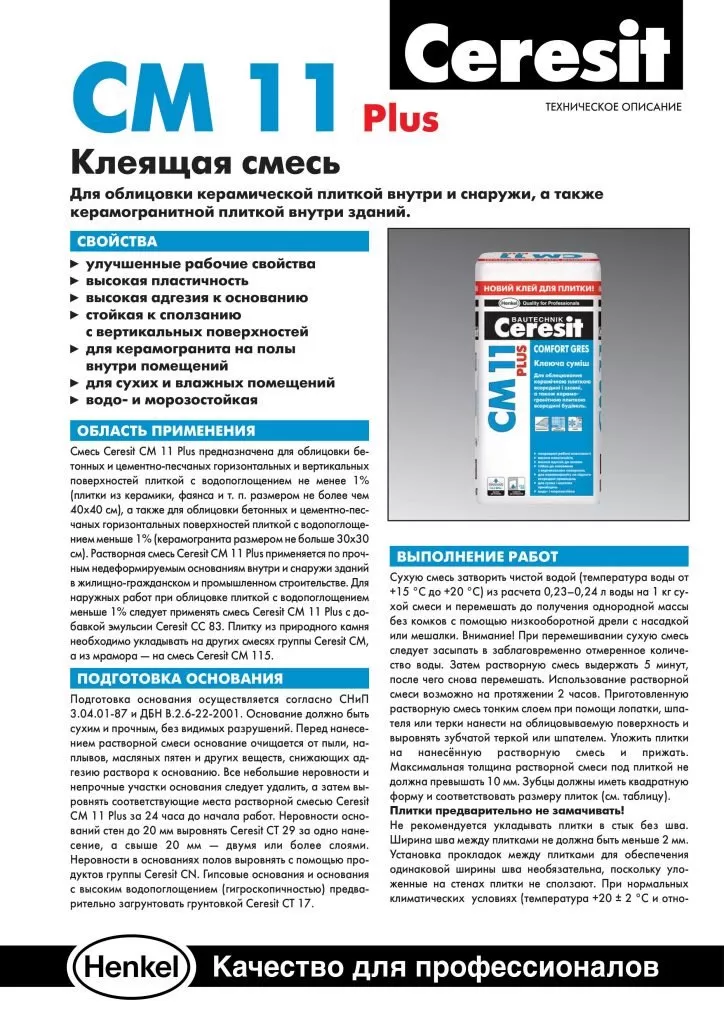

CM 11 Plus - for indoor and outdoor use

If gluing needs to be done outside, it is better to use CM 11 Plus. This adhesive mixture is used for fixing bricks and tiles. It is also added to cement, concrete and lime mortars.

CM 11 has a low level of moisture absorption, which is only 3%. It is thanks to this that the glue can be applied for outdoor work... The composition quickly hardens after use - within 30-40 hours.

CM 12 - for porcelain stoneware

People who are going to cover the floor with large tiles can use the special CM 12 glue for porcelain stoneware. This glue is used only for interior work; it is not suitable for exterior work due to its poor resistance to frost.

The main characteristics of the adhesive include:

- high plasticity, due to which the mixture has a thick and viscous consistency;

- resistance to dampness, which allows the use of CM 12 in rooms with high humidity;

- durability and reliable grip even on uneven surfaces.

CM 14

For working with ceramic surfaces, many experts recommend using the CM 14 adhesive mixture. It is considered universal, as it is suitable for interior and exterior decoration. The features of CM 14 include high temperature tolerance, which allows the use of glue for covering warm floors.

CM 14 has the following characteristics:

- thick consistency that reliably holds the tiles on vertical surfaces;

- not susceptible to the effects of dampness and frost;

- environmental friendliness and safety;

- compatibility with other types of glue from the Ceresit line.

CM 16 - for outdoor and indoor use

CM 16 is ideal for wall cladding with tiles, clinker, porcelain stoneware and decorative stone. The composition is elastic and not subject to deformation under the influence of high or low temperatures. CM 16 is not afraid of water and therefore it is used for cladding coverings on balconies, terraces and even in swimming pools. To improve adhesion, such glue is used together with Ceresit 65 or 51.

CM 17

It is an adhesive composition with high elasticity, used for outdoor and indoor use. Experienced builders advise using CM 17 only for working with deformed coatings. Moreover, it is used not only for gluing tiles. It is also suitable for working with chipboard, gypsum, drywall and concrete. Resistance to moisture allows you to apply CM 17 to damp surfaces.

