Variety of ceiling tiles

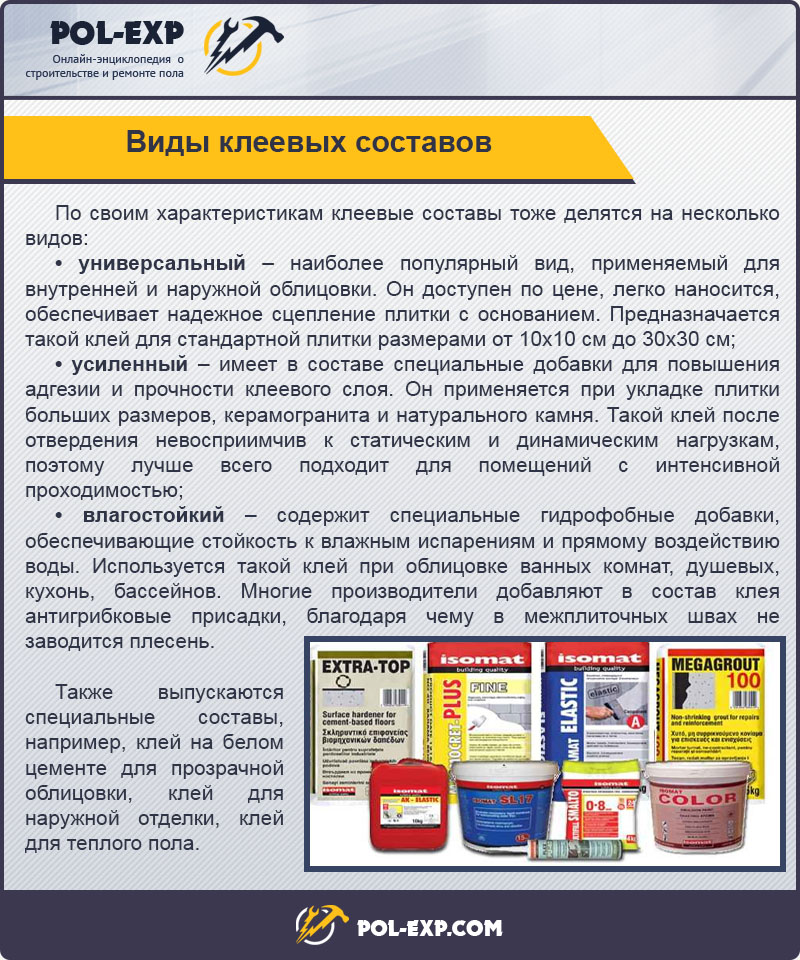

In stores selling building materials, they sell three main types:

- Pressed. Their name already reflects the essence of their manufacture. Pressure is applied to the polystyrene granules, during which they are pressed into a single element. Such material for repairing the ceiling covering is the most budgetary. It does not differ in strength and sound insulation properties.

- Injection. During manufacturing, heat treatment takes place. By heating, the material increases its strength and external noise suppression properties.

- Extruded. This type has high sound-absorbing characteristics and durability. The front side is treated with a special protective compound, which forms a protective layer on the surface. Thanks to their protection, they can be washed with mild detergents. And also, the extruded view can be installed in rooms where humid air often accumulates.

Figure 2. Types of tiles

Due to its small size and light weight, there are cases when the budget or the first available product is selected. This behavior is wrong, not every type of bonding agent is suitable for all types of ceiling decor. To understand which glue will be better to choose for ceiling tiles, it is necessary to study the features of the adhesive.

Figure 3. Glue - the key to a strong hitch

Due to the characteristics of the adhesion product, the most suitable option for the ceiling tile can be selected:

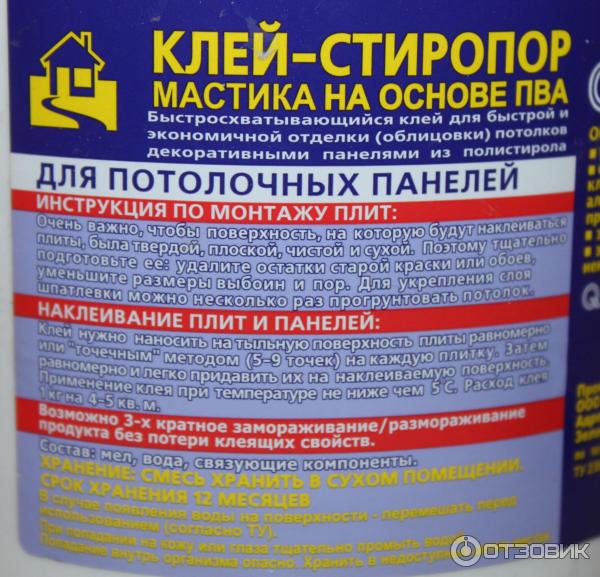

- The composition should not contain solvents. Even a small dose of solvent corrodes polystyrene foam and not only does not fix the material for repair to the ceiling, but also spoils it, making it unusable for further use;

- Evaluate the adhesion, that is, the reliability of its adhesion to the ceiling covering. This characteristic determines the degree of fixation of materials after the adhesive has solidified and, consequently, the reliability of the fastening of surfaces to each other;

- Viscosity grade. When choosing, you need to look at the density of the substance. If it turns out to be too liquid, then it will be dispersed over the surface of the building material and the degree of adhesion to the ceiling will be extremely low. If the glue is too thick, it will also be problematic to glue the tiles, since the level of adhesion will also decrease;

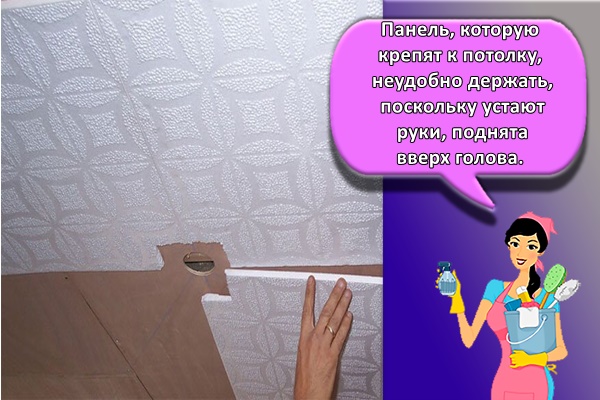

- Setting time. When working under a stream, the period for which the sticky mass will have time to "grab" plays an important role. If it hardens for a long time, then the hands holding the material run the risk of getting tired before the tile is fixed to the ceiling.

Figure 4. Ceiling tile adhesive

The selected adhesive must be suitable for different surfaces.

The substances included in the composition should not emit toxic odors, including when in contact with the repair material or ceiling covering.

When choosing, it will also be useful to see what color it will become after drying. Since it is necessary to connect the joints of the ceiling curbs, their shade with a depression in yellowness can spoil the impression if at the junction there is a color other than white.

In addition to the characteristics of adhesive substances, you should also carefully study its composition indicated on the product label. If everything suits you by the presence of substances, then you need to understand whether such a glue for covering the ceiling and tiles is suitable.

Figure 5. Application of glue

What glue to glue the ceiling tiles

The construction market offers many adhesives that are used for various purposes. To choose the most optimal options correctly, you need to operate with several criteria:

The glue should set quickly, then you don't have to stand for a long time in a static position and hold the glued element;

Solvents are not allowed in its composition, otherwise, the foam will sag in the places of contact with it;

It is important that the color of the adhesive is white or transparent - partial transillumination can be observed on thin stamped sheets;

The adhesion of the adhesive is required to provide adhesion to the dry concrete surface;

Since the material of ceilings can be different (wood, concrete, OSB, drywall), it is advisable to purchase a universal product that is suitable for all conditions.

The following video looks at some of the fixing mix options:

Acetate formulations

Universal transparent adhesive mixtures with a pungent acetone odor, which are sold in liquid form in transparent plastic bottles, are acetate glue. In air, acetone evaporates, and a thin layer of liquid resin hardens, firmly fixing the bonded element.

While similar in appearance, different acetate adhesive products have markedly different setting rates and can greatly delay the bonding process and tire the worker. The most effective products are Titan and Dragon.

Among the most noticeable advantages of this type of glue is good adhesion - it allows you to fix directly on the whitewash.

