Why does antifreeze climb through the lid?

If the engine overheats or the expansion tank is inflated, many inexperienced drivers run to immediately open the lid and are very surprised, and many are frightened by the antifreeze flowing out under pressure.

We'll calm you down right away - that's okay. The fact is that when the serviceable tank lid is closed, a pressure of 1.5-2.0 atmospheres is created in the cooling system. Moreover, we all know from physics that the boiling point of any liquid is directly proportional to the ambient pressure. That is, the higher the pressure, the higher the boiling point.

Therefore, the pressure above atmospheric in the cooling system is specially created so that the antifreeze does not boil at 100C (1 atm.), But at 115C (1.5 atm.) And 120C (2 atm.).

After the engine is turned off and the cover is open, the process of pressure equalization takes place, the liquid flows from larger to smaller, while it continues to expand, since the engine continues to gain temperature for some time, i.e. the point of the beginning of its cooling has not yet been passed.

If the antifreeze has boiled, then the engine has overheated. In this situation, it is not necessary to open the lid immediately, since the coolant can splash out on the hands and face under pressure - a burn is inevitable. Just in such a situation, when the non-working lid of the tank, the latter can swell.

Choice of repair methods and adhesives

Radiators in trucks and cars are the most important part that helps to cool the mechanism and remove excess heat from the engine. Cool liquid circulates inside the device through pipes and hoses, and the convenient location of the upper part under the hood allows it to be blown with air.

Most cars are equipped with aluminum radiators. This material is ideal for this purpose - it is lightweight, durable, does not corrode, its thermal conductivity is high (it gives off heat, and the parts will not overheat). Aluminum and plastic cooling batteries have replaced brass and copper products, which are much more expensive. But due to the chemical characteristics, such tanks are much more difficult to repair, although nothing is impossible. The radiator is capable of cracking even from a small blow, and if it is made of plastic, even a large defect may appear.

The easiest way is to seal the crack with a suitable adhesive. But picking up the glue is not easy - most compounds do not hold, others quickly peel off. This is due to the regular changes in temperatures and pressures in the cooling system.

How to glue the radiator, and what other method can you use at home? Here are the main ones:

- Soldering. Heat-resistant plastic, from which radiators are made, as well as aluminum parts, can be fastened using a conventional soldering iron.

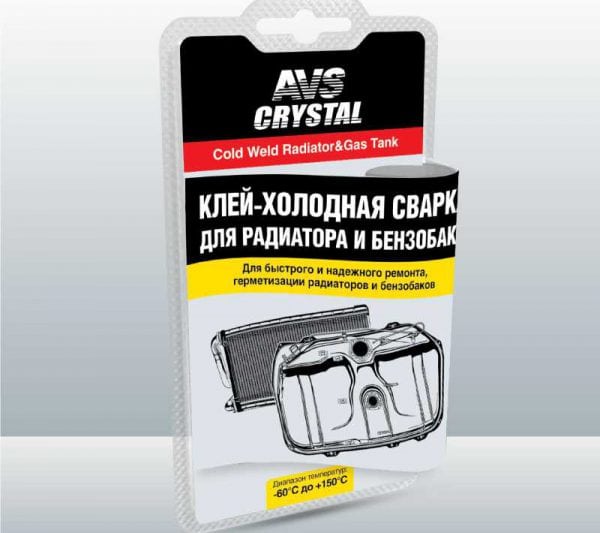

- Cold welding repair. The method is based on the use of special adhesives that melt the edges of the material and tightly seal the crack with a heat-resistant seam. Suitable if the radiator is plastic.

- Use of adhesive sealant. Only very small cracks in plastic radiators can be glued. Like other measures, this is temporary.

An effective remedy for sealing leaks is the 3M DP8005 two-component adhesive and adhesive. The composition contains acrylic, which can glue even the most complex types of plastic, for example, polypropylene. If the radiator bursts, this material will be perfect. The seam created by it does not collapse from the action of moisture, aggressive chemicals, temperature drops. But the price of such a tool is very high (up to 1,500 rubles), so you need to think about the advisability of buying it in comparison with replacing the radiator.

Another glue is Hosch plastic welding.If the radiator is plastic, you can buy the product without hesitation. Pressure up to 12 atmospheres is not a problem for the seam after complete hardening, and with this glue you can glue any defects.

