Types of plastic products

There are a large number of firms engaged in the production of adhesives exclusively for plastic structures. The polystyrene type is perfect for assembling models. Such manufacturers as Zvezda, Tamiya, Italeri, Revell and others are actively involved in its release.

As stated earlier, polystyrene glue acts on the principle of melting plastic. In other words, when applying the "Star" or other means, its smallest particles penetrate into the surfaces to be glued, and then harden, thereby adhering the plastic parts of the model. Finally, the parts dry out in a day, but use is possible after 60-120 minutes.

Revell glue manufacturers make special cans with a needle to ensure maximum ease of use. How to use it can be seen in the video. Tamiya manufactures brush cartridges. Thus, the bottle is able to help you out if you are dealing with cracks. But the adhesive from the company Zvezda does not include any other device in its kit to facilitate its use.

How to build models

The main thing is a comfortable and well-lit workplace. We lay out everything so that it is at hand and not lost, we proceed. You can also follow the instructions.

We carefully bite off the parts from the frames, as much as necessary for one assembly - so as not to get confused. The main thing is not to cut off the excess, not to spoil the part. Further - the processing of the part, it is necessary to remove casting defects - flaking (frozen puddles around the parts), displacement of the halves of the form (on cylindrical parts - 2 stripes along the edges), sinkings (pits where there was not enough plastic) and traces of pushers (small circles where they shouldn't be). We carefully cut off the flash, trying not to touch the part.

Carefully grind the offset with a file or sandpaper, trying not to make the cylinder flat. We cover the dips with putty. Traces from the pushers: if they come out - with sandpaper, if inside - we cover it with putty and grind it.

Before gluing, we fold the parts dry, without glue, see if they fit well, if necessary, cut them. We press the glue from a needle, the less it is, the better it will stick together. If more is squeezed out than necessary - immediately erase it with your finger, or after an hour or two, carefully cut off the frozen drop with a knife and grind it. You can paint either according to the instructions, in the assembly process in parts, or at the very end, when the entire model is assembled.

Additional tips and tricks

Modeling is painstaking work that requires a systematic approach. It usually takes about 3 minutes to glue the two parts together, but it takes about 1 hour for these elements to dry completely.

Modelers spend more than one day on creating volumetric models. The quality of work depends on adherence to basic rules. There are various nuances that are not immediately apparent:

- Too much adhesive liquid is not poured onto the joint, as the excess will drain over the surface, stain the elements and hands.

- When a drop of glue hits a part of the model, the glue is not erased, but left to harden, in order to then remove it by sanding the area.

- Places connected with superglue are additionally degreased to minimize the risk of disengagement.

- When gluing, take into account the structure of the surfaces to be joined, follow the instructions on the packaging.

- When working with toxic formulations containing volatile compounds, use a protective mask and gloves.

- The work surface is covered with oilcloth or special films to prevent damage to property.

- Applicators do not always help to accurately apply the base, so designers often use cotton swabs or toothpicks to distribute the drop.

- When using heavy-duty compounds, they work as accurately and quickly as possible in order to have time to fix the composition before it has time to grab.

With some adhesives, it is common to use paint brushes, which can be purchased from the clerical department.

Share link:

Examples of effective adhesives

When working with parts, models take into account different characteristics. Moving parts involve gluing with a subsequent change in the angle of rotation. The connection of parts on which additional elements are attached implies the use of heavy-duty compounds.

Kristal KLear

A one-component compound produced by a Swiss company for bonding materials of different structures. The glue is used on construction sites. It is used when connecting a volumetric part with a larger base. No additional solutions are used for hardening, the glue hardens under the influence of moist air. The adhesion of the parts has a high level of strength.

K-19

The composition is characterized as superfluid, with the ability to connect small parts. It penetrates to hard-to-reach elements, glues gaps, joins joints. After drying, it becomes transparent, it is used to adhere transparent parts, since the seam has no pronounced boundaries, it is not visible from the side.

