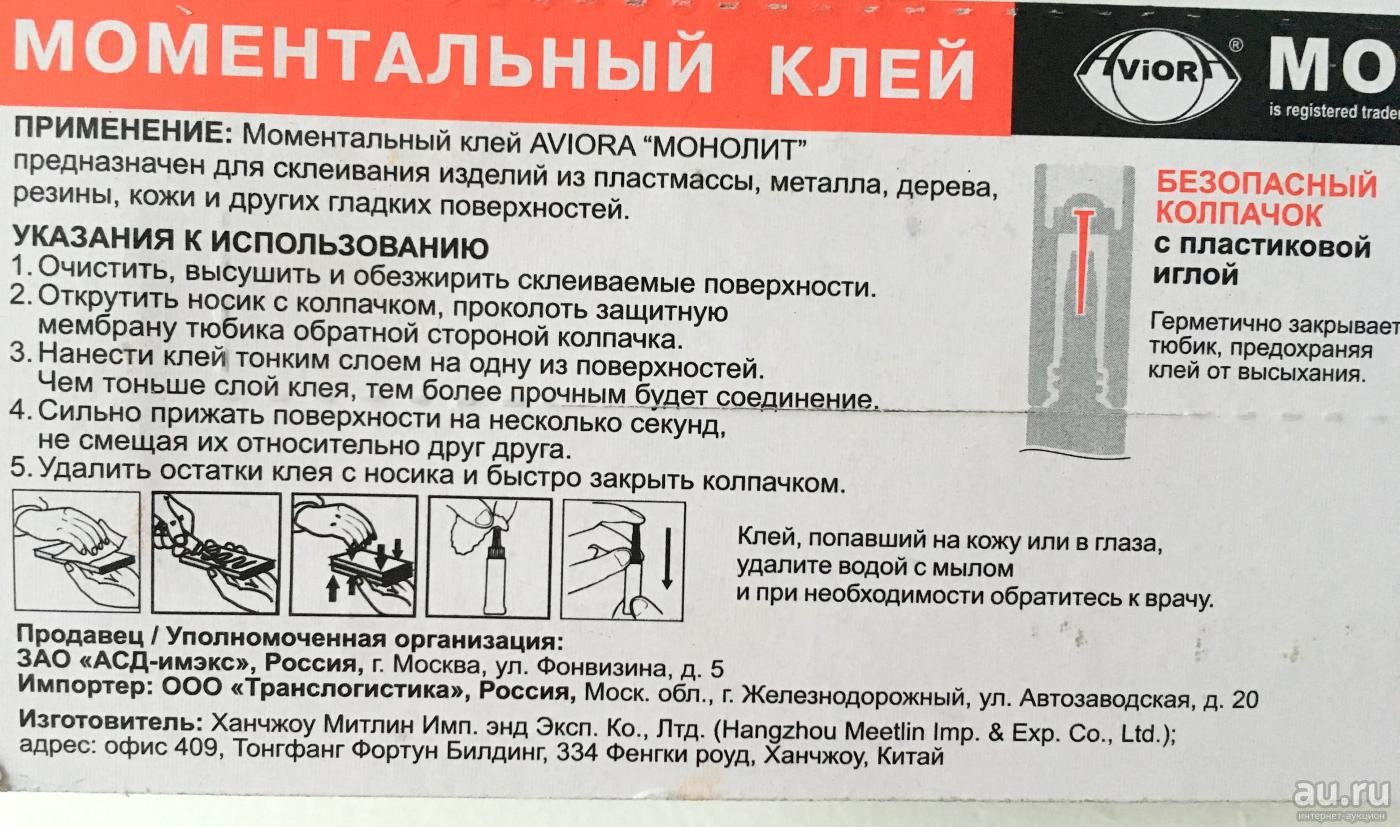

Precautionary measures

When working with EDP glue, it is necessary to observe the following precautions:

- The room where the work is carried out must be well ventilated, have a working ventilation system.

- It is imperative to use IZ products for the skin and respiratory tract.

