Features of the choice of material

Naturally, you will need certain fabrics or substitutes that you can use to update your salon. In order to correctly carry out the hauling of the car interior with your own hands, you will definitely need special glue, sound insulation (it is not always required). Now you need to figure out what kind of material you need. You have a fairly large selection. You are invited to:

- Alcantara. This material is produced on a filamentous fine fiber base. It has good strength, softness, and a silky surface. Moreover, it is resistant to pollution and can last for a very long time. That is why the presented product is now the most popular among motorists.

- Leather. She's very expensive. However, your salon will look very beautiful and prestigious. In addition, the presented material is very durable, resistant to stretching and mechanical damage, environmentally friendly (natural)

It is not easy to work with him, because leather costs a lot of money, and requires very careful and thoughtful processing.

- Carpet. It is also a fairly popular noise-insulating material on an artificial basis with a pile coating. It's cheap, available at any car store, and comes in a wide variety of colors.

- Velor. A very beautiful material that allows for a rich interior appearance. However, now you can often buy a fake, so try to be careful when choosing and give preference to a special car velor. Please note that this material is very susceptible to mechanical damage.

- Leatherette. It is very cheap, easy to process and looks natural. However, it is less durable than leather, stretches quickly and has an unpleasant odor that does not fade for a long time.

- Vinyl. For the most advanced car enthusiasts, this material will be ideal. However, it is most often used to decorate rigid interior elements. It is very easy to cut and glue. In addition, a huge variety of textures and colors will help you decorate your car in an original and tasteful way.

Now you can independently choose which material to use for the upholstery of the cabin.

How to make a do-it-yourself banner

There is no need to give the car to the service center masters. Padding is not complete without:

- fabrics;

- glue;

- a set of screwdrivers;

- degreaser;

- fine-grained abrasive;

- hard sponge;

- rollers for leveling the surface;

- masking tape;

- hair dryer (preferably construction, with the ability to adjust the temperature).

To hide the fasteners of decorative elements, you will have to break off the plugs. So buy them in advance.

Step-by-step instruction

Full hauling consists of ten stages.

- Dismantling.

- Removing the old coating and cleaning the base with a hard sponge.

- Removing the remnants of the old adhesive with a degreaser.

- Grinding the frame with an abrasive paper.

- Applying a strip of adhesive to the central part. The length of the strip is up to ten centimeters.

- Smooth the center of the fabric with a roller.

- Application of similar stripes on the left and right sides at a distance of 10-15 centimeters from each other.

- Stretching and smoothing the fabric.

- After completing the application of the fabric, re-leveling with a roller.

- Tucking and gluing fabric edges. The remains must be trimmed.

The renovation is considered complete after re-installation together with lighting and decorative elements. The naked eye will see how well the interior will be transformed.

Major mistakes

The main mistake is the use of Moment glue instead of the compositions indicated earlier.In summer, the car gets very hot, which is why the glue will not be able to hold the fabric on the frame.

It is necessary to start from the center. If you start to stretch from the edges, it will be difficult for the wearer to align the fabric in places with sharp transitions.

Features of self-cladding

When working with each area of the cabin, it is necessary to take into account the design features. Therefore, we will give recommendations for the main surfaces of the upholstery replacement.

Armchairs

Processing of the seats requires their preliminary dismantling from the passenger compartment. The upholstery is cut at the seams to save the pattern for further processing.

Padding of armchairs

Using a sewing machine, you need to connect the parts. If it is not possible to make covers yourself, then you can buy them in a store for common car brands.

Door upholstery

Patterns for a door panel should have a margin of 1-2 cm around the perimeter. This is necessary for a high-quality interference on the base. In embossed places, it is necessary to coat the inner side of the upholstery and the interface plane with glue so that sagging of the fabric does not appear. The hole for the window regulator and the door handle should be small in diameter so that they are covered with decorative overlays.