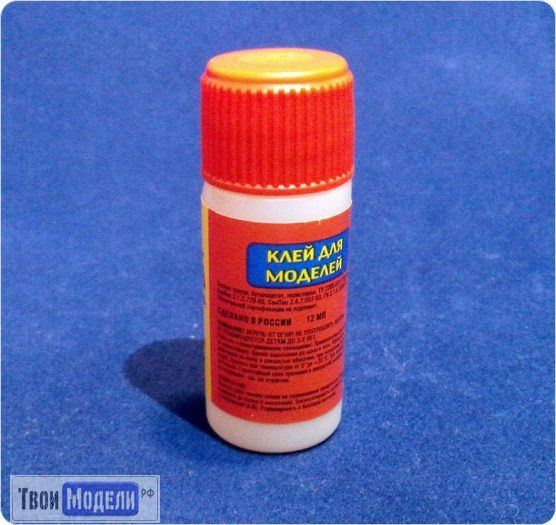

Star

The adhesive base does not have a pronounced odor, it is easily washed off, in contrast to superglue based on butyl acetate. It is purchased for gluing plastic parts of collapsible models. It bonds paper and small wood elements.

Information! The disadvantage of the composition is considered to be inconvenient packaging. The glue is produced in small bottles of 12 milliliters. Users note that containers are poorly stable, prone to overturning and leakage.

What does marking on plastic mean?

Since some adhesives may dissolve rather than bond the plastic, it is advisable to examine the markings on the broken product. The plastic type icon looks like a triangle formed by arrows (recycling symbol). Inside it there are numbers from 1 to 7, and below there is an inscription. These identification marks determine the belonging of the material to one or another type of plastic, which will allow you to choose the right glue.

What types of plastic exist:

- 1 (PET) - stands for polyethylene terephthalate. It is used to produce food packaging for liquid products.

- 2 (HDPE) - high density polyethylene, intended for the production of packaging and shrink films.

- 3 (PVC) - polyvinyl chloride, better known as PVC. Plastic windows, linoleum, etc. are made from it.

- 4 (LDPE) - low density polyethylene, from which toys for children, pipes, bottles, packaging containers are made.

- 5 (PP) - polypropylene, heat-resistant material. It is used for the production of food packaging, medical disposable instruments, household appliances, pipes, thermal dishes.

- 6 (PS) - polystyrene. Disposable tableware is made of it. Expanded polystyrene is widely used in construction.

- 7 (O) - This type of plastic is not recyclable, consists of a mixture of polymers, paper, foil.

Glue second

Glue second

Information

To make the model very similar to the original, you need to find out as much as possible about the original. You can go to the museum, take pictures. You can read books and albums on military equipment - usually sold in the same place as the models themselves. You can also search the Internet, ask around on the forums - they will definitely help you. Take photos of the model during the assembly process, and when you are finished, post photos on the forums - you will receive both useful advice and an assessment of your work. See the work of other modelers, notice how they did what on their models, ask if something is not clear or you see it for the first time.

It is also very useful to watch all the episodes of the Japanese TV series Custom (if anyone is in Riga - bring 4 matrices DVD 4.7Gb - I will record it free of charge) - you can find and download it here:

Superfluid adhesives.

This category of adhesives is characterized by increased fluidity and penetrating power. The principle of operation is the same as the above formulations. This glue is good for working in hard-to-reach places, you can glue cracks, etc. It practically leaves no marks on the surface of the model.This type of model adhesives dries quickly, so you need to work with it quickly. For ease of application, it is best to use a brush. The composition is based on the same butyl acetate, so this substance can be used for work in the absence of a proprietary superfluid glue. And on sale you can find an inexpensive composition of the company "Akan" - superfluid model glue "Akan-profi".

Types of glue for assembling models

- Superfluid glue. Differs in increased penetrating power, liquid composition. The parts are held together by partially dissolving the plastic. The advantage of this glue is the ability to penetrate between folded parts. Another important plus - it almost leaves no traces after hardening, only a slightly rough, cloudy surface remains. This adhesive for model airplanes, cars, ships sets very quickly. For ease of use, the use of a synthetic brush is recommended.

- The glue is transparent. Designed to work with transparent parts. The fastening of the parts is carried out not due to the welding effect, but due to the base, which becomes transparent when dried. The mixture is applied to the surfaces of the parts for 5-10 minutes, and then joined.

