Description and properties

Moisture-resistant grout for joints is an environmentally friendly material, which is presented in the form of a dry construction mixture. It can be cement, epoxy, and each of the above options does an excellent job of sealing. Grouting is necessary not only for aesthetic reasons, but also so that the surface on which the tiles are laid is frequent, without mold and mildew.

Moisture-resistant cement-based grout is in great demand due to its low price. The composition contains not only cement, but also inorganic pigments, additives to improve the properties of the mixture and plasticizers. It is very simple to use them, so even an amateur can cope with this task.

Everything based on cement is divided into two types - for sealing joints from and up to 5 mm. On sale you can see dry and ready-made sealants. The latter cannot boast of their practicality, because over time the grout changes its properties.

In the photo, cement grout for tiles in the bathroom

The advantages of cement grout include: ease of preparation and use, frost resistance and affordable price. The disadvantage is the impossibility to withstand aggressive liquids and moisture, mechanical phenomena and not a wide selection of shades.

Epoxy

In the manufacture of this type of moisture-resistant grout, a resin was used, which contains a hardener and fillers. They are necessary to obtain the desired shade. They are used for sealing joints not only for bathtubs, but also for kitchens and heated floors. The grout has a high viscosity, ease of use.

In the photo, epoxy grout for tiles in the bathroom

And after grouting, the seam turns out to be smooth and elastic. The epoxy mixture is used in a room where there is high humidity.

The advantages of the material include:

- resists moisture, chemicals and mechanical influences;

- high strength;

- resists mold and mildew;

- long service life.

On the downside, epoxy sealant is very expensive. This is the only drawback of the material.

Silicone

Silicone waterproof grout is an elastic material that has stretchable and compressive properties. And thanks to this, flexibility and plasticity are achieved. You can use a silicone-based sealant at home when the amount of work is small. The sale of material is carried out in tubes and cartridges.

In the photo - silicone grout for tiles in the bathroom

The advantages include: high adhesion, resistance to the influence of water, ease of application and a wide range of shades. The disadvantages of the material include the short service life of the grout.

There are several types of seams in the bathroom, between which you need to put a protective sealant.

They are conventionally divided into 3 types:

- Seams between individual tiles. However, such processing requires the use of more material and time. The less tiled layouts are done, the more effort must be made to seal them. Especially demanding for grouting mosaics.

- The joints between the bathroom and the wall surface. To prevent the liquid from penetrating into hard-to-reach places under the bathroom, this space must be treated with a sealant.

- Seams that are between skirting boards, borders and fillets. Sealing the space between these elements and the finish is important to prevent water seeping in and mold forming.

On the video rating of grout for tiles in the bathroom:

When choosing a moisture resistant sealant for a bathroom, the following parameters must be taken into account:

- Resistant to water.

- Shrinkage degree.

- Strength indicators.

- Moisture absorption rate.

When buying a waterproof grout sealant, consider the shade as well. It should match the color scheme in the interior and the color of the tiles. Today, there should be no problems with this, since waterproof grout is present in a wide range in terms of color design.

What is the best moisture-resistant grout for joints, this article will help you understand.

But how you can replace the grout on the tiles in the bathroom and whether you can do it yourself and how, this article will help you understand.

But this article will help you understand what litokol epoxy grout is and in what cases it can be used:

But how it is used and where exactly the grout for ceresit ce 33 joints is used can be seen in the photo in this article.

Tile grout: famous brands

Along with the aforementioned companies producing high-quality grouting mixtures, other well-known brands are equally popular.

Brand # 1: Atlas

The competition between the German Ceresit grout and the Italian Mapi is made by the products manufactured by the Polish concern Atlas.

Craftsmen love to work with Atlas building materials as they are easy to mix and apply to tiled surfaces. After drying, the grout does not crack and does not spill out of the tile joints.

The plastic mortar does not scratch the edges of the tiles; it fills narrow joints that do not exceed 6 mm in width without any problems.