- If the composition comes into contact with the skin epithelium, rinse with running water and wipe with alcohol. In case of contact with eyes - urgent medical consultation.

- Mixtures, formulations are stored in living quarters in dark, dry places, inaccessible to children. Pre-tightly closed. If the remains of the composition do not require further use, then they are disposed of.

- When using solvents, work should be carried out away from open sources of fire.

- The containers in which the mixtures are stirred are practically not washed from the dried composition.

We advise you to watch the video:

Security measures

Both purchased and home-made gluing products are highly reactive and harmful to human health.

To maintain health, you should follow the safety rules:

- work in a well-ventilated area;

- when working with dichloroethane, use exhaust ventilation;

- use protective gloves and goggles.

In case of accidental contact with skin or mucous membranes, or if swallowed, consult a doctor immediately. Be sure to take a tube with you.

If you find an error, please select a piece of text and press Ctrl + Enter.

As they say, everything is new, forgotten old.) In short, out of the corner of my ear I learned about chemistry alone, called dichloroethane. I bought it at a radio parts store. Sold said that this thing is as old as the world, only everyone has forgotten about it, they buy moments and cosmophans with superglues in tridorogo, although these adhesives are just based on EDC, just with additives.

With what it is eaten. In short, this liquid liquefies plastic, plexiglass, and even some rubber into porridge, allowing you to get molding after evaporation of this liquid from the plastic. I found the application right away - I restored a broken piece of plastic on the cover of the electric saw. It turned out so, as if it were so - a monolith. As I did. I found plastic that EDC can do, cut it into small pieces and melted it in a cork from under a bottle to jelly

and poured it on the cover of the electric saw, trying to give the shape of the previously broken off and lost piece, supported the shape with a piece of cotton rag (so that it breathes and DZHE evaporates from the porridge through it). While the poured contents were freezing (a thick layer for about a day) -JE, which was present in my plastic porridge, flooded the restored part itself and it all grew together and mixed into one whole.

The result is a monolith. I finished the irregularities with a file after hardening and that's it! Ready! I know for sure that I would never buy such a saw cover anywhere, because EDC helped me a lot! If I had known earlier, I could have restored the torpedo on my former 99, there is just that plastic that dissolves EDC with a bang. I also heard that car mats can be welded to them, I'll check it somehow. By the way, I also fused the sole of the boot with a bang, did not burst when walking. Well, maybe someone will come in handy ... And this bottle costs only 35 rubles!))

How to use dichloroethane glue for plastics

There are a lot of adhesives. And the point is not that manufacturers do not want to make universal glue for everything and everyone, but that mixtures connecting different materials must somehow compensate for this difference. Otherwise, bonding as such will not occur. As a result, there are tons of options for stone, concrete, wood, metal, and of course polymeric materials.

EDC

Plastic adhesive Dichloroethane is one of them.

Features of gluing polymers

Polymer materials of this kind are not highly durable, at least those that are most often used in everyday life, and which are most often repaired by hand. Therefore, the classic option for fastening parts is, of course, glue. However, a lot of nuances arise here.

Oddly enough, plastic is hard to glue. Glass, ceramics, and metal are much easier to bond despite their hardness, mass and low porosity.

The problem with polymers is their high chemical inertness: substances simply don't bond.

As a result, it is possible to connect plastic parts only with special compounds, and besides, especially for a certain group of polymers. So, for example, glue based on dichloroethane is not suitable for gluing polyethylene products.

The following adhesive mixtures are used for repairs.

Liquid - water-based and solvent-based. When gluing, the solvent evaporates, and the substance hardens and firmly holds the parts together. Such glue is quite suitable for repairing porous materials - fabric, plastic, wood, but it is useless to glue sealed materials to them, the composition will not even harden.