There are a little more disadvantages:

- The mixture does not allow to mask the joints, as it is completely transparent;

- Has a pungent chemical odor, therefore, it is required to carry out work with good ventilation;

- A good fixation cannot be achieved if there are noticeable irregularities on the substrate or if there are heavy adhered elements (decorative skirting boards, injection or mirror tiles.

Wallpaper glue

All types of mixtures that are used for gluing wallpaper can be used as fixators for plastic panels: Bustilat, PVA, non-woven and vinyl glue. The technology for using these compositions is very similar to the process of gluing wallpaper, when the glue is abundantly applied both to the product and simultaneously to the ceiling surface.

The disadvantages of wallpaper mixes are significant:

- Very long drying time. You will need to simultaneously glue and hold several sheets at once in order to speed up the process at least a little;

- The technological features of the application are such that it is so convenient to fix only thin stamped types of tiles;

- It is not possible to mask the seams with this glue, as is the case with the acetate composition.

Acrylic adhesive putty

Acrylic putty meets all the requirements for gluing ceiling tiles. It is white, quite viscous, instantly fixes and holds any plastic sheets and skirting boards. In addition, it can be used to mask small flaws and joints in injection ceiling coverings.

The method of using acrylic putty is somewhat unusual. It is applied with a thin putty layer on the ceiling, filling in all irregularities and defects of the base, and then decorative elements are fixed on the sticky surface.

Among the disadvantages are the following:

- Increased consumption;

- High price;

- Incompatibility with colored laminated panels.

Liquid Nails

The best options for use with plastic panels are colored fixing compounds called liquid nails. They not only perfectly fix PVC tiles, but also allow you to mask the joints on sheets of any color, just buy the glue of the desired shade.

Due to the nature of this product, it is enclosed in special tubes for a pistol. The amount of glue to be applied depends on the weight of the tile and, usually, a sufficient contour coat. Due to the low consumption of this tool relative to the total squaring of the ceiling, it turns out to be not much more expensive than acetate glue.

Manufacturers overview

There are unconditional leaders on the market that produce the most demanded mixtures. You can also find "young" brands that are of no less quality.

Litokol

Professional glue of this manufacturer Litoflex K80 is used for laying porcelain stoneware, wall tiles. It can even be used in the tile-on-tile technique, for arranging underfloor heating, plinths, facades. The mass consumption is very low due to the high adhesion.

Mapei

These adhesives are fast drying - in just 12 hours the surface will be ready for use. They contain polyurethane components, which impart high plasticity to the mass. Isacyanate hardeners and special fillers provide excellent adhesion. With Mapei adhesives, tiles can be glued even to concrete, asphalt, reinforced polyester, gypsum, asbestos.

Ceresit

The Ceresit brand produces several high quality elastic adhesives. Ceresit CM17 25 kg (D) is very popular, it is appreciated by professionals and beginners. Thanks to sufficient adhesion, new tiles can be glued onto old, glossy tiles. The glue is moisture-resistant, frost-resistant, the presence of polyurethane allows it to withstand sharp temperature fluctuations. Ceresit R-710 is used for gluing quartz vinyl tiles and a number of other unusual materials. Ceresit CM-11 is bought for finishing uneven surfaces, the glue is very easy to use.

Kiilto

Kiilto PL 250 glue is produced in Russia and is made on the basis of polyurethane. In addition to tiles, you can use it when installing insulation, polystyrene, PVC. It is permissible to work with the product even at low temperatures - up to +5 degrees.

Knauf

Knauf Flex glue is ideal for working with difficult surfaces, floor and wall tiles of any type and texture. The material is considered economical, inexpensive, and highly elastic.

Ilmax

Ilmaks 3130 is produced in Belarus and is in high demand due to its low price and high quality. Special additives allow gluing tiles to the product even in the area of stoves, fireplaces, not to mention ordinary, "cold" substrates.

Bergauf

Bergauf Mosaik is recommended for working with the most capricious materials, including various mosaics and transparent tiles. It is ideally white in color, perfect for wet rooms, and is not afraid even of direct contact with water (after hardening).

