What is the glue for plexiglass

Adhesive for plexiglass is chosen depending on the wishes of the consumer himself.

new one-component Wiko Plexy adhesive for plexiglass (plexiglass)

There are two types of glue used to repair, restore the integrity of products:

Adhesive mixture of acrylic with solvent, used for extrusive (cast) acrylic (it is also plexiglass, plexiglass). Professional glue. During the connection of two identical components under the influence of the third active substance, a strong connection of the bases occurs due to the dissolution of the surface molecular layer of plexiglass. The gluing is monolithic. There are some nuances. Although this group is intended directly for bonding plexiglass (plexiglass), not all adhesives in this group will be able to bond all types of these materials.

This is very important, there are exceptions, so you need to be careful when choosing a composition for certain brands of PLEXIGLAS, which is the general name of the trademark.

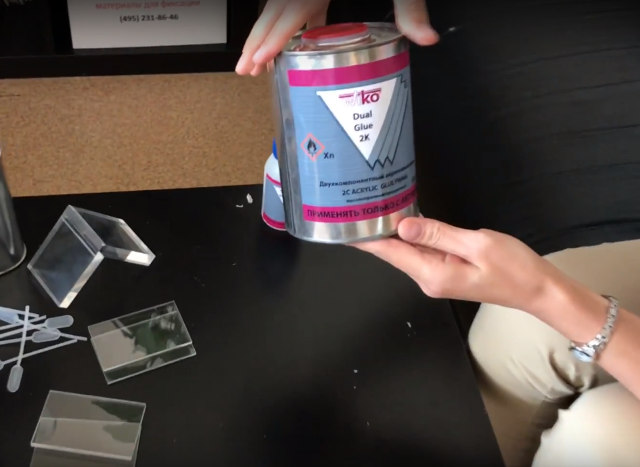

Two-component adhesive based on epoxy resin or cyanoacrylate. With their help, you can quickly glue individual parts

Suitable in some cases, and can be used for a small area of work.

Household adhesives for joining plexiglass are divided into two groups according to the principle of action:

- The former include active substances that are applied to the joints before gluing. The surfaces are melted. The master glues them while the material is liquid. After drying, a monolithic seam is formed.

- Compositions forming a connecting layer between the individual parts. A less durable seam is formed than during the melting of the surfaces to be joined.

In order not to be mistaken during the selection, it is necessary to consider the most popular products for gluing plexiglass.

new two-component adhesive Wiko Dual Glue for plexiglass (plexiglass)

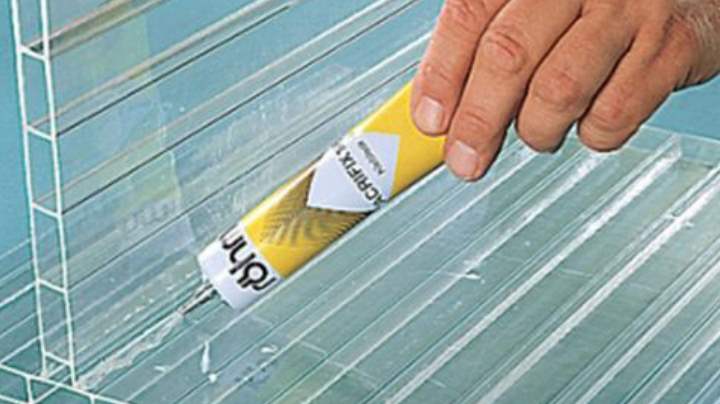

Acrifix 116 glue

Acrilfix plexiglass adhesive, which produces high-quality substances that are used when joining various materials. Product 116 is a transparent formulation, a thick mixture (more viscous than Acrifix 117), which is similar in consistency to a flowing resin. Packaged in 100 ml tubes.

Used for gluing rough parts with uneven edges. Effectively fills in the voids caused by chips, creates a homogeneous surface. One component adhesive. It hardens by evaporation and absorption of solvents by the parts to be joined.

Acrifix 117

If a person does not know how to glue plexiglass, any experienced craftsman will call him Acrilfix 117 glue. This mixture is considered the best for gluing acrylic-based materials. He has a number of strengths and weaknesses.

Advantages:

- High strength of the finished seam.

- Dries quickly.

- The lowest level of toxicity compared to analogues.

- Long shelf life.

- Penetrates small cracks, fills them to the ground.

- The transparent seam is practically invisible in the total area of the glued surface.

Disadvantages:

- Very high price.

- Rarely comes across on the shelves of hardware stores.

- It is impossible to buy a small capacity. The standard package size is 1 liter.

Experienced craftsmen recommend mixing Acrilfix 117 with 116 (10/1) in order to reduce the consumption of expensive glue. In addition to this, the mixture better fills the voids of microcracks. The quality of the seams does not deteriorate.

Colacril 20 glue

When gluing plexiglass, craftsmen often use Colacril products. It costs less than Acrilfix, however, its properties are close to expensive mixtures. Item 20 is a flowable adhesive that can be used to make transparent, strong, durable seams.Similar in its actions to the previous brand, but cheaper.

Colacril 30

It differs from the name 20 - in consistency. It is thicker, so that 30 is mixed with 20 to get the desired thickness of the adhesive. The lack of adhesives from this company is that they crack at the bend. This violates the integrity of the connection, degrades the appearance.