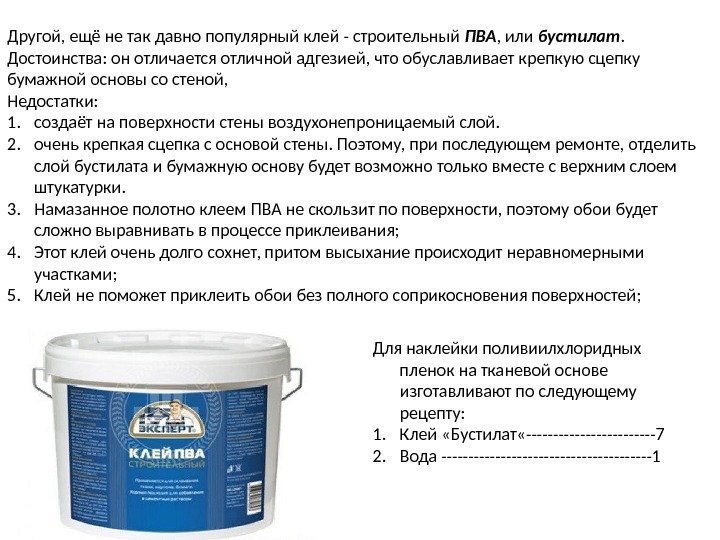

A typical example of the first category is the well-known PVA, a sample of the second is a composition based on dichloroethane. The latter is usually used by professionals, since the substance is poisonous and can only be used strictly according to the instructions. The photo shows the packaging of the glue.

Contact - with or without hardener. The principle of operation is as follows: glue in a viscous state is applied to the surfaces to be glued, where it should dry a little, and then the surfaces are connected and held under pressure.