Working with elastic adhesives is easy, even a beginner can handle it. They should not be applied to a wet surface, this will lead to a rise in capillary moisture and ruin the masonry. Observing the technology, you can do the job efficiently, it will last for many years.

The main stages of ceiling work

Before starting gluing, it is worth preparing a work surface. If the ceiling was treated with just whitewashing, then it is necessary to rinse it thoroughly. Otherwise, the chalk layer will later be removed along with the glue and tiles.

If the ceiling was painted and painted with oil paint, then it must be thoroughly rinsed. If water-based paint (VD paint) was applied to the ceiling, then the surface is passed with a metal spatula, removing the top layer of VD paint.

Figure 16. Ceiling preparation

If wallpaper has been pasted on the ceiling, then it must be removed. If traces of old adhesive remain on the surface of the ceiling, then they should be removed using additional means, for example, a metal spatula. Ideally, the ceiling should be cleaned down to the concrete layer.

To fix decorative elements, the ceiling must be cleaned of past building materials, well washed, degreased and dried.

Figure 17. Methods of gluing

The most common tiling methods are the parallel and diagonal methods. If everything is clear with parallel marking, the laying takes place in a horizontal and vertical row. When gluing diagonally, the work differs only in the correct marking, which must be applied before starting work.To start gluing, it is worth finding the center of the room. For this, their corner into a corner, crosswise draw two straight lines. The place of their intersection will be the center of the room when laying.

Figure 18. We make gluing

If the tile is attached to an adhesive of a universal composition that can glue a variety of materials, then it is worth applying the composition to the surface of the building decor, attach it to the ceiling, then remove it for half a minute and glue it again. This will allow the liquid glue to "grab" and become a little thicker and enhance the properties of the composition.

Figure 19. Starting from the middle

For proper installation of the ceiling decor, the first tile is located in the center of the room, while its corners coincide with the marking lines. The next ones are laid from the first along the lines of intersection. In this way, the entire space of the room is filled. After gluing all materials, the ceiling plinth is fixed. It is fixed in such a way that one side of the plinth is in contact with the tiles, and the other with the wall. In the corners of the room, you can glue the caps to the ceiling plinth.

Figure 20. Ceiling plinth

Dry and ready-made consistencies: advantages and disadvantages

Purchase of adhesive for tiles can be in finished form (in buckets) or in the form of a dry composition (in bags) for manufacturing. What is their difference and which mixture to choose?

At the base of dry consistencies is cement. The main advantage for the glue is that it can be laid on non-aligned walls that have different curvature differences. Glue, apart from the head purpose, makes the role of a smoothing layer.

A significant plus of dry glue is its affordable cost. With a monotonous amount of self-prepared consistency and purchased glue, the cost of the first option will be an order of magnitude lower.