Dry grout for tile joints from the Atlas company occupy a worthy place in the building materials market, second in popularity only to the promoted brand Ceresit

Brand # 2: Kiilto

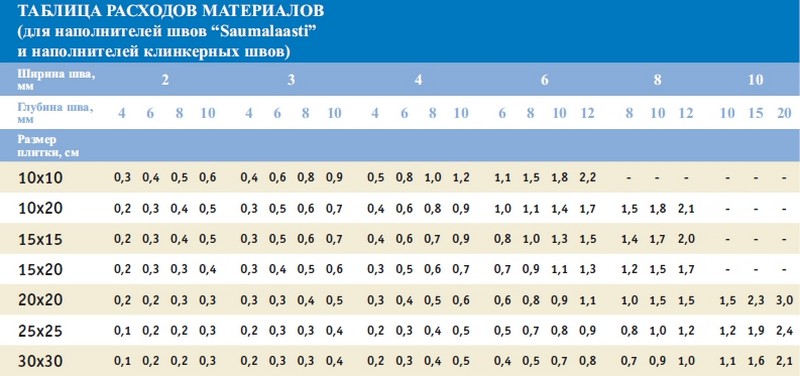

Finnish cement-based grout Kiilto Saumalaasti is intended for sealing the joints between tiles for wall and floor cladding.

The mixture can be used to fill joints with a width of 2 to 6 mm. The mixed solution remains viable for 2-3 hours. Differs in heat, frost, water resistance. The color gamut has three dozen basic shades that can be mixed and new colors can be obtained.

Kiilto high quality epoxy grout is designed for filling the joints between ceramic tiles by professional tilers who are skilled in working with similar technological materials.

Brand # 3: Litochrom

The Italian epoxy grout LITOCHROM STARLIKE is used to grout joints with a width of 1 to 15 mm, formed when laying glass mosaics, ceramic, wood and metal tiles.

The choice of shades is huge: the manufacturer offers 103 options for exclusive colors, among which there is even a luminescent grout that shines in the dark.

In terms of elasticity and abrasion resistance, it is 9 times superior to trowel mixtures made of cement. After hardening, no cracks or pits form in the seams. The material can withstand temperature differences ranging from -20 ° C to + 100 ° C.

It is used not only in the decoration of bathrooms, but also in the construction of swimming pools.

The grout mixture from the Litochrom company has several packaging options, which allows customers not to purchase extra kilograms of grout

The best grout for tiles in the bathroom: which one to choose according to its composition

When, in essence, the purpose, therefore, and according to the requirements, everything is more or less clear, it is also worth familiarizing yourself with the main selection criteria. The key point here will be the type and type of grout, which should be selected in each case individually. There are several main types, it will not be so difficult to navigate among them, especially if you delve into the essence of materials and their properties.