VIDEO ON TOPIC

- Cyanoacrylate glue. In our country, it is better known as Superglue or Super Glue

... It was invented in the USA during World War II by a scientist looking for clear plastic for telescopic sights. Then the substance was not used, it happened only in 1951, when the Americans needed a heat-resistant coating for the cabins of military aircraft. Then, seven years later, the composition hit store shelves and literally amazed everyone. Today it is produced under the brands "Claybury", "Secunda", "Monolith", "Super Moment"

and others. It is an instant adhesive, the maximum bond strength is reached after two hours. Suitable for working with porous as well as moisture-containing materials. In modeling, he took a leading place, as it allows you to fasten parts from different materials. In stores, you can buy regular and gel-like super glue. The second option is more convenient to apply, as it does not spread. - Epoxy glue. When mixed with a hardener, epoxy resin bonds well glass fabric, wire, wood, but dissolves polystyrene parts. Epoxy two-component adhesives are presented not only in ordinary tubes, there is also packaging specifically for modeling. For example, the glue “Contact

»Both resin and hardener can be squeezed out at the same time, and they will be mixed in a special compartment in equal proportions.

Views

If the parts are purchased, but the glue is not, you need to think about which mixture is more suitable. It is known that the majority of craftsmen prefer domestic producers. A good option is the Star, used for assembling models.

However, this does not mean that you need to immediately run to buy just such a glue. First you need to determine the material from which the model will be made:

- paper;

- plastic;

- resin;

- metal.

Next, you need to determine the means of connecting products. You can use the following options:

- epoxy resin products;

- cyanoacrylic;

- water based;

- polystyrene.

Let's understand a little in the principle of the operation of polystyrene glue. It is based on melting the surface of polystyrene, which is glued to a similar surface. When the parts come into contact, the coatings melt together, the agent penetrates into the structure from one product to another.

When the mixture evaporates, the molten zones solidify. The product will be ready for use in a few hours. However, the manufacturer is still recommended to squeeze out a day. In addition, the drying time of the glue is determined by the thickness of the glue layer. After the product is ready, high bond strength is ensured.

It should be noted that a good adhesive connection will not work if it is not polystyrene that is connected. In this case, it is better to use dichloroethane. It is a caustic substance that requires careful handling. With it, the glue provides a good bond. For these purposes, Star glue is used.

Another group is cyanoacrylates. A fast and strong connection is ensured. However, shear strength is not very good. If there is high humidity, such glue hardens quickly and is poorly stored. Therefore, we need a low level of humidity and a small temperature corridor - from plus 5 to plus 10 degrees. At home, you can use a household refrigerator for storage.

The higher the content of cyanoacrylate in the mixture, the fewer additives, the higher the bond strength will be. Such a composition is used for the assembly of resin and repair of radio-controlled models. Some craftsmen use an adhesive mixture for plastic models.

The principle of action of epoxy mixtures is based on interaction with a hardener. In this case, the resin hardens, a strong contact of the surfaces is obtained. This type of glue is used for gluing parts of radio-controlled models.

There are epoxy resins that make it possible to create entire models or clone parts. Such a composition cannot be used for gluing plastic parts. The resin will not stick to the plastic.

Fiberglass, resins, wood - this is what epoxy adhesives bond well. Metal parts can also adhere to these materials. The composition can dry from 1 to 24 hours. To shorten the time, you can apply heat.

Note that all the options presented are toxic, so you can work with them only in a well-ventilated room, or better - outdoors. The mixture should not get on the skin, eyes, mouth. Otherwise, you need to promptly flush the organ with water, it is recommended to consult a doctor.

Varieties

Adhesive bases are classified according to several main characteristics. When modeling, a suitable option is selected that meets the requirements.

Normal

An all-purpose standard construction adhesive consists of several parts butyl acetate and polystyrene. The bonding effect is achieved by partially dissolving plastic particles on the bonded surfaces. For a reliable connection of parts, both sides are treated with a compound, pressed against each other and left for some time.

Superfluid

The fluidity of the bases is due to the increased content of butyl acetate. Such foundations are used when working on hard-to-reach places. The peculiarity of the composition is instant setting, so you need to work with glue quickly and accurately. It is customary to use a brush for application.

Transparent

Clarity, as a physical characteristic, is important for adhesives. Some models, when designing objects of small size, involve gluing with bases that are invisible from the side without a clear definition of the boundary of the glue seam.

Cyanoacrylate

The composition is based on cyanoacrylate. With its help, parts are quickly glued together, but with the mobility of some elements, insufficient joint strength is found. Cyanoacrylate-based liquid bases set faster than thick formulations. The difficulty arises when storing glue. Optimal storage conditions involve maintaining the temperature regime at the turn of +5 to +10 degrees with simultaneously low air humidity.