Tuning doors

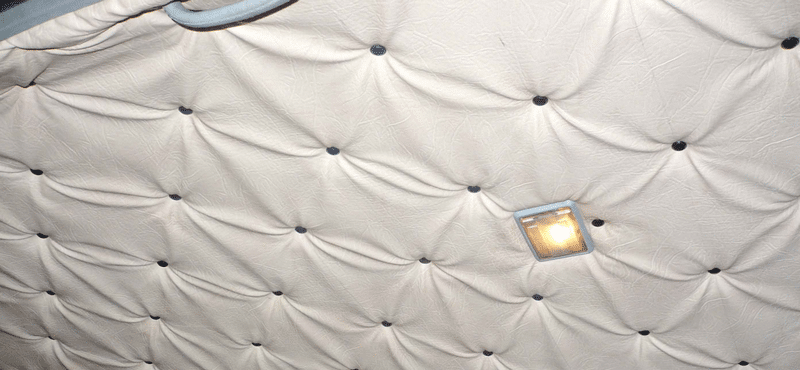

New headliner

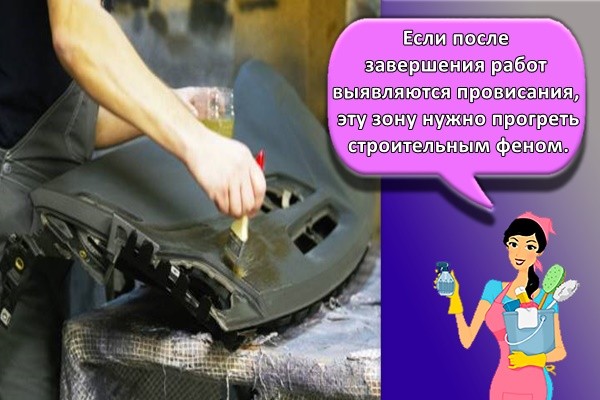

New upholstery for the ceiling is installed after removing panels, lamps, handles. If the material is leatherette, then it must be preheated to increase plasticity. At this stage, you cannot do without an assistant.

Padding of armrests

Leather is the most suitable material for armrests. The cut pieces must be coated with glue for a snug fit. The surface must be blown with a hair dryer to evenly distribute the upholstery over the plane.

How to properly glue the ceiling in a car

You can start gluing from the central part (in this case, an assistant is needed) or from the edge (you can do it alone). When pulling from the center, the glue is applied in small strips (up to 10 centimeters in length and width). The material in this place is pressed tightly.

The next section is processed with an adhesive composition, the fabric is straightened onto it. In the place of bends and protrusions, the upholstery should be especially carefully fixed to the panel. At the edges, the material is folded under the ceiling, glued, the excess is cut off. Then holes are made for fasteners and the panel is installed in place.

If the constriction starts from the edge, then the edge protrusion and ¼ of the panel surface are coated with glue. After carefully fixing the material on the glue base, the rest of the panel is smeared, and the gluing process is completed. The choice of the waist method depends on the material: the thin one is glued from the edge, the denser one - from the center.

Why do they overtighten the interior of the car?

Basically, there are two global reasons why the salon is being pulled over. The first is worn fabric, the second is tuning. With a good interior, the car greatly increases in value, looks much better. In addition, the hauling can increase the practicality. For example, the leather interior is able to suppress unnecessary noise and vibration.

Upholstery

Upholstery

When tightening upholstery, it is not at all necessary to look for the same material as before. It is quite possible to find something radically different, more modern and durable. It is imperative that you need a consultation with experts so that they can orientate what material is better to take. After all, some of them can be used not in the entire cabin, but only not in some of its elements. Also, the sheathing may differ in practicality depending on the class of the car.

Step-by-step instruction

Doing it yourself saves money. However, during work, there are often difficulties associated with errors or fasteners in unexpected places. This can be avoided by studying the car's device and step-by-step instructions in advance.

Dismantling and disassembling the seats

Dismantling is necessary in order to sew new covers as accurately as possible.Before starting work, it is better to disconnect the battery from the car, and then unscrew all electrical connectors (if any). Frame-by-frame fixing of the process will also help to collect the details. In addition, from the photographs it will be possible to understand how the fabric is attached. After that, you can unscrew the self-tapping screws with which the chairs are attached to the runners.