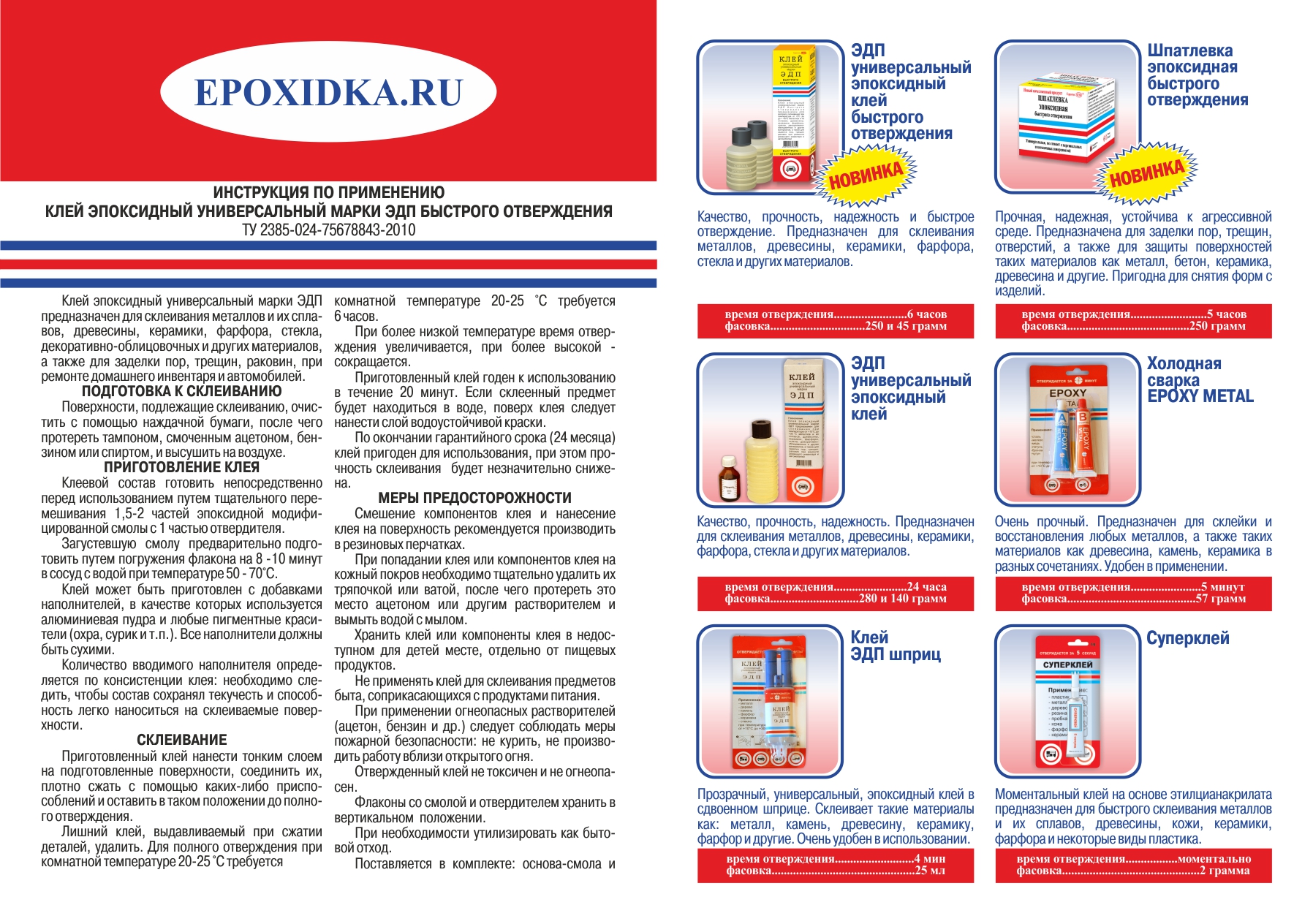

A typical example is Rexant, a hardened epoxy mix. The mixture is universal, it is used for gluing plastic materials as well. Rexant, like all other representatives of the contact group, freezes within 24 hours.

- Hot melt glue or reactive - heated before application in order to go into the liquid phase and harden upon cooling. Hot melt glue is perfect for attaching large items. A typical representative is "Moment".

- Reactive - one- or two-component. This is an instant grab option. Therefore, here you need to pay special attention to the correctness of the connection. The one-component version is ready to use. The two-component mixture must be premixed. Such a composition remains working for no more than 20-30 minutes, so it should be cooked in small portions.