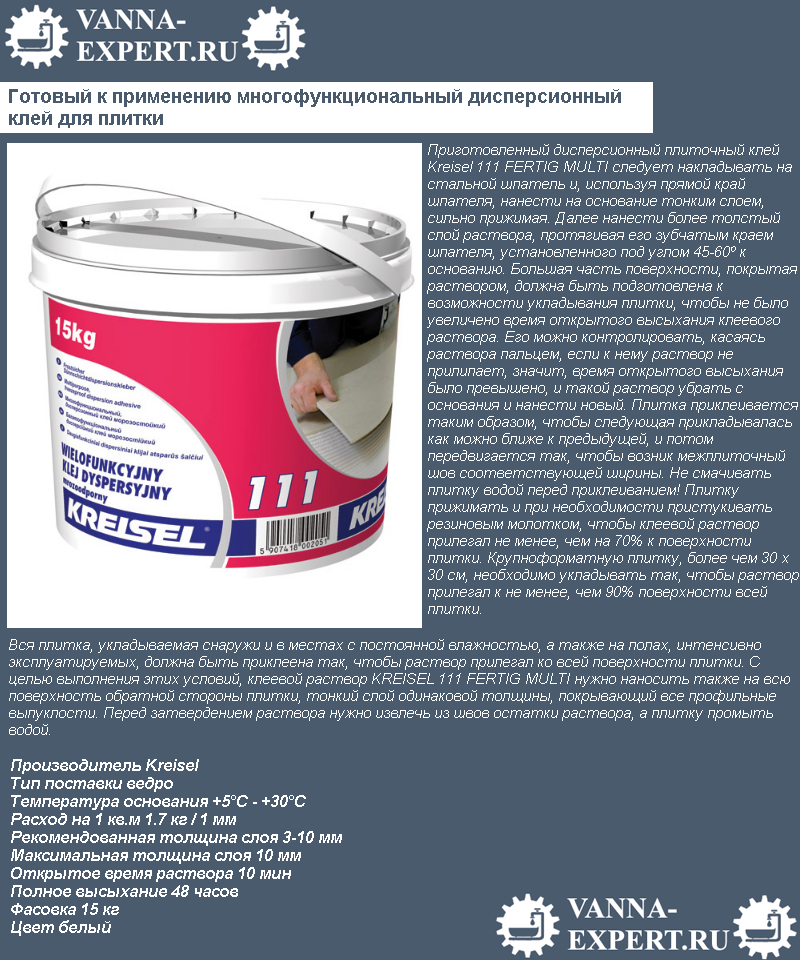

For the application of ready-made consistencies (polymer-based) a smooth base is required. But such a composition is more durable and reliable than cement-based glue.

Technical characteristics of tile adhesive

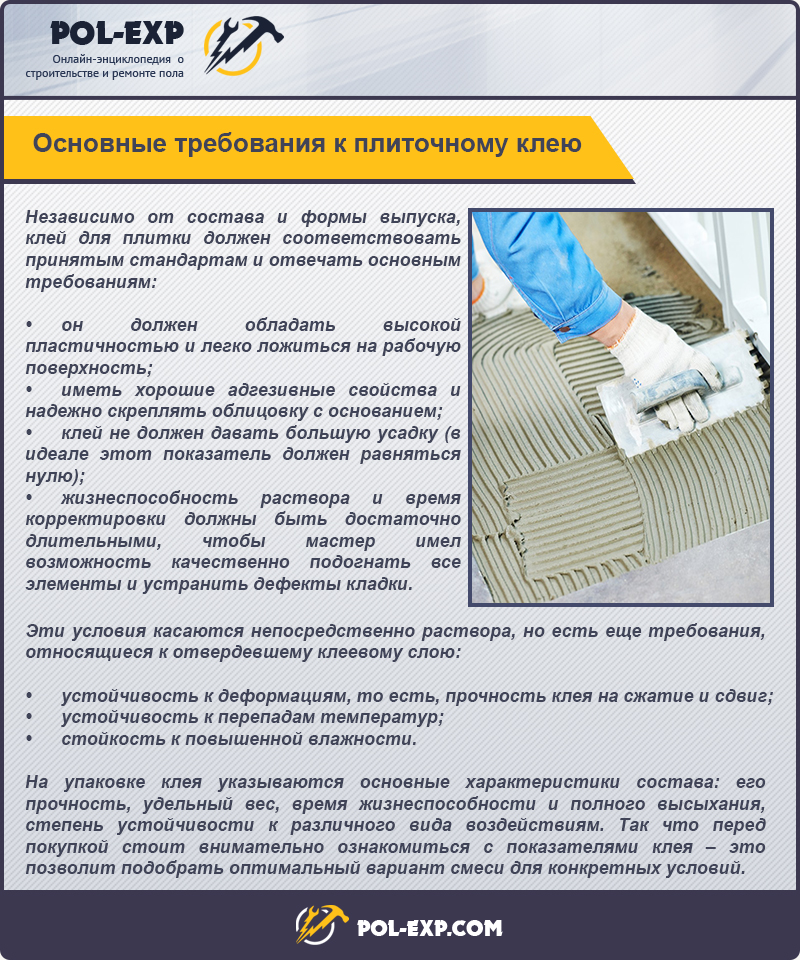

Technical characteristics affecting the quality of the cladding:

Adhesion is the ability to adhere to various materials. Accordingly, the larger this coefficient, the more reliable the adhesion of the tiles of the finishing surface will be.

Plastic. This parameter affects the speed of solidification of the mixture. When carrying out work on the walls, it is worth choosing solutions with less plasticity, in order to avoid slipping of the tiles, and on the horizontal - more plastic mixtures will be more convenient.

The use of more plastic mixtures will allow you to lay out a perfectly smooth surface with an economical consumption of adhesive solution.

Permitted period of use. It can vary from 10 to 45 minutes. When choosing an adhesive, it is also necessary to take into account your own ability to perform cladding. If the specified time interval is exceeded after mixing the glue solution, it becomes unusable.

Operating temperature range. Consumption. Final hardening time

It becomes important if cladding is an intermediate stage, it is necessary to wait the specified amount of time before continuing with further finishing work and furniture installation.

Shelf life. If the expiration date is exceeded, the physicochemical properties may change.

Consumable indicators

The consumption of glue when laying tiles depends on:

- The properties of the facing material - the size, texture and porosity of the tiles.

- Techniques for applying glue, thickness of the glue layer.

- The properties of the base - the presence of irregularities on the surfaces, which requires filling.

Based on these parameters, it is necessary to calculate how much ready-made mixture is needed. per 1 square meter and, accordingly, the entire coverage area. Considering that the assortment of Litokol glue mixtures is quite wide, consider the average consumption of glue by type of composition.

Cement adhesive: with a thickness of 1 mm, an average of about 1.3 kg is consumed per square meter of base

REFERENCE: some articles are more expensive (for example, BETONKOL K9)

- Dispersion adhesive: a layer of 1 mm thick for an area of 1 square meter consumes approximately 2.5 kg of adhesive

- Reactive glue: an average of 2.5 kg of ready-mixed mixture is needed per 1 square meter of the base

- Elastic tile adhesive: 1.3 kg per 1 square meter

Expenditure indicators are rather arbitrary and the final result depends on all factors influencing it. For ease of calculating the consumption of the Litokol mixture, there are special calculators.

By specifying individual parameters, you can independently estimate the required volume of consumables.

Manufacturers

Litokol

The company produces a two-component reactive tile adhesive. It provides excellent adhesion of the tile to the substrate. Such glue is suitable for laying not only on familiar substrates like concrete, but also on plastic or wooden surfaces.

In addition, this manufacturer produces reactive two-component adhesive LITOELASTIC. It is a highly elastic adhesive composition for outdoor and indoor wall and floor cladding, as well as for waterproofing measures in rooms and buildings with high humidity. LITOELASTIC composition does not shrink after hardening, is very easy to prepare and versatile in use.

Mapei

The Italian company produces polyurethane mixtures, with the help of which it is possible to professionally glue tiles of different parameters. The main components of two-component emulsions are isocyanate hardener and synthetic fillers, which increase the adhesion of the solutions.

Popular is the two-component polyurethane tile adhesive Mapei Keralastic T. It is suitable for laying tiles on screeds, plaster, concrete, asphalt, wood, metal, reinforced polyester, asbestos concrete, gypsum and plasterboard frames.

Ceresit

Ceresit is one of the most famous companies producing building mixtures. The adhesive products of this manufacturer are known as moisture and frost resistant. Due to the inclusion in the formula of mineral components and polymer compounds, polyurethane does not react to strong temperature changes and high humidity (even over 70 percent).

For example, two-component adhesive for ceramic tiles Ceresit CU-22 can be applied to a deformed substrate with high temperature and humidity during work, both on the inside and on the facade of the building. Among its advantages are such properties as resistance to chemical attack, high strength, water resistance, absence of solvents in the composition.

Ceresit R-710 two-component adhesive can be used for laying tiles made of rubber, quartz-vinyl and other unusual materials.

Kiilto

The Russian company produces a two-component adhesive for tiles based on Kiilto PL 250 polyurethane in the absence of a solvent. This glue is commonly used for bonding ceramic tiles, insulation materials, PVC, polystyrene and other materials.

This composition is able to form a strong, but at the same time flexible seam. It is possible to carry out work at low temperatures (+ 5 ... +10 degrees Celsius), but the hardening time in this case is extended.

Additional properties

Adhesives C1 and C2 can have a number of additional parameters, which are indicated by the corresponding symbols:

- F (Fast) Fast curing. The adhesion index indicated on the package is achieved in 6 hours (sometimes in 2-5 hours). You need to work with such adhesives quickly.

- E - increased open time. That is, if the glue is applied to the surface, and the tile is applied to it only after half an hour or more, then the level of adhesion does not decrease. In this case, the composition, on the contrary, hardens more slowly, which makes it possible to work in quieter conditions.However, it is more difficult to use when working with vertical or sheer surfaces.

- T - increased viscosity. Such formulations are more convenient to apply, since they do not creep.

- S - elasticity (or deformation property). If the symbol S1 is indicated on the marking, this indicates that at a distance of 20 cm, a 3 mm thick plate bends at least 2.5 mm and maximum 5 mm. That is, this type of glue is able to withstand deformation loads of this parameter. The S2 marking indicates that the deformation can exceed 5 mm and at the same time the adhesive retains all its properties. Compositions of increased elasticity are most often used for laying tiles on the street, where products can deform to a greater extent. Also, this type of adhesive is suitable for slabs larger than 60 cm.

Healthy! There are adhesives on the market that are marked R or D. These are mixtures based on epoxy or polyurethane resin. Such compositions are not included in the category of dry adhesive mixtures, respectively, and are standardized by other requirements.

How to save

If you independently carry out repair work for yourself, you can save money and get more expensive C2S2 glue by mixing cheaper C1 glue with liquid latex (in this case, no water is added to the dry building mixture). Also, the advice is suitable if you already have a cheaper glue, but you understand that its characteristics are not enough for the planned work. In addition, liquid latex has additional properties. For example, there are additives that increase the density of the composition and its adhesion in relation to the edges of the tiles. Polymer additives reduce the porosity of the adhesive and moisture absorption.

There are other additives that can improve the performance of the "weak" adhesive. As a rule, all of them are used for dry mixes instead of water (but it is better to read the instructions carefully before use).

Review of effective brands

Such formulations are most often used.

"Eltitans"

Eltitans universal adhesive does not contain methanol, does not lose its adhesive properties at subzero temperatures, it is used for cladding walls and facades, installing ceiling tiles. When gluing "Eltitance" forms a strong layer, does not turn yellow, but it takes about 40 minutes for the composition to solidify. The thickened substance is diluted with ethyl alcohol.

"Titanium"

In the 90s, Titan transparent glue was released to join the expanded polystyrene tiles with plastic, glass, and metal coatings. When applied to a surface, the composition forms a layer 3-4 mm thick. It dries in 60 minutes, but it takes another 23 hours for the joint to become strong.

"Master"

Inexpensive colorless glue for fixing ceiling panels and skirting boards takes a long time to cure, not everyone can tolerate its specific smell, but it is applied to the surface pointwise, which significantly reduces consumption.

"Moment"

It sets quickly, provides a very strong connection between the surface and the tile, there is no smell of the universal Moment glue. It contains thickeners, and the product does not spread, a very strong seam is obtained.

"Format"

The tool used for fixing ceramics, wood, polystyrene tiles does not burn, does not contain harmful substances. When applying Format glue to a cleaned coating:

- No traces remain.

- The seam does not flake off.

- The composition quickly sets and dries.

The surfaces to be joined are pressed for half a minute. Glue is used even at -10 and temperatures exceeding 30 ° C.

"Bustilat"

A substance of artificial origin has high adhesion, is indispensable in the decoration of walls, ceilings, and holds various materials together. "Bustilat", which is produced by several Russian companies, in addition to latex, contains chalk, preservatives, carboxyl methyl cellulose. When a viscous mass is applied to concrete, wood, plaster, a strong elastic seam is formed. Finally, the product dries up in a day, does not turn yellow, and remains transparent.

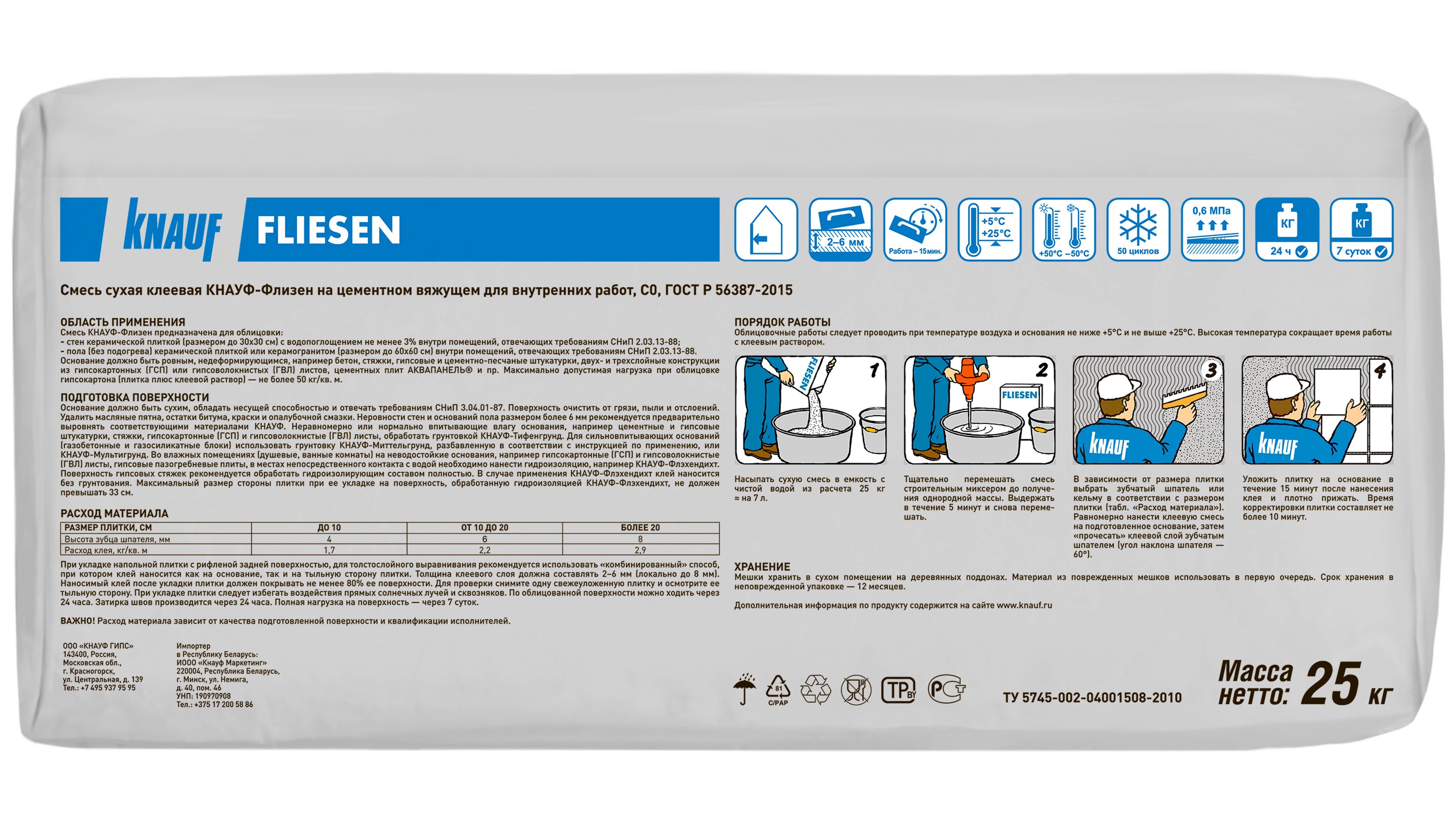

Glue category C0

This is an adhesive composition intended for interior work with a normal adhesion rate of 0.5 mPa. During production, such mixtures pass only one test for the level of adhesion under normal conditions. That is, how well the adhesive adheres to surfaces is determined after 28 days in a normal climate.

This means that formulations bearing this mark may not withstand moisture, cold environments or high temperatures.

Accordingly, the composition of C0 is suitable only for dry rooms. Such glue can be used when working with small ceramic tiles with low moisture absorption (no more than 5%). You can also use the C0 mixture when working with a kitchen apron, in small areas near the sink, that is, in those places where the mechanical stress on the tile is minimal and splashes may fall.

Another condition is that the base must be rigid (high quality cement plaster or concrete slab).