BRAUBERG glue

This transparent adhesive is versatile for a wide variety of materials, differing in their structure. Sold in a package called a show box. Glues and joins products made of wood, metal, PVC of any hardness, polystyrene, porcelain, ceramics, plexiglass, glass. Also glues rubber, felt and leather.

Advantages:

- Versatility.

- Water resistance.

- Elasticity of the sealed seam.

- Bonds porous materials.

- Glues plexiglass and plain glass.

- A symbolic price.

Possible side effects

There are secrets in the preparation and use of mastic jewelry, the knowledge of which allows you to prevent an unexpected end result:

- the powdered sugar used for the manufacture of mastic is prepared carefully, ground very finely, otherwise the layer will break during rolling;

- mastic should not be applied to a raw crust (sour cream, impregnation), since it can dissolve when it comes into contact with moisture;

- before applying the mastic to the butter cream, the dessert is placed in the refrigerator so that the cream hardens well;

- small decor details can be glued by moistening with water or protein with powdered sugar;

- if the figures are glued and put in the refrigerator, they can absorb moisture and fall off, so the decor is attached before serving the dessert on the table;

- parts made of marshmallows can be painted with food colors;

- when the mastic cools, it loses its elasticity, which can be returned by placing the decorative material in a microwave oven or a heated oven;

- the remnants of the mastic are stored in the freezer - up to two months or two weeks on the refrigerator shelf;

- dried but unused figurines are placed in a box and stored for 1.5 months.

What glue is right

Manufacturers offer many varieties of adhesives suitable for gluing paper and cardboard. The composition of the funds is different, so they must be used correctly.

Glue stick

In children's creativity, this type of tool is often used. The advantage of the glue stick is that it:

- easy to use;

- economical in consumption;

- firmly glues different types of paper, cardboard, textiles.

The product does not stain the child's hands, it does not stain clothes.

A glue stick is used to temporarily fasten the sheets, to decorate the applique. You can not use the product for bulky crafts, since the parts will quickly move away from each other after drying.

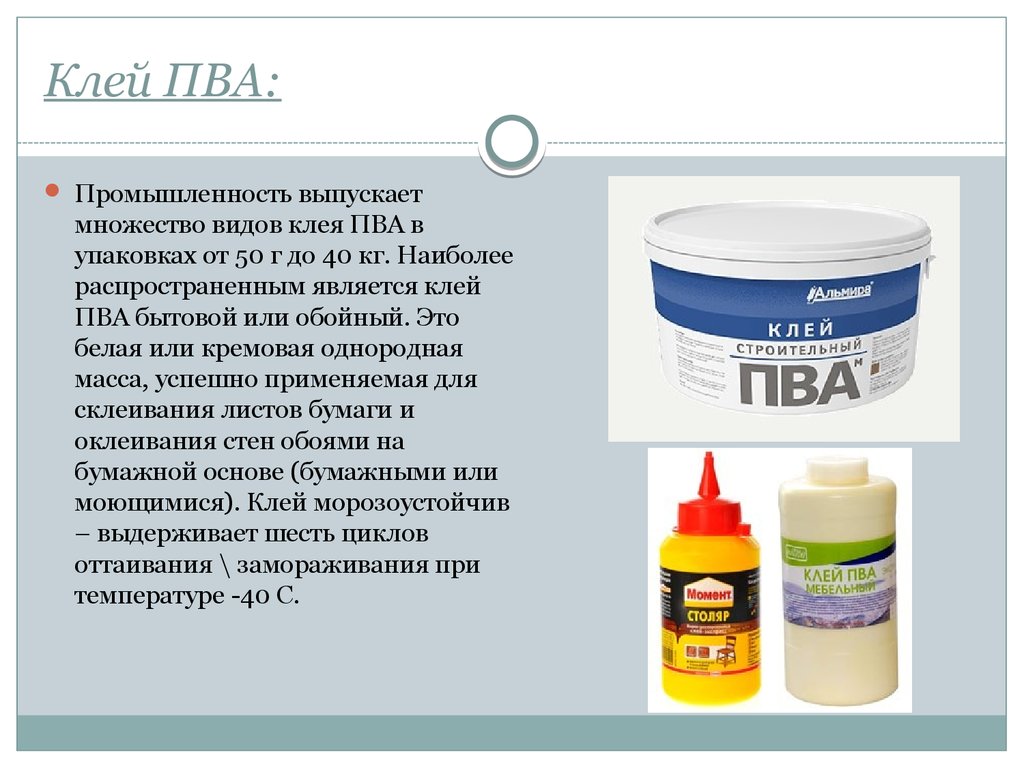

PVA

This material is based on polyvinyl acetate, a substance with excellent adhesive properties. The harmless adhesive does not have a pungent odor. It is used for gluing natural material onto cardboard. During application with a thin layer of PVA, it does not deform the paper. Already after 3-4 minutes, the glue dries partially, leaving no stains. The product is left for a day under a press for better bonding. The convenience of applying strips of glue is noted, since the product is packaged in bottles with a nozzle.

Super glue

The adhesion force of the cyanoacrylate substance, which is used for the manufacture of the adhesive composition, is great. The viscous mass grabs instantly, so you should connect the parts of the object correctly immediately. Then it will be more difficult to correct the situation.