Pattern creation

The final appearance of the salon will depend on the accuracy of the pattern, so you need to do it as carefully as possible. If the old paneling has still retained its shape, then you can use it as a template. It is better to number the sides so as not to forget which part is adjacent to which. If the old casing is too damaged, then it is better to draw up a template on paper, having previously measured all the details. But it is better not to throw away the worn-out fabric for now, since it can serve as a hint for further action.

Important information!

When cutting, it is better to place the patterns as close to each other as possible in order to reduce material consumption.

Sewing covers

When the parts are ready, you can start sewing new covers. To get started, you can learn from the headrest trim. If everything worked out, then you can proceed to more complex elements. Certain seams are used when restraining the seats, which affect the appearance and strength of the upholstery:

- basic - the simplest option, which consists in stitching along the edge of two folded pieces of fabric;

- double - two parts are sewn together, pressed against each other with the front side;

- edging - a durable seam that prevents the fabric from unraveling. It is recommended to use it for the manufacture of car covers;

- decorative - does not hold anything together, but is used exclusively for decoration.

If new covers are made of leather, then it is better to process them with a basting stitch before starting work so that they are of the correct shape. In addition, do not forget about the 2 cm margin, which must be retreated from the edge. In order not to be mistaken with the size or order of the parts, you can from time to time apply the cover to the seat and try it on.

Note!

Those places where there are airbags in the seats cannot be stitched.

Dressing and assembling the seats

After that, you need to glue foam rubber to the details. This is best done with a can of glue that penetrates the pores of the polyurethane foam and securely holds the material together. The flaps of the seams also need to be glued with high-temperature glue using a brush.

It takes a lot of time and effort to stretch the resulting product. This is especially true for the backrest, which has a closed shape. The process of trimming the cabin ends with drying with a building hairdryer and steaming the seats.

Sequence of work

Padding of the car interior is divided into several stages:

- replacement of covers on previously dismantled chairs;

- replacing the trim on door panels;

- carrying out upholstery work with armrests;

- renewal of upholstery on the ceiling.

In this sequence, work is often performed at the station or during self-replacement.

Reinforced ceiling

The step-by-step instructions for updating the interior may differ slightly in different cars, but the general algorithm will be as follows:

- fasteners and accessories are removed in the cabin;

- the wiring must be disconnected, for this we fold the battery terminals and, if necessary, disconnect the connectors;

- dismantling of old upholstery material is carried out to use it, if possible, as an example for cutting, as well as cleaning the surface of dried glue;

- metal surfaces are degreased;

- patterns of future upholstery are formed on cardboard or thick paper;

- the surface of the new upholstery is coated with glue and fixed in place; if necessary, an industrial hair dryer is used to smooth out creases;

- after the do-it-yourself hauling of the cabin is finished, the glue has dried, you can return the fasteners and decor to their places.

Preparation for work

Now you can get to work. Naturally, first you need to collect the entire tool. But the hauling of the interior with eco-leather or other material does not start immediately. All surfaces must be prepared first. For example, you need to remove all devices from the front panel, and handles from the doors.

Next, you need to pull out the seats and thoroughly clean the interior. Naturally, this removes all old upholstery from the ceiling, doors, seats and other parts of the car. This is done carefully. During preparation, you will have to use a knife and screwdrivers

Perform all actions carefully so as not to damage the base.

Since the job will be quite dusty, try to vacuum the interior before you start upholstering with new material. Naturally, wear work clothes. Padding of the interior with leather, vinyl, Alcantara or other material can be done in the garage or on the street.

Required tools and materials

Padding of seats in a car is a rather complicated procedure. To update the covers, you will need the following tools:

- sewing machine. To sew thick leather in several layers, you will need a special device with a "walking" foot and a thick needle. Professional machines are several times more powerful than conventional ones, so they can sew dense material;

- reinforced threads for sewing;

- tailor's scissors and a stationery knife;

- nippers;

- rings that will secure the upholstery;

- small pliers;

- industrial dryer;

- rollers and spatulas;

- chalk and marker;

- foam rubber;

- long ruler;

- glue for leather.