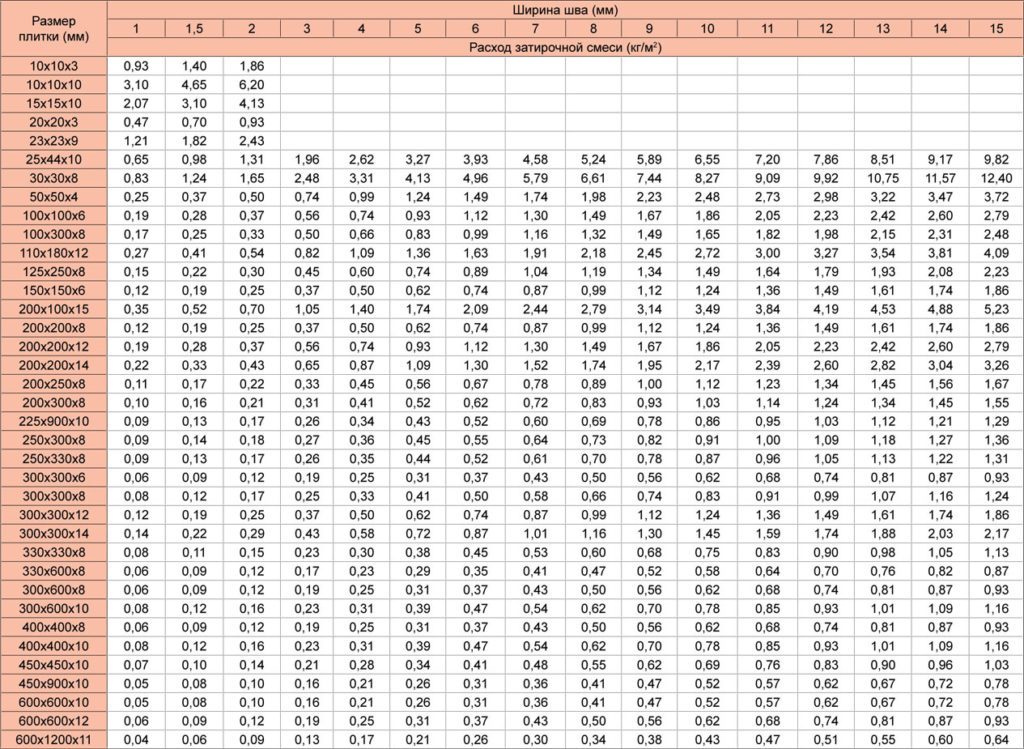

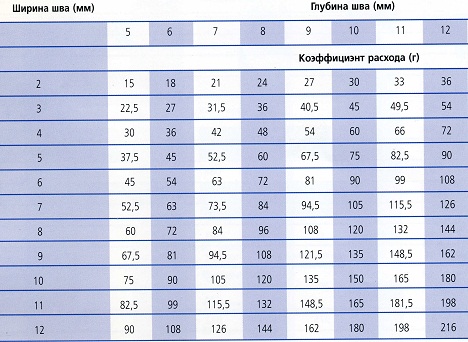

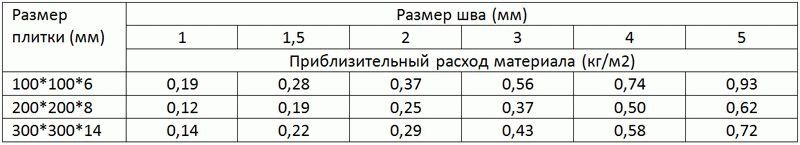

Classic and traditional cement composition

The most common on the market can be safely called a grout, which is made on the basis of the usual Portland cement, which already has sufficiently high performance, but to impart special properties, other components, minerals, plasticizers, and so on are usually added to the composition. Moreover, cement-based grouting is recommended for sealing only those joints between tiles that are small in area.If the seams are more than four to five millimeters wide, it is worth adding ordinary washed river sand to the cement mortar. Moreover, grouting of such a plan can be sold in the form of a free-flowing dry mixture, which. You need to breed it yourself, or maybe in a ready-made, pre-diluted form.

In addition to plasticizers, antiseptics, impregnations and so on are also added to the grout, which prevent the appearance of fungus. Moreover, impregnations of this kind can be glossy and matte. This will not affect the "speed" at all, but the external visual effect will be completely different. However, there are disadvantages, the main of which is the lack of ability to repel moisture. Among other things, the range of colors of this type of grout is quite small, you will have to be content with gray-stormy and white shades.

Epoxy resin: which grout to choose for the bathroom

The second option is a safer bet and is a grout in the bathroom, kitchen and elsewhere. As is clear from the original name, the basis of the composition of such a material is epoxy resin, the amazing qualities of which are already well known to the modern consumer. Moreover, in this kind of grout, pigment-dye of any color can be easily added, as well as hardeners, which make the resin solid and monolithic after complete drying. Moreover, the real advantages of such a grout are simply colossal:

- This material does not absorb water at all, thus also protecting the tiles from its influence. Such a grout for tiles is waterproof and therefore there should be no questions here.

