Do I need to glue the joints

The consumer wants to see a monolithic floor covering, which is achieved by purchasing wide canvases up to 4 meters or fitting and butt-laying narrower strips up to 1.5 meters.

Careful gluing to the base allows you to hide the lines of alignment of the stripes, making them almost invisible. Practice shows that without processing the joints, dirt gradually accumulates, affecting the state of the seam, its deformation and general appearance. In order to prevent premature clogging and moisture penetration into the crevices, additional processing is necessary, despite the seemingly tight connection.

For joining very dense material or making artistic applications, an apparatus for gluing linoleum is used.

Hot welding technology is available to professionals. To carry out the work, a special gun for gluing linoleum has been developed. Large-scale production facilities require an invitation from a foreman and the availability of equipment.

In domestic conditions, a special glue for gluing linoleum joints is convenient, which will allow you to hide the seam, with a colorless composition to firmly solder the canvases and protect them from wear. High-quality sealing of the joint is completely invisible to the eye, it can only be determined by careful study of the coating.

Adhesive selection criteria

The effectiveness of the fixing of the floor covering will depend on how correctly the adhesive mixture is chosen. You can decide which glue to glue linoleum with, based on the following criteria:

Concrete, wood, plywood and other materials from which the main floor is usually made have different water absorption rates. Accordingly, for each of them, glue with one or another percentage of water and active substance will be optimal. For linoleum on a wooden floor, a soluble mixture is suitable. If the coating is placed on a surface that does not absorb moisture at all (for example, a tile), then you will have to do with joining the joints with hot or cold welding - the main canvas will not stick.

Linoleum type.

There are three types of coverage; for semi-commercial linoleum, one glue is intended, for household - another, for commercial - a third. This is due to the different density and structure of the material, different thickness of the protective PVC layer, the substrate material and other characteristics. The choice is also influenced by whether the coating is homogeneous or heterogeneous, natural or synthetic, etc.

Room area.

In small rooms (up to 10 m2), glue is not needed at all. If fixation of the material is required, then with a small area, the mixture is applied without the use of a solvent to the subfloor in a continuous layer. In large public, commercial, industrial premises, a more effective two-component compound is used, which is applied to the floor locally. For the treatment of seams, the hot welding method or reaction adhesive for linoleum joints is used.

Learn more from the video:

Since it is often not possible to find one specific option, they are also guided by the consumption of glue per 1m2. It depends on many characteristics; the average consumption calculated by the manufacturer is indicated on the package. It is roughly 300–400 g per m2.

Which to choose?

The variety of adhesives is so great that it is not always possible to correctly navigate the choice. To get a high-quality result, you should take into account the following factors:

- Application area. If you are planning to lay linoleum on the floor, then you need to look in the direction of water-dispersible compositions. It should be noted that they are completely harmless and can be used in domestic premises.When you need to glue the seams, then cold welding is the best option here.

- Surface type. Adhesives are intended for certain types of floors. Some can withstand moisture, while others need a minimal amount to deteriorate. You can find out all these characteristics on the packaging of each glue.

- Linoleum type. This characteristic is one of the most important. Almost all types of adhesives work with PVC-based materials, but there are products for natural substances. Cold welding can often be used for homogeneous foamed sheets, as this will produce a reliable and flexible seam. For commercial and semi-commercial linoleum, varieties of bustilate or polymer compounds are suitable.

Terms of use

In order for the flooring to last more than 30 years, it is necessary to strictly follow the installation technology. There are no universal rules, since each type of floor has its own nuances.

On a concrete floor

The entire surface must be stripped down to clean concrete before installation. The final layer is cleaned and sanded, potholes, cracks are putty.

Be sure to seal the joints between the wall and the floor. Small gaps are sealed with concrete mortar, large ones - with sealant or polyurethane foam.

Bonding points are degreased. Glue is applied to the concrete pavement. Linoleum is glued to the oiled area. The surfaces are firmly squeezed together and cured until dry. The complete gluing process takes an average of 24 hours.

On a wooden floor

The composition of the glue must be evenly distributed with a spatula. First, it is applied to a wooden base, and then to linoleum. The surfaces are glued together.

Before gluing the linoleum end-to-end, a tape of glue is applied to the seam. Scotch tape is cut at the seam and the glue is squeezed out into the gap. After 10–20 minutes, the fastening material is removed.

You can also resort to cold welding (a sealant that is designed to secure the edge). It can be colorless or colored.

How to use it correctly?

It is quite simple to glue the joints between linoleum sheets using cold welding. To do this, you first need to stock up on some tool:

- Long ruler. It is advisable to use metal models in this case, since they are smoother and do not lend themselves to deformation.

- Masking tape. If it is not there, then you can use a two-way analogue.

- Cutting knife. It must be sharp, since the quality of the seam and joining of sheets depends on this.

- Substrate. Often, thick cardboard is used for this, which is placed under the seam so as not to cut along the floor. A sheet of old plywood, old linoleum or chipboard is also suitable.

- Remedies. This includes gloves and a mask to prevent inhalation of corrosive vapors.

To weld linoleum with high quality, you should get an even joint of the elements. This will allow the adhesive to evenly fill the gap and form a strong bond. This process is quite simple and consists of several operations:

Initially, two sheets must be superimposed on each other with an overlap of about 5 cm. This factor should be taken into account when buying material. Under them, you should first put a sheet of chipboard or old linoleum along the entire length of the joint.

After that, a mark is applied to the top sheet, which will indicate the place of the joint.

Note that it is located approximately in the center of the overlap.

At this stage, you need to cut off the extra pieces.

To do this, use a ruler, which is placed along the future seam.

It is important that two sheets of linoleum lie under it. After that, using a sharp knife, cut along the ruler

You need to cut two sheets at the same time, which will allow you to form an even and minimal joint.

Bonding linoleum consists of several sequential steps:

First of all, you need to read the instructions for use.Depending on the type of glue, there may be some nuances that should be taken into account. Manufacturers also indicate under what temperature conditions it is possible to glue the material with high quality.

After that, the sheets are joined together by those sides that were previously fitted

It is important to make sure that the material does not move when performing such operations, and also there are no air bubbles under it. They can subsequently "migrate" under the seam, which will subsequently collapse.

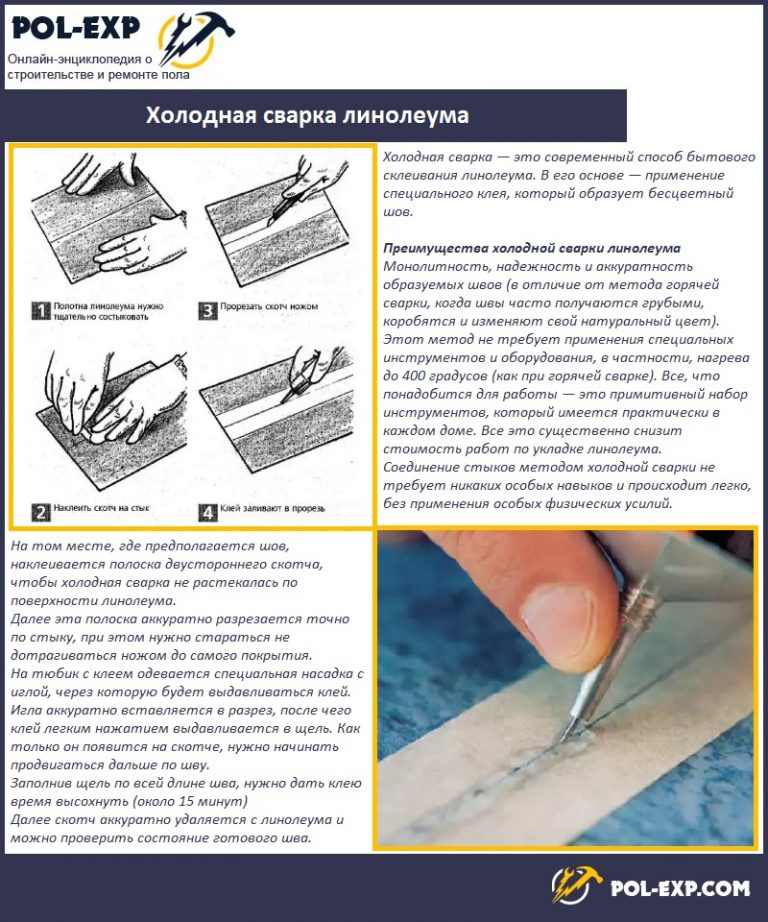

To avoid getting glue on the linoleum surface, masking tape should be glued along the entire length of the joint.

After that, a channel is cut with a knife, which corresponds to the direction of the gap between the sheets of linoleum. This must be done carefully so as not to damage the material from the side.

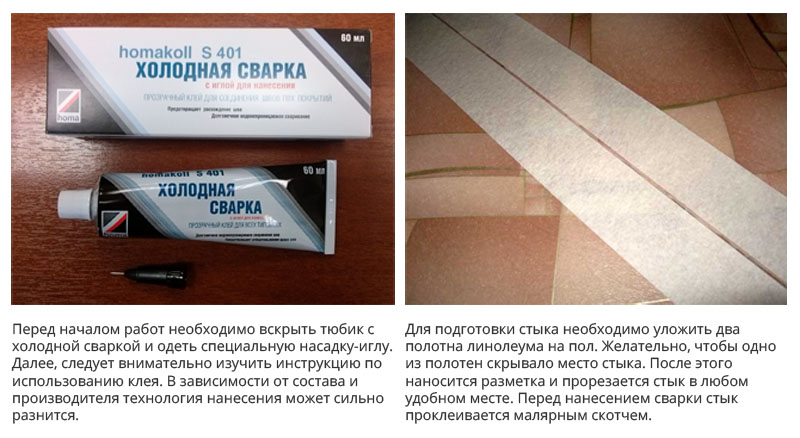

For welding, a special nozzle in the form of a small needle is put on a tube with glue. After that, they begin to feed the solution into the gap between the sheets. Initially, you need to fill the joint until a mixture with a diameter of about 3-4 mm appears on the surface of the tape. After that, you can consistently move along the entire length of the seam, feeding the glue inward in a similar way.

When the joints are full, leave them for about 15 minutes. After this time, you can remove the tape. Full bonding will occur in about 3 hours.

If the mixture gets on a clean linoleum surface, do not try to wipe it off right away. Let it harden and then just cut it off with a clerical knife. Cold welding technology is a simple operation that only requires care and safety.

More on how use cold welding for linoleum, you will learn from the following video.

Consumption

Glue is a solution in small tubes. There are some factors that affect its consumption:

- How qualified the performer is. The master is able to make the joint of high quality, using a minimum of glue. And if a person is new to such matters, he needs to get used to it in order to determine how to save the solution.

- Coating thickness. The higher the indicator, the more fluid will be required. Almost all PVC linoleum is thin. The latter is used for the top layer, and the solvent is not able to influence the substrate.

- Which glue is chosen. Type A is the most common, flow rate is about 50 ml per 25 meters. But type C for 25 meters requires about 80 ml.

Views

Manufacturers of glue for linoleum produce several of their modifications, which differ in composition and environment of use.

Depending on these characteristics, these compounds can be divided into 2 large groups:

- Water-dispersive. The composition of such a substance can include both PVA glue and water-based acrylic. It all depends on the manufacturer and the purpose of a particular brand of glue. Similar compositions are used to fix the canvas to the floor covering.

- Reactionary. The peculiarity of this substance is that it enters into a chemical reaction with linoleum. During this interaction, the material melts to form a liquid. After hardening, this mixture turns into linoleum again. Use reactive adhesives for joint bonding or repair. Most formulations are designed to work with PVC coatings.

Dispersion glue, in turn, is divided into the following groups:

- Bustilat. This is the most common adhesive and has been in use for a very long time. This substance consists of CMC, latex, chalk and auxiliary components. The solution is perfect for linoleums that have a felt base.

- Polymer compositions. Such substances are based on resins that allow you to bind vinyl linoleum of almost any kind. A prime example of this solution is Homakoll 208.

- Acrylate. A similar solution consists of an acrylic mixture, which is intended for heterogeneous and homogeneous linoleums. This adhesive can even be used on surfaces that do not absorb liquids well.

- Humilax. The glue of this brand is made from a mixture of rubber and natural latex. It is used to fix natural linoleum materials.

- Conductive. This is a special glue that is used when installing antistatic linoleum. Such coatings are not capable of accumulating electric current, which makes them very popular when a warm floor or other similar systems are formed.

Reaction glue is also very common for linoleum applications.

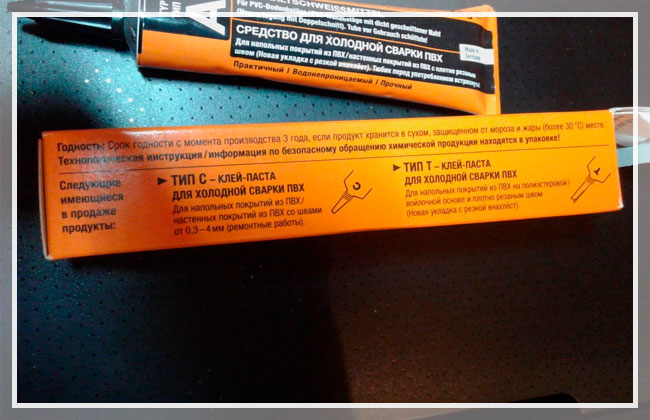

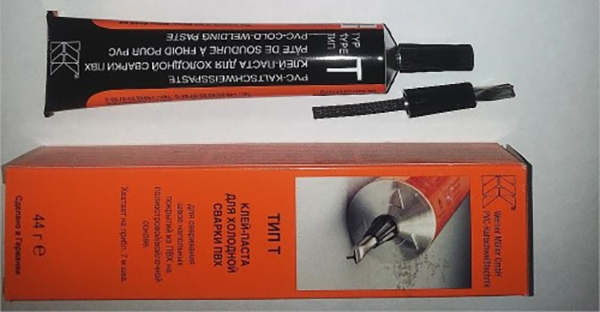

Today there are several types of cold welding adhesives:

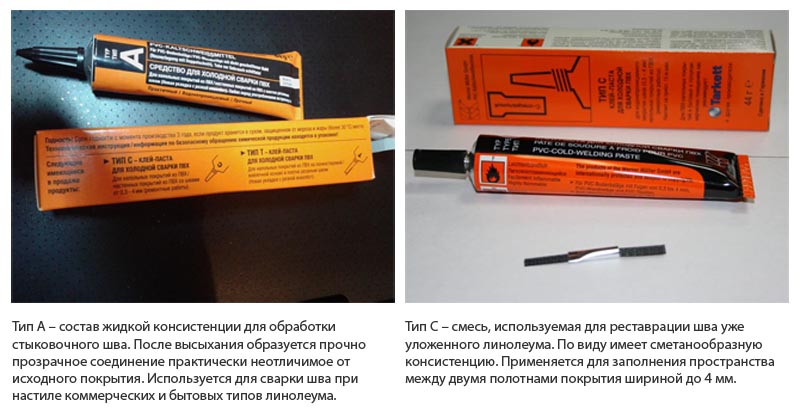

- Type A. This adhesive is used for joining minimum seams of no more than 2 mm in size. This is due to the fact that the substance has a liquid consistency and is not able to grasp materials at a great distance. Cold welding of this type makes it possible to obtain not only a water-resistant and frost-resistant, but also practically invisible seam. Experts recommend using glue for new linoleum sheets, since they have flat ends and can be joined with a minimum gap.

- Type C. The composition of the solution already contains much more PVC filler and a minimum amount of solvent. Therefore, the mixture is already much thicker, which makes it possible with its help to close gaps up to 4 mm in size. This type of adhesive is great for repairing linoleum (cuts, etc.).

- Type T. A mixture of this type is used to combine linoleum based on several components. The composition can react with polyester and PVC products. This adhesive is suitable even for semi-commercial type coatings.

Instructions for use

How to glue a linoleum joint with cold welding? To carry out all the work correctly, you must strictly follow the instructions. It is described step by step below.

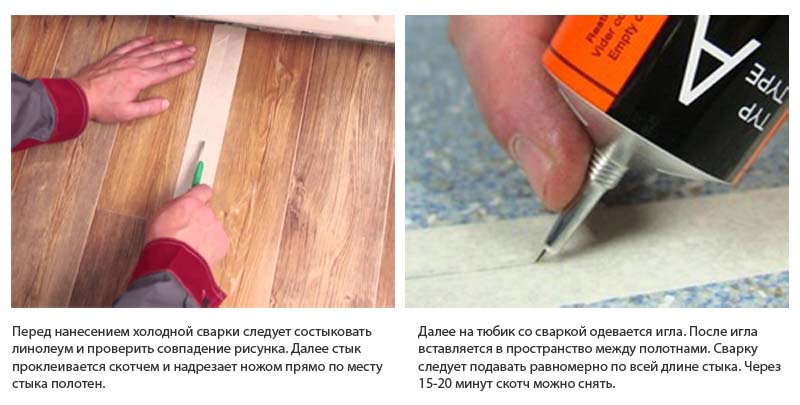

Seam formation

After purchasing the coating, its approximate fit, you need to form an optimal seam. To do this, lay both pieces as they will lie on the floor. In this case, the overlap should be 5 cm. Next, you will need a strong metal ruler and a pencil. Fasten both edges of the coating together with double-sided tape so that they do not move during cutting. Then markings are applied strictly in the middle, tightly pressing the coating with a ruler. Then they cut along the markings with a sharp knife to get even edges.

Cleaning the base and seam

Before gluing, you need to thoroughly clean the floor from dirt, remove the remnant of the old coating, and vacuum. Before work, all parts must be dried. Also, as a preparation, the edges of the linoleum should be protected from damage. Cold welding contains aggressive components that can corrode the material. Glossy linoleum is particularly affected. To avoid such troubles, you need to buy a wide masking tape and paste over the edges of both canvases with it, leaving a few millimeters for the glue.

Cold welding

Before work, you need to prepare a clean cloth or cotton swabs to remove excess and glue drips. There are two ways to apply the product:

- First. Using a tube nozzle, squeeze the adhesive onto both edges at once. At the junction, the linoleum will become liquid, the edges will melt.

- Second. Lubricate only one edge, apply it to the floor. Then glue the second edge and place it tightly next to the first. Smooth, smooth the seam.

After a few hours, you can walk on the floor without fear, the exact drying time is indicated in the instructions for the glue. When the linoleum is dry, you need to remove the masking tape.

Removing excess glue

Often, excess composition flows out. Do not touch them while the edges are being welded, as this can cause the floor covering to peel off and break the seam. Dried cold welding is removed in 2 steps. Since the fresh seam is elastic, a crater may remain under strong tension and shearing. It is better to first cut off the excess protruding on the surface, and after a day, bring the matter to an end. You can do all the work yourself, without the help of masters. Installation of a welded seam is a painstaking business, but quite real!

Recommendations for the selection and application of glue

So, the main criterion for choosing an adhesive is the type of subfloor. Different formulations are used for absorbent and non-absorbent substrates, and if you use inappropriate glue, strong attachment will not work. Absorbent surfaces include cement and concrete screed, solid wood, plywood flooring, chipboard, fiberboard, OSB.

Wood is a highly absorbent surface

Linoleum is glued to them with water-soluble compounds, but there are also some nuances here. Board materials, such as plywood, fiberboard and others, can deform from excess moisture, so thick adhesive mixtures with a minimum water content should be chosen for them. For a concrete floor, the consistency of the glue does not really matter.

If the floor is concrete, the consistency of the glue can be any

Non-absorbent floors are considered to be tiled with natural stone, porcelain stoneware, tiles. Here, already water-soluble compounds will be ineffective, since there is nowhere for moisture to go out, and high-quality adhesion between surfaces will not work.

For such substrates, reactive adhesives are used, during the application of which precautions must be taken - use protective gloves and masks, ventilate the room

If the floor is tiled, it is better to use a reaction adhesive.

You need to buy glue with or after linoleum to make sure that the composition is suitable for this particular coating. On the packaging of the glue, it is always indicated for which types of linoleum it is suitable, what the base of the coating should be. Be sure to check the expiration date, because expired glue will not hold the canvas. It is best to buy adhesives in building supermarkets or large stores where there are conditions for the proper storage of such materials. This is especially true for water-soluble adhesives, which completely lose their adhesive properties after freezing. The exception is special dispersion agents with frost-resistant additives: they can withstand from 3 to 5 freezing and thawing cycles without losing their main characteristics.

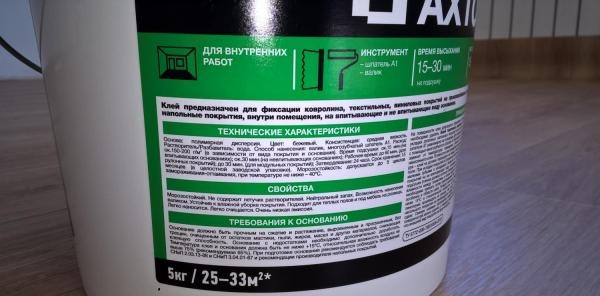

Universal adhesive fixer for linoleum and carpet Axton

Information about the glue is always on the packaging.

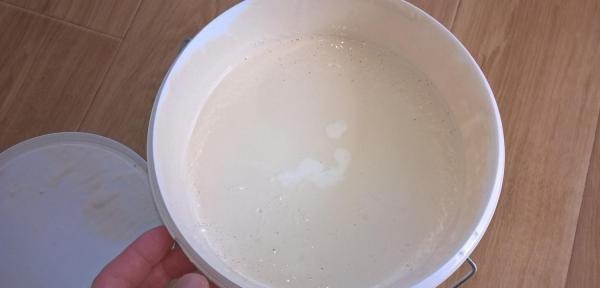

It looks like glue for linoleum

In order not to overpay, before buying, you should calculate the required amount of glue. To do this, you first need to measure the room and calculate the total coverage area. As a rule, consumption varies between 200-500 g per m2 (this is influenced by the type of work surface and the base of the coating). For example, a fabric or felt base requires more glue than foam and rubber, and a plank floor requires more than a concrete screed.

To reduce the consumption of glue, it is recommended to prime the floor. Glue should be bought with a small margin so that you do not have to interrupt the installation and go back to the store.

Linoleum and glue must be in the room where the coating will be laid for at least a day. Work should be carried out at a temperature not lower than 15 ° C and an air humidity not higher than 75%. In this case, the moisture content of the floor base should not exceed 8% for wood and 2% for screed.

Let the linoleum sit at room temperature for 24 hours

Immediately after applying the glue, it is impossible to lay linoleum, you need to let the composition dry a little for 5-10 minutes (the exact drying time is indicated on the package). Also, you cannot apply glue in a thick layer: the canvas will not hold on better from this, and excess glue will appear as thickenings and bumps on the surface of the linoleum.

Cold welding

Cold welding is another option than gluing linoleum at the joints. The method is quite simple and reliable.

The following tools are required:

- masking tape;

- knife;

- ruler;

- cold welding.

Linoleum is glued using the following technology:

- The edges of the sheets should fit perfectly to each other, if desired, you can make the drawing match.

- The edges are aligned.

- Then the edges are pasted over with masking tape.

- A slot is made.

- It is then filled with cold welding.

- When the welding is completely dry, you can remove the masking tape.

The advantages of this method include:

- easy to use at home;

- you can do everything yourself without involving a specialist;

- can be used to repair linoleum flooring.

Which welding to choose cold or hot depends on several factors:

- material type;

- following installation measures;

- required seam shape.

If you need to get a strong and durable connection, then it is better, of course, to choose welding, and no matter which one (in more detail: "Welding of linoleum seams - the pros and cons of the methods"). It will be much safer than gluing linoleum with tape

The most reliable way to join linoleum sheets is to use cold or hot welding. Only from the point of view of economy, or if this is the only possible option (joining a coating based on felt), the use of scotch tape or a sill for joining linoleum can be justified.

The article examined how to properly glue linoleum in various ways.