The disadvantage of the material is that when gluing, you can connect the skin of the fingers. Then it is difficult to wipe off the pieces of glue from it. And the product has a pungent smell, so it is better to deal with the connection in a ventilated area or in the fresh air.

Gum arabic

The glue composition is made from arabic gum diluted in water. Its advantages are that it:

- harmless to human health;

- has a high degree of adhesion;

- reliable and gives strength to the seams to be glued.

It is difficult to obtain ready-made glue. More often it is prepared independently by mixing 10 grams of gum in 20 milliliters of water.

Acrylic

A feature of acrylic adhesives is that they hold together even thick cardboard with high quality. They produce glue in tubes, hence the convenience of applying the product. But since the base in the material consists of water, a large amount of the applied substance leads to deformation of paper crafts.

Dextrin

Previously, a paste made from flour or potato starch was used to glue paper elements. Now, in the production of dextrin glue, they act on starch with high temperatures. Within 1.5 hours in a cabinet that is heated to 160 degrees, starch is split and converted into dextrin. The resulting substance is dissolved in water and a little glycerin is added. The product is used for gluing paper.

Spray adhesive

The new glue-spray was highly appreciated, because it is evenly sprayed from the can onto the sheet. At the same time, there are no traces left on the hands, table, clothes. Quickly adhere when sprayed on fabrics, all types of paper.

Joiner

This type of glue is natural and differs in that it firmly adheres parts of the object.

It is important that the product is transparent. Long-term storage of a substance in a liquid state leads to the formation of mold inside the bottle

It is better to purchase the glue in the form of a brownish powder and dilute with water, slowly heating the mixture in a water bath. For 1 part of the substance, 2 parts of water are needed.

Photo glue

It is better to glue photographs into an album with rubber glue. Even after drying, if necessary, you can remove the photo, and clean the cardboard surface of the album with an eraser.

How to glue plexiglass

For general understanding, the general principle of mechanical processing of plexiglass looks like this. For example, a jigsaw (hacksaw).

Algorithm:

- The stroke function must be at zero for slabs up to 4mm.

- Medium feed (1st or 2nd stroke) for thicker slabs.

- Saw at high cutting speed (rpm).

- For a circular saw, the speed is 4200 rpm with a blade diameter of 320 mm.

- Only not offset (!) Discs with teeth from 9 to 15 mm.

- Full start before cutting.

- A dense installation on a protective film (or an aqueous solution of PVAL) is required, which cannot be removed.

- Cool with water or compressed air. It is unacceptable (!) To cut a slab over 3 mm thick without cooling.

- Carbide saw (disc) or diamond-coated.

Anyone can glue the plexiglass together. You don't need any practical experience to do this. It is enough to perform a series of actions in a specific sequence.