Choice of fabric

Drivers pull over the interior of the car for two reasons: wear or design. Standard fabric upholstery in gray or black looks boring and ordinary. The choice of motorists is not very large, but still there.

Leather

Genuine leather has many benefits: it is soft and durable. The leather interior looks best in classic cars. Before going to the store, it is better to remember the cons of the material:

- high price;

- susceptibility to sharp objects;

- difficult care;

- fast heating in the sun.

In order for the leather to serve as long as possible, it must be treated with care: do not carry heavy objects in the cabin and treat it with air conditioner and cleaners.

In order for the leather to serve as long as possible, it must be treated with care: do not carry heavy objects in the cabin and treat it with air conditioner and cleaners.

Other types of fabric

The most popular material for constriction is artificial leather. It looks very natural, at the same time it costs less and does not require such gentle care.

Another possible material for the constriction is faux suede. Unlike natural, it is resistant to fading, stains and abrasion. Do not forget about the usual fabric, which remains a popular and cheap material for the salon. Most often, seat upholstery is made of nylon and polyester.

Threads

Upholstery threads must be strong and durable. You need to choose them based on the material of the seats:

- for leatherette, elastic polyester threads (AMANN Synton, Gütermann) are suitable;

- it is better to choose nylon threads for fabrics, which have high wear resistance and strength ("Blue Swallow").

Interesting to know!

Important! Synthetic or nylon threads can only be used on static seams, since there they will not stretch and wear off.

Seat padding should be comfortable and soft to provide comfort to the driver and passengers on long journeys. The backing is usually made of foam rubber

It is important that the material is moderately stiff and does not deform after the first ride. Also, the foam must be impregnated with a special compound that reduces the flammability of the material.

Resilience is important for driver comfort. In this case, the substrate does not need to be made too thick - it is better to choose polyurethane foam with a thickness of 5, maximum 10 cm.

Work order and valuable advice

The ceiling frame has already been cleaned of the remnants of old fabric, foam rubber. You can sand it with 80-120 grit paper for better adhesion.Before pasting, you need to remove the remnants of dust and grease from your hands - we use degreasers, but it is not recommended to apply a lot - having impregnated the top layer of the frame, the composition can cause delamination of the material. Therefore, we are testing this method in a hidden area.

Pasting the frame with material

The ceiling has been laid on the table, the fabric has been purchased, the jar of glue is open. Let's get started!

Safety precautions require the use of goggles, a respirator and rubber gloves. It should be noted that the glue that gets on the front surface of the ceiling will spoil the appearance and will not clean up, so we apply the glue with rubber gloves and smooth the fabric without them.

Apply a thin layer of glue to the frame with a brush. We wait for the instructions for a while, lay the fabric and press it in order, paying more attention to the bends and grooves. A small roller, a plastic spatula, fingers and a cloth will help to press the fabric.

It is important that the layer of glue is small and even, it is not advisable to rub the same place with your fingers - you can leave a stain

Do not cover the entire frame with glue - there is a risk of not having time to press the fabric. Therefore, we apply in strips of 30-40 centimeters, this slowness will help to avoid mistakes.

The fabric along the edges can be cut with a sharp knife along the edge, or you can bend it to the back side of the frame by 1–2 centimeters, cutting it with “teeth”. In this case, the fabric will hold better. However, it should be borne in mind that it will be more difficult to install the ceiling - it will become wider by the thickness of the fabric.

Video: car ceiling plywood in a workshop

What mistakes can a novice master have:

- applying a large amount of glue. It can saturate the fabric and protrude from the front side, ruining the appearance;

- violation of the instructions for the use of glue. The adhesive has not adhered sufficiently or is dry. In this case, the fabric will lag behind;

- poor pressure on the fabric, air bubbles;

- getting glue or dirt on the surface of the fabric;

- lack of material for pasting. Crookedly laid fabric at the beginning of work may "go" to the side at the end;

- poor-quality finishing of the edges of the frame.

The ceiling is glued - we give it a shutter speed, the time of which depends on the instructions for using the glue. After that, we proceed to the installation of the ceiling.

Ceiling installation

To mount the ceiling, you must first carefully place it in the vehicle interior. Practice shows that it is easier to get the ceiling out of the car than to put it in place. Therefore, you should use the services of an assistant, wear clean gloves. We define the ceiling in place and fix it. An assistant should support the sagging parts of the ceiling to prevent the frame from breaking or bending. If this is not done, wrinkles or folds will appear, which will ruin the appearance of the finish.

It is better to select the fasteners in advance to match the color of the sheathing so that it does not stand out. It is also better to replace the clips broken during disassembly. When tightening the screws, you should be extremely careful, a torn off screwdriver will scratch the plastic or fabric.

Assessment of work and rewarding of the master

The responsible stage is the acceptance of the work performed. The new ceiling in the car always looks nice, but do not relax - we must consider all the shortcomings, non-gluing, dirty spots. We correct them if possible.

If you did the work yourself, be sure to reward yourself with a good emotion, if the work is done by a professional, in addition to money, you can leave a good review about his work, tell your friends about the talented master.

The installation of the ceiling of the car needs to be done only by two people: then the work will be done carefully

Choice of material for the waist of the front panel of the machine

The torpedo is constantly in sight, which means that its appearance and quality will be striking both for you and for the rest of the passengers. The selection of material for the front panel constriction should be approached responsibly. Most often, the following materials are used in the interior design of the car:

- leather (artificial and natural);

- alcantara (another name is artificial suede);

- vinyl.

Leather

Genuine leather is a good choice for front panel constriction. This is a durable material that is not afraid of temperature extremes, wetting and fire. In addition, its surface is resistant to mechanical damage. Of course, it is not worth scratching the skin with a nail on purpose, but the white stripes themselves will not appear on it either. The skin can be easily cleaned of dirt by regularly wiping it with a damp cloth. You can not be afraid that the panel will burn out in the sun - it is not afraid of ultraviolet radiation. And it's not even worth talking about the appearance of genuine leather: it will perfectly fit into the interior of even the most expensive and pretentious car.

genuine leather gives the car interior a sophisticated look

Eco leather

If genuine leather is too expensive for you, use its modern substitute - eco-leather. This type of material is called ecological, because it does not emit harmful substances during operation. It does not at all look like the cheap leatherette of the late 90s. It is a durable, moisture-resistant and vapor-proof material that is able to maintain its appearance for a long time. Do not be afraid that the eco-leather coating will crack in a short time. In terms of its performance, the material is not inferior to natural leather. In addition, eco-leather is suitable for allergic drivers.

eco-leather has good performance characteristics, but it is much cheaper than natural

Alcantara

Recently, Alcantara has become one of the most popular materials for covering the interior, including the dashboard. It is a non-woven synthetic material that feels like suede. It combines a velvety soft surface with easy maintenance and high wear resistance. Just like leather, it does not fade in the sun. High humidity and temperature drops also do not negatively affect it. Many drivers prefer to drag the entire cabin with Alcantara to create an atmosphere of home comfort. Others use it to design individual elements to dilute the severity of the skin. In any case, Alcantara is perfect for covering a torpedo.

alcantara is a synthetic fabric similar to suede

Vinyl

If you want to create an unusual interior design, consider using vinyls. There is a rich variety of textures and colors on the market today. You can choose a calm black or gray color, or you can find an acid green imitation of python fabric. Chrome films are very popular, as well as films with a carbon or metallic effect. It is even easier to care for them than for the skin. Vinyl films have, perhaps, only one drawback: they are easy to accidentally scratch. But the low price allows you to drag the panel as often as you want.

with the help of vinyl film, you can simulate various materials, including carbon

Review of popular brands

The market offers a wide range of products used for car interior upholstery. Some of these formulations are very popular.

"Moment"

"Moment" is a universal adhesive composition used for fixing various materials. However, this product is toxic and spreads over the surface. In this regard, "Moment" is usually not used for gluing the trim in the cabin.

"Kaiflex K414"

Another polyurethane-based product. "Kaiflex K414" stands out against the background of other adhesives in that it provides a strong fixation of the finish on the surface and reacts well to temperature changes, retaining its original properties when the interior overheats.

