Which glue to choose?

When choosing an adhesive to fix a hole in a chamber, it is imperative to analyze the situation and determine the most effective option. According to its properties, glue can be divided into four categories:

- per diems, which require holding the patch under pressure for 24 hours;

- assembly - ensure complete drying after 5-12 hours;

- fast-acting - guarantee the possibility of using the glued surface after 30 minutes;

- instant action. The glue of this group is quite convenient to use, since it provides for application on one surface and does not require drying time before gluing.

Tire puncture reasons

Damage to the rubber tube of a car or bicycle - puncture, cut or even tear - can be done when you run over objects lying on the road. Usually the cause of the problem is nails or self-tapping screws, pieces of sharp, strong wire. Thanks to careless people throwing bottles on the road, broken glass can ruin the wheel. It also happens that other iron parts that have come off the vehicles are in the driver's path.

Because of this "variety" there is a risk of finding yourself with a damaged tire even on the track, so it is better to always have a minimum rubber repair kit on hand. Most often, motorists who drive around on old, worn-out tires, or those who have purchased a low-quality product, encounter trouble.

This is interesting: How and how to properly glue a foam ceiling plinth - a step-by-step description of the methods: we study in general terms

What to do if the camera still lowers after repair

- The air continues to poison from under the patch. If you find this in one of the ways already described, you will have to do it all over again: remove the bicycle tire and stick the patch again;

- Check if there are any other punctures that are not as significant as the one already sealed? If there is, then they need to be glued;

- Air leaks at the nipple. They can be detected by applying a soap solution to the nipple. If characteristic bubbles are found, tighten the nipple with a wrench;

- The destruction of the metallized cord on the tires is great. The problem can be solved by replacing the tire. No amount of pulling the cord helps. If a bicycle tire is not replaced, tire punctures and sticking will occur regularly.

Dismantle the wheel

First, carefully remove the damaged camera wheel. This can be done easily according to the following scheme:

- Release the brakes slowly, smoothly. Be sure to remove the rims as they will interfere with the puncture finding process.

- Flip the bike.

- Unscrew the eccentrics or those bolts that hold the wheel to the hub.

- Remove the wheel itself and set it aside. If it goes tight, roll a little towards the seat and, lifting the edge slightly, pull it towards you.

The bicycle wheel is now completely ready to glue the tire.

Removing the camera

One of the hardest things to do is taking pictures of the camera itself. The easiest way to dismantle it from the wheel is by using a bead. If you do not have such a useful tool for repairing a bicycle yet, then take a regular screwdriver.

First, you need to completely lower the chamber by unscrewing the nipple valve. If you have a progressive bike, you will most likely have to pull out the groove in the cap. Cheaper models have a fairly tight spool.

Sometimes it is better to deflate before removing the wheel so that the rubber does not cling to the frame and brakes.

We turn the wheel over so that the nipple is at the back. Next, we insert the ends of the bead in such a way that the first end goes between the rim and the tire, but does not touch the camera at the same time.The second end of the mounting must be inserted in the same way, departing from the first at least 10 cm.

Further, the dismantling acts as a lever, with it you lift the tire by pulling it towards you. When the rim comes out over the edge of the wheel, grasp it with your hands. As a result, the bicycle tube is released and ready for the gluing process.

Looking for damage

The next step is to search for damage. This process is quite interesting, especially if you look for a puncture visually. Often it is almost impossible to determine the problem area by eye, since it is not visible, but the air continues to escape.

One of the most common ways is to find a puncture with a basin and water. We simply dip the tire into the water and see where air bubbles appear. The method is good for its simplicity. After that, the tire must be dried, wiped dry, otherwise the glue simply cannot take the patch.

You can find damage by hearing: pump it up well and, spinning the rubber in a circle in front of the ear, listen to exactly where the air comes out. This method is good in the field, when there is definitely no basin of water nearby.

Note! If the damage is located around the valve, then it will not be possible to simply glue the damage. You will have to resort to the vulcanization procedure (more about it below)

Glue

We proceed to the very process of gluing the bicycle tire. To do this, we clean the place of repair with acetone or gasoline. This is done in order to degrease the surface, so the adhesion of the patch to the tire will be more reliable, and it will be easier to glue it.

Next, we take sandpaper, lightly rub it over the entire surface. This is not necessary, but desirable, as it helps to seal the puncture even better.

It is necessary to remove the protective film from the patch, apply glue to the patch, and then firmly press it to the puncture site with a vice and hold it for a while. For a good glue, five minutes is enough. If you use the usual "Moment", and not a special glue for rubber or leather, then in order to glue the tire, you need a certain time. How much is required exactly, you can read on the instructions for the tube.

Putting it all together again

After the patch has been applied, do not forget to pump up the bicycle tube again to check how well the rubber was sealed. Is the tire deflating again?

Before reinstalling the tube, check if the tape inside the rim is intact. It is not secured, so you can move it while removing the camera. After checking, carefully put the camera back using the bead, making sure that there are no kinks. The tire should fit snugly, flat on the rim. Inflate it slightly so that the tire does not immediately stick to the rim.

After installation, we pump air into the tire until it stops. We put the wheel in place, securing it with bolts to the hub.

Anti-puncture tape - the feasibility of its installation

In stores you can find such a "device" for the wheels, as anti-puncture tape. It will protect the bike camera from unexpected punctures and cuts, and this, in turn, will prevent forced stops during a walk / hike and wasting time looking for damage, removing and installing the wheel.

In order for the anti-puncture tape to fully fulfill the declared functions, you need to be able to choose it - the main thing is to choose the right width of the tape. If you make a mistake in this choice, then the following can happen:

- if the tape is wider than the bicycle wheel tube, then this will lead to rapid abrasion of thin rubber due to constant friction against the wheel rim;

- if the tape is narrower than the chamber, then the puncture can occur in a place that is not covered by the device in question.

In addition to the fact that you need to be able to choose an anti-puncture tape, you need to be able to install it - it is unlikely that you will want to contact service centers with such a "trifle"

Yes, and this work is simple, does not require any specific knowledge - it is only important to adhere to the recommendations of specialists

Installing an anti-puncture tape with your own hands:

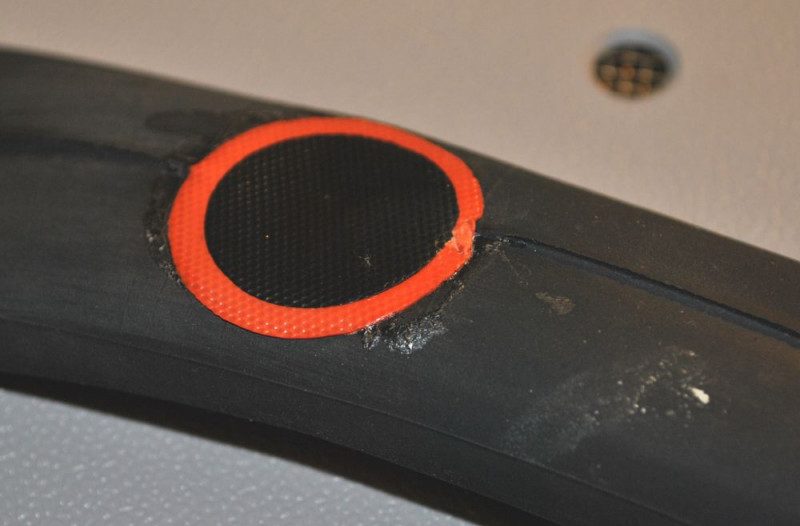

- Check the purchased anti-puncture tape - it must be of the required width. This can only be done by applying the tape to the camera.

- We disassemble both wheels. In order to remove the camera, it is not at all necessary to completely remove the tire from the rim - you can partially leave it in place.

- Before applying the anti-puncture tape to the camera, it is necessary to round off its edges with scissors.

- Now we lay the anti-puncture tape along the inner side of the tire, carefully pressing it against the rubber with our fingers.

This completes the work on ensuring the protection of the bicycle tube from punctures.

You can easily and quickly glue the bike camera with your own hands and at home. By and large, you don't even need to have a specific tool available for this.

Alternative repair versions

Did the puncture trouble catch you off guard? Are there no tools nearby? How to glue the tire in this case? You can do with any rubber pads and ordinary glue that is capable of gluing such material. Only industrial pastes that harden quickly in air can be considered unsuitable adhesives.

No glue

The hole can be repaired without glue. This is a case of extreme situations when, apart from household items, there is nothing at hand, and there is nothing to glue it with. For example, a cyclist rode out of town. How do you get home in this case? You can use physical laws and a regular plastic bag. Place polyethylene soaked in water over the puncture site. Inflate the tire vigorously. The air will press this simple patch so hard that the bicycle wheel will be as good as new for a while. The main thing is not to give it too strong a shock load and beware of bumps.

Advice! Clean the surface as much as possible before such an impromptu repair

It is important that there are no gaps between the polyethylene and the camera.

Curing

Another method of bonding the patch and the tire is vulcanization. This method is usually used for repairing car tires, but it is also suitable for a bicycle. The point is to create maximum heating of the tire and patch, in which they will simply fuse into a single whole. Any rubber can be glued in this way.

Vulcanization is the safest way to repair a leaky bicycle tire, but also the most time consuming. For it you need special tools: vulcanizers. They are purchased at auto parts stores or at construction sites. The vulcanization method is dangerous only because you have to work with an open flame.

Take note! There are household vulcanizers made by craftsmen on their own. They represent a hollow all-metal cylinder and a large crossbar on supports, pressing this makeshift "oven" to the patch. Small wood chips are stored inside the cylinder, set on fire, and a household vulcanizer begins to heat up the patch.

How to glue a car camera: procedure

To repair a wheel at home, you need to get a piece of old rubber. You will need high-quality glue, for example, "Moment" or another that is suitable for rubber products. Also, to fix the problem, you should prepare:

- medium grain sandpaper;

- a container with water (even a puddle is suitable on the road);

- a piece of soap;

- scissors;

- solvent or other liquid for degreasing;

- pump.

To repair cameras in any car store, you can buy a ready-made kit, however, its price will be higher.

Finding the site of damage

After a wheel puncture, a side cut, a shallow or deep crack, or a puncture may form. Such defects lead to a violation of the tightness of the product. Air begins to escape through the hole, the chamber is deflated.Finding a puncture site is sometimes difficult, especially in wet weather when the tires are dirty. Most often, the defect is formed at the "contact patch" - where the wheel comes into contact with the road. It is located no higher than 2/3 of the total height of the camera.

Less commonly, rim damage associated with deterioration of the rim tape occurs. Another possible problem is a tube burst from the crawled out iron threads of the tire cord. You can find the location of the defect using different methods. First, you need to get the camera using any non-sharp object or a special tire changer. After it, it is necessary to visually inspect for the presence of holes. In the absence of a result, you can use the following techniques:

- Submersion into the water. Put the camera in water, even a small container will do. Rotate the product in water until the emerging air bubbles are visible - this is where the puncture site will be. This method is even more effective when the water is soapy. Large car cameras can simply be lubricated with soapy water.

- Fine dust. This is usually found on roads in dry weather. It is necessary to bring the camera to the dust, press firmly on the product. When a trickle of air begins to emerge from the damaged area, the dust will scatter.

- Hand. In calm weather, you can simply hold a wet hand at a distance of 1-2 cm from the camera surface. This is enough to feel the breath of air from the hole. To increase the effectiveness of the method, you can involve an assistant who will press on the camera.

- Sound. If it is quiet outside, in the garage, you can hear the sound of air coming out (a slight whistle) from the puncture. First, the wheel should be inflated to maximum elasticity.

After identifying the hole, it must be carefully marked with a ballpoint pen. Then you can start repair work. Similarly, it is possible to repair other rubber inflatable products, such as a tubing for riding.

Patch

Applying a patch is a simple process. To properly prepare it, you need to take a piece of rubber (an unnecessary car camera or one taken from a cheesecake sled will do), cut an oval or round piece with scissors. The size of the patch should not be large, only covering the hole by 15 mm on each side.

Next, you need to sandpaper the place where the patch is applied, as well as the cut out element itself. So the adhesion strength of the parts will be better. After that, it is necessary to degrease both surfaces with acetone, alcohol.

Pasting the damaged area

Having prepared high-quality glue, you can start working with already degreased surfaces:

Apply glue to both substrates

Carefully smooth the adhesive layer with a small spatula, let dry for 3-5 minutes. If indicated in the instructions, carry out another layer on top of the first. Do not make a glue seam that is too thick, this can spoil the quality of the finished product.

Press the camera and the patch together. For a tighter fit of the part over the entire plane, the camera must first be laid out on a table, on another flat surface. After gluing, the patch should be at the top. Take a hammer, tap from the center to the edges of the patch with spiral movements so that the element sticks more securely. It is enough to go through the patch 3 times

Do not make a glue seam that is too thick, this can spoil the quality of the finished product. Press the camera and the patch together. For a tighter fit of the part over the entire plane, the camera must first be laid out on a table, on another flat surface. After gluing, the patch should be at the top. Take a hammer, tap from the center to the edges of the patch with spiral movements so that the element sticks more securely. It is enough to go through the patch 3 times.

After complete drying, you need to put the tube back into the tire, inflate it, return the wheel to its proper place.

Step-by-step instruction

Certain tools and materials will come in handy when fixing a bicycle tube.Before work, you need to prepare everything

Particular attention should be paid to the adhesive. Only then can you start disassembling the bike and fixing the problem.

A step-by-step master class explaining how to seal a bicycle tube correctly consists of the following steps:

- dismantling the wheel;

- removing the camera;

- search for the puncture site;

- gluing;

- assembly.

Selection of materials and tools

For repairs, you will need the following kit:

- A set of adhesive patches for a bicycle camera - sold in specialized stores.

- Plastic tool for dismantling and assembling the wheel. It is better not to use a screwdriver or wrench, they can damage the rim.

- Medium rough sandpaper.

- Pump.

- Chalk to mark the puncture site.

A set of patches, bicycle assemblies

A set of patches, bicycle assemblies Medium abrasive sandpaper

Medium abrasive sandpaper Pump

Pump

The main point is the right glue. In this case, it must be plastic after drying, so that during operation there is no divergence of the repaired areas.

There are several options for glue for rubber. The most popular are:

- "Moment" - budget composition, full bonding is achieved in 24 hours;

- special glue for Red Sun bicycles - works in 15 minutes;

- Tip Top SC 2000 is the most reliable two-component product and takes 2-4 hours to dry.

Moment

Moment Red sun

Red sun Tip Top SC 2000

Tip Top SC 2000

Removing a wheel

Camera repair begins with dismantling the wheel. It is quite simple to do this according to the following algorithm:

- Disconnect the rim brakes;

- if the wings interfere with disassembly, they must also be removed;

- put the bike with the wheels up;

- remove the wheel by unscrewing the mounting bolts.

Removing the camera

Dismantling the camera is the most difficult stage. You can do this with a beveler or a regular screwdriver. First you need to deflate the wheel by unscrewing the nipple valve. Sometimes this process is performed before removing the wheel.

The wheel should be gripped so that the nipple is at the back. One end of the bead is inserted between the tire and the rim. Second - at a distance of 10 cm and more from the first in the same way. Then, pulling the bead like a lever, you need to raise the tire. The rim should slide over the edge of the wheel, you just need to free it with your hands.

Search for damage

At this stage, the damage itself must be found. There are several ways. The most popular ones are:

- Place the camera in a bowl of water. Air will escape at the puncture site, forming bubbles. The easiest way, after which the tire must be thoroughly dried.

- Inflate the tire and listen to where the air comes out.

- In some cases, it is sufficient to inspect the camera well. This method is the least accurate, as the rest of the punctures can be overlooked.

- Apply soap solution to suspicious areas. Where there is damage, bubbles will appear.

The detected puncture site must be marked with chalk. It is definitely worth inspecting the tire from all sides, whether there are any foreign objects left there. If there are any, they must be removed before gluing.

Bonding and assembly

Before you glue the bike camera yourself, you need to degrease the damaged area. For these purposes, use gasoline, solvent or alcohol. Then it is recommended to sand the surface with emery paper for better adhesion of the adhesive and the patch.

The required amount of glue is applied to the patch, then it is firmly applied to the tire and pressed. Keep in this position for some time so that the glue sets. If necessary, the treated area is fixed with a load and left for several hours. Then you need to check how successful the repair was. To do this, the camera on the bicycle is pumped up and checked to see if air is escaping. If all is well, the tire is deflated and ready for assembly:

- the camera is neatly installed on the rim using the "mounting" - the tire should fit snugly;

- air is pumped into the tire;

- install the wheel in place by bolting.

Bicycle Camera Glue

When there is nothing to replace the punctured camera with, or you simply do not want to spend money on buying a new one, then glue and a rubber patch will come to the rescue.

Moment

"Moment" is the most popular clay on the domestic market, which is considered universal. He is able to work with many materials: to glue both homogeneous surfaces and in various combinations.

The manufacturer claims that all varieties have basic characteristics: for all surfaces (unless otherwise specified), water resistance, long shelf life and preservation of properties after freezing of the glue).

There are a sufficient number of "Moment" varieties suitable for repairing bicycle cameras:

- "Moment-1" is a universal glue, mainly used in everyday life. The advantage of this quality product is its low cost and the variety of its applications.

- "Crystal" is another variety. The polyurethane compound also provides reliable adhesion to surfaces. The main difference is that it leaves no traces.

- "Rubber" is a specialized glue. Glues homogeneous rubber surfaces, as well as in combination with others: leather, wood, metal, concrete. Additional components of this agent increase the tensile strength characteristics.

- "Extra" is the most common. Its low cost and universal application allowed this product to "settle" in almost every home.

- Other types: "cork", "carpenter", "moment of 60 seconds", etc.

Since the conditions in which the bicycle tube is used require the use of adhesives that can withstand tensile loads, be moisture-resistant and heat-resistant.

Note! To a greater extent, this is answered by "Rubber", but others: "Crystal", "Moment-1" and "Extra", are quite suitable for repairing a punctured camera. The glue of instant fixation, although it will quickly glue the patch, and at first the camera will not release, but with further use, due to the lack of elasticity, it may not cope with its task.

Red sun

The RedSun repair kit is irreplaceable on the road. RED SUN Sanglee Industry Co. Ltd, Taiwan. If on the way there was a nuisance in the form of an unexpected puncture, then this set will greatly help out the cyclist.

The Redsun kit includes 30-40 patches and glue. According to the reviews of cyclists, glue is practically not needed, which cannot be said about patches. They are rectangular pieces of rubber, protected with foil on the adhesive side.

It is a pleasure to use them - after finding the puncture site, the place is cleaned, and without applying glue to it, the Redsun patch is pressed. After a couple of minutes, the camera can be mounted back.

The glue from this repair kit is not used in practice, so the adhesive applied to the patch is quite enough, and the additional glue only increases the repair time. The patches glued in this way adhere very well and after a long time it is difficult to tear them off the bicycle tube.

By purchasing the RedSun kit, the cyclist provides himself with patches of bicycle cameras for a long time.

Tip Top SC 2000

Tip Top SC 2000 is one of the best solutions for bike camera problems. It is elastic, holds heat well, does not lose its properties for a long time (up to 4 years), and most importantly, the glued products can be used in two hours.

The composition of this glue consists of two components, allowing it to be used in places with increased stress.

In order for the result of using Tip Top SC 2000 to be positive, it is necessary to follow the recommendations for its use:

- Use at temperatures from 10 to 25 ° C.

- Avoid direct sunlight.

- Surfaces must be polished and degreased.

Note! A small amount of glue is mixed with a hardener (4% of the amount of glue). The greatest effect will be achieved if the glue is applied in two layers.

Adhesives of other brands

The domestic market offers a huge amount of this product, which many have never heard of. But this does not mean that you should not trust this product. They cope with their task no worse than others.

Here are some of the manufacturers:

- "Rogena", Moscow.

- Novbytkhim, St. Petersburg.

- St. Petersburg Household Chemicals Combine, Russia.

- ANAES, St. Petersburg.

- Barnaul chemical plant, Russia.

- Voronezh PO Impulse. Russia.

- Nova Roll Co. Ltd, Germany.

- Loctite, Deutschland GmbH, Germany "HI-TECHO"

- Loctite Co. Ltd, Ireland.

- JSC "Era", Tosno, Russia.

- Abro, USA