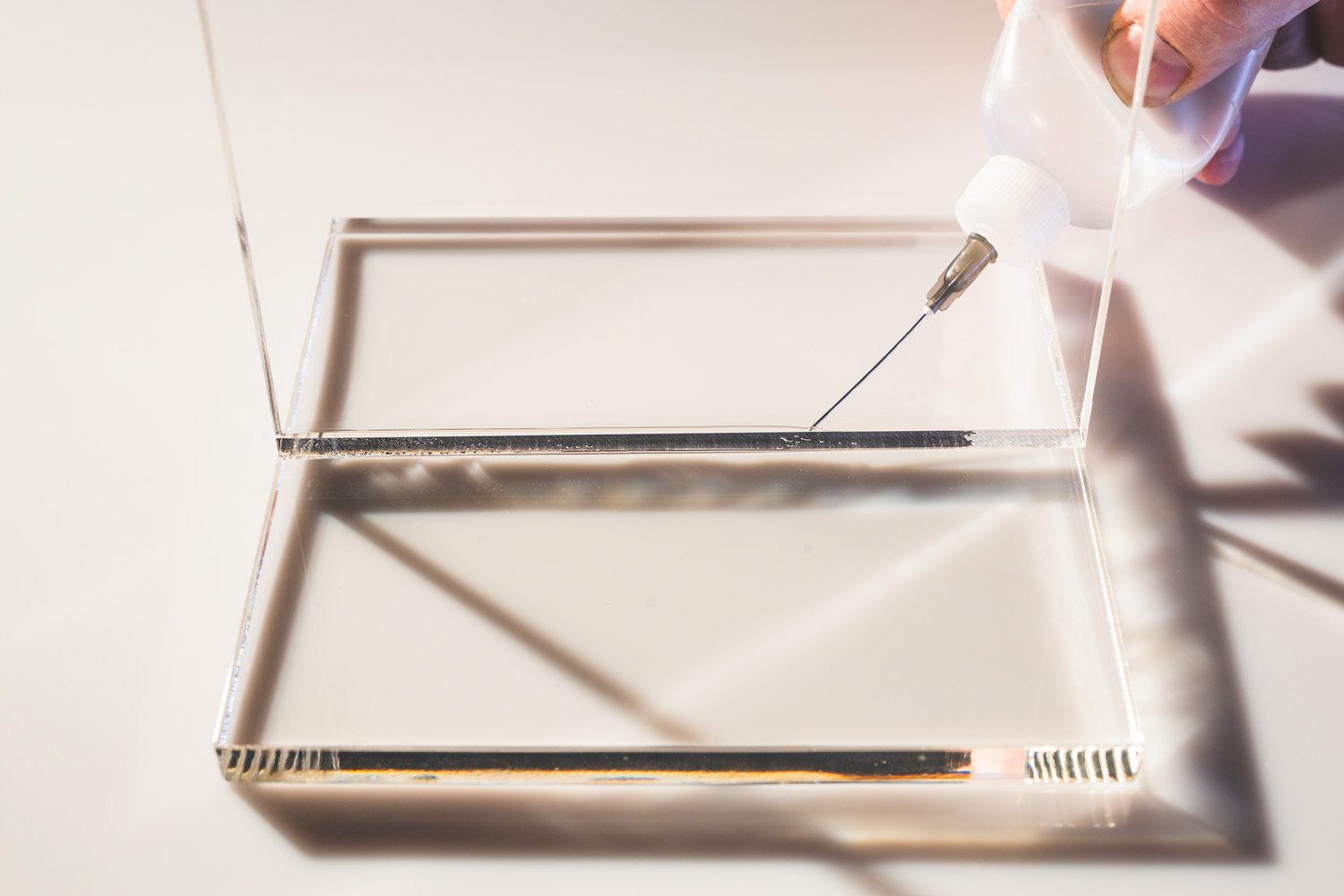

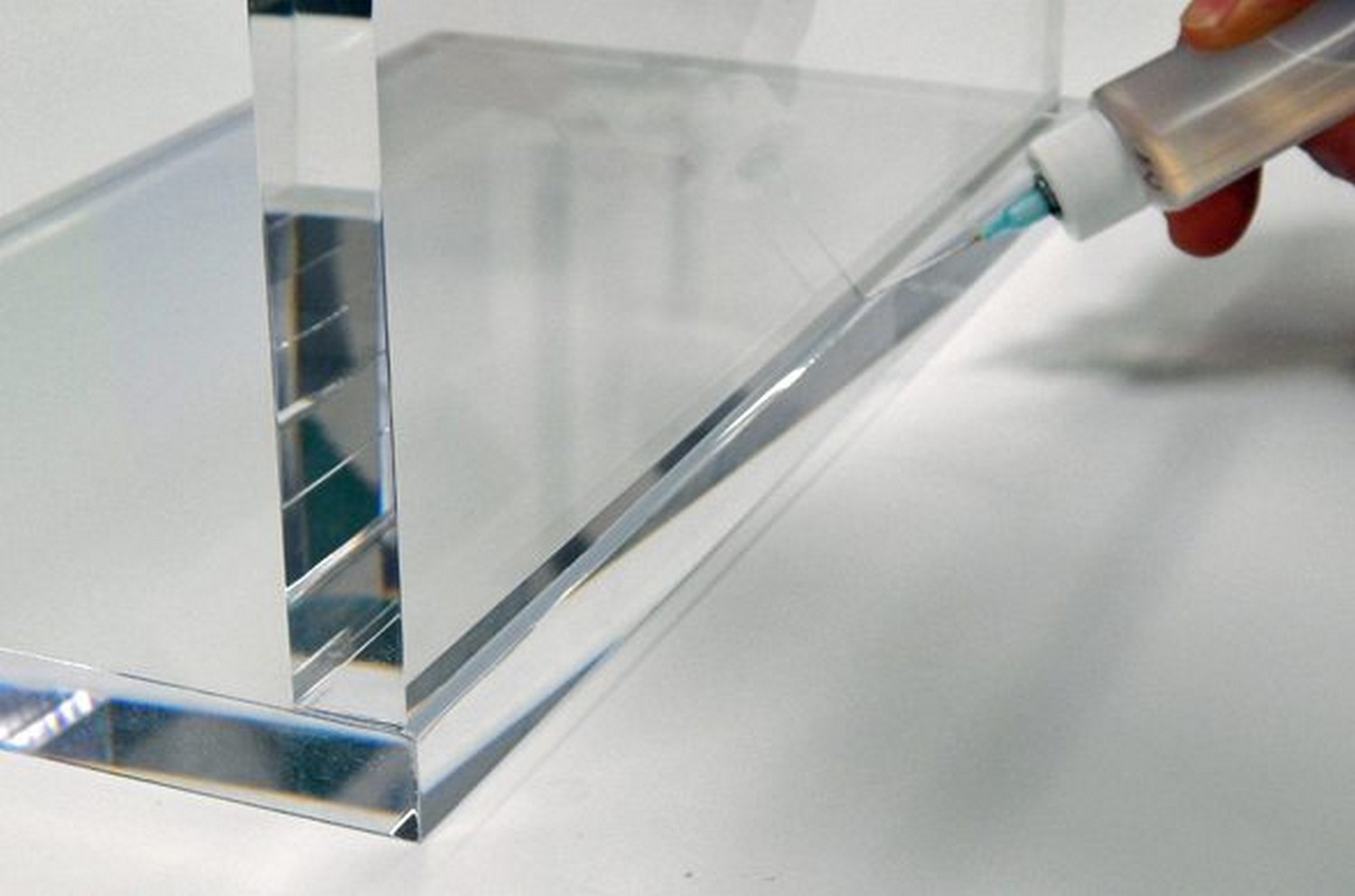

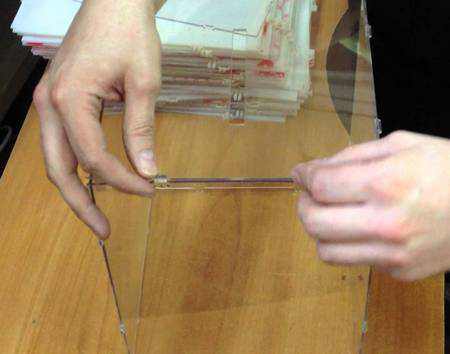

Step-by-step instruction:

- Wear gloves so as not to leave greasy marks at the gluing site. Treat the parts to be glued with a cloth soaked in gasoline or alcohol.