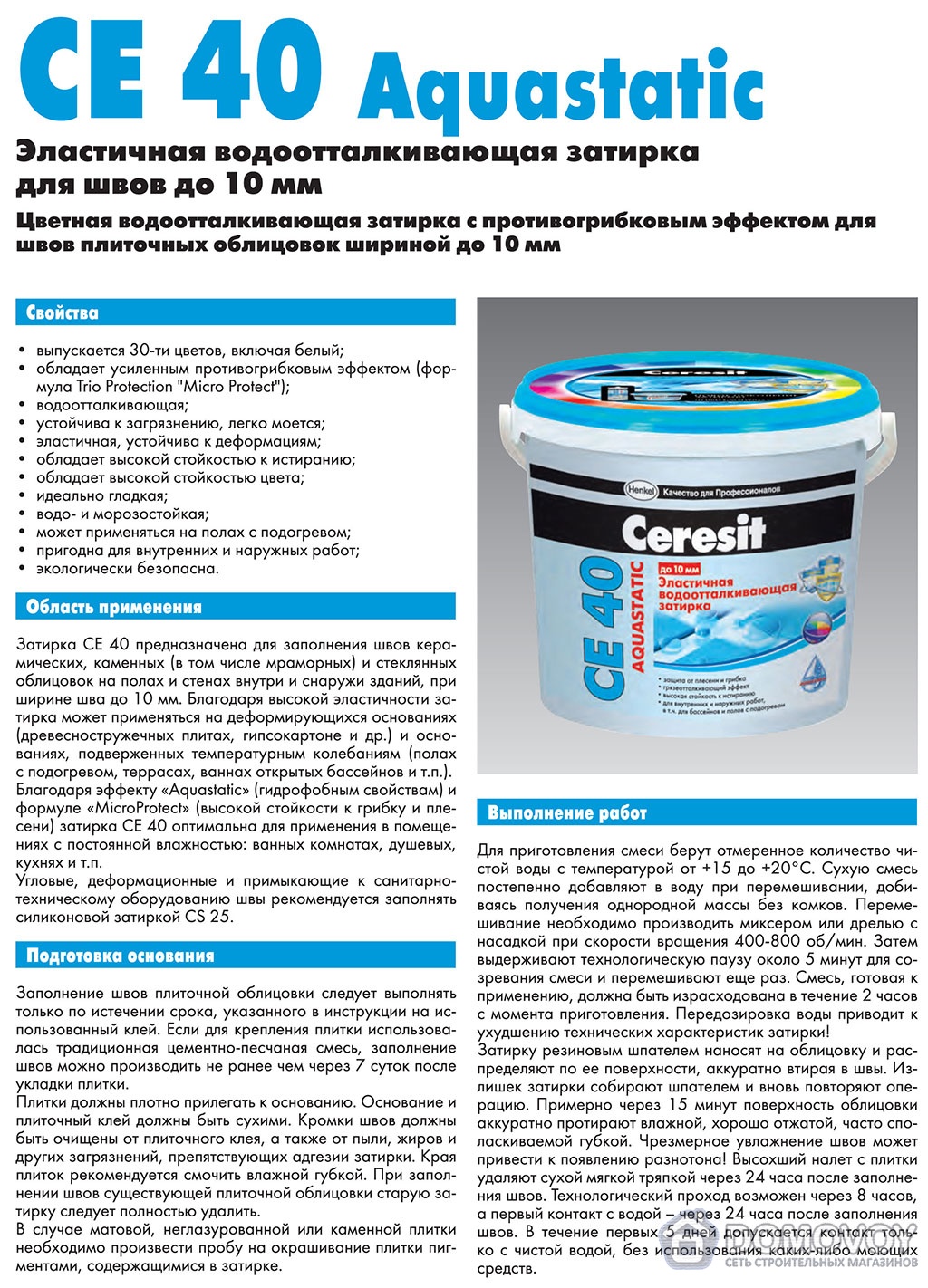

CM 115 - for mosaics

For fixing marble, glass and mosaic it is necessary to use "Ceresit" CM 115. The main advantages of this glue include the following:

- the possibility of using on the surface of the insulated floor;

- elasticity;

- frost resistance and moisture resistance;

- preventing the development of mold on treated surfaces.

To improve the properties of the glue, it is mixed with elasticizers before use.

CM 117 - frost-resistant adhesive for facade tiles

For cladding the facade with tiles, CM 117 is suitable, which is resistant to frost and high levels of humidity. This mixture can also be used indoors for gluing tiles in the bathroom.

Easy Fix for wet rooms

Experts recommend buying Easy Fix for laying medium-sized ceramic tiles. Adhesive properties allow this product to be applied to both vertical and horizontal surfaces. Easy Fix is not afraid of frost and high temperatures. Also, the composition is resistant to dampness, which allows you to use it outdoors.

