What are the adhesives in composition

Before choosing the most suitable adhesive solution, you need to understand the main varieties and determine what is included in such liquids.

Polyurethane

Polyurethane mixtures belong to the group of synthetic adhesives, which are extracted from substances used in the synthesis of polyurethanes. The main features of such an adhesive liquid include the following:

- protection against temperature changes;

- resistance to oils, acids and gasoline;

- high adhesive strength;

- durability.

Most often, polyurethane adhesives are used for gluing ceramic tiles. This composition is able to attach ceramics to any type of surface. Therefore, it can be used for cladding surfaces made of iron, wood, glass, steel, parquet and slate.

Epoxy

Among technical workers and amateur builders, epoxy mixtures are popular, which are distinguished by their durability and resistance to high humidity. A few years ago, epoxy resins were rarely used in construction, but over the past 5-10 years, new means have been developed for gluing various materials.

In the manufacture of epoxy mixtures, the following materials are used:

- powdery components, which include zinc, aluminum, silica and carbon black;

- carbon fibers;

- synthetic fibers.

Epoxy adhesive has unique properties that allow it to be used in many areas of activity:

- Construction. Often, epoxy is used in the construction industry for tiling walls or joining concrete and metal structures. It is also used to eliminate cracks in walls and join reinforced concrete products.

- Mechanical engineering. Epoxy resins are used in the repair of car bodies, upholstery and gas tanks.

- Shipbuilding. Epoxy is a common material used in boat hulls.

Cement based

Adhesive mixtures prepared on a cement basis are used for wall cladding with ceramic tiles, artificial stone or mosaics. The main advantages of such formulations include:

- versatility;

- ease of use;

- environmental friendliness;

- significant reduction in financial costs for repair work.

Also, the advantages of cement compositions include their resistance to high humidity, thanks to which the glue can be used in the bathroom, on the balcony, in the kitchen and in other rooms with high levels of humidity.

Dispersion tile adhesive

Dispersion adhesive is a composition made from synthetic resins, which is most often used to fix ceramic tiles on floors, walls or ceilings. The distinctive features of the mixture include:

- high adhesion;

- resistance to low and high temperature indicators;

- elasticity;

- durability.

Dispersion compositions are considered universal, since they are used when working with many types of materials. They are used not only when working with ceramics, but also when gluing plasterboard, concrete or cement products. This glue is considered waterproof, and therefore some builders use it for outdoor cladding.

Helpful hints

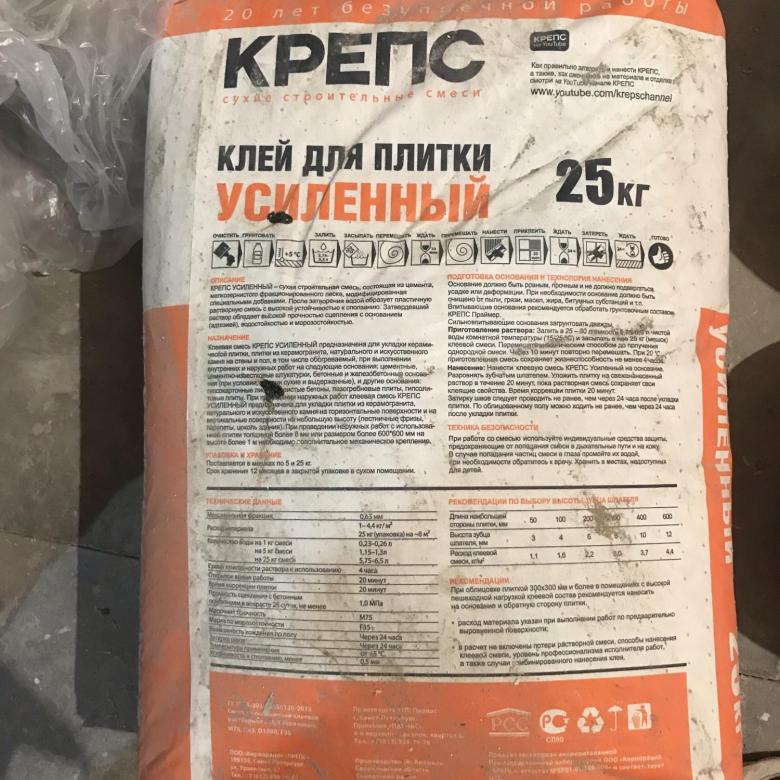

The recommendations of professional craftsmen will help you to qualitatively perform the tiling of the floor and walls with tiles using reinforced Kreps glue:

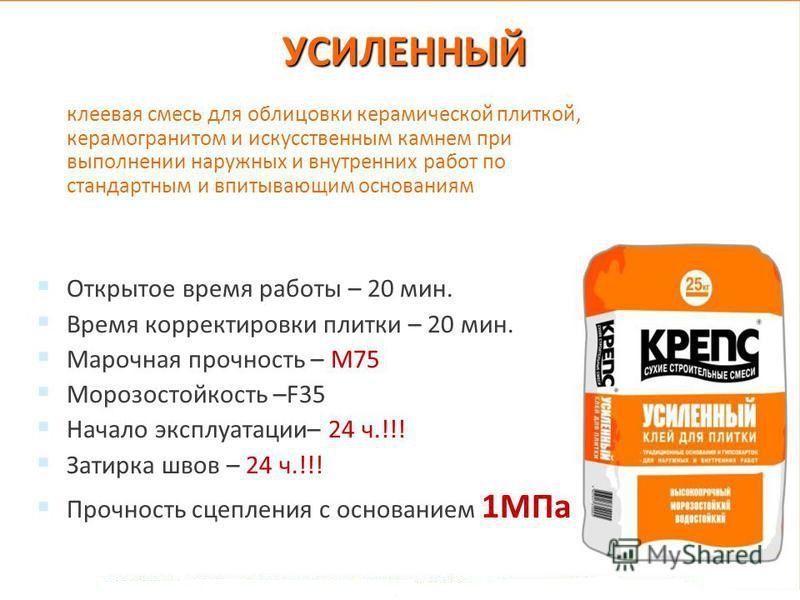

- The grouting of the joints on the walls is carried out no earlier than 48 hours after laying the tiles. For the floor, the waiting time should be at least 72 hours.

- The choice of trowel should depend on the size of the tile.So, with a facing material size of 15x15 cm, a tool with 6 mm teeth is required. If the tile is larger, then the spatula must be taken with teeth of 8 mm.

In addition, when working with the adhesive, it is necessary to observe safety precautions, use personal protective equipment.

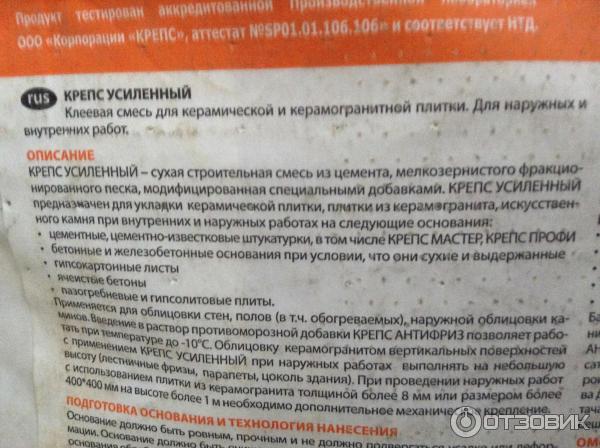

Features and Benefits

Reinforced adhesive composition "Kreps" is a dry mixture consisting of particles with a size of 0.63 mm, which includes:

- sand;

- plasticizing additives;

- cement;

- modifying substances.

Before use, the composition is diluted with water, as a result of which a dense elastic mass is formed, which has the following technical characteristics:

- adhesive strength –1 MPa;

- brand strength - M 75;

- frost resistance - F 35.

All these parameters are an order of magnitude higher than those of compositions labeled "Standard", which can only be used for gluing ordinary ceramic tiles. When using reinforced compounds, the duration of the open work time increases to 20 minutes, during which the masonry can be corrected. At the same time, the compositions have a high resistance to slipping - no more than 5 mm.

In addition, they are able to withstand temperatures in a wider range, which allows the use of reinforced compounds for laying tiles on a heated floor. Kreps mixes are sold in packages of 5 and 25 kg and meet certain technical conditions.