- Fasten both parts of the product symmetrically and so that there is a small gap between them.

- Prepare a medical syringe. The needle must be filed to cut the bevel. Its absence will exclude splashing of the adhesive during operation.

- Fill the syringe with glue. Apply in an even layer over the bonding area.

- Squeeze the plexiglass parts together. Leave them in the locked position for 1 hour.

Masking tape is used to protect the edges of the parts. Bonding of individual elements should take place in a well-ventilated area. After all work, rinse off the dirt with clean water or with the addition of a mild detergent. Wipe dry only after all microparticles have been completely removed.

How to glue plexiglass to metal

Often home craftsmen do not know what glue plexiglass to metal... To do this, you can use several adhesives:

- Dichloroethane.

- Glue 88.

- Liquid Nails.

Sometimes compositions appear on the shelves of hardware stores, which indicate that they can glue plexiglass with metal.

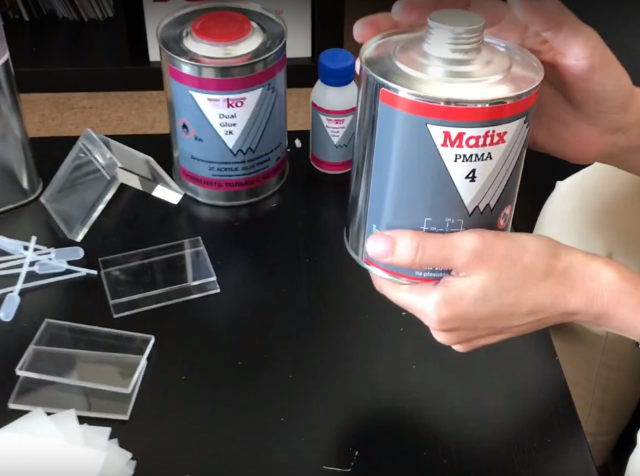

Plexiglass to wood

Again, not many people know how to glue plexiglass to wood. When choosing an adhesive for joining two different materials, you need to understand that the wrong choice will lead to the formation of a prominent seam.

The best adhesives include:

- MAFIX.

- Super glue.

- Cosmophen.

It is advisable to experimentally glue unnecessary parts together to see the quality of the connection.

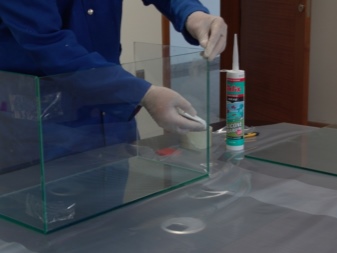

Plexiglass to glass

It is extremely difficult to glue plexiglass to the glass. Most often, the compound gets fragility in its properties. Experts recommend using the following formulations:

- COSMOPLAST 500.

- COSMOFEN.

- COSMOFEN PMMA.

These adhesives are very unstable to sudden changes in temperature. It is problematic to glue surfaces that tend to heat up during operation.

Main components

Food glue differs in that it is created on the basis of natural ingredients that are harmless to the human body. The industrial-made retainer most often includes:

- water;

- citric or acetic acid as a preservative;

- additive E466 - sodium carboxymethyl cellulose, capable of imparting viscosity to the mixture;

- potassium sorbate.

The release form can be of two types - liquid or powder. The first one can be used immediately, powder takes time to prepare. Today there are many recipes from which you can make food glue from common products at home. For this you will need:

- chicken egg whites;

- white or dark chocolate;

- lemon acid;

- flour;

- powdered sugar;

- sugar syrup.

The glue is easy to prepare, it sets quickly, easily tolerates temperature extremes. You should not cook the mass in large quantities, since its consumption is economical.

Magic Colors

Magic Colors food glue is a ready-to-use thick mass. The components that make it up are of plant origin. The liquid has good fluidity and density. The adhesion of the components is strong, so glue is often used to connect mastic elements, marzipan figurines.

The mixture is applied to the glued surfaces, which are connected, and after a while their fastening becomes reliable. Food glue comes in handy if small items have been damaged on the cake. The fix is easy with Magic Colors, just one touch with the brush. The composition will help if the culinary specialist is faced with the task of combining rather massive mastic jewelry.

Rainbow edible glue

The food glue of this brand is based on carboxymethyl cellulose. It is made from caustic soda and cellulose. The substance is tasteless and odorless. It is used to thicken and obtain viscosity. Rainbow edible glue is often used by professional pastry chefs to create designer cakes, wedding cakes.