- After solidification, the material is not afraid of practically any influence of chemically active substances and aggressive environments, at least those that we constantly use as household chemicals.

- The density of the grout is very high, due to which its durability is achieved, as well as a high degree of fixation of the tile due to a single structure.

It is clear that it will be more difficult to work with such a grout, because it is very thick and viscous in consistency, and if it gets on the surface of the tile and hardens, then it will have to be torn off exclusively with special chemicals, caustic and dangerous. That is why a special bag was invented for applying such a grout, similar to a culinary one, through which chefs decorate cakes and salads. However, if you have little or no experience in handling such things, you should invite a real specialist himself, so as not to bite your elbows.

Furan and silicone grout for bathroom tiles: rare, but nice

To finally understand, it is worth saying that there are also other types of grout, for example, furan, which also has the property, like epoxy, to solidify, that is, to undergo the polymerization process without the participation of an external heater. However, it can, and itself, warm up great, and its shades can be extremely dark. That is why such material is used extremely rarely in apartments.

Another popular move is the use of high-quality silicone sealant for grouting the joints between tiles in the bathroom, in the pantry, in the kitchen, and so on. A similar sealant is sold in convenient tubes, tubes and special containers for a pistol, which it is a pleasure to use. True, the cost of such a material is not comparable either with epoxy mixtures, much less with cement mortars, so its use will lead to very significant costs, and there is not so much sense from this, except that it is transparent and does not allow moisture to pass through, what and "epoxy" to cope with with a bang.

Types of grout for tiles

Cement

It is also customary to classify cement-polymer and cement-sand fugues to this family, depending on which additives are included in the main composition of the mixture.

Such grouting is used for joints with a width of about 4-6 mm, and the presence of mineral aggregates (sand) allows you to close up much wider gaps.

Pros:

Minuses:

- May absorb small amounts of moisture;

- Poor colors;

- They give slight shrinkage when dry;

- Freeze for a long time.

Cement grout is not recommended for use in very humid areas as it forms a porous surface that can absorb water.

As a result, mold appears on the seams, and they themselves begin to quickly collapse. This can be prevented by introducing an antiseptic and liquid latex into the cement mixture.

Epoxy

These are two-component mixtures of chemically curing resins, to which a fine aggregate is added for strength. For this, manufacturers often use colored sand: it not only strengthens the seam, but also acts as a pigment.

Epoxy grout, after the introduction of the hardener, quickly turns into a dense waterproof mass, similar in its properties to plastic. This is the best option for sealing joints when facing "wet areas" in the kitchen and bathroom, in the pool, sauna - in any place with extremely high levels of humidity.

Pros:

- Elastic and completely waterproof;

- Provides a pore-free surface that does not absorb moisture or dirt;

- They are not afraid of contact with detergents, aggressive chemicals and abrasives;

- Resistant to temperature extremes in the range from -20 to + 110 ° С;

- They do not fade or crack, they can last up to 30-50 years;

- A wide range of colors - up to neon, luminescent mixtures, "metallics" and "chameleons".

Minuses:

- They require skill when applied, as they freeze very quickly;

- Difficult to remove from the tile surface;

- They are more expensive than other grouts;

- Due to the high sand content, they give a rough surface to which threads and hair cling.

Epoxy grouts have practically no restrictions in their use - they can be used even outdoors. However, working with them requires experience, and considerable, otherwise you will ruin not only the expensive fugue, but also the tile itself.

Polyurethane

They are elastic grout with high water-repellency, with which it is possible to seal joints with a width of 1 to 6 mm.

They are ideal as a joint for ceramic cladding on movable bases, since they have a peculiar elasticity and do not crack, even if the tile starts to "play". They are painted, like epoxies, with the help of pigmented sand.

Pros:

- Do not absorb water and do not accumulate dirt;

- Even very thin seams can be easily filled;

- They do not require mixing - the mixture is already ready for use;

- Leave enough time to fix flaws;

- Easily removed from ceramic tiles.

Minuses:

Destroyed by chlorine.