Linoleum is one of the cheapest (the price per square meter of material is much lower than the price of laminate, parquet or cork) and unpretentious flooring options. It is perfect for rooms with regular high stress and humidity, such as a kitchen, corridor or hallway.

Varieties of adhesives for linoleum

Today there are several types of adhesives, which differ depending on the additives. The latter determine the performance characteristics.

Dispersion adhesives

The presented products are distinguished by a high adhesion rate, which exists in an aqueous suspension of acrylic, in latex, in PVC and carboxymethyl cellulose. This group of consumables is considered the least toxic, has no unpleasant odors and can be used without restrictions at home or in crowded places. The products go well with various types of linoleum, including felt, polyurethane, and so on.

Dispersion adhesives are often used to fix linoleum to wood floors.

The most famous types include the following.

- Acrylate. Possesses excellent indicators of resistance to water. It is used in buildings and premises where there is an average traffic.

- Bustilat. For its manufacture, a mixture of latex and carboxymethyl cellulose is used. Construction industry experts recommend using products for linoleum with a felt base.

- Humilax. The presented glue is created through the use of a special type of rubber. It has excellent compatibility with the rubberized base.

All products in question must be applied to a wooden surface using a spatula.

Clay Bustilat

Reactionary

This type of material is considered more expensive, but it is of high quality and practical use. The group refers to complex chemical compounds that are created by combining polyurethane and epoxy. Such a composition creates a reliable connection that is useful in commercial practice. Among the disadvantages can be distinguished an unpleasant pungent odor, as well as the presence of the risk of an explosion during work.

These types of products are often used for "cold welding". The connection is made by molecular diffusion. The type of joint when using reaction adhesives can be as follows.

A-type. Used for linoleum, which is completely aligned according to the pattern, and all edges fit snugly

It is important to note that the presented seam is invisible.

C-type. It is used in case of large gaps between individual pieces

Can be used at a distance of 0.5 to 3 millimeters. The reaction adhesive should have a higher thickening. Such variations of glue are often used for repair work.

T-type. The presented cold welding is professional. They are used only with a special technology. The seam requires sanding.

cold welding for linoleum

Repair of a broken joint

To begin with, a few words about why the seams of linoleum diverge. Most often, the reason is in violation of the laying technology. What are these mistakes? What rules are being violated? Yes, elementary. First. Linoleum should not rest against walls. It is cut along the perimeter so that a gap of about 1 cm remains to the walls. Second. The skirting boards must be nailed to the walls, and only pressed against the floor and floor covering. Then the seasonal fluctuations in size will pass imperceptibly to the eyes and without prejudice to the seams. And if your seam on the linoleum is open, remove the skirting boards, check the gap and attach them to the walls. Then the restoration of the seam is no longer required.

Gluing joints of old linoleum - for repair you need cold welding glue type C

Gluing joints of old linoleum - for repair you need cold welding glue type C

Further, in fact, how to glue linoleum together if it is sold out. First, we thoroughly clean everything with a vacuum cleaner. And what fell under the linoleum on the sides of the seam too. Next, degrease with any available means. Both the linoleum and the floor under the edge of the pavement.

On the linoleum on both sides of the joint we glue masking tape (it normally peels off afterwards, leaving no traces and is quite dense and resistant to chemicals). We cut along the edge with a knife. If the edges are loosened or wrapped, we also cut them off. But don't overdo it. Cold welding of type C looks normal with a seam width of no more than 3-3.5 mm. Further, it is already worth using a docking bar or sill. Or glue a strip of linoleum, expanding the seam.

Removing trash and degreasing - first steps

Removing trash and degreasing - first steps

Next, fill in the free space with glue. We level its surface, leave it to dry. Excess flows onto the coating, but it is covered with tape, so it's not scary. If there is too much glue, remove it from the tape with a piece of cloth, but do not blot the seam with a cloth. The surface will be uneven and dirt will accumulate in the unevenness.

After complete drying (the time is indicated on the package), the tape can be removed. Some manufacturers recommend a few hours of "rest" even after drying. If you need to move around the room, you can stick the same masking tape on the dried glue of the seam. It will protect the surface from litter and dust.