It does not belong to allergenic products, reactions of this type have not been noted. Vegetarians can eat foods using this glue, since there are no components of animal origin in the composition. Rainbow edible glue is manufactured in the UK. You can buy it in plastic containers of 25 or 50 grams.

QFC Essentials Edible Glue

British brand culinary glue has an edible "sugar" composition. It is ideal for making culinary mastic, from which flowers, decorations, and figures are made. Its high adhesive capacity helps to hold heavy dessert decorations. The composition of QFC Essentials sets quickly and is resistant to temperature extremes. Food glue is a colorless, viscous liquid. Packaged in plastic containers of 18 grams.

How to glue?

Polypropylene sheets, plastic, high and low pressure film cellophane - all these materials have a low adhesive ability. Their surface is not only smooth, but also has no porosity to absorb adhesives.To date, no special adhesives designed specifically for polyethylene have been invented.

Types of glue

Adhesives for polymeric materials are divided into 2 types.

- One-component adhesive - this composition is already completely ready-to-use and does not require any additional ingredients.

- Two-component adhesive - consists of an adhesive base and an additional component in the form of a polymerizing agent called a hardener. Before starting work, both components must be combined by mixing. The finished composition cannot be stored and is used immediately after preparation, since polymerization begins under the influence of oxygen.

According to the method of hardening, all adhesives are divided into 3 groups:

- cold curing - the glue hardens at a temperature of 20 ° C;

- thermoactive polymerization - for solidification, the adhesive composition or the surface of the material to be glued must be heated;

- mixed polymerization - the glue can be cured when heated or at room temperature.

Modern adhesives have additives that dissolve polymer surfaces, thereby creating conditions for better adhesion. The solvent tends to evaporate quickly, after which the polymer mass hardens, forming a seam. In the seam area, the surfaces of the two workpieces form a common web, so this process is called cold welding.

Top brands

The bulk of modern adhesives contains methacrylate, which is a two-component element, but without admixture of a primer-hardener harmful to the human body.

For gluing polyamide and polyethylene, adhesives of several popular brands can be used.

Easy-Mix PE-PP - from the manufacturer Weicon. As a primer, crushed glass is used in the form of a fine dispersion, which, when distributed over the surface of the parts to be glued, ensures good adhesion. In the composition there are no impurities harmful to humans, so the product can be used at home. Before applying it to the working surfaces, they do not need to be specially prepared in any way - it is enough just to remove obvious dirt. The mixing of the components of the paste-like glue occurs at the moment of its feeding from the tube directly to the gluing section.

In addition to smooth polyethylene, foamed polymer materials also need gluing. The porous structure of foamed polymers is flexible, so the adhesive connection must be quite reliable. For gluing such materials, other types of glue are used.

88 Lux is a Russian product. One-component synthetic glue that does not contain substances toxic to humans. The adhesive composition has a long polymerization period, the seam hardens completely only a day after gluing the surfaces. When using 88 Lux glue, the finished seam is resistant to moisture and sub-zero temperatures.

Epoxy bonding

This is the most affordable method when it comes to gluing, not welding. Before gluing the polyethylene, you need to prepare the surfaces.

Epoxy adhesive packaging

Epoxy glue is not a glue for gluing polyethylene, but, nevertheless, phenol-formaldehyde resin has very decent adhesion to the surface of polyethylene. In this case, you need to proceed as follows:

Coarse the surfaces with emery cloth, then degrease and dry.

Treat both surfaces with a 15-25% solution of chromic anhydride or 20-30% potassium dichromate

(Caution, caustic substances and dangerous carcinogens!) You can take another strong oxidizing agent: a strong solution of potassium permanganate. It is not much inferior in efficiency, but much safer

After processing, dry the surfaces again.

Prepare epoxy glue according to the instructions.

Apply a thin layer of glue to both surfaces and join together.

Keep at a temperature of + 30 ... + 45 ° C for several hours, but it is better to keep it for a day until cooked.

What adhesives are suitable for plexiglass

The list of means suitable for gluing plexiglass is determined by the chemical composition of the material. Plexiglass is a synthetic product, acrylic resin / plexiglass. Distinguish between high molecular weight, low molecular weight and molded polymer. Acrylic lends itself to the action of solvents, cyanates, strong acids.

> Under their influence, there are two types of chemical reactions that determine the strength of the adhesion:

- The surfaces of the parts soften, mix and, after hardening, form a monolith.

- The agent is partially absorbed into the pores of the plexiglass, forming a binding film.

The first method is called cold welding and produces the strongest seams.