In addition to the improved characteristics, the advantages of the Kreps cladding mixtures include:

- Good frost resistance (up to 35 cycles), which allows them to be used for laying tiles on building facades.

- High moisture resistance, which makes it possible to use them in rooms with high humidity.

- Relatively low material consumption (2-3 kg / m3).

- Fast setting.

- Possibility to use at temperatures from + 5 ° С.

In addition, some formulations additionally include refractory additives and antifreeze, further improving their qualities, enhancing strength and wear resistance.

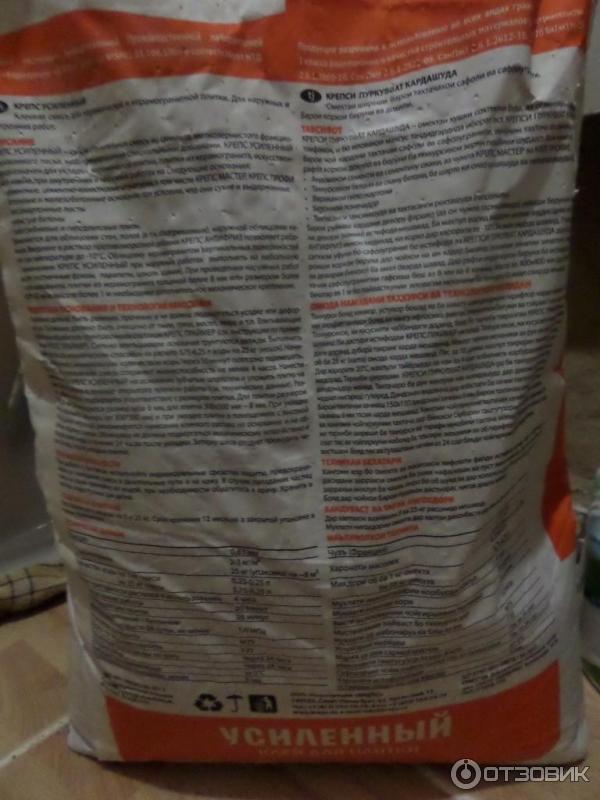

Preparation and storage of KREPS solution

After choosing the tile adhesive KREPS, it is necessary to learn how to properly knead the dry mixture, store the unprepared composition in an already open package. Before proceeding with the preparation of the working solution, it is required to prepare the tools for mixing the mixture.

These include:

- Mixing container.

- Water, adhesive composition.

- Putty knife.

- Drill with mixer attachment.

Preparation of glue from the KREPS company:

- Fill the mixing container with water. The amount of liquid depends on how much ready-made tile adhesive needs to be obtained. The proportions are indicated on the packaging.

- Pour the amount of dry mixture required according to the instructions into the water, and not vice versa.

- Mix the mortar thoroughly with a drill or spatula. There should be no lumps, dry areas of the mixture.

- Wait 15 minutes, mix the composition again.

Prepare the solution immediately before use. After mixing, the ready-made glue must be used no more than 4 hours.

Close the rest of the dry mixture tightly and store in a dry place.

Preparation and application

The package always indicates the exact rate of liquid that must be added to obtain the finished glue. Usually 6-6.5 liters is required for a large package of powder, but it is better to take the minimum amount of liquid (6 liters) first. Water is poured into the container, then the mixture is poured, mixed manually or with a construction mixer at low speed. You can also take a drill with a special attachment for this purpose. After 10 minutes, the mass is kneaded again, then it is considered ready for use. It is necessary to use the solution in 4 hours, no more.

When working with any tile, it is very important to properly prepare the base. It should not have drops, irregularities, deformation changes

All dirt and dust are removed from the surface, degreased by washing with household chemicals or treatment with alcohol.For perfect adhesion to the substrate, it is worth additionally applying the Kreps Primer. Highly absorbent, porous substrates are primed twice.

Further, the order of work is as follows:

- apply the product to the base, then level with a notched trowel;

- immediately process only the area that can be pasted over with tiles in 15-20 minutes;

- lay the tiles within the specified time;

- press the elements well;

- when laying, observe the normal dimensions of the tile joints, for which it is necessary to correctly install the crosses.

