Manufacturers

There are many types of adhesive mixtures on sale for wall and plinth cladding outside.

But still pay attention to specific characteristics, in particular, the maximum size and weight of the coating, because the composition may not be able to bear the load applied to it by the tiles.

The table below shows the most common adhesive mixtures for outdoor wall tiling:

| Name | Properties | Appointment |

| Ceresit cm 17 | Excellent adhesion, deformation resistant, water and frost resistant, apply over chipboard | Swimming pool cladding, screeding, cladding of building basements, walls with tiles. |

| Unis 2000 | Waterproof, frost-resistant, good adhesion to any substrates. | For interior and exterior work above the base, installation of natural stone |

| Ceresit cm 117 | Eco-friendly, resistant to moisture and frost, prevents tiles from slipping. | Universal adhesive for indoor and outdoor use. Underfloor heating. |

| Ceresit cm 9 | Waterproof adhesive with acceptable compressive strength | Suitable for indoor and outdoor use, except for the basement, tiles up to 45x45 cm in size. |

| Knauf flex | High elasticity, excellent adhesion to all surfaces. | It is used for plinths, facades, screeds on the underfloor heating system. |

| Knauf fliesen | Economical, acceptable strength for indoor installation of porcelain stoneware. | Unheated floors, walls inside and out, tile size no more than 30x30 cm. |

| Knauf fliesen plus | Versatility, excellent adhesion, minimal consumption. | Tiles 60x60 cm on the floor, walls 40x40 cm no more than 60 kg / m2. Finish the base / plinth. |

| Vetonit ultra fix | Vibration resistance, weather resistance, mold and mildew will not form. | It is used for tiling walls and floors inside and outside buildings. |

| Vetonit ultra fix winter | High frost resistance, work at negative temperatures. | It is used for outdoor work for the installation of large-sized tiles in places with heavy loads. |

| Kreiselschnell fix106 | Water-, frost-resistant composition with good adhesion. | For installing tiles and porcelain stoneware on stable surfaces. |

| Ivsil classic | Perform work at negative temperatures down to -15 degrees. | Installation of tiles inside and outside the premises. |

| Ivsilmaxiplus | It is laid in a thick layer, leveling out significant irregularities on the walls. | Indoor and outdoor gluing of medium format tiles. |

The right adhesive will guarantee a high quality and durable finish.

Methods for using frost-resistant glue

Before starting work, you need to purchase all the necessary materials, come up with a scheme for cladding the facade or other bases, and draw up a sketch. Next, you need to carefully prepare the surface: clean it, level it, remove all poorly fixed elements, especially the falling off plaster. When buying a special glue, it is even possible to put a new tile on an old one, but on the previous coating, notches should be made every 5 cm in a checkerboard pattern. All outdoor surfaces to be lined must be primed. Highly absorbent substrates are primed 2 times.

The glue is diluted according to the instructions on the package. The dry mixture is poured into a strictly measured amount of water, mixed with a drill with a nozzle or a construction mixer. The solution is applied to the base with a notched trowel, carefully spread it. The tile is pressed, pressed so that there are no voids inside, carefully tapped with a rubber mallet. Seams of the required width are left between the elements.

Experienced craftsmen use the following techniques when laying tiles on the street:

- a thin layer of cement is applied over the laid glue, which will bind water and improve the strength of the joint;

- PVA is sprayed on the back of the tile and sprinkled with dry cement, which gives a similar effect and helps the glue to be distributed more evenly.

Upon completion of the work, you need to leave the finished surface until it dries completely, without exposing it to use, and only then grout the joints. All work should be carried out at temperatures above +5 degrees (except for the use of profile compounds used at subzero temperatures).

Main features and composition of frost-resistant glue

Consider the following points when considering all commercially available frost and moisture resistant porcelain stoneware tile adhesive.

All of them are made on a single cement base, because it is the most effective binder component that provides the necessary strength of the finishing layer, but in addition to this element, there are additional substances in the composition that make the composition elastic, viscous and with good adhesion.

Tile adhesive for outdoor use is a special mixture, which contains special additives that enhance the qualities of the mounting layer.

In addition, the composition contains components that contribute to the removal of the composition while minimizing the amount of pore formation, therefore it does not enter moisture even in direct contact with the source

But not all mixtures have such properties, therefore, when choosing them, you should pay attention to such subtleties.

Tile adhesive for outdoor work when facing walls with ceramic or clinker tiles must have a number of qualities that will determine its properties. These include:

- compressive strength.

- adhesion;

- the degree of water absorption;

- frost resistance or the number of full freeze cycles.

What standards should frost-resistant glue comply with?

For the entire time of using glue for laying tiles on external surfaces as a decorative and protective wall covering, certain requirements have been formed for it, which should be taken into account when choosing one or another composition:

- The material should have minimal shrinkage, because the strength and durability of the finish will depend on this. This indicator is not indicated on the packaging by the manufacturer.

- Frost resistance must be more than 50 cycles. Brands offer materials with 70-100 full freeze cycles, which indicates a long service life, about 20 years, depending on the ambient temperature.

- The service temperature limit is the range in which a material retains strength while adhering to a variety of materials. There are compounds on sale that can withstand frozen temperatures from -60 to +80 degrees. The producers of such materials are Yunis, Ceresit and others.

- Also, the adhesive composition must have a low degree of moisture absorption, otherwise it will quickly collapse. Manufacturers indicate the characteristics in the complex. If it is able to withstand up to 100 freezing cycles, then the ability to absorb water is also low, no more than 3%.

Criteria for the smart purchase of tile adhesive

When choosing ceramic tiles or porcelain stoneware as a coating, and for its installation an adhesive composition, then consider only those options in the description of which the type of work is indicated. This will be evidenced by the inscription "for outdoor work".

Also consider the load capacity of a particular material.

Quite often, self-taught builders make mistakes due to ignorance of the elementary characteristics of the composition.

Therefore, they face problems, for example, the tile falls off the next year, and it was necessary to notice the inscription that it is designed for small sizes up to 45x45 cm.There are dry mixes on sale that are used for laying porcelain stoneware of much larger sizes than this value.

When buying tile adhesive for outdoor work, the following criteria are usually paid attention to:

- Temperature for doing work. All manufacturers recommend performing work of this kind only in conditions of positive temperatures from 10-15 degrees. Compositions are available on the market for a limit of +5, but it is still better to adhere to warmer conditions. At the same time, many construction firms declare that they will perform wall cladding in winter, which is strictly prohibited and impractical.

- Consumption. This indicator depends largely on the selected tile, its dimensions and weight. For example, if the tiles are 30x30 cm in size, then for their installation with a layer thickness of 4 mm, at least 5.7 kg per 1 sq. m of surface. Moreover, if it is even and smooth. If there are numerous irregularities, cracks and other defects on the wall, which are sealed at the same time when gluing the tiles, then the amount of the mixture will increase.

- Base. Each manufacturer indicates for which substrates their glue is suitable. But speaking of outdoor decoration, nothing else, like cement, can come up.

Most popular brands

There are a lot of adhesives, on the packaging of which it is written that it is moisture-resistant, frost-resistant. Below is a list of adhesives that have earned a good assessment of experts and users.

PC brand "Flizen" from the company "Knauf"

PC brand "Flizen" from the company "Knauf"

Knauf

Knauf is a renowned manufacturer of building materials from Germany. For outdoor tiling suitable, for example, "Knauf Flizen". Dry mix based on cement. Withstands twenty degrees below zero. The number of cycles is 50. The "Knauf Flex" mixture (100) has a large number of cycles. Unlike Flizen, Flex has no restrictions on the size and weight of tiles. "Flex" has high water-repellent qualities. It is recommended for use, in particular, for roof cladding of indoor swimming pools.

"Litestone K98 / K99"

Dry mix from the Litokol firm. K98 grade is made on the basis of gray Portland cement. It is used for laying natural stone, granite, dark marble, basalt and KP. K99 is produced on the basis of white cement. Used when working with white marble, shell rock, travertine. The glue dries quickly, withstands high loads. Operational temperature range from -30 to +80 degrees.

"Founding Graniplix"

It is used for cladding terraces, balconies, facades and plinths. The base is cement. The mixture works well in wet conditions (swimming pools, etc.). You can fix porcelain stoneware, other materials weighing up to 800 grams.

"Weber Vetonit"

The adhesive is produced by Weber. Several frost-resistant brands are known. For example, "Granite Fix" brand is used for fixing porcelain stoneware and any other tiles. It is used on almost all substrates (aerated concrete, bricks, cement-bonded particle boards, etc.). It is characterized by a very high degree of adhesion and elasticity. High frost resistance - 150 cycles.

The Ultra Fix Winter brand also has a very high frost resistance. She is able to withstand cold up to eighty degrees.

"Eunice 2000"

Russian-made product. Suitable for a variety of substrates. Operating temperature from -20 to +50 degrees. Frost resistance about 100 cycles. The glue is capable of supporting a weight of up to 50 kilograms per square meter.

White "Hardfix"

White "Hardfix"

"Hardfix"

Produced by the Russian company "Perfect". "Hardfix" is used at sub-zero (up to - 10 degrees) temperatures. Very good water resistance. The base of "Hardfix" is cement. In addition, the mixture contains fractionated sand and modifying additives that allow working with the solution at negative temperatures.

"Ceresit"

"Ceresit"

"Ceresit"

A very well-known trade brand in the building materials market. The brand belongs to the Henkel company, which has been producing various building materials for over a hundred years."Ceresit CM17 / CM117" perfectly holds not only tiles, but also other facing materials. СМ17 brand is intended for operation in the range from -50 to +70 degrees. Frost resistance reaches one hundred cycles. The SM117 has the same frost resistance. The difference between the brands is that the second glue holds the heavier material.

Facade cladding with clinker tiles

Facade cladding with clinker tiles

Siliconized compounds (acrylatex)

If you need a frost-resistant compound and a strong waterproof base, you should choose siliconized compounds. Basically, a sealant for stone, plaster, glass, wood and siding has the same characteristics as acrylic.

A durable and reliable composition perfectly tolerates temperature extremes, humidity, prolonged exposure to ultraviolet rays. Acrylatex sealants are suitable for all types of sealing: both external and internal.

As always, the current colors are: dark brown, light brown, close to the beige palette, white, black. Many would prefer a transparent option that suits all occasions.

General advice when choosing an outdoor adhesive

Natural stone is heavy, for strong adhesion, the compositions must have high adhesion.

The parameters of thermal expansion of the stone and the base can differ significantly, the glue must compensate for changes in linear dimensions.

The composition should not lose its properties under the influence of moisture and low temperatures. Remember that the renovation of facades is a difficult and time-consuming undertaking, in some cases it will be necessary to install scaffolding. It is much more profitable to prevent the occurrence of unpleasant situations than to eliminate them later.

Natural stone can have both smooth and uneven edges. Laying the second requires much more time to fit individual elements in size and configuration. Quite often, natural stones have to be cut or chipped, and this is an additional waste of time

In connection with such features of finishing with natural stones, the time of using the glue occupies an important place. The larger it is, the quieter the work is.

Remember that after the start of the polymerization of two-component adhesives, this process cannot be stopped; unused expensive glue will have to be thrown away.

Finishing the facade of the house with stone

What is natural stone glued to?

Natural stone is laid either on cement mortar or on tile adhesive. The second is, of course, better and preferable.

When working with cement mortar, various additives are added to it that improve its plasticity, frost resistance and other properties. Now you can find enough information about this, especially since many people on the Internet share their experience in facing and paving with natural stone.

When buying tile adhesive, the choice must be made in favor of brands well-known on the international market. You need to buy from a reliable and trusted supplier: today there are many fakes on the market.

Good adhesives for natural stone are Litokol, Ceresit, Knauf, Bergauf, Basf. Unis and Plitonit are often used because of their prevalence and optimal price / quality ratio; Plitonit is suitable for external cladding, we do not recommend Eunice for this purpose.

Features of silicone sealing

For outdoor work, silicone sealant for outdoor work with frost-resistant and water-resistant qualities is used. It is a viscous mass that is released in a cylinder. Polymerization of the product occurs due to exposure to air, humidity. It is multifunctional, resistant to sudden changes in temperature. Provides adhesion to all building surfaces.

A frost-resistant silicone sealant is produced on the basis of silicone rubber with the addition of a vulcanizer, which serves as a hardener.

Specifications:

- The outer seams become resistant to solar radiation, high moisture, temperature extremes.

- Flexibility provides increased adhesion when working with movable seams. The mass promotes full penetration into cracks and crevices.

- The qualities of strength and plasticity are connected.

- Withstands a temperature difference of -50 - 200 degrees. If based on heat-resistant rubber, then up to 300 degrees.

- The pre-priming of the surface is not included in the mandatory application conditions.

To improve the quality and impart improved properties, additives are included in the sealant:

- Organic extenders - reduce consistency.

- Organic extenders - increased adhesion.

- Fungicides - prevent the formation and spread of fungal formations.

- Pigments - when matching the color of the coating.

Thorough cleaning of the surface is required before application: old insulating materials are removed, dirt is cleaned, degreasing is carried out (with solvent, alcohol, etc.).

To prevent contamination of adjacent surfaces, cover them with mounting tape.

This type of acriplast is used: for roofing work, closing window seams, in the construction of greenhouses, external thermal insulation, sealing cracks in a building, repairing chimneys, sealing drainage systems, ebb tides, etc.

The process requires dry, warm weather.

Views

Knowing the different types of adhesives will help you make the right choice.

Depending on the composition of the components, there are three main types of adhesives for CP:

- cement;

- dispersive;

- epoxy.

In addition to cement, the mixture contains sand, various additives that enhance strength and water repellency. It is used for both external and internal finishing works.

The good thing about cement glue is that it is cheap and easy to use. Laying one square meter with it will cost twenty times less than using an epoxy. Even a beginner in the construction craft will be able to correctly prepare the solution and apply it to the surface.

Dispersion PC

Dispersion PC

It contains synthetic resins, organic additives and an inert filler.

It is enough to stir it before application. It speeds up installation as the glue does not need to be prepared. It also has the advantage that it has high ductility. They are mainly used in indoor areas.

For its production, epoxy-polyurethane resins, organic additives, filler and catalyst are used. The main disadvantage is the high cost.

There are also adhesives:

- universal;

- frost-resistant;

- reinforced;

- moisture resistant;

- heat resistant.

Popular universal adhesives, as they say, for all occasions. They are suitable for indoor and outdoor use in rooms with different functionalities. However, versatility isn't always good. For example, independent experts argue that manufacturers, for advertising purposes, exaggerate the moisture resistance and frost resistance of universal mixtures, and do not advise using them for outdoor work.

For such work, frost-resistant tile adhesive is better suited.

The reinforced adhesive is characterized by very high adhesion. It can be used, for example, for fixing large porcelain stoneware tiles. Since such a KP is mounted externally, the glue for porcelain stoneware must be frost-resistant.

Moisture-resistant mixtures are produced for use in rooms with high humidity (bathrooms, swimming pools, etc.).

Heat-resistant adhesives are used when the tiles are operated at elevated temperatures, from underfloor heating to facing fireplaces and stoves.

What to look for

The composition should have excellent adhesion and not change the original properties after hardening.It is not recommended to use universal mixtures, because in terms of frost and moisture resistance, they are not able to meet the requirements for mixtures that should be used in conjunction with natural stone. This is especially true in cold climates, where operating conditions are most difficult.

Specialists recommend paying special attention to the manufacturer when choosing a brand of glue. Those located in the northern countries take into account the frost resistance factor and produce adapted adhesives

Domestic companies have now mastered the technology of making high-quality mixtures. In all respects, they are not inferior to imported counterparts. However, the cost of Russian-made products is not much lower than foreign ones. The cost is sometimes unreasonably high.

Choosing reliable glue liquid nails - an overview of proven options

When choosing the most suitable brand of adhesive, consider the following:

- What materials need to be glued;

- What kind of load will the glue line experience;

- In what conditions will the glued product be used (inside or outside the room).

Today, the most popular among professionals is liquid nails from such manufacturers as: Moment (Henkel), Titebond, Makrofix, TYTAN, Krass, Kim Tec, Liquid Nails, Kraftool, Titebond, Quadro.

The following brands enjoy a very good reputation:

Glue Moment Installation MV 50 liquid nails - universal moisture-resistant express glue based on water dispersion (polyacrylate).

Perfect for joining different surfaces (wood, styrofoam, metal, plastic, ceramics, chipboard, MDF, cork coverings, polystyrene, gypsum, etc.) when carrying out installation work inside and outside the room.

Ideal for gluing plastic and wood skirting boards and other decorative elements, various profiles and panels indoors.

Glue liquid nails Titan Professional 901 - heavy-duty construction and assembly adhesive based on hydrocarbon solvents.

Provides fast and durable bonding of various types of surfaces (wood, metal, ceramics, concrete, plastic, stone, etc.). Resistant to temperature extremes, high humidity.

Suitable for outdoor use (frost resistant). Titanium Professional 901 is suitable for bonding heavy decorative elements and building materials.

Krass Extra Durable - specialized liquid nails for quick installation of plastic and tiles.

It is considered one of the best options for mounting heavy and light elements made of plastic (polystyrene, PVC), chipboard, MDF, ceramics, plaster, plywood, stone, metal.

Suitable for use in damp rooms, has excellent adhesion.

Comparison table of popular brands:

| Glue brand | Volume | Advantages | Price |

| Moment Installation MV 50 | 125 grams.; 250 grams.; 400 grams. | quick-setting, solvent-free, white. | about 300 rubles for 400 grams. |

| Titanium Professional 901 | 380 grams. | strong initial adhesion, forms an elastic seam, suitable for gluing heavy products. | about 100 rubles. |

| Krass Heavy-duty assembly | 300 grams. | convenient to apply on vertical surfaces, elastic, non-shrinking, odorless. | about 200 rubles. |

Instructions - how to properly glue with liquid nails using the example of PVC panels

Most often, liquid nails are used to attach PVC panels to walls and ceilings.

This method of installation eliminates drilling; moreover, there are no traces of fasteners on the front surface of the panels.

How to glue PVC panels on liquid nails KRASS "Extra strong installation"?

For this you need:

- Prepare the surfaces to be glued beforehand - they must be clean, dry and free from grease.

- Remove the protective cap from the tube, cut the plastic tip closer to the thread.

- Insert the glue tube into the assembly gun.

- Apply glue to the material to be glued in thin strips of the same thickness with an interval of several centimeters (depending on the weight of the product) or pointwise.

- Lean the PVC panel against the wall / ceiling, press down and fix for a few seconds. To correct the position of the panel, do not peel off the material, but carefully move it. It is recommended to additionally fix heavy elements with supporting structures until the glue is completely dry (24-72 hours).

- Immediately after completion of work, the tools should be cleaned of glue with warm water.

VIDEO REVIEW

Frequently asked questions

How to use a glue gun for liquid nails?

This is not difficult. It is only necessary to insert the tube into the gun body, having previously pushed the rod outward, and cut off the tip of the tube.

When the trigger is pulled, the rod is set in motion, creating pressure on the piston inside the tube. The glue is squeezed out through the hole. The intensity of pressing regulates the supply of glue.

What is the consumption of glue liquid nails per 1m2?

Average consumption is about 200 grams of glue per square meter of decorative panels. When gluing narrow profiles and panels, the average consumption is 20-40 grams per meter.

How long does liquid nail glue dry?

The time for complete curing of the glue is usually 24-48 hours (depending on the thickness of the applied glue), the setting time is usually 20-40 minutes.

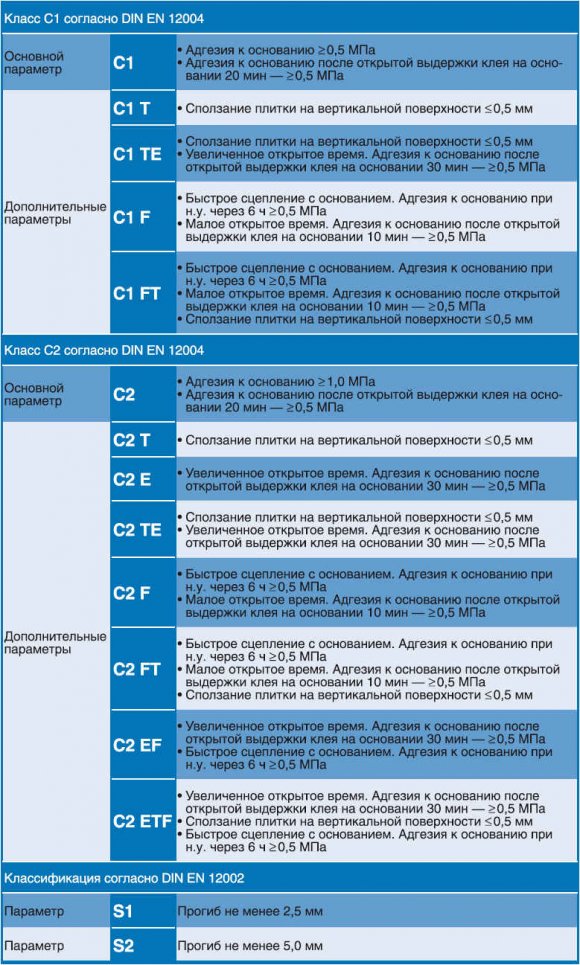

Features of marking

Regulatory documents (GOST R 56387-2015, EN 12004: 2007) record a number of standard markings that allow determining the main characteristics of the product. In particular:

- C - mixtures based on cement binder.

- D - dispersion tile adhesive.

- R - reactive type adhesive.

In practice, almost all letters are supplemented with numbers 1 and 2, which means "basic" and "enhanced". That is, D1 is the standard dispersion adhesive for indoor and outdoor use, and D2 is its improved version. The same is true for polymer formulations.

Let's take a look at marking using cement adhesives as an example. The EN 12004: 2007 standard approved a number of clarifying designations (classes):

- С0 - products for the installation of tile materials with a water absorption level of up to 5% by weight. Scope - indoors.

- C1 - adhesive for ceramic tiles and porcelain stoneware used for indoor and outdoor use.

- C2 is an adhesive composition, which is subject to increased requirements for a number of quality characteristics.

- F - mixtures with a short pot life (fast hardening).

- T - solution of increased thixotropy. That is, due to the introduction of special additives into the composition, it perfectly holds the tile on vertical and inclined surfaces, preventing it from slipping during gluing.

- E - mixtures with prolonged pot life (open layer).

- S1 - adhesives from a series of elastic, which, after hardening, give a deflection of up to 2.5 mm.

- S2 is a highly elastic compound designed for highly deformable substrates. Deflection limit - up to 5 mm.

Thus, even the most complex marking is deciphered quite simply. For example, the name "Kerabond C2ES2" means that this is a reinforced cementitious adhesive with a prolonged open layer life and a high degree of deformability.

In addition to the special marking, the standard one is also used. On the packages you can find such pictograms as the thickness of the mixture, consumption, time before walking, operating temperature and others. They, as a rule, are as simple and understandable as possible, even without explanation.

Popular adhesives

For gluing tiles and mosaics, imported and domestic products are used. The greatest demand is for the mixtures of the Ceresit company. They are used to glue ceramic and clinker glazed tiles, marble and glass mosaics.

There are many modifications, the packaging indicates which material is preferable to work with.

For more information about Ceresit glue, read the article - Ceresit tile glue: varieties and features

Other brands also deserve attention:

- Farvest Pool C2TE25 - universal waterproof, the basis is cement and sand. They are used in work with ceramics, any mosaic, natural and artificial stone. Plastic, frost-resistant, resistant to temperature fluctuations in the range of -50 ... + 60 ° C.

- The winner is the TM-16 Pool - frost-resistant, durable, with high adhesion, designed for ceramics. Contains cement, quartz sand, modifying components.

- PCI Collastic is a polyurethane, with high consumer properties: no priming is required, it dries quickly - grouting is possible after 6 hours. After the same time, you can walk on the tiles, and it is allowed to fill the bowl with water after 12 hours.

- PCI Nanolight is a dry mortar for all substrates and ceramic tiles. Completely inert to chemicals, increased water resistance. A mixture of white and gray colors is produced.

Experts identify formulations that are of reasonable price and high quality. This is a frost-resistant adhesive for outdoor pools Ceresit CM 117 Flex, a high-strength polymer Tenaflex H 40. They are flexible, easy to use.

High adhesion to different surfaces in the Greek mixtures Isomat and French Arexgroup, but the cost is higher than that of the previously named ones.

The manufacturer's recommendations say that white compounds should be used for mosaics. Experienced craftsmen believe that gray will work, but a high quality grout is required for the color of the tile.