"Titanium"

"Titanium" is rarely used for waist upholstery. This product dries for a long time and does not tolerate temperature extremes.

"Demoskol"

"Demoskol" is recommended to be used for upholstering the interiors of old cars. This composition is characterized by increased moisture resistance.In addition, DemoSkol is not affected by temperature extremes.

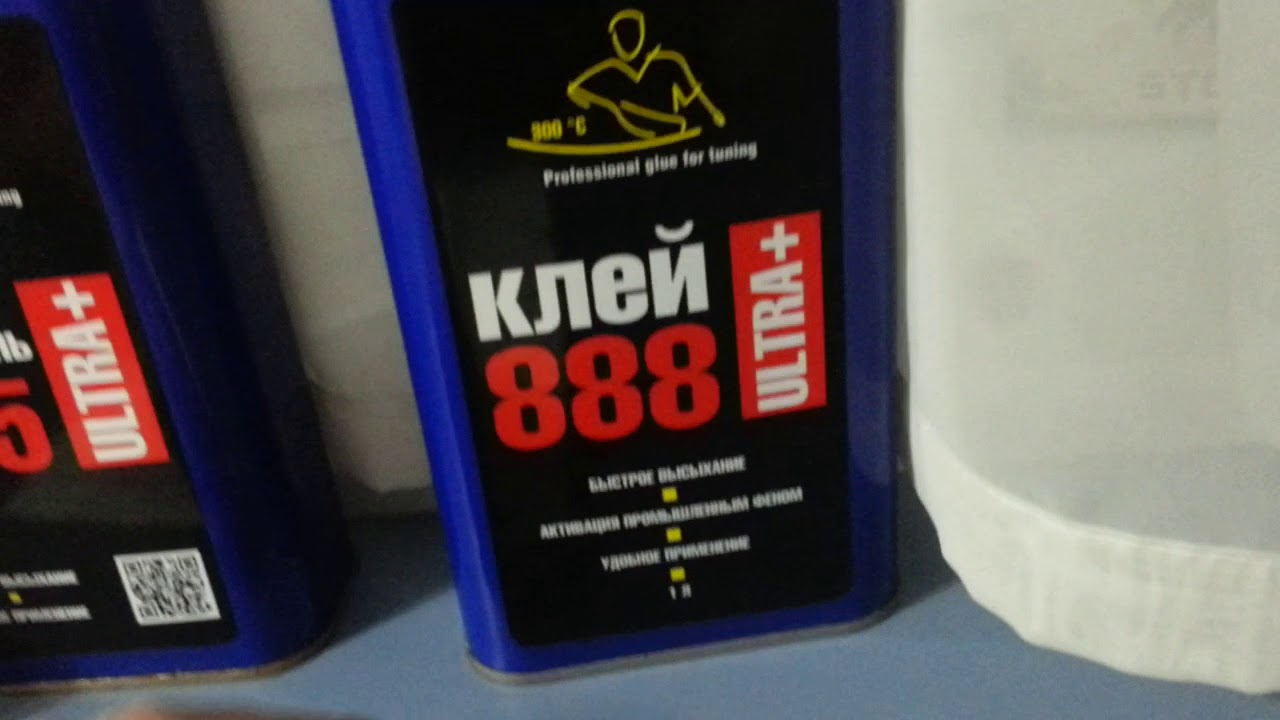

"Glue-88"

A universal tool for restoring the upholstery of the passenger compartment. Glue-88 is used for fixing various materials, including alcantara and natural leather. This product is highly resistant to moisture and temperature extremes. The disadvantages of the product include the fact that "Glue-88" does not provide strong fixation of the sheathing to the surface and exudes a pronounced unpleasant odor.

"GTA Boterm"

GTA Boterm stands out for its ability to withstand exposure to high temperatures and humidity. However, working with this lineup is more difficult than with the previous ones. To gain strength, the glue requires temperature exposure (treatment with a building hairdryer).

"Mah"

"Mah" is considered the optimal adhesive composition for the constriction of the upholstery of the car interior. This product exactly meets all the requirements for such products.

v class = 'yarpp-related yarpp-related-none'>