Solvent based acrylic

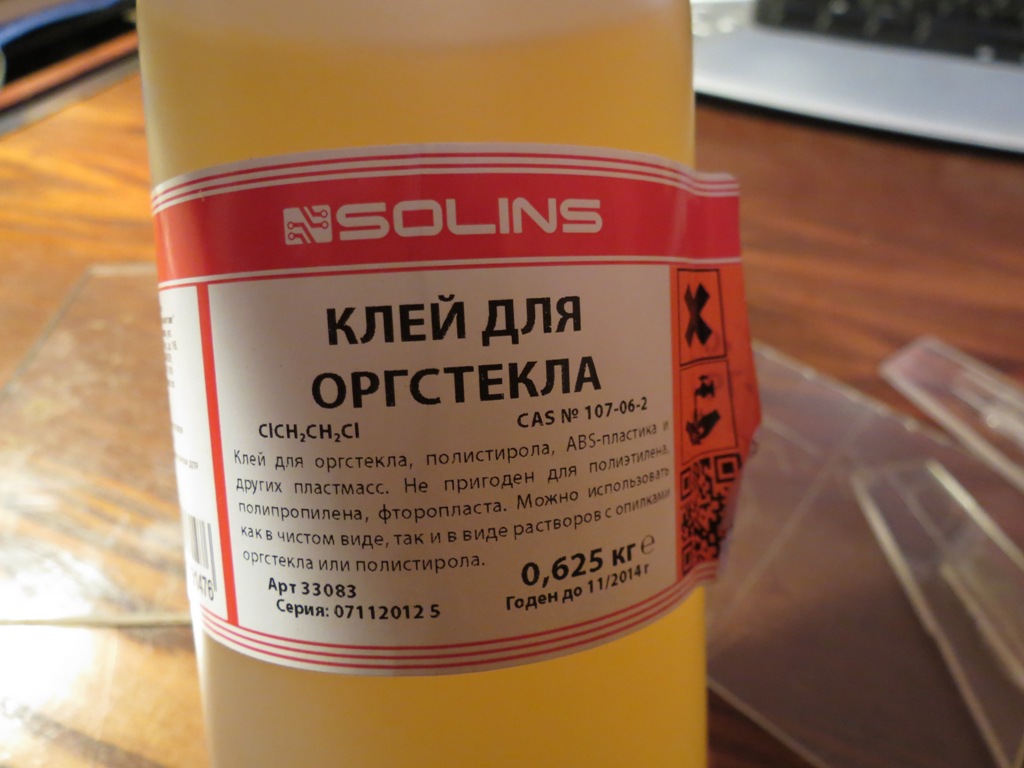

Adhesive for plexiglass based on dichloroethane is transparent, can have a liquid or viscous consistency. The adhesive softens the upper layers of the parts to be glued, after which it partially evaporates, partially absorbed into the polymer.

Epoxy resin

The epoxy is suitable for bridging shallow cracks to restore the surface layer. The intermediate layer penetrates into the pores of the plexiglass, smoothing out irregularities.

Uv

Photopolymer glue, which contains methacrylate (organic glass is a polymer of methyl methacrylate). The hardener is the UV radiation received from the LED flashlight.

Modifications of UV adhesives are intended for gluing:

- plexiglass with plexiglass;

- metal;

- tree;

- plastic.

The resulting compound has:

- high resistance to mechanical stress;

- temperature extremes;

- transparency;

- durability.

The absence of solvents and non-flammability makes it safe to use.