How to attach tiles to tile adhesive

To properly fix the tile, you need to familiarize yourself with the features of its installation.

Preparing the tiles

Before laying porcelain stoneware, it is necessary to prepare the laying material. First, you need to determine the optimal number of tiles, which will cover the floor or walls. In this case, such important criteria are taken into account:

- The total length of the tiles does not always match the dimensions of the rows. Therefore, when laying, you will have to cut too long materials yourself.

- Having decided on the required amount of porcelain stoneware, add another 12-15% to the resulting value.

Preparation of the base for application

The most important stage when laying a tiled surface is the preliminary preparation of the base. The final result will depend on the correct surface preparation.

Often the material has to be laid on an uneven surface. Therefore, before carrying out work, you must carefully inspect the flooring or walls. If irregularities were found during inspection, you will have to get rid of them with a putty. After drying, the surface is cleaned with fine sandpaper and cleaned from dust and dirt.

What substrates are not recommended for tiling?

There are several materials that should not be laid on ceramic tiles. Experts do not advise gluing porcelain stoneware on foam concrete and aerated concrete bases, which have a porous surface. On such materials, the tiles will quickly peel off and begin to crumble. In order for it to last longer, the surface will have to be treated with waterproof agents.

Preparation of the adhesive mixture

After preparing the tiles and the work surface, you need to prepare the adhesive composition.

Calculation of the required amount of consumables

First you need to figure out how much glue to knead so that it is enough for gluing the tiles. The average consumption of dry mix is about 120 kilograms per 1 m3. Therefore, it is enough to purchase a package with an adhesive mixture, the weight of which is 25-30 kilograms.

How to breed: proportions and schemes

To dilute and prepare the adhesive composition, perform the following sequence of actions:

- Mixing with water. When diluting the glue with water, observe the proportions indicated on the package.

- Adding sand. Experts advise adding sand with fractions of about 2-3 millimeters to the liquid.

- Adding cement. To improve adhesion, cement is added to the solution. In this case, the following proportions are observed: three parts of sand are mixed with a part of cement.

How to determine the correctness of the prepared solution

When preparing the adhesive, it is necessary to ensure that its consistency resembles thick sour cream. If the solution is too liquid, some more cement and sand are added to it, after which the mixture is thoroughly stirred.

How long does the glue dry

Many people are interested in the drying time of the solution. When determining the drying time, the characteristics of the glue used are taken into account. For example, in quick-hardening mixtures, shrinkage does not last long, and therefore it hardens for about 15 hours.

Application of mortar and laying of tiles

The prepared mixture is spread evenly over the wall to completely cover the entire surface. When performing the work, it is recommended to use a wide trowel equipped with teeth.

Some experts advise treating the tile surface with a solution, but this is not necessary.The only thing to do is to slightly moisten the inside of the material.

When the tile is laid, it is carefully pressed against the wall so that the remaining mixture crawls out of the seams.

Grout filling

All seams must be treated with a special grouting mixture to protect them from moisture. To resist the working solution, grout powder is added to a bucket of water, after which the composition is mixed and infused for about ten minutes. Then the grout can be used to process the joints between the tiles.

Varieties

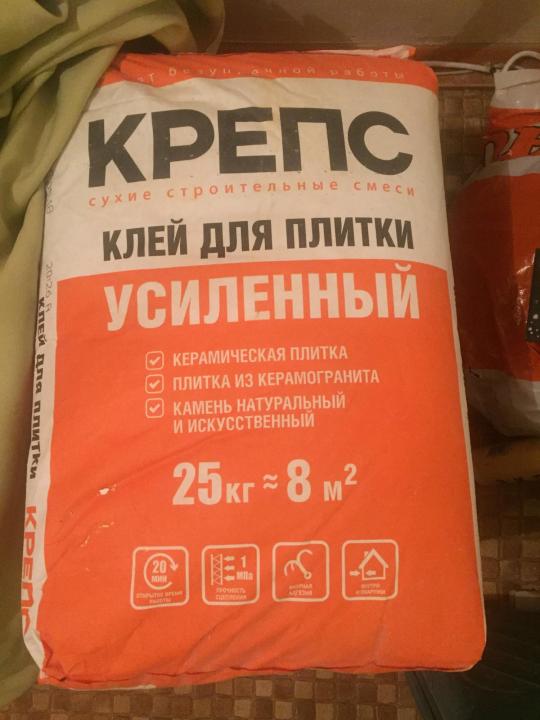

"Kreps" has several modifications. All of them are used depending on the operating conditions, the type of coating. The difference between adhesives is in the types of additives and their amount, which determines the physical and mechanical properties. Here are the main types of glue:

- "Reinforced". It has a high level of adhesion, allows laying heavy porcelain stoneware slabs, marble, even on vertical substrates.

- Reinforced White. This glue differs only in white, other characteristics are similar to the previous tool. In addition to white cement, it contains a dye of the same shade. It is more often used for glass, mosaics, light tiles.

- "Reinforced Express". It is characterized by the highest solidification rate, since it includes additives (catalysts) that accelerate drying. After 4-6 hours the surface can be used.

- "Kreps Super". Designed to work with glass, mineral, wood, metal base materials. Also, this glue can be used to create heated floors, polymer coatings. It is characterized by increased elasticity and enhanced traction.

As for the brands and manufacturers of Kreps glue, the following are considered the best:

- Bergauf Keramik Pro. Produced in Russia. Can be used in rooms with high humidity. It has a low consumption (up to 2.5 kg / sq. M.), A long pot life of the mixture, adhesion of more than 1 MPa, low water absorption rates - up to 1.5%. The tool has a low thermal conductivity, which is ranked among its disadvantages.

- "Perfect Holder". It is a reinforced adhesive for ceramic tiles and porcelain stoneware. Suitable even for the assembly of large-format panels. It has great strength, since it is reinforced with special fiber fibers. When gluing a vertical surface with heavy tiles, the elements will not slip. The consumption is very small - only 1.5-2 kg / sq. m., frost resistance is enormous (50 cycles of freezing and defrosting). Minus - a high percentage of water absorption (3.5%).

- Mixity. The glue is suitable for indoor and outdoor use, for rooms with any level of humidity. It has excellent fixing ability, therefore it helps to adhere even the most heavy tiles. You can apply the adhesive in a thick layer (up to 1 cm), leveling the base.

Distinctive features of the manufacturer

The Kreps company was founded over 20 years ago. All this time, it produces dry substances that are used in construction. The assortment of the company includes more than 50 types of goods. These include tile adhesive and plaster. The manufacturer also offers cement-based dry substances.

All products are subject to rigorous checks before they go on sale. This helps to minimize the likelihood of purchasing substandard materials. Clay Kreps Strengthened is sold in bags of 5 and 25 kilograms. It is a dry cement based powder. Also in the composition there are modifiers, sand. There are also plasticizers in it. This glue differs from the standard glue by a significant improvement in technical properties.

In addition, this tile adhesive is characterized by high frost resistance. It is able to withstand up to 35 freeze and thaw cycles. The composition tolerates a wide range of temperatures and can be used for fixing outside and inside the room.

Features of reinforced mixtures

Such mixtures, in the process of dilution with water, form a sufficiently dense and elastic mass, most often they are packed in bags of 20 - 25 kg.

The high-hold tile adhesive contains special components such as:

- fractional sand;

- plasticizers;

- modifying substances;

- cement.

The glue with improved technical parameters is suitable for laying large-format heavy slabs made of marble, porcelain stoneware and other mineral materials. In addition, there are mixtures that include antifreeze. Due to this, it is possible to lay facing materials at temperatures not exceeding -10 degrees.

Useful tips for masters

People who are laying out tiles for the first time will find it useful to learn recommendations from experienced craftsmen.

These include:

It is important to choose the correct thickness of the applied adhesive layer. The best option is a 4 mm layer.

When the size of the tiles exceeds 300x300 mm, you need to increase it to 7 mm

If the working base has irregularities, it is necessary to make the layer larger - from 9 mm.

The choice of tools is required, depending on the size of the tiles. For example, if individual elements do not exceed 15x15 cm in size, it is necessary to choose a spatula with teeth of 6 mm.

It is not advisable to start grouting joints located on the walls earlier than 48 hours after laying the slabs.

If the glue comes into contact with the skin, rinse the contaminated area under running water. Work in overalls. This is standard safety precautions.

Varieties

The improved Kreps glue is produced in several modifications:

- Reinforced. Due to its good ability to bond the surfaces of tiles and substrates, it is used for laying heavy types of cladding.

- Reinforced white. It has the same qualities as the previous modification, but additional dyes are included in its composition, giving the composition a white color. Used for fixing glass tiles and mosaics to floors and walls.

- Express. It hardens faster than other compounds, since special substances are added to it, which accelerate the drying process. You can walk on the tiles glued with such a solution after 4-5 hours.

- Super. Perfectly bonds the facing material to metal, mineral, wood, glass and polymer substrates.

This choice of formulations allows you to choose the most optimal option for each specific case.

Rating of the best tile adhesives

Many people who have never used adhesive solutions cannot choose the best one. Therefore, it is recommended that you familiarize yourself with the rating of adhesives in advance and figure out which solution is best to buy.

Glims WhiteFix

Many experts who have been laying tiles for several years advise buying Glims WhiteFix. This solution is designed for working with ceramics, as well as with artificial and natural stones. Glims WhiteFix is a versatile product that can withstand high and low temperatures. This allows it to be used for external and internal cladding.

The advantages of the solution include:

- profitability;

- water resistance;

- frost resistance;

- high density.

"Eunice 2000"

Another popular solution used when laying waterproof porcelain stoneware is Eunice 2000. This is a high-strength adhesive that is often used for cladding the facades of private houses. When laying a floor surface, experts advise using a material measuring 60 x 60 centimeters. For walls, it is better to choose a smaller tile - 30 x 30 centimeters.

Also "Eunice 2000" is often used when leveling irregularities on surfaces.

Bolars WallFix Keramik

Experts recommend using Bolars WallFix Keramik when gluing terracotta or glass mosaics. Also, the solution is used for installing tiles, which have a water absorption of more than three percent. It is better to fix the material to concrete, gypsum surfaces and cement. The heat resistance of the solution allows it to be applied to floors equipped with an additional heating system.

Litoflex K80

High quality mortar made from additives and cement that increase the strength of the adhesive.Litoflex K80 is frost, moisture and high temperature resistant. Thanks to these features, it is used both outdoors and indoors. Litoflex K80 is also used for facing deformed surfaces.

Ceresit CM-11

Some people think that this compound is suitable for outdoor use, but it is not. When laying Ceresit CM-11 porcelain stoneware, use only inside. It cannot be used in rooms with high humidity, as the glue loses its adhesive properties due to dampness.

Keraflex Maxi

An improved adhesive for laying ceramic surfaces up to 15 millimeters thick. When creating the composition, modern technology Dust Free was used, which cleans the mixture from hazardous components that are harmful to human health. Keraflex Maxi is not afraid of damp and frost, so it can be used outdoors.

KNAUF Fliesen

The composition is intended for facing:

- Sten. In this case, a ceramic plate with dimensions of 35 x 35 centimeters is used.

- Paul. The adhesive is suitable for cladding floors that do not have a heating system. Porcelain stoneware with a size of 65 x 65 centimeters is used as a facing material.

General rules of application

There are a number of rules that are recommended to be followed when using the substance.

Preparation of the working staff

After choosing a tile glue, it is worth mixing the dry composition correctly. In this case, it is recommended to prepare everything necessary for the preparation of the substance. The tools you may need include the following:

- mixing container;

- water, glue;

- drill with mixer attachment;

- putty knife.

To prepare a working composition, it is recommended to follow these rules:

- Pour water into a mixing container. The amount of liquid is determined by the amount of tile adhesive you plan to receive. The ratio is indicated on the package.

- Pour powder into water, following the instructions. On the contrary, it is not recommended to do it.

- Mix the composition well with a drill. You can also use a spatula. There should be no dry fragments or lumps in it.

- Wait a quarter of an hour and mix again.

Make a solution right before use. After mixing, the finished substance should be used no more than 4 hours. After this period of time, it will lose its fixing characteristics. Remains of dry matter should be tightly closed and kept in a dry room.