Adhesive for plastic Dichloroethane

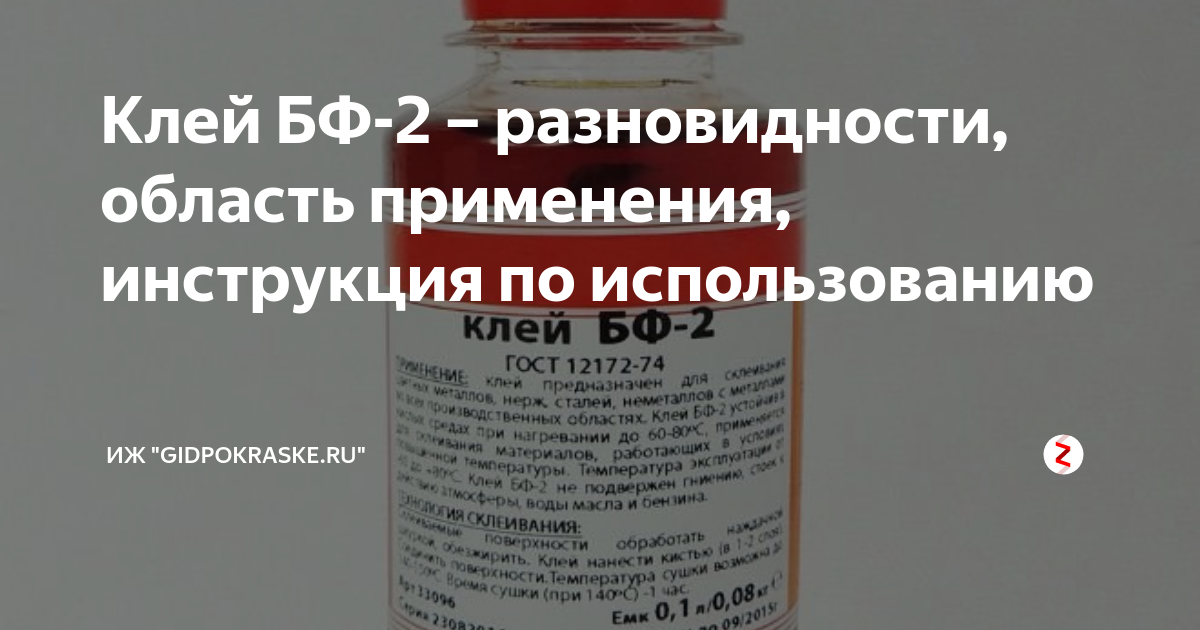

The substance itself is the least similar to an adhesive mixture. EDC is a volatile liquid, soluble in alcohols and fats, and has a pungent, strong odor. A solution of dichloroethane is on sale - a transparent liquid, highly toxic, usually in glass bottles with a volume of 30 ml. EDC is highly corrosive and will dissolve plastic.

To make glue out of it, it is necessary to dissolve the required amount of polymer material in a liquid - this is approximately 2% plexiglass or 20% polystyrene.

Thanks to this, the setting is slowed down, so the location of the parts to be glued can be adjusted.

How to glue with dichloroethane: instruction

The composition is stored in a glass bottle with a volume of 30 ml. You can use polyethylene - all other plastics will dissolve dichloroethane.

The substance is poisonous, moreover, it evaporates quickly. You can work with it only in a well-ventilated room and in the absence of sources of fire or heating. EDCs are not just plastic corrosives, so measures must be taken to prevent spills. Given all these limitations and the real toxicity of the substance, it is clear why it is used mainly only in production.

The instructions for use are quite simple.

- A fraction of the plastic is dissolved in the small volume required to join the plastic parts.

- The surface of the materials is degreased with acetone.

- The glue is applied only to the seam areas.Do not allow the solution to hit the surface, since the substance will corrode the material.

- The edges of the seam are pressed tightly against each other and fixed for 1–6 hours.

The video demonstrates how to glue plastic with dichloroethane.

Other uses for ethylene dichloride

Dichloroethane ethylene is used to obtain substances such as ethylene glycol, ethylenediamine, polysulfide rubbers. If we talk about such an industry as paints and varnishes, then here it is widely used as the main reagent for the manufacture of paint thinners. Agriculture also actively uses this composition as an insecticide for the treatment of grain crops, vineyards, soil, grain storage. It is also actively used to control pests such as the Colorado potato beetle and several other insect species.

If we talk about the construction industry, then here it is used as a solvent for plastics, rubber, rubber, fats, oils, wax, etc. Due to its qualities, the substance is capable of not only dissolving but also sticking plastic. Dichloroethane is used when working with facing material used for building structures. It is worth making some clarity here. It is strictly forbidden to glue any items related to kitchen utensils. You can also use the reagent in tandem with an element such as plexiglass. Dichloroethane is used to repair parts from this composition. It is able to remove cracks and chips from the surface of these elements.

The better to glue plexiglass

Both for repairing broken parts and for assembling new products, a suitable adhesive should be used.

How to glue plexiglass:

Specialized compounds for gluing plexiglass are of two types:

- Compositions based on acrylic fillers and strong organic solvents. In composition, they are very close to the substance of plexiglass, which makes it possible to obtain a homogeneous and sufficiently strong connection.

- Epoxy based adhesives are great for filling and repairing cracks, the joint takes a long time to harden, but the epoxy can bond tightly.

In addition, plexiglass can be dissolved, which means it can be glued with strong acids:

It will not be possible to glue the plexiglass with food vinegar (acetic acid with a concentration of 7-9%), you will need at least 70% vinegar essence. Acetic acid does not dissolve the entire surface layer of the material, but only softens it, so the parts will have to be strongly compressed and held for a long time.

Glue at home

- The surface to be glued is degreased. It is necessary to moisten a rag or sponge in alcohol or gasoline, thoroughly wipe the surfaces on which the agent is supposed to be applied. Poor degreasing causes a decrease in joint strength.