Latex

Very plastic mixtures capable of filling joints up to 2-3 cm wide.In pure form, they are rarely used due to their high cost, but they can be added to cement joints to improve performance or applied as an upper reinforcing layer.

Latex grouts are resistant to bending and compression, do not react to temperature changes and retain their color for a long time.

Pros:

- Very elastic;

- Highly resistant to cracking;

- Glue wide seams well;

- Impervious to water;

- Huge selection of colors.

Minuses:

- Not cheap;

- If the grout is not removed from the tile in time, a cloudy film may form on the surface;

- They do not tolerate steam cleaning.

Furan

The closest "relatives" of epoxy grouts are also made on the basis of a curable resin with the addition of latex (for greater elasticity) or Portland cement, which provides high joint strength.

According to its characteristics, the furan composition after solidification resembles an epoxy, only with different chemical properties.It is resistant to aggressive acids, but it can react with other substances, releasing harmful compounds into the air, therefore, such grouting cannot be used in residential premises.

Pros:

- Impermeable to moisture;

- Forms a very hard seam;

- Resistant to acids and UV radiation;

- Elastic and will not crack over time.

Minuses:

- Difficult to find freely available;

- Available in only one color - black;

- Chemically active;

- They can only be used in industrial premises and outdoors.

How to choose the right type

When choosing the right type of grout, it is recommended to follow an integrated approach and take into account a number of criteria. Thus, it will be possible to find the best option for a specific situation.

By appointment

Each type of inter-tile grout has its own purpose. Depending on the type of tiles used and the characteristics of the use of the room, you need to choose an acceptable option. As a rule, the purpose of the material is indicated in the attached instructions from the manufacturer.

By operation features

Each type of grout is designed for use in specific conditions. When choosing, this factor should be taken into account so that the material will serve for a long period without premature destruction.

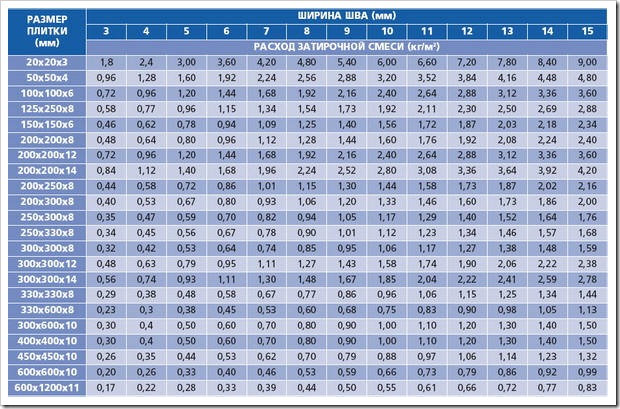

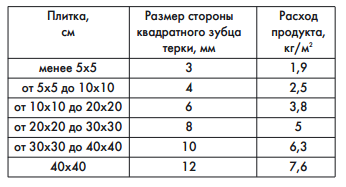

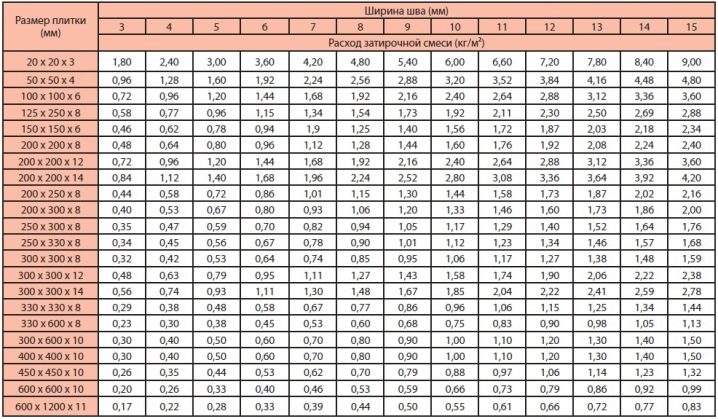

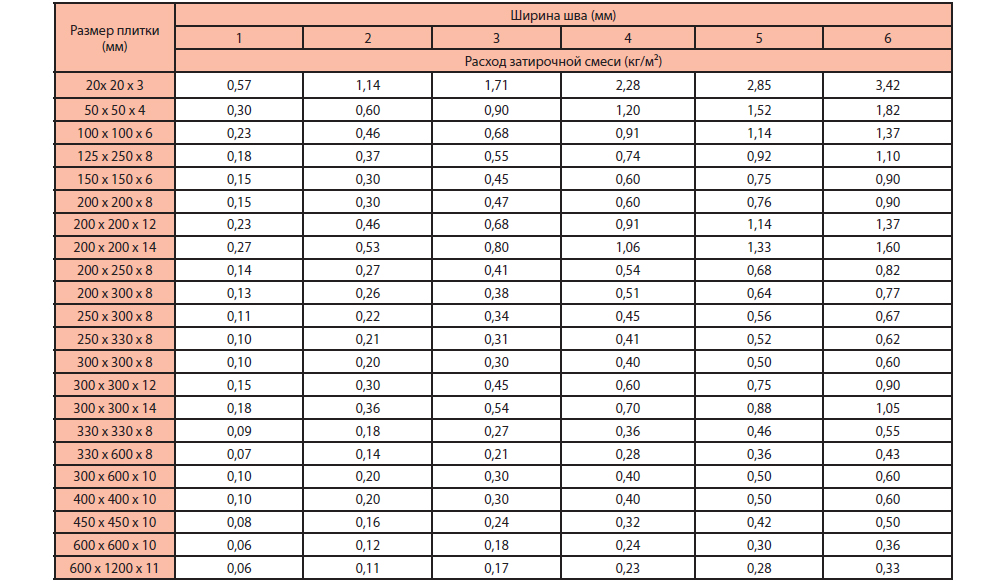

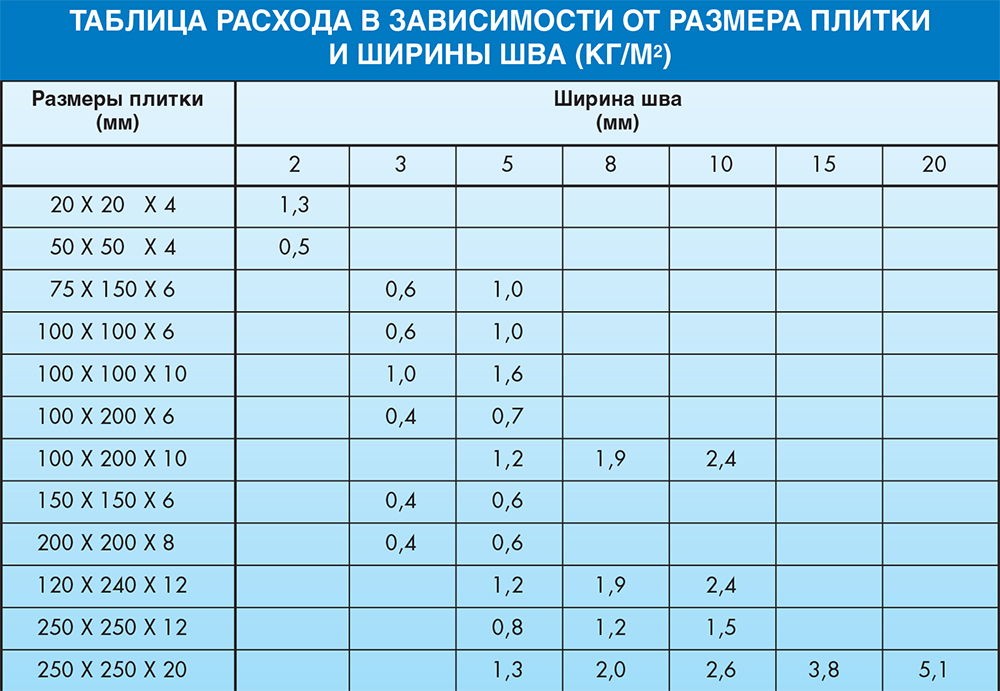

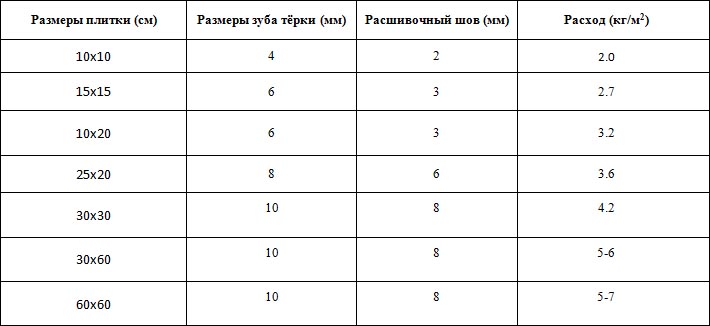

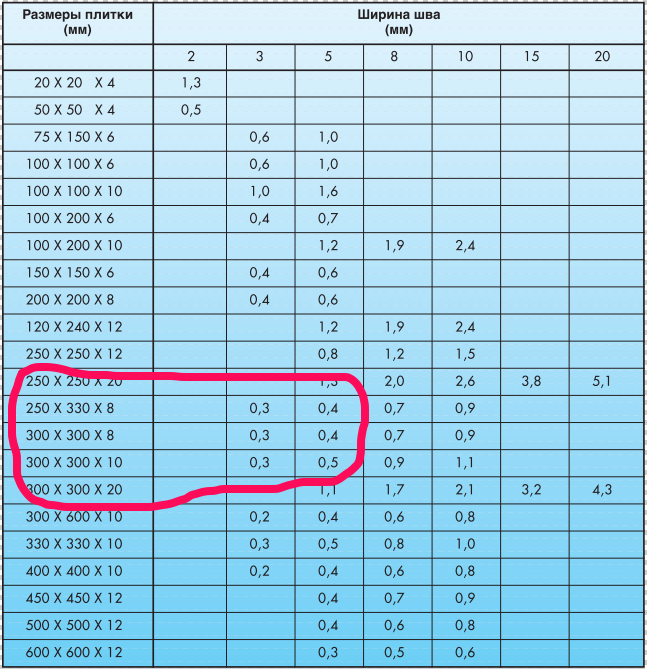

Seam width

Cement-based grout is used to process joints up to 5 mm wide. The epoxy material is suitable for inter-tile spaces of about 6 mm. In narrower gaps, the grout does not fit correctly due to the increased viscosity.

The width of the joints between the tiles is determined based on personal preference. Narrow seams visually suppress the tiles. If the wall is decorated with elements measuring 10-30 cm, then a seam with a width of about 3 mm is considered optimal. When using tiles of irregular shape, a wide seam is more appropriate, but its dimensions should not exceed 12 mm.

Finishing features

Finishing nuances also influence the choice of the right grout. Since different types of grouting material differ in texture and resistance to external factors, you need to think in advance about the decoration of the room and make a choice based on all the planned features.

Colour

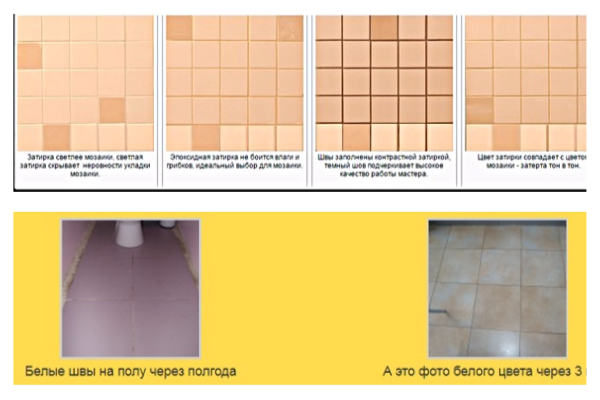

A well-chosen shade of grout allows you to improve the interior. The presence of contrasting seams helps to emphasize the strict geometry of the tiles, tying together the cladding, decor items and various equipment used in the bathroom. Having trouble choosing the right shade of material for processing the inter-tile space, it is better to focus on the color of the tile and buy a harmonious filler. In the case of a combination of several types of tiles, it is allowed to choose the color of the grout to match one of them.