Procedure

After the adhesive has been prepared for use, it is important to apply it correctly to the substrate and tiles. To do this, it is recommended to perform the following actions:

- Prepare the base for laying. It is recommended to level it and remove the old tiles. The base is cleaned of dust and oil stains, and then primed. To achieve perfect adhesion, use Kreps Primer. If the surface has a porous structure, the procedure is performed 2 times.

- After the preparatory work, it is worth applying the ready-made solution. To do this, use a notched trowel.

- When laying, it is recommended to control the dimensions of the joints between the tiles. To do this, it is worthwhile to correctly put crosses.

After finishing the laying, it is forbidden to expose the tiles for 24-72 hours. It all depends on the brand of Kreps glue.

Advantages and disadvantages

Glue Kreps is used in cases where ordinary solutions do not give results. The composition is considered to be of high quality. It provides high adhesion and prevents the tiles from slipping, even under adverse conditions. When using adhesives with low to medium moisture resistance, low elasticity and insufficient frost resistance, the adhesive seams quickly collapse. This will deform the tiles. The same applies to heat resistance.

The use of simple compositions for laying a warm floor provokes cracking of the seams after a short period of time. This is due to the expansion of the tile when heated. Moreover, the glue does not expand.

The key advantages of Kreps adhesives include the following:

- preservation of characteristics with increasing, decreasing or temperature drops;

- economical consumption;

- high strength;

- fast solidification;

- can be used for all substrates and different types of tiles;

- high thermal conductivity;

- excellent moisture resistance;

- the ability to use in difficult conditions;

- frost resistance;

- fire resistance - for some varieties of Kreps.

The adhesive composition has significantly fewer drawbacks. When carrying out work, you should strictly adhere to the instructions

It is important to act as quickly as possible, as the glue hardens in a short time. It is difficult for inexperienced craftsmen to control the process, monitor the layer thickness and uniformity of application.

This is important when laying large tiles that will fall off if the layer is too thin.

Features of enhanced solutions

For facing work in special conditions, strong compositions have been created that are able to withstand thermal, chemical, vibration and other influences. Such mixtures are packed in bags of 20-25 kg and are intended for dilution with water. In the finished form, they are a dense elastic mass of high density.

Reinforced glue is suitable for laying slabs of marble, porcelain stoneware and other mineral materials. The scope of such products is repair work in open areas and terraces, in swimming pools, bathrooms, on the facades of buildings.

For such works, the Kreps glue has proven itself well. It comes in several modifications:

- Express - the composition contains catalysts that allow the composition to dry quickly. The coating is usable 5 hours after laying.

- Super - the scope of application has been expanded. It is a suitable adhesive for wood, plastic, glass and polymers.

- Reinforced - a compound with high adhesion rates, used for the installation of heavy tiles.

- Reinforced white - unlike ordinary enhanced white, it has not gray, but white color due to dyes. This allows it to be used to install glass tiles.

Why is reinforced glue better than regular glue?

Some types of reinforced mixtures contain special refractory additives.

As practice shows, ordinary adhesive solutions do not have the necessary parameters that would allow the material to be used in extreme conditions. Mixtures with medium moisture and frost resistance, as well as low elasticity, break down very quickly, which leads to deformation of the facing materials.

For example, when using ordinary glue in a floor heating system, cracks will appear on the coating after several heating and cooling cycles. In the process of heating, the ceramic undergoes thermal expansion, but the adhesive solution does not. This creates an additional load on the binder, which begins to crack as a result of stretching.

Tile adhesive

KREPS Corporation offers tile adhesive for indoor and outdoor use, adhesive for porcelain stoneware, ceramic tiles, mosaics, including reinforced ones. In addition, in our range you will find quick-drying tile adhesive and special winter frost-resistant tile adhesive for outdoor use. You can buy tile adhesive in the city's hardware stores. You can easily calculate the consumption of adhesive for tiles for 1 m² or for the entire volume - by pressing the button "calculate consumption".

Glue KREPS "Strengthened" is intended for laying ceramic tiles, porcelain stoneware tiles, natural and artificial stone on walls and floors, including heated floors, when performing interior and exterior work on the following bases:

• cement, cement-lime plasters; • concrete and reinforced concrete foundations, provided that they are dry and seasoned; • and other bases: • gypsum plasterboard sheets; • cellular concrete; • tongue-and-groove plates; • gypsum boards.

PARNAS plant: ROSS RU D-RU.RA01.B.56962 / 19 from 27.11.2019 valid until 30.11.2024

ARAMIL plant: ROSS RU D-RU.RA01.B.57453 / 19 from 28.11.2019 valid until 30.11.2024

Class C1T (GOST R 56387).

Glue KREPS "Strengthened" is intended for laying ceramic tiles, porcelain stoneware tiles, natural and artificial stone on walls and floors, including heated floors, when performing interior and exterior work on the following bases:

• cement, cement-lime plasters; • concrete and reinforced concrete foundations, provided that they are dry and seasoned; and other bases: • gypsum plasterboard sheets; • cellular concrete; • tongue-and-groove plates; • gypsum boards.

PARNAS plant: ROSS RU D-RU.RA01.B.56962 / 19 from 27.11.2019 valid until 30.11.2024

ARAMIL plant: ROSS RU D-RU.RA01.B.57453 / 19 from 28.11.2019 valid until 30.11.2024

Class C1T (GOST R 56387).

Glue KREPS "White Reinforced" is intended for laying ceramic and porcelain tiles, light grades of marble, transparent facing materials on walls and floors, including heated floors, for interior and exterior work on the following bases:

• cement, cement-lime plasters; • concrete and reinforced concrete foundations, provided that they are dry and seasoned; • and also: • gypsum plasterboard sheets; • tongue-and-groove plates; • gypsum boards.

Declaration of Conformity: Plant PARNAS: ROSS RU D-RU.RA01.B.56623 / 19 from 25.11.2019 valid until 30.11.2024 Plant ARAMIL: ROSS RU D-RU.RA01.B.57501 / 19 from 29.11.2019 valid until 30.11.2024

Class C2T (GOST R 56387).

KREPS "White Reinforced" is intended for laying ceramic and porcelain tiles, light grades of marble, transparent facing materials on walls and floors, including heated floors, for interior and exterior work on the following bases:

• cement, cement-lime plasters; • concrete and reinforced concrete foundations, provided that they are dry and seasoned; • and also: • gypsum plasterboard sheets; • tongue-and-groove plates; • gypsum boards.

Declaration of Conformity: Plant PARNAS: ROSS RU D-RU.RA01.B.56623 / 19 from 25.11.2019 valid until 30.11.2024 Plant ARAMIL: ROSS RU D-RU.RA01.B.57501 / 19 from 29.11.2019 valid until 30.11.2024

Class C2T (GOST R 56387).

Glue "Reinforced winter" KREPS is intended for laying ceramic tiles, porcelain stoneware tiles, artificial stone when performing interior and exterior work on the following bases:

• cement, cement-lime plasters; • concrete and reinforced concrete foundations, provided that they are dry and seasoned; • and other bases: • gypsum plasterboard sheets; • cellular concrete; • tongue-and-groove plates; • gypsum boards.

Declaration of Conformity: Plant PARNAS: ROSS RU D-RU.RA01.B.56962 / 19 from 27.11.2019 valid until 30.11.2024 Plant: ARAMIL: ROSS RU D-RU.RA01.B.57453 / 19 dated 28.11.2019 valid until 30.11.2024

Adhesive composition KREPS "Super" is intended for laying ceramic, porcelain stoneware tiles, tiles made of natural or artificial stone on walls and floors, including heated floors, when performing interior and exterior work on standard and complex substrates, including those subject to deformation, including:

• plasterboard sheets; • cellular concrete; • tongue-and-groove plates; • gypsum boards; • old ceramic tiles; • surfaces previously painted with non-aqueous compounds (oil and enamel paints); • metal and wood elements. • plastic, glass; DSP, DSP, ADC. Recommended for pool cladding.

Declaration of Conformity: Plant PARNAS: ROSS RU D-RU.RA01.B.57364 / 19 from 28.11.2019 valid until 30.11.2024 Plant ARAMIL: ROSS RU D-RU.RA01.B.57364 / 19 from 28.11.2019 valid until 30.11.2024