- The structural elements are fixed, while there should be a small gap between them.

- Both parts must be carefully treated with adhesive. You can apply the product with an ordinary medical syringe, which can be done evenly. When using a needle from a syringe, it must first be finalized by removing the bevel with a file or an abrasive bar. Otherwise the mixture will splatter. With a syringe, the mass fills the gap between the fixed parts of the structure.

- The parts are connected to each other, pressed tightly and fixed until they are fully connected. If the plexiglass is thick, it is clamped with clamps or a vice. Fragile structures are wound with electrical tape.

- In this position, the structure is held from 1 to 30 minutes, depending on the amount and type of glue.

To glue organic glass to wood, you can use Moment, liquid nails or Glue 88. The same compounds combine acrylic glass with metal.

Application

Dichloroethane is an organic chemical that negatively affects the human body, but at the same time, many household products cannot be obtained without it.

Where is dichloroethane used?

- Its main role in the chemical industry is the basis for the production of vinyl chloride. That is, it is from ethylene chloride that the familiar and affordable polyethylene is obtained, without which modern life cannot be imagined. Bags, vinyl records, stretch ceilings, artificial leather, washable wallpaper, furniture edgebands, wires and cables are all the result of this chemical reaction of the interaction of dichloroethane with other substances.

- Vinyl chloride is necessary for the synthesis of the simplest dihydric alcohol - ethylene glycol.

- Dichloroethane is used in the production of the rubbery substance thiokol, from which rubber is made.

- It is the ideal solvent.

- With its help, varnishes and paints are made, as well as means for their removal.

- It is found in surface degreasers and furniture polish.

- Dichloroethane has good disinfecting properties, therefore, grain and its storage facilities are processed with it.

- Used to disinfect the soil for vineyards.

- In medicine, it is used as an anesthetic.

- The substance has successfully proven itself in the fight against the Colorado potato beetle.

- Dichloroethane is used in everyday life; it is used for gluing plexiglass, plastic and other things.

- Thanks to dichloroethane, it is possible to degrease woolen products, carry out a full-fledged processing of the leather before the tanning process.

- It is added during the production of vegetable oil as an extracting component.

- It is the initial product in the production of many chemical compounds such as ethers, amines, alcohols.

- Dichloroethane is used for treating surfaces against fungus.

- Vinyl chloride is not only beneficial - it is part of the poisonous substances that are sprayed on the enemy in wartime.

The chemical industry cannot do without this compound, because the modern world is difficult to imagine without it. When is dichloroethane poisoning possible? When does it happen?

Plexiglass adhesive options

Speaking about the popular compositions that can be used to glue plexiglass, it is worth dwelling on the following:

- formulations of the Acrifix family, specially designed for acrylic-based materials;

- mixtures based on dichloroethane;

- acetic acid and its essence;

- Colacril family compounds;

- Cosmofen glue. It is also used to hold wood and plexiglass together;

- adhesives produced by Era-Henkel: Moment, Moment - seconds and others.

Acrifix 117 glue

One of the most popular formulations for gluing plexiglass has a long and well-deserved popularity among home craftsmen.

It has the following advantages:

- excellent bond strength;

- high transparency of the suture material;

- short setting time;

- low toxicity, especially compared to dichloroethane;

- high penetrating power makes it unnecessary to squeeze the parts hard.

Unfortunately, the Acrifix 117 also has disadvantages that make it difficult for DIYers to access it:

- packing in liter cans;

- high price.

Experts recommend adding one tenth the volume of Acrifix 116 to Acrifix 117. This contributes to better filling of microroughnesses and increased adhesion.

Acrifix 116 glue

In composition, it is close to grade 117, but differs in greater density and viscosity. It is packaged in convenient 100 ml tubes, which makes it easy to use in home workshops.

They can glue rough surfaces that do not have perfect smoothness.

Dichloroethane

Budget replacement for expensive formulations. It is sold in stores of chemical components and stores of radio components. If the surfaces are perfectly smooth and even, they can be glued with dichloroethane without any additives. It is applied using a medical syringe into the gap between the parts to be connected. The seam turns out to be perfectly smooth, with high transparency. If the surfaces are properly prepared, the seam will be bubble-free.

If the surfaces are not perfectly smooth, then there is another way to glue them together.A little plexiglass shavings (sawdust) are poured into a bottle with dichloroethane after dissolution, a thick composition is obtained, which can be applied with a spatula or wire.

In the room where they work with dichloroethane, it is imperative to have high-quality ventilation.

Vinegar essence

This is another inexpensive substitute for commercial pro formulas. Allows to glue plexiglass firmly enough.

Serious internal mechanical stresses occur on the folds of the parts, which can lead to cracking of the plexiglass.

Experts recommend using vinegar essence to glue small items that are not subject to heavy loads.

Colacril 20 and colacril 30 glue

The Colacril family serves as a functional replacement for the expensive Acrifix family of adhesives.

Colacril 20 is highly fluid and Colacril 30 is viscous.

Experts blend them to obtain the optimal consistency for each specific compound.

Compositions allow you to glue the parts and get a beautiful and even seam, transparent and without bubbles.

The disadvantage of the Colacril family in comparison with Acrifix is the formation of small cracks in the place of the plexiglass bend, caused by internal mechanical stresses. At the same time, the appearance deteriorates, but the strength remains.

Seconds glue moment and Cosmofen

Most instant adhesives are cyanoacrylate based. Regardless of the type of packaging - in metal, plastic tubes or bottles with a narrow spout for application - they are very similar in their properties.

The general property is that they do not dissolve plexiglass, but create an intermediate adhesive layer.

Therefore, experts do not recommend using them for joints subject to any stress. The most that they can do is to grab a small piece to a toy or decoration.

The adhesive layer is opaque, the junction is very noticeable.

Dangerous! "Moment" can glue the skin of your fingers so that you have to see a doctor. Use of protective gloves is mandatory.

How to cook

To make dichloroethane glue, dissolve the same material that you want to glue in EDC. This will reduce the aggressiveness of the substance and at the same time increase the strength of the joint. With the addition of polymer, the shrinkage of the seam decreases, since EDC evaporates less intensely.

Cooking instructions:

- Take a small dish with a hermetically sealed lid.

- Place shavings and small pieces of plastic in a container.

- Pour over EDC so that it completely covers the pieces.

- Close the lid as tightly as possible and place the container in a dark place until the polymer is completely dissolved, after which the mixture is ready for use.

Adhesive self-adhesive films

Self-adhesive tapes are a good alternative for repairing plexiglass products. Their undoubted advantage is the ability to glue both two plexiglass parts and plexiglass with other materials.

There are three main types of such films on the market:

- Baseless adhesive films. In fact, it is a thin layer of adhesive several tens of microns thick. It is stored between two transport polyethylene films, which are removed just before gluing. Such adhesive films can bond smooth, perfectly flat parts with a low coefficient of thermal expansion.

- Films with a thin transparent base, several hundredths of a millimeter thick. Also requires a smooth surface, but the requirements are somewhat lower. The connection turns out to be less strong and theoretically detachable - you can try to remove the film.

- Films with a thin foamed base, similar to the so-called double-sided tape. The base thickness ranges from tenths to several millimeters.Plexiglass can be glued with such films, even if the surfaces are not very even, but the bond strength is very low. Suitable for structures that are not subject to heavy loads.

Requirements for surface preparation and the maximum loads that the joint can withstand are specified in the manual enclosed with the specific film.

Features of work

It should be said right away that it is very difficult to glue the plastic. Materials such as ceramics, metal or even glass are much easier to join with an adhesive mixture. The whole problem of polymer substances when gluing them is that they have a fairly high chemical inertness. In other words, such materials simply do not form bonds. Because of this, a special composition is required for gluing polymers. In addition, for each group of such substances, it is necessary to use a different composition of the glue. For example, you cannot glue polyethylene with dichloroethane.

In general, all adhesives are divided into two groups: liquid with a water base and liquid with a solvent base. The principle of operation of solvent-based glue is that after its application, the solvent base completely evaporates, and the remaining elements harden, connecting the material. However, only porous raw materials can be glued in this way; it is completely useless to use it for a sealed base.

General properties of ethylene chloride

Dichloroethane - what is it, in terms of properties? It is a reagent that is toxic, flammable and explosive, and it evaporates quite quickly and easily. If you inhale this substance, then it will cause a state of narcotic intoxication, as well as poisoning. In addition, the composition is considered a carcinogen and a mutagen. For humans, the lethal dose of this substance is 20 ml if it is ingested through the mouth, skin or air. The chemical is hazardous to the environment and has a half-life of 50 years. Due to its high toxicity, the use of dichloroethane is rather limited. It is popular only in the chemical industry. Here it is used in many areas, since in addition to its toxicity, it also has a number of positive qualities. To obtain EDC, ethylene chlorination is used. The production of this substance is carried out in tens of millions of tons around the world.

Precautionary measures

Standard safety precautions must be followed to ensure safety when using dichloroethane adhesives. You can store the working mixture only in glass or plastic bottles, since the substance dissolves all other types of plastic

The liquid is also capable of corroding many other materials, so spills should be avoided.

When handling the adhesive, it is recommended to wear protective gloves, a respirator and long-sleeved clothing to protect the skin. Taking into account all the listed restrictions and the toxicity of the substance, its operation is allowed only for production purposes.

Types of adhesives for plexiglass

Adhesives are primarily distinguished by their basic characteristics and can be used only for gluing plexiglass or creating strong bonds with other materials. Also, an important factor when choosing an adhesive should be considered a relatively safe composition and price of the product. As a savings, you can use improvised means like vinegar or give your preference to specialized adhesives.

Solvents

With the help of solvents, it is possible to interconnect plexiglass, but such a seam is most likely to be fragile and subsequently a crack may occur. For a better connection, it is recommended to dissolve plexiglass shavings in the selected liquid, after which the hardened seam will be more durable.Acids are most often used as solvents, for example, formic or acetic acid.

It is not recommended to use acetone-containing agents as a solvent or additive to it, the dissolution time in such Plexiglas compositions is about 10 hours, with regular stirring of the mixture.

Dichloroethane

The use of this product is one of the most budgetary options; you can buy it at any store that sells chemical components.

If it is necessary to glue flat surfaces, then dichloroethane can be used as an independent adhesive, while the seam turns out to be quite transparent and perfectly even. With proper preparation of materials, the seam does not contain bubbles, but if they appear, then the technology was violated during the processing of parts.

When working with dichloroethane, it is imperative to observe all safety precautions, since this substance is hazardous to health. When storing it, a tightly closed container should be provided.

Epoxy resin

The use of epoxy resin or glue with its content provides instant bonding tightly, while guaranteeing a transparent seam at the joint when it dries. Epoxy is transparent on its own, which makes for interesting combinations, especially when used with wood.

Adhesive film

In order to glue two pieces of plexiglass together, a self-adhesive adhesive film is ideal, which ensures a strong connection.

In contrast to the pursued goals, it is necessary to choose one of the three most popular options for such a film:

- Baseless adhesive film. The choice of this option will be especially relevant if the task is to maintain the transparency of the plexiglass product. It is recommended to apply the film on the most even surface.

- Film with a thin transparent base. A distinctive feature of this type of film can be considered the possibility of its subsequent removal. It is applied on a flat surface of two plexiglass elements or for joining plexiglass with other materials.

- Film with a thin foam base. This option vaguely resembles dense double-sided tape, with the help of such a film, even uneven surfaces can be glued, but the connection may be of poor quality, this method is suitable for structures that do not imply serious loads in the future.

Attention should be paid to the composition of each type of adhesive films, especially the indication of the optimal load that they can withstand, as well as the recommended service life.