Hydrogen evolution case

When using aluminum radiators, it happens that water decomposes into hydrogen and oxygen components. This process is caused by the fact that the metal builds up a static charge, which is not good. During the production of batteries, the inside of the device is coated with a protective layer. During operation or due to the negligence of production workers, the layer may be disturbed. The result is a very rapid destruction of the radiator by corrosion.

After two years of use, the radiator becomes unusable. It is possible to determine whether hydrogen is present in the system as follows: the constant appearance of plugs, when oxygen has long been displaced from the system and no additional water addition was made, indicates that hydrogen is present in the system. You can verify the presence of gases by turning off the valves that release air, and control using Mayevsky taps. This problem is eliminated only by replacing the radiators.

Expansion tank in the heating system

Boiling coolant

If antifreeze (antifreeze) boils, then make sure:

- Does the radiator fan work and when it turns on - the sensor may be faulty;

- Does the thermostat work - the coolant moves in a small circle constantly, thereby not cooling;

- Is the pump working properly?

- Is the cooling system clogged, including the radiator;

- Is the system airy?

- Is the valve on the lid working properly - the reduced pressure in the system can cause premature boiling of the antifreeze.

As for the airiness, then, for example, in the VAZ 2110, 2111, 2112, from the experience of their operation, the system is practically not airborne due to its special design.

In other cars, when replacing the coolant, an airlock may end up in the stove and, over time, make itself felt by overheating of the engine and a burnout of the cylinder head gasket

It is important to follow the readings of the devices.

Reasons for repair

In most passenger cars, the gas tank is located at the back. The part is shifted to the right side to the lower part of the body. This arrangement is due to the formation of the correct center of gravity.

The main disadvantage of this engineering solution is mechanical damage to the gas tank. Sharp stones can make a serious gap in the case and then it will not be possible to do without repairs.

Also, don't forget about corrosion. European cars undergo special processing, so rust begins to corrode their gas tanks after 7-10 years of operation.

... But it's different with Chinese cars. Until recently, the lower part of the body was not processed at all.

The result of the lack of anti-corrosion treatment resulted in a shorter service life. Moreover, not only the gas tank is susceptible to corrosion, but the entire body. As a result, after five years, most of the cars need serious repairs, and some simply cannot be restored.

With European and American cars, everything is much easier. Their gas tanks undergo special treatment, so repairs in most cases are needed due to mechanical damage.

Important!

In order not to damage the gas tank while driving, try to drive only on good roads. Crushed stone, which is often covered with country roads, can seriously harm the gas tank.

Cracks appear in the tank during the formation of corrosion. Moreover, rust corrodes the part not only from the outside, but also from the inside. If this happens, then the repair will be complicated several times.

Important!

From the outside, moisture acts on the gas tank, from the internal water, which, although in small quantities, is always present in it.Despite the fact that European and American gas tanks are much more reliable than Chinese ones, even they need repairs after many years of use.

The fact is that it is impossible to completely protect the part from rust.

Despite the fact that European and American gas tanks are much more reliable than Chinese ones, even they need repairs after many years of use. The fact is that it is impossible to completely protect the part from rust.

Fortunately, finding out that you have a problem with your gas tank and need repairs is easy enough. A persistent smell of gasoline or diesel fuel will always be present in the cabin. Gasoline will also be consumed faster. In the end, you can just look under the bottom and find a leak.

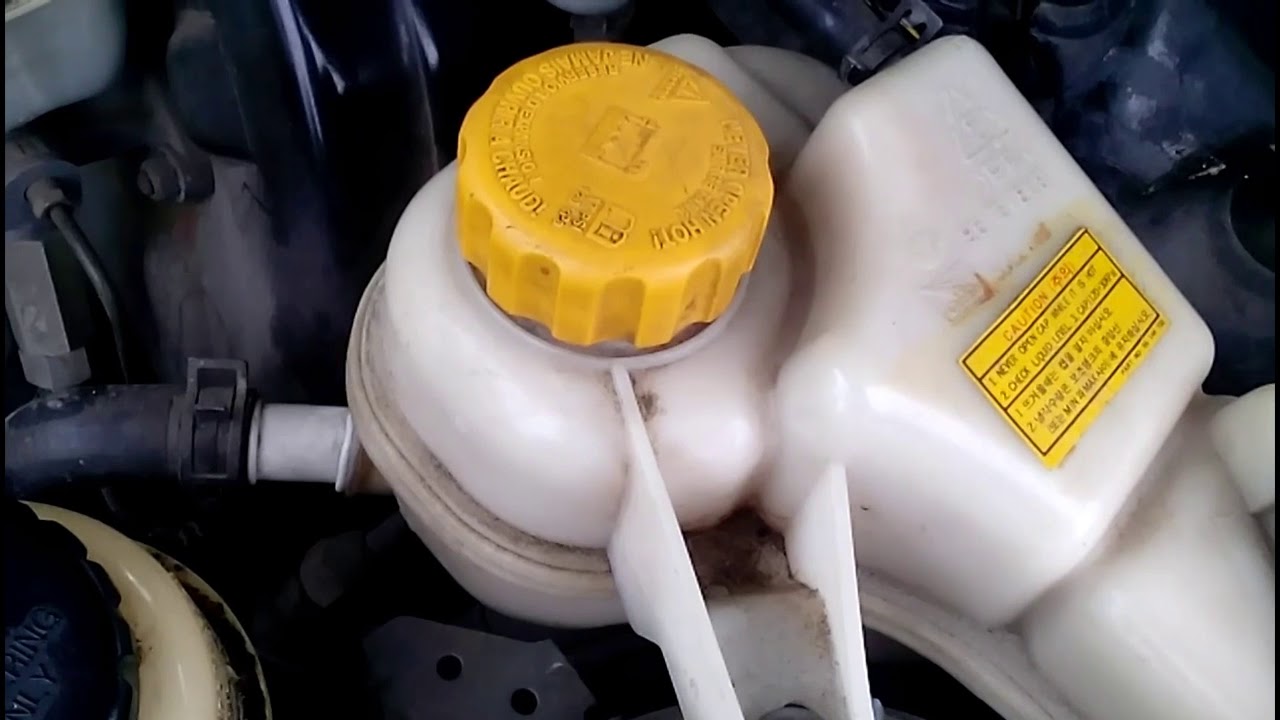

Expansion tank purpose

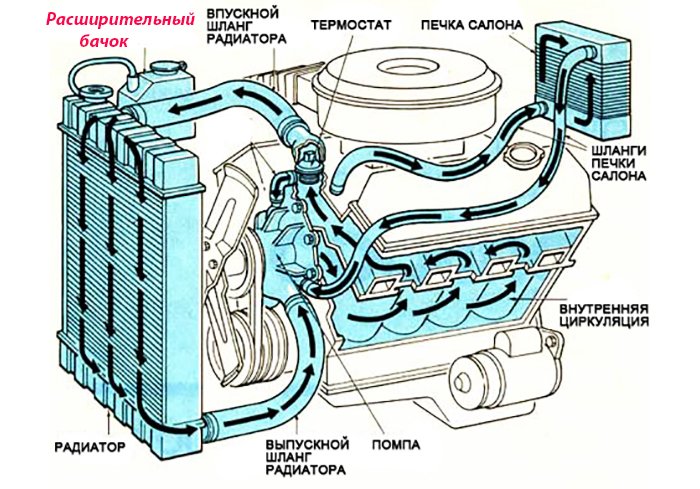

The cooling systems of various cars contain from 5 to 20 or more liters of antifreeze liquid - antifreeze (antifreeze). During operation, the engine, and with it the antifreeze, heats up from low temperature in winter to high in summer.

During engine operation, a pressure of about 1 bar develops in the expansion tank

Since any liquid expands in volume when heated, a surplus forms in the cooling circuit of the car, which needs to be directed somewhere. Antifreeze is an incompressible medium, therefore, when it expands, it will create a high pressure in the system that can rupture the radiator pipes and honeycombs. Conversely, when cooled, the liquid will decrease in volume and create a rarefaction (vacuum), acting with the same force.

To ensure the normal operation of the cooling system of the power unit and to avoid pressure surges, an expansion tank is integrated into it. Its functions are as follows:

- perceive an additional volume of antifreeze that expands when heated;

- relieve excess pressure through a plug with a built-in safety valve;

- give fluid back to the system when the engine cools down, preventing the formation of air locks.

Large expansion tanks are used on trucks

Gases in the expansion tank

The presence of gases in the expansion tank indicates that the cylinder head gasket has burned out. This is one of the main reasons why it can be inflated.

The burnout of the gasket could have occurred due to engine overheating, unless, of course, the time for its overhaul had come, since it was 150-250 thousand km. mileage calculated service life of this gasket.

But there is an important point - the reservoir will not expand if the valve in the roof is working properly, since the excess pressure will still be released, but the engine will overheat. But, if the flow of gases is very strong, then the valve will not have time to release the pressure and the tank will still inflate and even burst.

In order to detect the presence of gases in the cooling system, it is necessary:

- Visually inspect the coolant in the barrel with the engine running and check for the presence or absence of bubbles. If there are bubbles, the gasket is most likely broken.

- A more accurate method is to use a gas analyzer. The device will accurately indicate the presence of gases.

- Apply balloons or analogs (you get the idea). The ball is put on the neck of the tank and tied tightly with threads. You need to start the engine on a cold one, while the heated coolant has not yet begun to expand strongly. If the product inflates quickly, then exhaust gases enter the cooling system, this is possible only through the cylinder head gasket.

- Check engine compression. If the car's mileage is not very high, then the compression should be normal, since the cylinder-piston group has not yet worn out. But if the gasket under the cylinder head is broken, then the compressor will show readings below normal.

You can also check in the area of which cylinder the gasket is punched. To do this, pressurized air into the cylinder through the spark plug hole, while the tank cap must be removed.

If the cylinder head gasket is punctured, bubbles in the tanks and air hiss will be visible.

The pressure in the cooling system is checked with a 3 bar pressure gauge. To do this, you need to make a tee and connect the device to it.

Start the car and observe the readings. Readings greater than 1.5 atmospheres should already be alarming, 2 - not every barrel will withstand.

We glue the burst washer reservoir on the car in stages

Let us consider in more detail two methods for repairing a burst washer reservoir - glue and glueless (soldering).

Method one - using two-component Hosch glue:

- Preparation. Both surfaces to be bonded should be cleaned of dirt with acetone.

- Glue application. The liquid cyanoacrylate component is applied in a thin layer to the crack or hole. On top, add welding granulate from the second bottle and cover again with a small amount of impregnation glue.

- Gluing. The glue seizes almost instantly, therefore, within a few minutes after applying the composition, the tank can be returned to its place and filled with washer fluid.

Do not inhale the vapors generated during the reaction.

VIDEO REVIEW

Method two - soldering:

- The surfaces to be joined must be degreased with acetone.

- We heat the soldering iron to the maximum temperature.

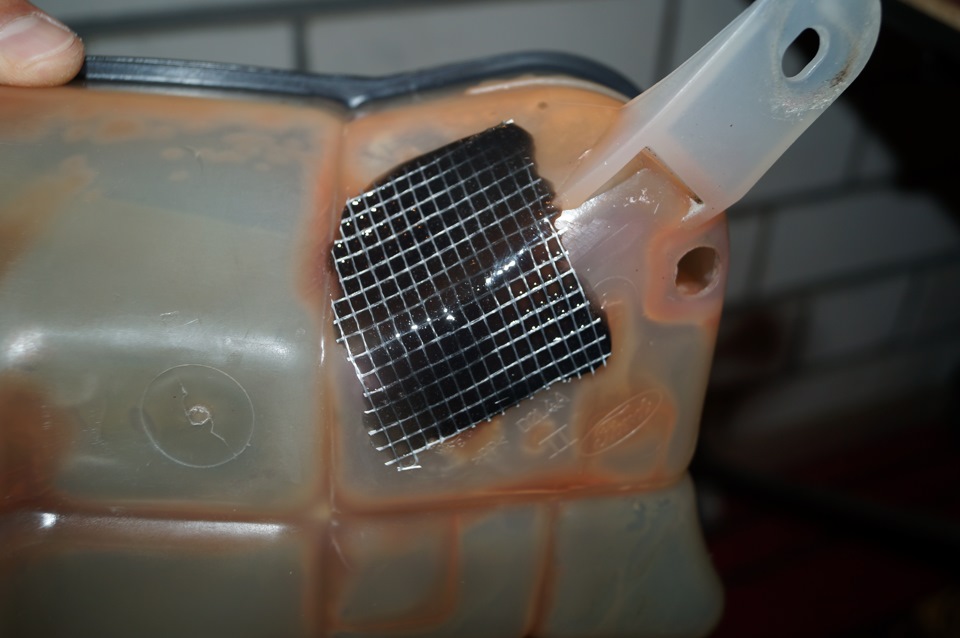

- We apply the mesh over the seam in such a way that the edges of the mesh overlap each side by at least 2-3 centimeters.

- We gradually heat up the metal mesh by melting it into the plastic.

- We smooth out the top layer of polyethylene so that the layer turns out to be monolithic.

- We check the tank for leaks and install it on the car.

When performing work, you should also observe safety precautions. Soldering is allowed only in a well-ventilated area.

Place of the tank in the cooling system

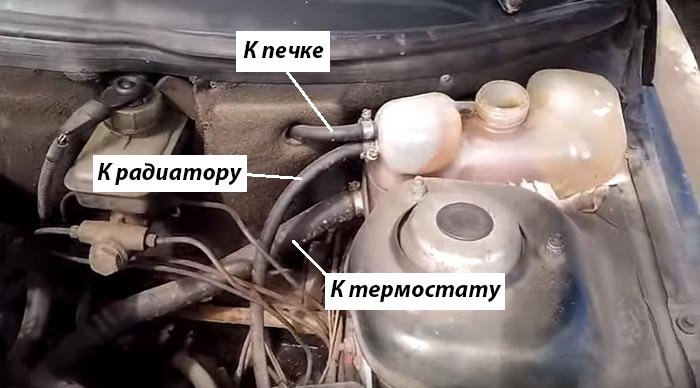

A tank for compensating for expanding antifreeze can be installed in different places, the location depends on the car brand. The reservoir is attached to the body parts - the side members and the interior bulkhead using a rubber clamp or a special bracket. As a rule, the tank is placed on the side where the upper radiator pipe is located for connecting it.

Usually the tank is installed closer to the radiator pipe

There are containers for 2 and 3 fittings. The latter are connected with three hoses to the following units:

- A thick branch pipe connected to the lower nozzle of the vessel connects it to the main line of the cooling circuit - a small circle of liquid circulation, which is always open. The antifreeze that increases in volume enters the tank precisely through this hose.

- A thin tube running from the radiator to the top fitting. Designed for direct discharge of liquid and steam from the radiator.

- The second thin tube, connected to the middle fitting, comes from the radiator of the cabin heater. Its task is the same - the removal of excess antifreeze and steam into the container.

Excess antifreeze from three units is supplied to the tank for 3 fittings

The expansion tank is the highest point in the motor cooling system. This is done so that the liquid from the tank can flow into the circuit according to the law of communicating vessels. When the level of antifreeze in the tank is 3-4 cm higher than the Min marks on the body, all pipes and units are filled with antifreeze. The highest of them is the throttle valve cooling circuit.

Residual air from the system is removed through the throttle heating pipes

The better to seal the washer reservoir

The simplest, most affordable and effective way to eliminate cracks in the washer reservoir is to solder with a soldering iron and a fine metal mesh.

The metal mesh is used as a reinforcing material. It is necessary to eliminate large cracks, if the damage is small, you can do without mesh.

A metal mesh can be found in the car market; it is sold as a reinforcing base for repairing plastic bumpers with 15x11.5 cm sheets. One such fragment costs about 100-150 rubles.

You can also glue the cracked washer reservoir with a special glue.

Suitable for gluing various types of polyethylene and polypropylene, especially strong special glue for plastics DP 8005 3M.

This two-component, acrylic-based structural adhesive is capable of bonding polymers without prior surface preparation.

The glue line formed by DP 8005 3M glue is resistant to water, high humidity and aggressive solutions; therefore, this compound can be used to repair a washer fluid tank.

The only drawback of this glue is its high price (it costs about 1,300 rubles per package of 38 grams), but if it is necessary to repair the tank of a rare foreign car, then such costs can be justified.

- WEICON Easy-Mix for PE-PP is another effective two-component structural adhesive for bonding polyethylene and polypropylene. This special methyl acrylate adhesive has excellent adhesion to low energy polymers (PE, PP and TPE). It sticks together quickly and, as they say, tightly, but it costs even more (about 3 thousand for 38 grams).

- A two-component adhesive-welding for polymers from the German company Hosch will help to repair a rare expensive part.

This adhesive effectively binds holes and cracks in any plastic product. The glue seam retains its elasticity in cold weather, withstands pressure up to 12 atmospheres.

In most cases, the joint is often stronger than the plastic itself. Hosch adhesive is supplied in a set of two complementary components - liquid cyanoacrylate ester and fine powder granulate.

The composition of the welding powder contains metal oxides and catalysts, which accelerate the setting of the glue seam and improve the degree of adhesion. The average cost of a set is 1,500 rubles.

Bonding of plastic parts of a car radiator

Most plastic repair products are two-component - ready-made compounds do not provide such strong adhesion to the surface. How to properly seal the damage on the radiator? Here is the technique for working step by step:

- Prepare both components for welding the seam on the cooling tank, as well as sandpaper, gloves, cotton swabs, degreaser (acetone).

- Clean the area around the leak from dirt, dust, grease, using acetone.

- Mix the glue components as directed in the instructions. Drop the product onto the crack area. Some formulations are applied in a different way. First you need to sprinkle the plastic with a powder, and then cover it with a liquid one.

- If the hole is large, the procedure should be done in several steps until it is completely tightened.

- After 15 minutes, sand the seam until smooth with fine-grain emery paper.

You can also glue the edges of the crack on the plastic using epoxy glue. The radiator is removed, the area is sanded, degreased. The place of damage is poured with epoxy resin, dried for a day. You should not rely on the durability of such a seam - it can hold out for a couple of weeks at most, then you need to purchase a new car part.

Looking for a leak

Loss of the hermetic state of the heating system leads to a loss of pressure. After a complete inspection of the heating device and pipe system, leaks can be detected. Leaks with the naked eye are determined by the accumulation of moisture at the joints or holes with a characteristic white coating.

When examining, it is worth paying attention to the connecting elements, couplings at the soldering points and direct connection to heating devices. A system with metal pipes can leak at longitudinal seams

As soon as the place of the leak is found, it is worth taking care of its elimination. The joints are repacked, gaskets and gland seals are installed, slightly thicker than the previous one. In case of damage to the pipeline, it is necessary to replace the damaged section.

Tools and materials

To carry out this repair operation, you cannot do without the necessary materials and tools.

To carry out this repair operation, you cannot do without the necessary materials and tools.

Before soldering the expansion tank of the car, you must prepare:

- soldering iron with a flat tip, 40 W;

- a piece of fine-mesh brass mesh;

- scissors for metal.

A soldering iron can also be used with a higher power, but then during work you need to be careful so that the plastic material is not pushed through at the soldering points of the metal mesh. The brass mesh can be removed from the car's gas pipe, which is located directly in the tank

This mesh is used in the vehicle power system as a filter. Once leveled, it can be used as a reinforcing layer to seal expansion tank leaks.

The brass mesh can be removed from the car's gas pipe, which is located directly in the tank. This mesh is used in the vehicle power system as a filter. Once leveled, it can be used as a reinforcing layer to seal expansion tank leaks.

After the preparatory work is completed and the place of the antifreeze leak is established, the tank is thoroughly dried in order to remove the remaining moisture.

How to seal the crack?

It is not recommended to use even high-quality glue for such a do-it-yourself car repair.

It is not recommended to use even high-quality glue for such a do-it-yourself car repair.

High humidity, temperature and significant pressure do not allow for a high-quality repair of the expansion tank using such substances.

It is much more reliable to eliminate the tank leak by soldering. Plastic is easy to melt even at relatively low temperatures, so you can use a regular soldering iron to perform the operation.

The soldering process is carried out in the following sequence:

- The tank is placed on a flat surface with a crack up.

- The soldering iron heats up to operating temperature.

- A metal mesh, which must be cut in advance so that its length and width are slightly larger than the crack, is applied to the damaged area.

- With a soldering iron tip, the mesh is soldered into the plastic along the entire length of the crack.

The leak must be eliminated immediately.

If you find a fuel leak in the area of the gas tank, you should stop using the vehicle for the sake of your safety and those around you. Repairs should be carried out on a removed and thoroughly rinsed container. Thus, it is possible to conduct a complete revision of the product that has broken through and pinpoint the location of the problem area. Most often, these are longitudinal cracks or destruction of the welded seam connecting the elements of the fuel system, which is a consequence of mechanical impact from the outside.

Tank preparation for repair includes a number of operations:

- Draining fuel. There is a drain neck at the base of the gas tank; by twisting the lock plug from it, you can drain the fuel;

- Washing the container. At home, caustic soda is used for washing, using it in the proportion - two glasses per 10 liters of warm water. The mixture is poured into the tank and infused for at least 5 minutes, after which the container is shaken and the liquid is drained. The procedure is repeated at least 3 times;

- Drying. This operation must be carried out very carefully. It can be done naturally, but it will take a long time. It is better to use an industrial hair dryer, thus ensuring the effect of a pressure air blow.

Tank filling fluids

Today's cars, built with the widespread use of new technologies, are very demanding on all process fluids, including cooling. The list of requirements is as follows:

- the liquid should boil at a temperature not lower than 110 ° С;

- freezing threshold - from minus 20 to -60 ° C, depending on environmental conditions;

- no foaming on contact with the pump impeller, minimum viscosity;

- the composition of the liquid should contain non-aggressive additives that prevent the appearance of scale on metal parts;

- the chemical composition should not change within 3 years or 60 thousand kilometers.

Antifreeze is a purely domestic product, synthesized during the Soviet era

All these requirements are met by antifreeze or antifreeze, which is the same thing. The name antifreeze comes from the English word antifreeze, which means “non-freezing”. Antifreeze is a substance created on the same basis from ethylene glycol in the former USSR. The word consists of the abbreviation TOS (technology of organic synthesis) and the ending "ol", inherent in the names of chemical preparations.

The basis of antifreeze and antifreeze is the same - water + ethylene glycol in different ratios. Differences between products from different manufacturers may consist in a package of inhibiting additives, so it is undesirable to confuse fluids. Fatal consequences will not occur, but some substances can neutralize the action of others and the properties of "non-freezing" will deteriorate. In this case, the color of the liquid does not matter - it is just a dye.

Distilled water can be used to fill the tank in the following situations:

- for diluting the antifreeze concentrate to the required freezing point;

- in case of an emergency - complete or partial loss of coolant along the way;

- for the purpose of flushing.

The color of the antifreeze does not affect its properties, the additive package is important

Distilled (demineralized) water does not meet the above requirements: it freezes at zero temperature and boils at 100 ° C. Therefore, it is poured temporarily or as a solvent for antifreeze.

Tap water saturated with salts must not be poured into the expansion tank. An exception is a breakdown and loss of antifreeze on the way and the absence of a nearby auto shop. Repair the leak, fill the cooling system with tap water and get to the garage or service station, then drain it immediately. Otherwise, deposits will form on the inner walls of the water jacket of the engine and other units, impairing heat transfer.

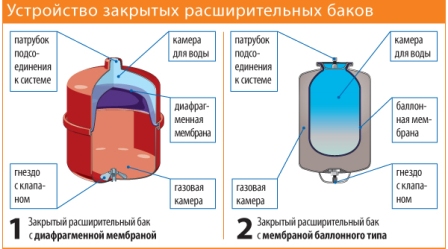

Membrane replacement process

If the diaphragm is worn out, the following types of work should be performed:

- disconnect the tank and drain;

- relieve pressure with a nipple;

- in the place where the pipeline is connected, there is a membrane. The membrane flange is dismantled. After the holder is released;

- the membrane is removed;

- the inner surface of the expansion tank is checked for dirt and rust. If necessary, flushing is carried out;

- you need to know that the membrane is sensitive to oils. So it is unacceptable to use them as anti-corrosion agents on the inside of the case.

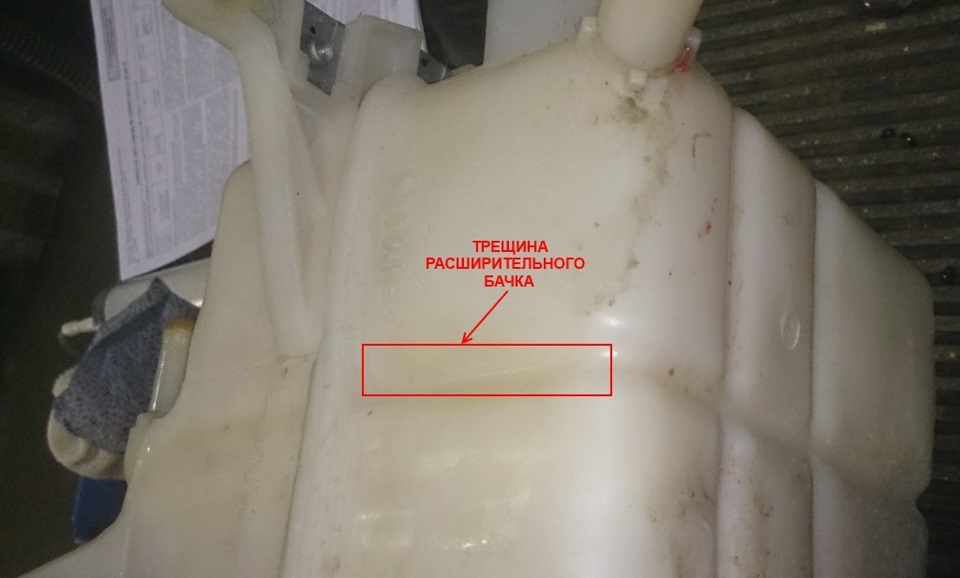

About malfunctions and tank repair

During the operation of the machine, the following breakdowns of the expansion tank may occur;

- contamination or failure of the plug bypass valve;

-

rupture of the tank body;

-

leakage of antifreeze from under the lid.

Most motorists, when a valve or body breaks down, simply change the part to a new one. This is justified by the lack of time for repairs and the cheapness of these spare parts. Although, if desired, the burst plastic of the tank can be sealed, and the lid can be disassembled and cleaned.

Leaks from under the cork occur with a loose fit or due to the design features of the container. For example, on VAZ 2110 cars, the jet from the upper small fitting connected to the radiator hits directly into the throat, which causes a leak. The way of elimination is the installation of a more perfect reservoir from "Priora".

Video: tank housing repair

The expansion tank of a car is considered one of the most reliable parts. Often they serve the entire life of the car, especially on foreign cars. In order not to have to change the container ahead of time, it is recommended to periodically check the condition of the valve in the lid. If it is in order, then the plastic of the vessel will not burst from high pressure.

Home →

Maintenance and Repair → Repair →

Expansion tank cleaners

For cleaning and washing RB, motorists use various means - cleaners, solvents, citric acid, washing powder, etc.

If the level of contamination is so high that nothing helps, you can try the following.

- Fill the tank 15% with fine gravel.

- Pour half of warm water into the tank and add dishwashing powder.

- Shake the tank with both hands.

- Empty the tank and rinse it with water.

The tank should be cleaned.

You can use ready-made products such as DIMER wash concentrate.

In this case, cleaning is carried out as follows.

- Fill the tank 15% with DIMER concentrate.

- Shake the tank by tapping on its body with your hands and leave for 10 minutes.

- Fill the tank halfway with warm water.

- Use a long-handled brush to clean the inside of the tank.

- Pour out the solution and rinse the tank with warm water.

DIMER Concentrate is quite effective when cleaning the expansion tank

There are many other ways to clean up RB.

Video: flushing and cleaning the expansion tank

A serviceable and clean expansion tank is an important element of the engine cooling system.

Any of its malfunctions can be easily diagnosed and eliminated by hand.

To do this, you just need to carefully follow the recommendations of specialists.

Do-it-yourself expansion tank repair

During operation, the expansion tank is constantly affected by deformation: the capacity narrows and expands due to temperature changes - this is the mode of its operation. At peak values, cracks appear on the walls of the tank. The problem can be solved in two ways: buy a new tank or repair the old one.

Expansion tank crack

The material used in the manufacture of expansion tanks does not react with any adhesives, regardless of brand. This suggests that it will not be possible to repair the tank qualitatively by gluing. Those car owners who decide to restore capacity usually resort to the following methods:

- solder the cracks of the case using a metal mesh;

- use epoxy resin, special sealant or cold welding.

Due to the constant impact on the expansion tank of high pressure and temperature, cracks appear on the vessel over time.

It is worth noting that cold welding and epoxy fix the problem only temporarily and you will still have to return to repair or replace the tank. Some motorists are wondering how and how can the cracks in the plastic housing of the expansion tank be repaired? To carry out the procedure at home, you should:

Some motorists are wondering how and how can the cracks in the plastic housing of the expansion tank be repaired? To carry out the procedure at home, you should:

- clean the case in the place of the crack with a clean cloth or napkin;

- degrease the area with a solvent, then dry;

- cut a piece of brass mesh with small cells along the length of the damage;

- apply a strip to the repair site;

- with a heated soldering iron, solder the mesh to the edges of the crack so that a reinforced layer is formed over the entire area of the mesh;

- grind the seam;

- apply a putty, a layer of primer and paint.

The most common and affordable way to restore the expansion tank is to solder using a fine metal mesh.

This procedure requires a soldering iron with a minimum power of 40 W with a flat tip. You can restore the tightness of the tank using the special red Done Deal sealant, which is designed for plastic. Before applying the substance, the body is thoroughly cleaned and degreased.

Outcomes

As you can see, it doesn't matter at all where you are.Gas tank repair can be carried out even in the field

For this, there are enough available tools like laundry soap or a plastic bottle. Even simple glue can be a good sealant if you find an unnecessary rag.

Many modern vehicles are equipped with plastic elements in their design. There have been attempts to produce completely plastic-based bodies, but due to globalization, automakers continue to stubbornly use metal as the basis for their production. But some automotive plastic parts are gradually replacing conventional metal products.