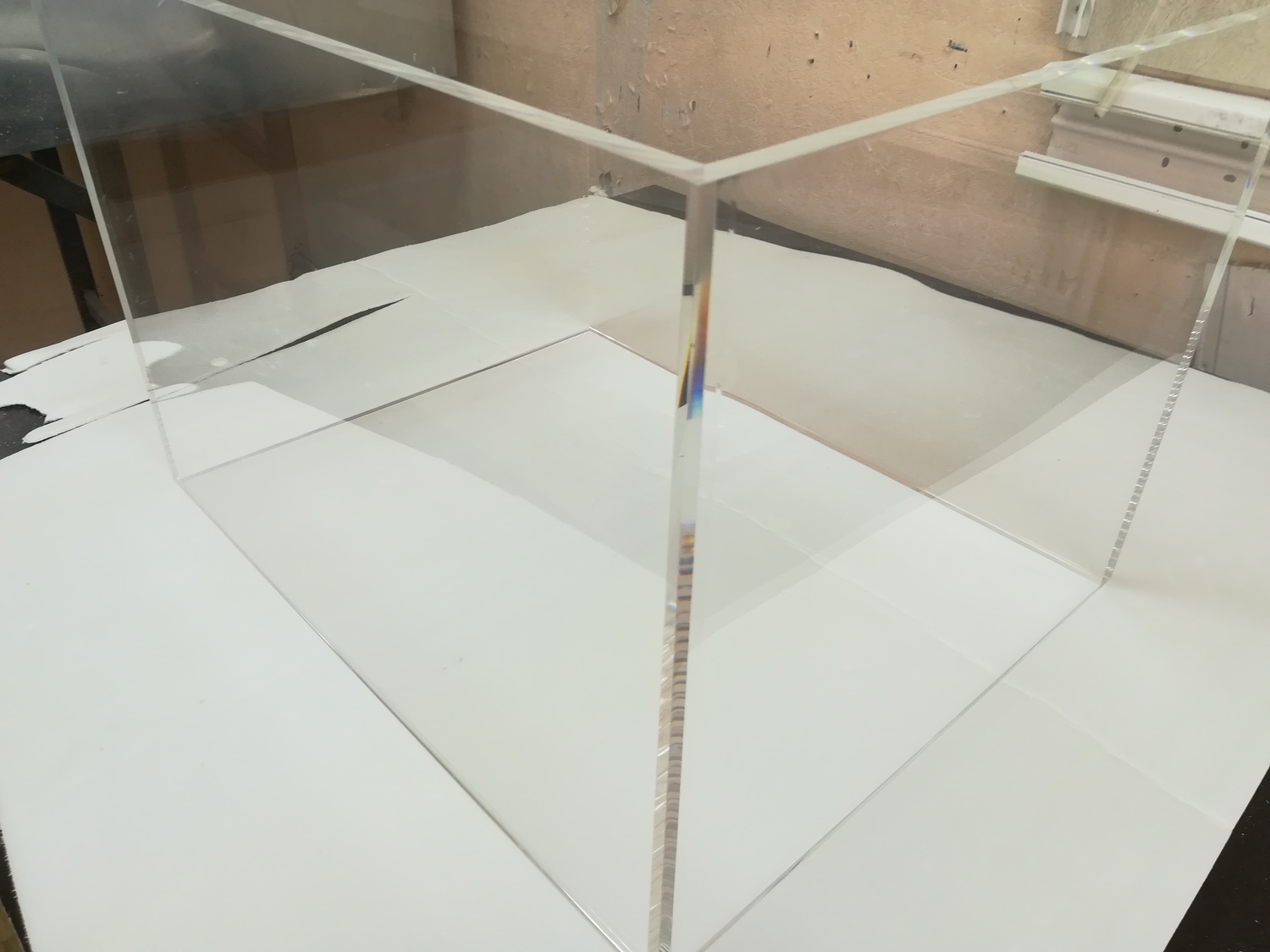

How to glue plexiglass together

To glue plexiglass together, you need to study the important features of this process. You should first prepare the material, wipe it with ethyl alcohol and degrease the surface, this will provide better adhesion. The product must be clean and smooth.

Standard way

Plexiglas is usually glued using popular adhesives containing acrylic, solvent or epoxy. But to get a strong and durable seam, you need to do everything correctly.

So how to glue plexiglass at home? The following instruction will help with this:

- The surface is degreased beforehand. A cloth or napkin is moistened with a solvent or gasoline, and after the plane on which the glue will be applied, they are well wiped;

- Further, the elements of the product must be fixed, there must be a gap between them;

- The adhesive is applied to both parts in the form of a uniform layer. To make it convenient to apply the product, you can use a medical syringe. It is better to cut the needle a little so that the composition does not splash;

- Then the components are connected, tightly compressed until they are fully connected. For better fixation, you can install a load;

- In the squeezed position, the product should be kept from 1 to 30 minutes.

Vinegar bonding

At home, for fixing products, you can use an affordable and inexpensive tool - vinegar essence. Only concentrate is suitable for gluing, but even it cannot create a strong and transparent seam.

Plexiglas gluing with vinegar is carried out as follows:

- The liquid must be applied to the area of the edges of the product;

- After the edges are tightly compressed;

- The top layer softens, this is what allows you to create a solid seam;

- The products to be glued should be pressed down with a load and left for a day.

2> Requirements for glass adhesive

For gluing glasses to each other or material to other surfaces, it is necessary that the glue meets a number of requirements:

- Increased adhesion to any materials.

- Ability to withstand loads.

- Has no tint (colorless).

- Fast fixation.

- Medium viscosity, fluidity.

- Flexibility.

- Thermal water resistance.

- No toxic compounds.

- Long shelf life.

When gluing glass and ceramic surfaces, the mass must have excellent adhesion properties. Application should not be inconvenient. Fixation should be fast and strong, as long-term fixation of the glued surfaces is not always carried out.

Viscosity and flowability vary depending on the material. When connecting porcelain or earthenware parts, the mass must be more fluid in order to fill all the irregularities. If glass sheets are connected, then more viscosity is needed, less fluidity.

If the objects to be glued are in a living room, then the glue mass should not contain harmful compounds so that there is no negative effect on the body.

What are used as solvents and fillers

Before using the glue, it is necessary to familiarize yourself in more detail with the components from which it is made.

Chlorine compounds

Most rubber mixtures contain chlorine-containing compounds. Manufacturers try to add the minimum amount of such components, as they are characterized by a high level of toxicity. Therefore, when choosing an adhesive for further work, you need to familiarize yourself with its composition and make sure that it does not contain many compounds in which chlorine is present.

Eticelate with nephras

Many adhesive liquids are made with the addition of nephras and ethyl acetate. This chemical compound improves the quality of the mixture and increases its adhesion. Therefore, experts recommend using glue containing refined products mixed with acetic acid.

Latex with water content

Latex is added to almost all adhesives. However, this element is added to cheap rubber glue not in pure form, but together with water. The addition of liquid to the latex negatively affects the adhesive properties of the product and makes the connection less reliable. Because of this, such an applied rubber mixture adheres to the surface at times worse.

Resin and polystorole

In adhesives, which are characterized by increased strength, polystyrene with resin is often added. Therefore, in order to more reliably glue the surfaces, it is recommended to use just such means. However, buying glue with too much polystyrene and resin in it is not worth it. A large amount of these components negatively affects the elasticity of the joint.

Sulfur, amines and metal oxides

Adhesive mix firms often add metal oxides, amines and sulfur to them. It is thanks to these substances that the vulcanization process takes place, during which the plastic rubber turns into rubber. The amount of additives directly depends on how much rubber is contained in the glue.

Consistency stabilizers

Some inexpensive adhesives will gel over time and bond less well. Most often, this problem appears if there are no consistency stabilizers in the composition of the product. These include diethylamine or ethanol. These components maintain the liquid consistency of the glue.