Epoxy

Epoxy is used to bond wood, glass, resins and similar materials. They are not able to connect plastic parts due to the nature of the structure. Most often, glue is produced together with a solvent. It is used to dilute the resin in a 1: 1 ratio. Both formulations are available in convenient syringes with an applicator. Before starting work, they are mixed on a prepared clean surface.It should be borne in mind that resins promote active hardening, therefore, the modeler has about 5 minutes of free time to process and join parts.

Adhesive for paper models

A separate type of modeling is paper and cardboard models. It has its own peculiarities in work, assembly and painting. For example, PVA glue is best suited for assembling such models. Usually it is a thick white liquid, practically odorless. To achieve the required consistency, PVA can be diluted with water. But if it has completely hardened, then, unfortunately, it is no longer possible to dilute it. Also, PVA glue can be used to glue wood or veneer, for example, when building bench wooden ship models. Before using PVA, it is necessary to thoroughly shake or stir, as over time, the composition delaminates.

Product examples

What can be found on the shelves of hardware and hardware stores:

- Momentplastic is a type of glue that connects many types of plastics. It has a transparent base, sets quickly and forms a strong bond. It is a water and heat resistant compound. However, it contains toxic substances and is not used to repair products that come into contact with food or skin.

- "Super Moment" is a second glue.

- 3M Scotch-Weld PR100 is an epoxy adhesive that cures in 20 seconds. Simple and easy-to-use composition.

- Cosmofen is a brand that offers several types of glue for plastic. Among them are adhesive sealant for transparent plastic, Plus composition for PVC, PMMA - adhesive for polystyrene and acrylic surfaces.

- Sekunda is a superglue for hard plastics. One of the fastest-acting formulations.

- For minor car repairs, special car sealants for plastic are sold.

- Rexant is a hot melt adhesive available in the form of rods. It can be transparent or colored (to mask joints if colored parts are connected).

- Akfix HT300 is a heat and water resistant compound. Withstands temperatures up to +300 degrees. This adhesive contains silicone. It reacts to humid air.

This is far from the entire assortment offered by the adhesive industry. This is not to say that some kind of glue is better or worse. Each train is designed for specific types of work. Read the instructions carefully and follow all recommendations.

Rexant and Akfix HT300

Rexant and Akfix HT300

Basic requirements for model glue

Model glue is the basis for a high-quality assembly. With the help of adhesives, structural elements made of various materials are held together.

Several types of requirements are imposed on the compositions, which ensure the correct operation of the models and compliance with the established standards:

- Exploitation. The basis involves the creation of a reliable glue seam, ensuring a strong connection of parts, matching the sides in shades.

- Process technology. Compliance with standards on the toxicity of chemical compounds, comfort of use due to the viscosity of the composition.

- Ecology. Reduced corrosiveness of the adhesive base, no chemicals harmful to health.

- Special conditions. The ability to create a transparent seam, resistance to oils and other liquids.

How to make it yourself

Adhesives are quite expensive. For home crafts, you can make a composition from improvised means.

First recipe

Starch, sugar, vinegar and water are used as components for the emulsion. Add 3 tablespoons of sugar to a glass of warm water and bring to a boil. Then pour in 1 tablespoon of vinegar and let it boil. Measure out potato starch and dilute with warm water: 1/3 cup - 1 tablespoon of water. Pour the prepared suspension in a thin stream into the boiling syrup, stirring constantly until bubbles appear. The cooled adhesive composition should resemble sour cream in consistency.

Second recipe

The method consists in thickening the cream with cognac. The same amount of cognac is added to 100 milliliters of heavy cream. Stir without beating.The finished composition is applied to the prepared surface and kept for about an hour, after which the potal is used.

How to use model glue correctly

When working, before using the glue, you must familiarize yourself not only with the instructions, but also with the rules for applying:

- A large amount of applied adhesive will stain the surface, hands, tools. Therefore, the application is done in moderation and carefully.

- If drops get on the surface, do not immediately rub with a cloth. This will aggravate the situation, leaving divorces. It is necessary to wait until it is completely dry, try to remove the drop with a sharp object or clean it with fine-grained sandpaper.

- When using super glue, the joint will be brittle, so do not press on these points.

- Before applying the glue, you need to make sure whether it is suitable for the given material.

- If you cannot apply glue from the applicator or you cannot use a brush, then a toothpick is used for spot, small application.

- Some mixtures involve the use of IZ agents. If work is done on the knees, then they are covered with oilcloth.

- Avoid leaking under the masking tape, as plastic will float under it.

- For each gluing method, use the model only after all joints are completely dry.

We advise you to watch the overview video: