Varieties

There are 4 types of decorative brick varnishes for outdoor use: polymer, acrylic, solvent, fireplace / stove and sealing impregnations.

Features of the varieties:

Polymeric. The composition includes alkyd resins, acrylic copolymers, as well as organic solvents and various additives. After processing with such compounds, the brick acquires a beautiful appearance "a la wet stone", while its wear resistance increases. It is possible to work with polymer varnishes even at negative temperatures (down to -10 ° С).

Acrylic. They are used to protect brickwork during both external and internal work. One-component, based on organic solvents, the compositions are well absorbed into the brick, protecting it from microcracks, mechanical damage, and prevent the formation of efflorescence.

Solvent. These are varnishes based on solvents of the same name with the addition of silicone resins. They penetrate deeply into the brick, creating a durable coating that does not crack, peel or fade

Solvent varnishes are fire hazardous, so you need to work with them with extreme caution.

Fireplace / stove. KO-85 or KO-815 - special refractory varnishes

They are used both for external work and for internal (strengthening of internal surfaces of furnaces and protection against condensation). The application of such varnishes gives the brick walls heat resistance, water-repellent properties, prevents washing out of the oven seams, and strengthens the masonry of the stove or fireplace.

Sealing impregnations. Made on the basis of silicone and acrylic resins, they give the brick maximum resistance to wear. Impregnation is fluid due to a complex mixture of aromatic and aliphatic solvents, which ensures its high penetrating power. Such a coating does not turn yellow for many years. The resulting protective layer is resistant to water, chemicals, UV rays, oils, reagents. After application and drying, it gives the brick an unobtrusive shine with a "wet stone" effect.

Acrylic sealants

This type of sealant is used to seal joints and cracks between concrete or stone surfaces. Acrylic sealants retain their elasticity for a fairly long time, the surface of the sealant is well covered with various dyes, and acrylic sealants are immune to strong vibrations.

Acrylic-based sealants do not contain solvents, are most effective for use both inside and outside buildings, mainly used for sealing cracks with slight deformation.

Acrylic sealants have excellent adhesion to concrete, brick, wood, plaster, etc., and therefore perfectly lend themselves to painting and plastering.

The described sealing materials, when dry within 15 minutes, form a film. Acrylic sealants after application are immune to temperatures in the range from -25 ° C to + 80 ° C, have good resistance to light and ultraviolet rays.

Since there are no highly toxic substances in the composition of acrylic sealants, they do not pose any harm to human health; when working with them, you do not need to use special gloves and a respirator.

Sealants are sold in standard packaging (tubes) of 300-500 ml. The sealant must be protected from frost during storage. The shelf life of the sealant at an average temperature of + 20 ° C is at least 1 year.

Is it possible to plaster walls with tile glue

During repairs, a situation often arises when after laying the tiles, several excess bags of tile glue remain. Owners start to wonder how to use it so they don't store unnecessary material.Many people have the idea to use the composition as a plaster. This idea seems to be a good option for using glue, but inexperienced craftsmen have doubts.

During repairs, a situation often arises when after laying the tiles, several excess bags of tile glue remain. Owners start to wonder how to use it so they don't store unnecessary material.Many people have the idea to use the composition as a plaster. This idea seems to be a good option for using glue, but inexperienced craftsmen have doubts.

There is no consensus regarding the suitability of tile adhesive as a material for plastering. There are supporters of this method, there are also opponents. At the same time, there are no serious objections to such use of the compositions. The main reason is the higher cost of the adhesive compared to conventional plaster mixes. Opponents of the method simply argue - if there are cheaper specialized materials, experiments with other compounds seem unnecessary. The idea is quite logical, but it has nothing to do with the main question - is it possible to use tile adhesive as plaster.

Experts answer in the affirmative. Adhesion, strength, ability to create even and smooth surfaces make it possible to obtain a high-quality and attractive finish using the material.

What is an adhesive

Today there are many building materials that are used to fix different types of materials. Usually, such mixtures are understood as cement or a special adhesive composition for tiles. But in reality, there are many more compounds and their varieties.

> Gypsum glue is worth mentioning separately. It is often used in such cases:

- When fastening tongue-and-groove plates and gypsum-fiber sheets. Such materials are impressive in size. They are used to quickly erect partitions. Therefore, it is worth using a composition that sets in a short time. In such a situation, instead of polyurethane foam, it is advisable to use gypsum glue.

- For finishing coatings with artificial stone. Also, the substance is suitable for fixing gypsum tiles. Such a composition is often used for indoor work.

- When you need to fix plasterboard sheets on the ceiling or walls. They are used as a rough finish.

This type of glue has many advantages, which makes it one of the most demanded materials. These include the following:

- simplicity of making a solution - instructions are given on each package;

- lack of lumps in the mixture;

- quick drying of the mixture - this helps to complete all tasks in a short time;

- high strength of the glue after drying;

- the ability to work without the use of a frame;

- economical consumption;

- the possibility of applying the substance in a thin layer, which helps to save the area of the room;

- durability of the coating.

At first, it seems that the gypsum adhesive does not have any drawbacks. However, in comparison with other substances, it is worth highlighting the following disadvantages:

- fragility of the composition after curing - therefore, the substance is not suitable for installation of floor coverings;

- lack of moisture resistance - upon contact with liquid, the glue loses its characteristics, therefore it is forbidden to use it for cladding rooms outside or in conditions of high humidity.

Let's analyze the most likely glue consumption (in relation to vinyl wallpaper):

1. When the surface needs preliminary priming, the mixture (dry) is diluted with heated water in a ratio of 1:40. This proportion is obtained by dissolving a standard pack (300.0 g) of the substance in a container with 12.0 liters of water. The amount of glue obtained is enough for a full-fledged primer of approximately 100.0 sq. m. of concrete and brick walls.

2. For the implementation of gluing textured, textile or vinyl wallpaper, a rather thick adhesive mass is required. The dry powder of the fixative (300.0 g) must be thoroughly diluted with heated water (6.0 l) - a ratio of 1:20. The prepared amount of the mixture will be enough for a thorough processing of approximately 36.5-40.3 sq. m.

3. Thin, light wallpaper can be glued with less dense glue. You can dilute a 300.0-gram package with 9.0 liters of water in a ratio of 1:30.The resulting volume, with proper application, will cover 45.5-50.3 square meters. m. working surface.

How much solution is needed for 1 m2 of masonry

The consumption of the masonry mixture depends, first of all, on its thickness. It is generally accepted that for the construction of a wall one standard brick thick, up to 80 liters of mortar will be required, thus, when laying one and a half bricks, the consumption will increase to 115 - 120 liters. Consumption of mortar for different thickness of masonry is given in the table.

|

Wall thickness, bricks |

Masonry mortar consumption, m3 |

|

0.5 (120mm) |

0,19 |

|

1 (250 mm) |

0,221 |

|

1.5 (380mm) |

0,234 |

|

2 (510 mm) |

0,24 |

|

2.5 (640mm) |

0,245 |

In addition to the thickness of the masonry, the plasticity and mobility of the solution have a significant effect on the consumption: the higher these indicators, the less the consumption of the masonry mixture.

Only the use of high-quality mortar will ensure the strength, the required bearing capacity and the long service life of the brickwork. During the preparation of the mixture, it is necessary to strictly observe the proportions and sequence of mixing the ingredients. Even minor violations of the recipe and cooking technology can lead to a violation of the solidity of the masonry and the destruction of the building.

How to properly knead a mortar for brickwork

In addition to strict adherence to the recipe, to obtain a high-quality masonry mortar, kneading should be done in the following sequence:

- Prepare all required components. Sift sand and cement, if necessary, dilute lime or clay to the required consistency. For the preparation of the masonry mixture, only clean cold water can be used.

- Mix cement and sand thoroughly without adding water. The quality of the finished masonry mortar depends on the homogeneity of the cement-sand mixture.

- Add water or milk of lime gradually, mixing the composition thoroughly. If we take the amount of cement as 1, 0.8 - 0.9 parts of clean cold water will be required to obtain the required consistency of the mixture. The amount of milk of lime is determined in accordance with the recipe.

Important! Cement-based masonry mortar loses its properties within 1.5 - 2 hours. During this time, it is necessary to fully develop the mixture

Properties of heat-resistant adhesive

The process of final drying and hardening of the glue is extremely fast, but for the effect of the greatest strength, it is recommended to keep it glued for a day.

Properties of heat-resistant glue:

- It is used for the upcoming processing, it can be dyed.

- The maximum resistance temperature is not less than degrees.

- The strength index of gluing surfaces is 1.2 MPa.

- It is produced in a snow-white color; it does not change color during implementation.

Table.

Norms of physical and mechanical characteristics of heat-resistant glue, which it must comply with

| Indicator name | Norm | Test Method | |

|---|---|---|---|

| 1 | Appearance | Silver-colored viscous mass | By |

| 2 | Viability, h, not less | 1 | By |

| 3 | Elongation at rupture at temperature (20 ± 2) ° С,%, not less | 12 | According to GOST and |

| 4 | Destructive shear stress at a temperature of (20 ± 2) ° С, MPa, not less | 10,0 | According to GOST and |

The adhesive has good adhesion due to its constituent component - polymer.

When using heat-resistant glue for plastic, it is also necessary to take into account that the glued itself must likewise be heat-resistant, since the glue performs only an adhesive function, not a protective one. Therefore, it will not be able to protect ordinary plastic from deformation at high temperatures.

With the help of heat-resistant glue, you can connect virtually all types in, regardless of their structure. For example, such glue is suitable both for gluing iron parts in the decor, and for gluing brick, wood, concrete, painted surfaces. Regardless of the type of surface, its level of adhesion will be similar.

The only condition in work with heat-resistant glue is the preparatory preparation of the surface to be glued, and specifically its painstaking cleaning from third-party parts. After the introduction of the adhesive, priming can be performed, but this is often not necessary.

Silicone sealants

Silicone sealants are used as insulators when installing window frames, doorways, and metal structures. Ensure tightness against the penetration of water, odors, etc. They are used both inside and outside the premises.

Silicone rubber, which is part of silicone sealants in the form of a base, has good adhesion to glass, wood, non-oxidizable metals, enamel, ceramics, as well as high temperature resistance and resistance to weather conditions.

Silicone sealants fall into two categories: neutral and acetic-hardened.

Neutral sealants are recommended when working with glass and metal, since they do not give any oxides when interacting with a metal surface. Acetic sealant has a high degree of purification, therefore it is recommended to use it in rooms with increased sanitary requirements (kitchens, bathrooms, etc.).

Due to the fact that it is not recommended to paint silicone sealants, they are available in different colors, from colorless and white to black.

Silicone sealants are environmentally friendly and safe in relation to human health, they can be worked with without special protective equipment.

Silicone sealants are sold in special packs starting at 310 ml.

Main varieties and their properties

The assortment of the company includes many types of adhesives. They differ in composition.

Tarbicol

This category includes a wide range of wood adhesives. They can have a different basis. The compositions are made on the basis of alcohol, polymers, polyurethane, vinyl. Means are used for fastening floor coverings. These include parquet, laminate, PVC, carpet.

The tool is used for the manufacture of furniture, fixing veneer. It can also be used to attach laminated paper. The composition is suitable for work inside and outside. In the second case, they are performed under a canopy. The company also offers black glue, which is designed to form decorative seams.

Sealants

These sealants are suitable for both outside and inside seams. Such substances are very effective in overground construction. Such funds are used for doors, roofs, windows. They are used for structures made of wood and metal.

Adhesives from this category are used for fastening products from different materials. They can be applied to various types of surfaces. The sealant can be applied to metal, concrete, gypsum. It is also applied to plaster, brick surface, wood.

Vinicol

This adhesive is intended for artificial surfaces. It is suitable for construction work. Also, the composition is used to repair boats, swimming pools, tents and other products. The substance provides reliable fixation of all types of synthetics, including hypalon and neoprene. The composition is available in the form of a semi-viscous liquid.

Wallpaper

Bostic adhesives can be used for fixing different types of wallpaper. There are special substances for fiberglass and fiberglass. All types of adhesives have excellent adhesion to different substrates. With their help, it is possible to glue wallpaper to concrete, drywall sheets, painted surfaces.

The main types of the company's wallpaper adhesives include the following:

- Wall Standard - the product can be used for wallpapering in dry rooms.

- Wall Super - the substance can be used in high humidity conditions.

Wallpaper adhesives include starch and PVA dispersions. Such substances are considered completely safe, since they do not lead to the release of harmful substances. For use, the composition should be mixed with water.

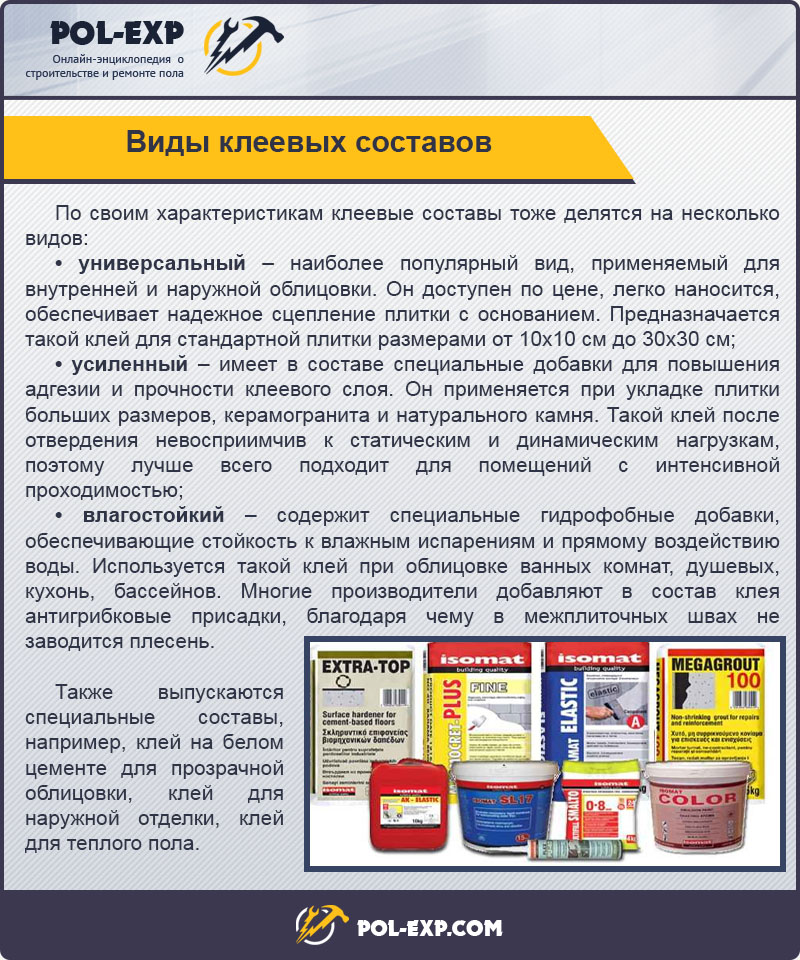

How to choose the right adhesive?

Even glue, called universal, is not suitable for all types of finishing work. When choosing an adhesive, one should be guided by the following conditions and nuances:

- the size of the tiles, their texture and the base material of manufacture;

- the type of surface to be veneered;

- operating conditions of the finish.

To hold heavy tiles, you will need glue with increased binding properties and adhesion rates of at least 1 MPa.

If the ceramic elements are small, glue with an adhesion of 0.2-0.3 MPa will do. The floor tiles will reliably hold glue with a high concentration of plasticizers and elastanes in the composition.

The glue should be chosen especially carefully if it is planned to cover the outside of the building. The product must not only withstand increased stress, but also be resistant to frost, heat and temperature extremes.

Furnaces and fireplaces are lined with heat-resistant glue. For arranging a warm floor, an elastic adhesive composition that can withstand linear expansion of the screed is ideal.

In dry interiors, ordinary cement glue will work just fine. It is also suitable for the bathroom, but in this case, fungicidal additives must be included in the composition to prevent the appearance of mold.

Advice! Plasterboard cladding is recommended to be carried out with elastic adhesives after thorough priming of the surface.

Pasting the walls with the selected wallpaper

After preparing the wall surfaces and diluting the adhesive, you can start gluing wallpaper. The whole process of such finishing is simple and basically consists of:

- precise cutting of the material;

- neat application of glue;

- transfer and sticking of sheets covered with a fixative on the walls.

1. If paper (thin) wallpaper is used, then only the wall surface should be covered with an adhesive solution. This type of wallpaper cannot be wetted when gluing, otherwise the sheets will break and burst during manipulation. In other cases, the varieties of wallpaper must also be covered with a layer of glue.

2. It is more efficient and convenient to spread the glue with a paint roller or a flat wide brush

During application, it is important to work through each section of the wallpaper strip so that there are no dry areas

Explanation! Most modern adhesives take on a pink or blue tint after dissolving. This helps to visually control the quality factor of processing the back side of sheet strips. The color disappears completely after drying!

4. The time for full drying of the pasted wallpaper directly depends on the type of material:

- paper - 10-12 hours;

- vinyl and non-woven - 22-25 hours;

- glass wallpaper and paintable coatings - at least 32 hours.

5. The drying process cannot be accelerated in any way (fans, opening windows, etc.), otherwise the decorative material will move away from the surface, deform in places or “bubble”.

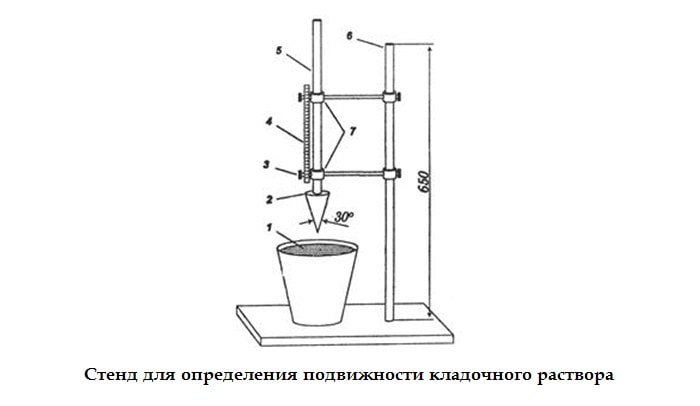

Determination of the mobility of the solution

Under the mobility of the masonry mixture is meant its ability to spread under the influence of its own weight. To determine the mobility of the finished solution, the Abrams cone is used. This device is a cone weighing 0.3 kg, the height of which is 150 mm, and the apex angle is 30.

Determination of the mobility of the solution is carried out as follows:

- The working container 1 is filled with the ready-made mixture so that the distance from the edge of the container to the surface of the solution is 10-15 mm.

- The laid mixture is bayonetted 25 - 30 times and shaken by light tapping.

- The cone is installed in such a way that its top touches the surface of the mixture, and is fixed with a clamping screw 3, after which the location of the pointer on the scale 4 is marked.

- The locking screw 3 is released, as a result of which the cone begins to plunge freely into the solution.As soon as the sinking of the cone stops, the locking screw is tightened again and the reading on the scale 4 is again noted in the laboratory journal.

- The immersion depth of the cone is determined as the difference between the primary and secondary measurements, and the mobility of the composition is determined as an arithmetic mean value based on the results of two experiments.

The recommended values of the mobility of the solution, depending on the purpose, are given in the table.

|

Scope of the masonry mixture |

Immersion depth of the cone, cm |

Mobility grade, P |

|

A. mortars for masonry |

||

|

- for rubble masonry: |

||

|

vibrated |

1-3 |

NSTo1 |

|

non-vibrated |

4-6 |

NSTo2 |

|

- for hollow brick or ceramic block masonry |

7-8 |

NSTo2 |

|

- for monolithic brick masonry; ceramic blocks; concrete stones or stones from light rocks |

8-12 |

NSTo3 |

|

- for filling voids in the masonry and supplying the solution with a pump |

13-14 |

NSTo4 |

|

- for the device of a pillow when installing walls from large concrete blocks and slabs; jointing horizontal and vertical joints in walls made of panels and large concrete slabs |

5-7 |

NSTo2 |

|

B. Cladding solutions |

||

|

- for installation of slabs of natural stone and ceramic tiles on finished brickwork |

6-8 |

NSTo2 |

|

- for the installation of cladding products, lightweight concrete panels and blocks in the factory |

||

|

B. mortars for plastering |

||

|

- for priming |

7-8 |

NSTo2 |

|

- spray solution |

||

|

with manual application |

8-12 |

NSTo3 |

|

with a mechanized method of application |

9-14 |

NSTo4 |

|

- coating solution: |

||

|

without the use of plaster |

7-8 |

NSTo2 |

|

using plaster |

9-12 |

NSToZ |

Types of masonry mortar

Masonry mortar allows for reliable bonding of bricks into monolithic masonry. The strength and durability of the brickwork depends on the quality of the binder mixture. There are several types of masonry mortar:

- cement;

- cement-clay;

- cement-lime;

- lime.

Each of these mixtures has its own area of application and characteristics.

Cement mortar

Due to the simplicity of preparation and the minimum amount of ingredients, the cement mixture is often used for brickwork, plastering and in the installation of floor screed. Before mixing, it is recommended to sift the sand and cement, this will avoid foreign inclusions. This type of masonry mortar is characterized by high strength, rigidity and low mobility.

Cement-clay

This type of masonry mixture has the ability to retain moisture longer than cement mortar, which allows it to be used at lower temperatures. The clay included in the composition is finely ground and cleaned from unwanted impurities. Before adding this component, mix it thoroughly until a homogeneous dough is obtained.

Cement-lime

The strength and plasticity of the cement-lime mixture allows it to be used when laying any brick. The presence of lime dough greatly simplifies the application of the mortar and contributes to good adhesion to the surface of the blocks. For preparation, the cement-sand mixture is closed with milk of lime, the resulting mixture is thoroughly mixed.

Mortar

The low strength and fragility of lime masonry mixtures limit the scope of their application to plastering and the construction of one-story buildings. Sifted sand and ground quicklime are used as ingredients. The ratio of lime and sand is determined by the fat content of the latter and can be from 1: 2 to 1: 5.

At present, ready-made dry mixes for the preparation of various types of masonry mortars can be purchased on the building materials market. In order to obtain a ready-to-use composition, it is enough to mix the contents of the package with the indicated amount of water and mix thoroughly.

How to Choose Heat Resistant Fireplace and Stove Adhesive?

Fireplace

The hearth heats up to low temperatures, especially if they are used infrequently.

But the furnace structure, during constant operation, asks for compositions that can work with constant heating.

Accordingly, the type of heat-resistant glue is selected depending on the operating criterion.

- For cladding a fireplace, heat-resistant adhesive consistencies are completely sufficient. The outer surface of the hearth is not so hot as to require the most heat-resistant options. They use here both cement-based compositions with polymer additives, like Cerezit, and special synthetic mixtures.

- For facing the furnace, the composition of the same category is most often used, but the strongest.

The structure not only heats up more feasibly, but also operates longer: one bookmark of firewood is enough for a day of work. Accordingly, all this time, the cladding is obliged to accumulate heat and give it to the room. The heat-resistant tile adhesive must withstand the constant heating effect, that is, it must be heat-resistant.

- The laying of the stove structure, in particular the firebox, requires the use of much more severe adhesive

Furnace masonry

mixtures. Constant heating up to + C allows the use of only heat-resistant refractory consistencies. But using the same composition for laying tiles is economically unprofitable.

- Another application of heat-resistant glue is electric ovens and gas ovens.

A rather fragile part of them is glass, or, more precisely, the junction of glass and alloy. Despite the not very high heating temperature of the oven - the absolute maximum C, the sealant at the junction evaporates over time. To update it, you need heat-resistant glue - Moment, for example. Can be used for glass and any heat-resistant sealant for the highest reliability.

Extra options

In addition to resistance to heat, adhesives for tiling or brickwork must correspond to some other sign:

- coefficient of thermal expansion - under the influence of temperature, the size increases.

If the coefficients of the adhesive solution and are very different, the connection will be quickly destroyed. Complete coincidence of characteristics is unrealistic, but it is possible to achieve sufficient elasticity of the seam;

- solution viscosity - adhesive characteristics. A very high consistency does not hold the tiles to the surface. At a very low viscosity, the tile slides along a vertical surface;

- gas tightness - combustion products should not enter the room, which means that the acquired seam must have the highest performance;

- the composition for the dishes should differ by special parameters.

It is essential that the glue is not only heat-resistant, but also has food inertness. The consistencies for plastic food containers are selected with particular care.

How is outdoor glue used?

The technology of using frost-resistant tile adhesive for outdoor use is no different from similar operations indoors. First you need to prepare the base, that is, clean it, thoroughly soak it with high penetration soil and let it dry.

The glue mixture is applied to the prepared surface with a spatula or trowel with notches from 4 mm in height, depending on the size and weight of the tile. If a small mosaic is used, then a layer of 4 mm will suffice, but if a heavy marble is used, then the layer should be 10 mm.

Smear both the surface and the tile itself, the main thing is that the glue is evenly distributed over it.

Features of choice

When choosing an adhesive, the following circumstances must be taken into account:

- masonry conditions (indoors or outdoors);

- shelf life (the characteristics of the composition change over time);

- tightness of packaging (cans);

- total area of work and product consumption;

- temperature that will affect the masonry.

Problems with the choice of glue do not arise if the material is purchased for laying decorative stone or brick indoors.Buyers generally experience difficulties when it becomes necessary to build a stove or fireplace. As noted, in this case, heat-resistant glue is required.

When choosing such formulations, you can pay attention to the following products:

- "Terracotta". Differs in increased adhesion, therefore it is popular. "Terracotta" can withstand temperatures up to +250 degrees. But this adhesive does not tolerate mechanical stress, and therefore is not used for laying the lower rows of bricks.

- "Profix". This adhesive, characterized by increased elasticity, is recommended for those cases where it is necessary to minimize the consumption of cement when laying bricks. This material allows you to create thin seams between the rows.

- Ceresit Flex CM 16. This product is recommended for novice installers, as it allows laying bricks and facing uneven surfaces with artificial stone.

- "Scanmix Fire". This composition is able to withstand temperatures reaching +1200 degrees. Finnish glue has proven itself among stove-makers.

When working with bricks, there is often a need to lay the material on metal surfaces. In this case, the following products will help:

- Belife Silicone. As the name suggests, it is a silicone sealant that can replace masonry mortar. This material is mainly used for repair work.

- Dow Corning Q3-1566. An adhesive characterized by increased elasticity. This composition is able to withstand heating up to 350 degrees. But if the temperature exceeds the specified limit, then the applied glue does not spread and will hold the seam even after the metal has expanded.

- "Penosil Premium +1500". An expensive composition that stands out against the background of competitors by its own versatility. This glue is able to fix the brick on various surfaces, including metal ones.

It is also recommended to study the instructions on the packaging for the glue before purchasing. This will help you more accurately select the product and calculate the approximate amount of material required to complete the brickwork.

Application technology

Working with varnish is not much different from applying regular paint. The temperature regime at which the composition lays down as evenly as possible is -10 + 30 ° C. There are only 3 methods of application: brush, roller, spray. For the latter, it is necessary to slightly dilute the varnish with a suitable solvent. The number of layers is at least 2, each must be allowed to dry thoroughly (at least 1 hour).

Tools and materials

Before painting, it is necessary to examine the surface quality. After that, analyze what materials and tools you need. A standard set, providing the ability to completely clean the wall from the old finish, as well as grout small and large cracks, in addition to varnish, includes:

- a loofah or brush made of stiff steel wire;

- soapy detergent for washing walls;

- brushes with hard nylon bristles or a roller;

- manual (auto) spray gun or spray (spray gun);

- a sponge with a hard surface;

- scraper knife or spatula;

- sandpaper for grinding rubbed cracks;

- putty or grout;

- cement M-400;

- primer;

- rubber gloves and goggles;

- flat synthetic brushes;

- rollers of various sizes.

Surface preparation

Before applying varnish, you need to tidy up the brick wall. If it has an old finish (paint), it must be removed when help building hair dryer or solvent. Slices from cement mortar are knocked down with a chisel and a hammer. If there are small cracks, they must be repaired with latex brick paint, and dried paint off the surface with sandpaper. If there are large cracks or ugly seams, they need to be "embroidered", cleaned, dust removed and repaired. Then sand with sandpaper.

Further actions:

- Rinse the brick to remove dust, dirt, and efflorescence.This can be done with dish soap and a large, soft sponge.

- Dry the surface. It is good if the weather is sunny and warm at this time.

- If after drying, efflorescence appears again, rinse the surface again using a sponge with a hard surface.

- Wait until the brick is completely dry.

- Treat the walls with a deep penetrating primer. Pick it up correctly. It is better to buy a composition from the same manufacturer as the varnish.

The subtleties of working with varnish

After the surface is completely prepared and dry, it can be varnished. This is done with a long-pile roller (bristle length up to 2 cm) or with a thick stiff brush. Adjacent strokes should overlap each other by at least a few millimeters (overlap). The best result will be obtained by using a spray gun. Work starts from any upper corner of the wall. Each subsequent one is applied after the previous one has completely dried, so that the coating turns out to be even.

It is better to cover brick walls with varnish in summer, in dry weather, otherwise there is a high probability that the composition will lie unevenly or the coating will "go" with stains. This kind of finishing is much easier in terms of labor costs and cheaper financially than plaster or other cladding. Maintenance of the varnished surface is simple - wash it a couple of times a year with warm soapy waterand then rinse with clean water.

Adhesives for different types of work

Each individual construction process requires adhesives with different properties that are needed to interact with different materials, be it wallpaper, linoleum, parquet or wall panels. All building adhesives can be divided into several groups:

- Parquet adhesives - when carrying out this type of work, fire-resistant adhesives, such as PVA, are required, which can be used to adhere to concrete, wood and other surfaces. They are also quite economical and quite effective.

- Floor adhesives - for gluing linoleum and cork coverings, synthetic substances are often used that have good properties and are environmentally friendly. They are also cost effective and have a drying time of one to three days.

- Wall and ceiling adhesives - this type is very similar to parquet adhesives as it requires increased safety when used indoors. Such adhesives are excellent for bonding to concrete, wood, as well as chipboard, drywall and much more.

- Special adhesives - as an example, you can take polyurethane foam, which is also an adhesive that has additional properties of thermal insulation, filling voids and bonding. Also, this can include "liquid nails", which do not need to be applied to the entire surface, and a point distribution is used to install any structure.

By purchasing adhesives from well-known manufacturers, you can be sure of the quality of the product and its reliability and durability.

Please note that each package describes in detail the purpose of a particular adhesive. Just a huge selection in modern building supermarkets will allow you to choose what you need specifically in your situation.