Tile parameters

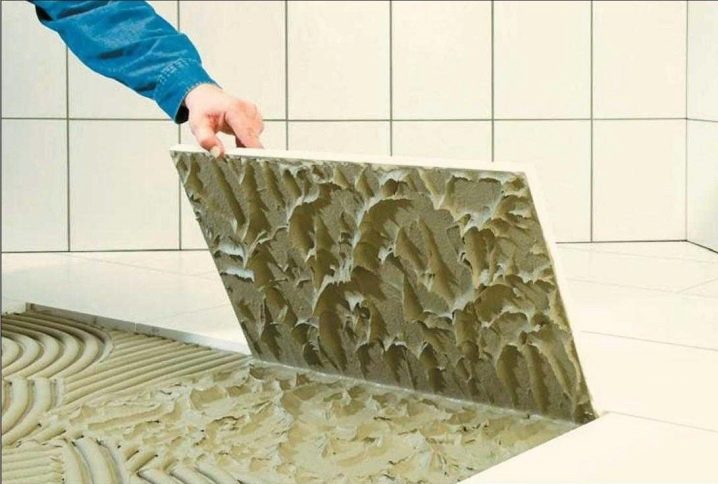

The smaller the tile floor, the faster you can start loading it. When laying large tiles, there is a risk of voids and increased stress on the adhesive.

Such moments need to be adopted even when a suitable duration of curing of the adhesive composition is established. However, remember: the time cannot be less than that indicated on the label by the manufacturer.

Is the quick curing of the adhesive a cause for joy? Experienced workers answer this question in the negative, because it suggests that the horizontal surface was not properly primed, as a result of which the substrate quickly pulled water out of the adhesive. As a result, the adhesion of the adhesive solution was broken, and this can contribute to the fact that the tiled coating simply begins to peel off.

It's bad if the glue dried very quickly - most likely, the tile simply did not have time to adhere to it and will soon fall off

As a rule, it is allowed to exert mechanical pressure on the tile covering after 24 hours.

However, the following tips should be taken into account.

- Shoes with unsteady soles should be worn.

- No need to wear shoes or other shoes with heels.

- It is not recommended to drop objects that are heavy on the floor.

- It is worth postponing the installation of heavy-duty items and furniture.

Remove plastic crosses with care.

Special properties

Adhesive for decorative tiles must have special properties and quality characteristics. So, important properties of such a composition are:

Plastic

It should be moderate. Otherwise, the composition will spread strongly, and you will not be able to apply a layer of the required thickness for gluing this or that type of tile. Typically, this property characterizes rubber-based formulations.

Spreadability

This characteristic is very important for the installation of floor tiles. The spreadable compounds fill all the gaps between the tiles and prevent them from peeling off the walls or floor. If the covering adheres most evenly and tightly, when heavy things fall on the floor tiles, this element or part of it will not split, the covering will remain intact.

Adhesion characteristics

This indicator should be high. It characterizes the ability of the adhesive to hold tiles, regardless of their size or weight. Adhesive, which has adhesive properties, allows the tile to adhere faster, adhere to the surface

You should pay special attention to this characteristic if you plan to install large porcelain stoneware.

Heat resistance

This characteristic is characteristic of the composition intended for application to warm floors. Thus, a good heat-resistant adhesive can withstand temperatures up to + 100 ° C. Such compositions additionally have a special coefficient of plasticity. The manufacturer usually indicates on the packaging for which type of underfloor heating this glue is intended.

Acid resistance

This property of the glue makes it possible to use it in rooms with aggressive conditions. So, if you plan to lay tiles in industrial premises or where you will often use powerful chemicals, then this composition will be an excellent solution.

It is resistant to various irritants. Moreover, it can be laid even on a damp base. The glue dries quickly. These types of mixtures do not include harmful impurities. A feature of acid-resistant formulations is the absence of odor.

When choosing an adhesive, you should also pay attention to the alkali-resistant composition. Characteristics such as hydrophobicity, speed of solidification, as well as durability are important.

A good glue should be waterproof, moisture resistant, plastic. The complexity of installation, as well as the duration of work and the specific purpose of the glue, directly depends on these quality characteristics.

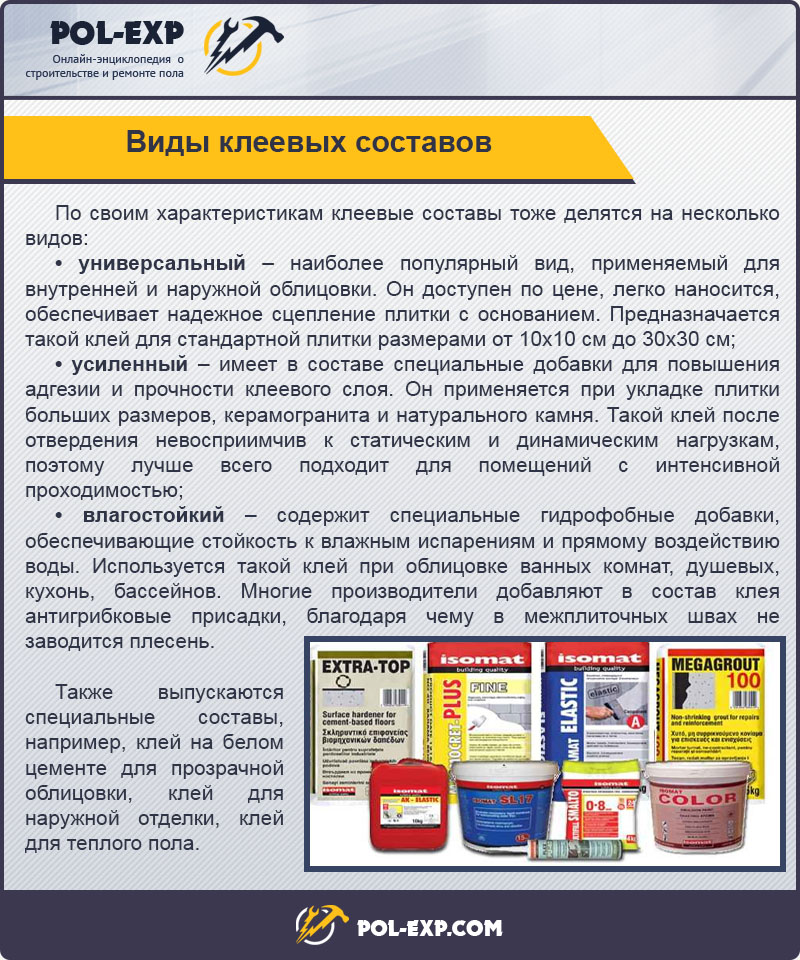

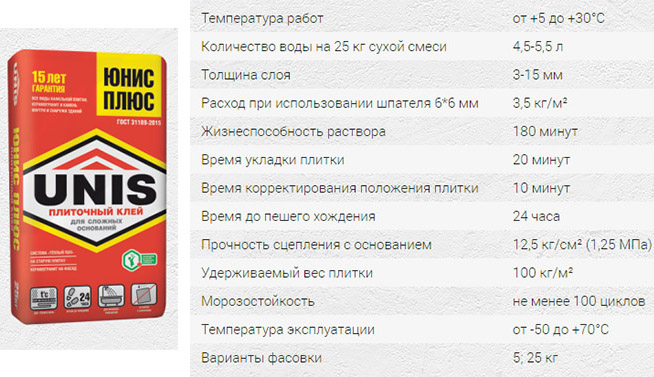

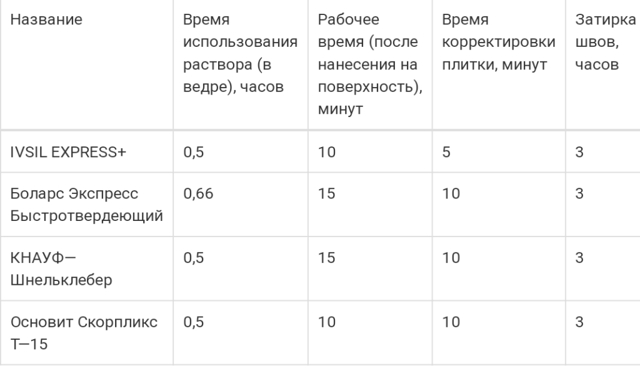

Types of adhesive mixtures and their average drying time

The duration of solidification is influenced by the composition and specific properties. On the construction market, there are many materials for laying tiles with similar and completely different characteristics.

The table below shows the time it takes for various tile adhesives to dry:

| Trademark | Mix type | Being in the container, h. | Wall application, min. | Correction time, min. | Primary solidification, h. |

|---|---|---|---|---|---|

| Ceresit CM | 9 | 2 | 10 | 15 | 48 |

| Ceresit CM | 11, 14, 117 | 2 | 15-20 | 15-20 | 24 |

| Ceresit CM | 12, 16, 17, 115 | 2 | 20-30 | 25-30 | 24 |

| UNIS | XXI, 2000, Pool | 3 | 10 | 10 | 24 |

| UNIS | Beflix, Granite | 3 | 15 | 10-15 | 24 |

| UNIS | A plus | 3 | 20 | 10 | 24 |

| UNIS | Hi Tech | 5 | 25 | 15 | 24 |

| Bolars Express | Fast hardening | 0,66 | 15 | 10 | 3 |

| Knauf | Snellkleber | 0,5 | 15 | 10 | 3 |

| Founding Scorplix | T-15 | 0,5 | 10 | 10 | 3 |

| IVSIL | EXPRESS + | 0,5 | 10 | 5 | 3 |

Please note that the data indicated on the packaging of the adhesive mixture is oriented to the use of the solution under normal conditions, that is, at a temperature of about 20-22 degrees and an air humidity within 60%.

During tiling, it is important to know how long the grout dries. On average, a standard mixture hardens within one hour after application and hardens two to three more.

This is especially true for floor cladding. If we are talking about wall tiles, they start cleaning within the first hour. The final acquisition of the properties of the mass declared by the manufacturer occurs after 10-12 days. Epoxy based grout is completely cured after 20 days.

The fugue freezes in one hour

Impact factors

It is important to take into account the environmental conditions that affect the drying time of the tile adhesive. These include:

- Air temperature. At a low degree, the solidification period increases, and at a high degree, on the contrary, it is reduced.

- Humidity level. The accumulation of water microparticles in the air affects the rate of moisture loss in the solution.

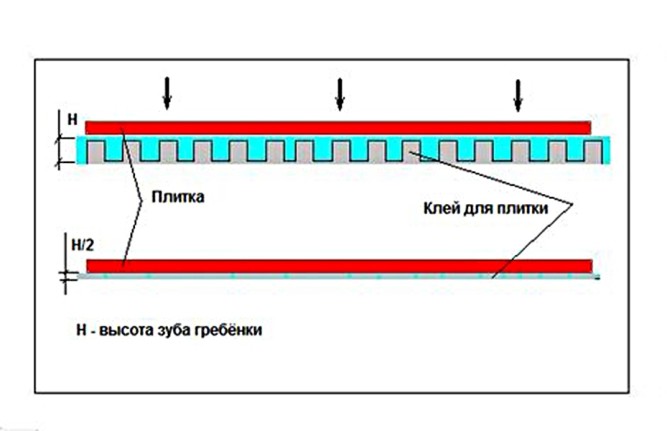

- The thickness of the applied layer. The thinner it is, the faster it dries.

- Mix type and composition. Specific additives affect. Cement adhesives and polymer adhesives differ in almost everything.

- The quality of the base. If the surface has a high degree of water absorption, it will accelerate the curing process of the solution.

- Direct sunlight. The sun heats up the mixture and evaporates moisture from it, which accelerates its solidification, especially in the upper layers.

- Seam thickness and depth. This indicator affects the rate of drying of the grout.

The drying time depends on the height of the tile adhesive layer.

The drying time of the glue or grout used depends on the duration of laying the tiles, sealing joints and cleaning the surface. You should not delay with this, but too early intervention will disrupt the position of the elements of the new coating.

About the manufacturer

The Prospector company appeared on the Russian market in 1992. Initially, the company specialized in the production of fillers. Over time, it was decided that it was necessary to expand the range of goods by producing ready-made building mixtures.

Having adopted the relevant European experience, the organization's specialists quickly managed to establish a full-fledged production cycle for products that are very popular with builders.

The main advantages of the Prospector company are as follows:

- production of more than 80 types of products for various construction tasks;

- fully automated production;

- significant development dynamics, which allowed the brand to become the market leader;

- introduction of modern technologies in the process of manufacturing goods;

- the presence of 15 high-tech production lines;

- constant checks of product quality at various stages of its manufacture.

The company Prospectors has established a process for certifying its own products in the GOST system. Additionally, all types of products constantly undergo an appropriate sanitary and epidemiological examination, confirming their full compliance with the requirements of Rospotrebnadzor.

Base types

All bases on which the tiles are glued are divided into two large groups:

- Simple - these surfaces are practically not subject to deformation. Such bases include concrete, brick, cement screed. Laying tiles on them is quite simple.

- Difficult - the surface suggests some difficulties in laying and in the process of using the tiles. So, they can deform or be subject to vibration, poorly withstand high loads. Therefore, only the lightest tiles are selected for such a finish. Wood, drywall, metal, plastic, glass, chipboard, OSB, plywood are also considered complex bases. The hardest part is to glue the tiles to the marble wall.

The technology of fixing tiles with glue will also change from the characteristics of the base:

If the base is leveled and the differences do not exceed 3 mm, then a thin-layer installation is used. The glue is applied in order to ensure better adhesion of the tile to the subfloor, therefore it is applied in a thin layer:

- for tiles - from 2 mm;

- for porcelain stoneware - 4-5 mm.

If the substrate is uneven and has large differences, then the consumption of glue will be greater. For such surfaces, you can use a leveling compound. It is also of great importance whether this surface is horizontal or vertical. Depending on the location of the base, it is necessary to apply a sufficient amount of the substance in order to adhere well and to avoid the appearance of voids.

It is applied:

- for wall tiles - up to 10 mm;

- for floor tiles - 15 mm;

- for porcelain stoneware - 20-22 mm.

The application method is called high build.

Low temperature conditions

As it was previously found out, the lower the temperature in the room, the longer the drying period of the adhesive will be. The adhesion of the adhesive solution is reduced under these conditions.

If the room temperature is less than 5 ° C, the water in the glue will freeze. As a result, the solution will not dry out, but simply freeze. If the tile covering has been laid under such conditions, after 48 hours it is still not allowed to step on it - otherwise, due to inadequate adhesion of the tile to the floor, there is a risk of cracking of the coating.

If the tiles are laid out in a cold room (where the air temperature is not higher than +5 degrees), you need to leave the tiles to dry for a longer period

Do not forget that the liquid, when solidified, acquires the property of increasing volumes, and this affects the evenness of the floor. Before starting the installation of a tile covering in a room with insufficient heating, it is necessary to properly warm up the surface. The room should be warmed up not only at the time of laying the tiles, but also during the period of solidification of the adhesive solution. If this condition is met, you can start rubbing the seams after a day.

How to work with cement based adhesive?

Applying tile adhesive

Applying tile adhesive

Again, pretty simple. When properly prepared, the adhesive can be easily applied with a spatula to the base of the tile installation - floor or wall.

It is quite elastic, its quantity is easily "regulated". For those who are going to lay ceramic tiles with their own hands, experts advise to approach this process “in squares”.

This means that the glue is applied according to the same principle.When installing "light" types of ceramic tiles, the glue is applied only to the base, in cases with "heavier" tiles, it may be necessary to apply "double" glue - to the tile and the surface - but for such tiles, it is better not to use cement glue, choosing "reinforced" types glue.

Facing work using cement glue must be carried out under certain "atmospheric" conditions.

So, the minimum allowed temperature for laying ceramic tiles is plus 5 degrees Celsius. However, the ideal temperature is 20 degrees Celsius and humidity is no more than 60%. In such conditions, the glue adheres better and dries faster.

By the way, depending on the composition of the plasticizers, the glue can be “fast”, that is, it can have a very short “working” period - in other words, it can dry quickly. Check before buying whether you have purchased "fast" glue, otherwise you may not have time to glue the tiles even "in squares".

Regular cement glue dries - depending on temperature conditions - usually from 12 to 24 hours. "Fast" glue dries in 6-12 hours. The drying time of the glue should be indicated on the packaging.

What is the best choice?

The answer to the question depends on the priorities: the most budgetary option, the maximum ease of work, the special operating conditions of the room, or the need to hide irregularities with the help of foam plates.

Inexpensive construction PVA is rarely used for such situations. The connection will be unreliable, but the finish will have to be held for a long time, irregularities of more than 3 mm cannot be hidden. The best application is for bonding skirting boards and rosettes.

The main advantage of water-based universal polymer adhesives is the optimal balance between cost and quality of joint joints. They are thick and plastic, resistant to high humidity and temperature extremes. The adhesive labeled "for interior use" can only be used in dry rooms.

For the purpose of prevention, the walls and ceiling are pretreated with an antibacterial composition. For putty and plastered walls, a reinforcing primer is suitable, for brick and concrete - with an increased ability to penetrate deeply into the ground.

Not the most budgetary, but effective option is acrylic putty. It will not only glue the styrofoam, hide irregularities, but also neatly hide the seams before painting. It is sold ready-made, does not shine through the thinnest material, does not shrink, is frost-resistant, adheres to almost any type of surface.

Environmentally friendly acrylic glue is suitable for the living room, bedroom and kitchen. This water-soluble type of liquid nails is used for lightweight foam forms, including porous ones. The best option for rooms with large temperature fluctuations and high humidity is made of synthetic rubber based on organic solvents. The second option dries faster, but it should not contain toluene.

Hot melt adhesive is best suited for adhering small parts of decoration or in rooms where serious cleaning of the ceiling is periodically carried out. It is easy to work with compound glue, but efficiency is required: adhesion is maximum from the first seconds. The formulations are toxic and require the use of protective equipment.

Popular brands of quick-drying tile adhesives

Ceresit CM 14 Express

This adhesive mixture is intended for accelerated finishing of floors and walls inside and outside buildings with ceramic tiles and porcelain stoneware with an element size of up to 30x30 cm. Its advantages:

- high degree of adhesion;

- water resistance;

- frost resistance.

Substrates for which the Ceresit CM 14 Express quick-setting tile adhesive is suitable:

- concrete;

- brick;

- cement-sand and cement-lime surfaces.

If it is necessary to glue the coating on deformable bases (old tiles, drywall, chipboard, etc.), then the Ceresit CC 83 emulsion is added to the composition. The main characteristics of the glue:

- You can use the prepared adhesive mixture within 30 minutes.

- Setting time on an open surface is 10 minutes.

- It is possible to adjust the position of the tiles to be glued within 10 minutes.

- You can start grouting in 3 hours.

Ceresit CM 14 express

Ceresit CM 14 express

Founding Scorplix T-15

This fast drying tile adhesive is designed to work with ceramics, natural and artificial stone. Its advantages:

- water resistance;

- suitability for installation on complex surfaces;

- high level of adhesion.

Types of subfloor surfaces for which the Osnovit Scorplix T-15 adhesive is suitable:

- concrete and foam concrete (including cellular):

- brick;

- plastered;

- drywall;

- old tiles.

Main characteristics:

- You can use the prepared adhesive mixture within 30 minutes.

- Setting time on an open surface is 10 minutes.

- You can adjust the position of the glued tile within 10 minutes.

- You can start grouting in 3 hours.

Founding Scorplix

Founding Scorplix

Knauf Schnelkleber

It is a tile adhesive mixture for indoor and outdoor use. It is based on fast-setting cement. Advantages:

- suitable for thin layer application;

- heat resistant;

- moisture resistant;

- very high adhesion.

Knauf Schnellkleber is suitable for cladding with ceramic tiles, porcelain stoneware and natural stone:

- concrete (including porous);

- fiber cement boards;

- self-leveling floors;

- gypsum fiber boards;

- drywall;

- plaster.

When adding a branded Knauf modifier to the glue, it is possible to glue tiles on waterproof chipboards, warm floors, balconies, terraces, and old tiles.

Main characteristics:

- You can use the prepared adhesive mixture within 30 minutes.

- Curing time on an open surface 15 minutes.

- The time during which you can adjust the glued tile is 10 minutes.

- Grouting is possible after 3 hours.

Knauf Schnelkleber

Knauf Schnelkleber

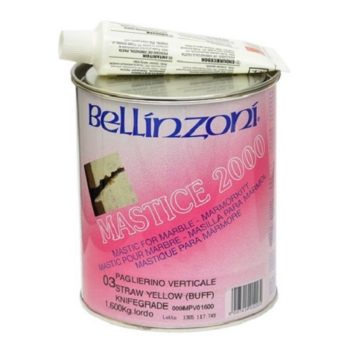

Glue-mastic "BELLINZONI MASTIC 2000"

This is a two-component composition of polyester mastic and a catalyst for gluing marble, granite, artificial stone (including porcelain stoneware), mosaic concrete ("terrazzo"), creating mosaics and inlays. The components are mixed immediately before use. Drying of the glue takes 3 - 6 minutes, which means that when working with it, the utmost precision and accuracy is required. The mastic is produced in 13 color options typical of natural stone. Disadvantage - the glue is dangerous if it comes into contact with the skin and inhales its vapors. Therefore, to work with him, you will also need a respirator or mask.

Glue-mastic "BELLINZONI MASTIC 2000"

Glue-mastic "BELLINZONI MASTIC 2000"

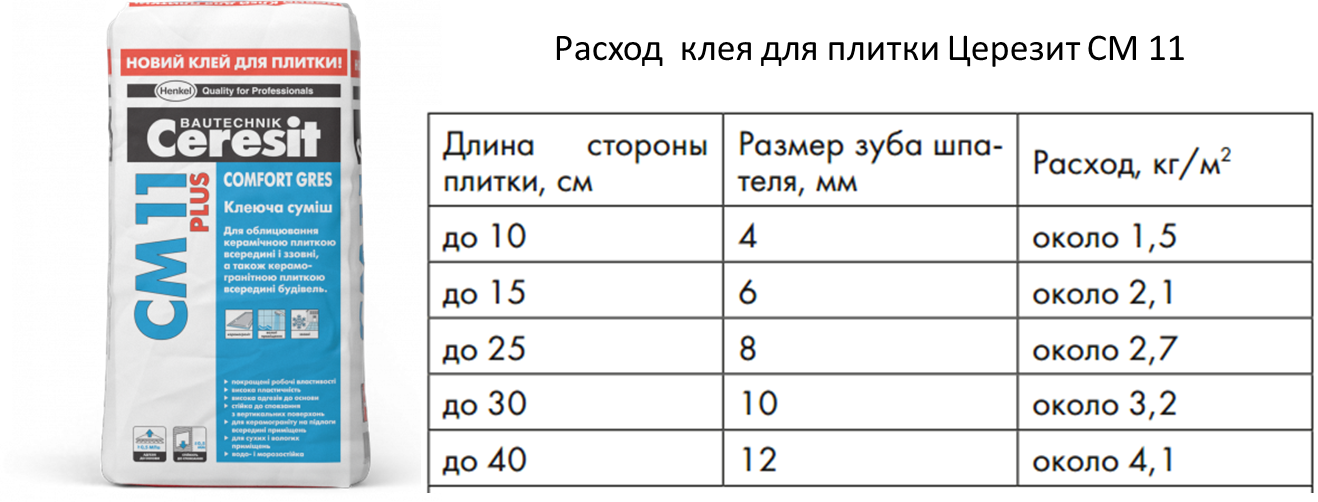

Quantity calculation

Calculating the glue consumption is a rather difficult task. When calculating, it is necessary to take into account not only the surface area on which you are going to lay the tiles, but also a number of other factors:

- First of all, you need to consider what type of glue you will be using. Consumption will vary depending on whether the composition is liquid or thick. Cement adhesive has the highest consumption. As a rule, from 1 to 2 kg of this composition has to be used per square meter.

- The exact consumption is determined depending on the thickness of the layer of the applied composition, as well as on the need to level the surface. If you need to level a wall or floor, then you will use up three times more glue. But if the surface is flat, then the consumption will be greatly reduced.

- The consumption is influenced by the characteristics of the tile and its quality of water absorption. So, glazed tiles absorb the most of the adhesive, so a lot of glue must be used for it. But porcelain stoneware, as well as cotto tiles and durable handmade models absorb little glue, so the consumption in this case will be reduced.

- If the backing material is porous, it will absorb a lot of glue. Therefore, it is also necessary to build on its qualities when calculating.

- The glue consumption is strongly influenced by the technique of work.Usually, craftsmen who professionally deal with tile laying consume much less composition than beginners. The latter usually use too much glue solution.

- During work, different tools can also be used, which also affect the consumption of glue. So, if you apply it with a V or U-trowel, then a more economical consumption will be provided. Square-notched spatulas consume a lot of glue. The larger the teeth, the greater the flow will be.

To calculate the amount of glue you need, you should use one of several methods:

- The first involves using the instructions that are indicated on the glue package. After calculating the surface area that you plan to tile, you can see on the packaging how much glue is required for this. Thus, this calculation is the simplest, but not the most accurate.

- The second calculation method is designed to acquire the required amount of cement composition. In order to find out the consumption in this way, it is necessary to multiply the weight of the glue by 1 sq. m, indicated on the pack, for the thickness of the layer or the thickness of the tile. Thus, the result will show the required amount of composition per 1 sq. m.

Classification

All adhesives can be divided into several groups depending on the main component from which they are made. Each group of formulations is described in more detail below.

Polyurethane

Features of polyurethane adhesive mixtures are as follows:

- characterized by a high degree of elasticity, capable of gluing any type of surface, even different ones, for example, glass with metal;

- used if necessary to provide additional waterproofing;

- some compositions are capable of expanding after hardening, therefore, they are not always suitable for laying ceramic fragile tiles;

- are characterized by high strength, elasticity and resistance to sudden changes in temperature conditions.

There are one-component and two-component formulations. One-component polyurethane adhesive hardens due to the influence of the environment, enters into a chemical reaction with air. Two-component formulations harden by combining components after mixing in a certain ratio.

Cement

On sale, this type of glue can be found dry in bags. The main composition is Portland cement, sand and modifying additives. Additives in the glue are not more than 5%. Due to the sand, the glue is durable and at the same time has a low weight, which provides a low load on the base.

Depending on the modifiers that are present among the components of the glue, its properties differ:

- when plasticizers are added, the solution turns out to be viscous and plastic;

- due to antifreeze additives, a high level of frost resistance is achieved. Such adhesives are used for outdoor work;

- water-retaining additives prevent moisture from evaporating and give the surface an increased level of strength.

There are two types of cement-based adhesives:

- thin layer. They are used in works where the tiles are laid on a base with irregularities of no more than 1 cm;

- thick layer. They are used if it is necessary to level the differences up to 3 cm on the base, for example, if there is a need to tile the walls, then using thick-layer cement glue, you do not have to engage in preliminary plastering and leveling the surface.

Important! Be sure to evaluate the level of elevation differences!

Dispersive

Produced in the form of a paste-like homogeneous mixture, thick in consistency. Mix immediately before application. They can only be used on a flat concrete or plasterboard base, previously plastered.

It can be used to lay tiles both on the wall and on the floor. Their composition is an aqueous dispersion based on acrylic, latex or polyvinyl acetate.

Epoxy

The composition of the epoxy type of glue is resin and hardener. The components are mixed immediately before use. Due to the hardener, the mixture is strong, pressure-resistant, because the resin itself does not have such characteristics.

The main advantage of this type of material is a high level of adhesion.

Used for laying ceramic tiles on a wooden or metal surface.