The most difficult thing is to choose a contrasting color of the material, since you need to have artistic taste or experience in the field of design. If it becomes necessary to experiment with shades, it is better to do it in a special program for modeling the room being repaired. White grout is considered a universal option. It matches the bathroom fixtures and complements any colors used in the decoration of the room.

Manufacturer

The products of certain manufacturers are in great demand in the market. This is due to the proven quality and long service life of the grout.

Cement-based grout: types and popular brands

On the market for building materials, cement-based grouting is presented in the form of:

- dry mixes, diluted before use with water or liquid latex, sold in paper bags;

- ready-to-use viscous solutions sold in plastic buckets.

If the width of the joints between the tiles exceeds 3 mm, then the composition of the trowel mixture must contain sand.

Cement-based fugues are used when laying ceramic, glass, stone tiles on plastered surfaces and solid bases made of brick, concrete, drywall, etc.

It is undesirable to apply grout containing sand to glazed tiles and marble. Such cement-based grouting mixtures as Ceresit CE33 Super, CE35, Fuga Ekspreja 703, Fuga De-Lux Impresja 700 managed to gain popularity among finishers.

For bathrooms, it is recommended to purchase cement-based grouts, which include various fillers that improve their quality. Polymeric modifiers and mineral additives can act as a filler.

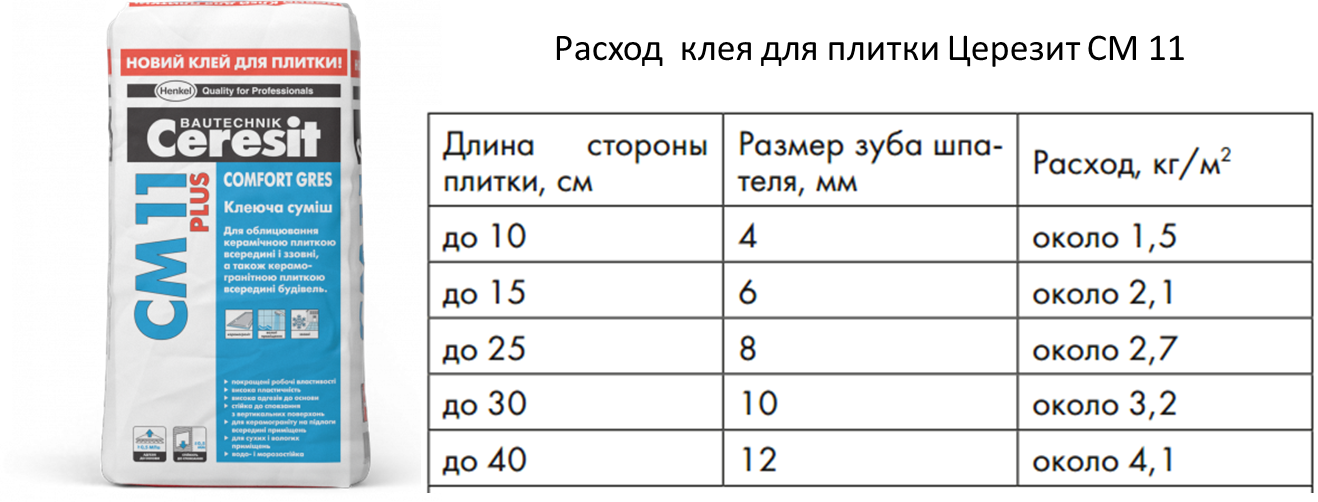

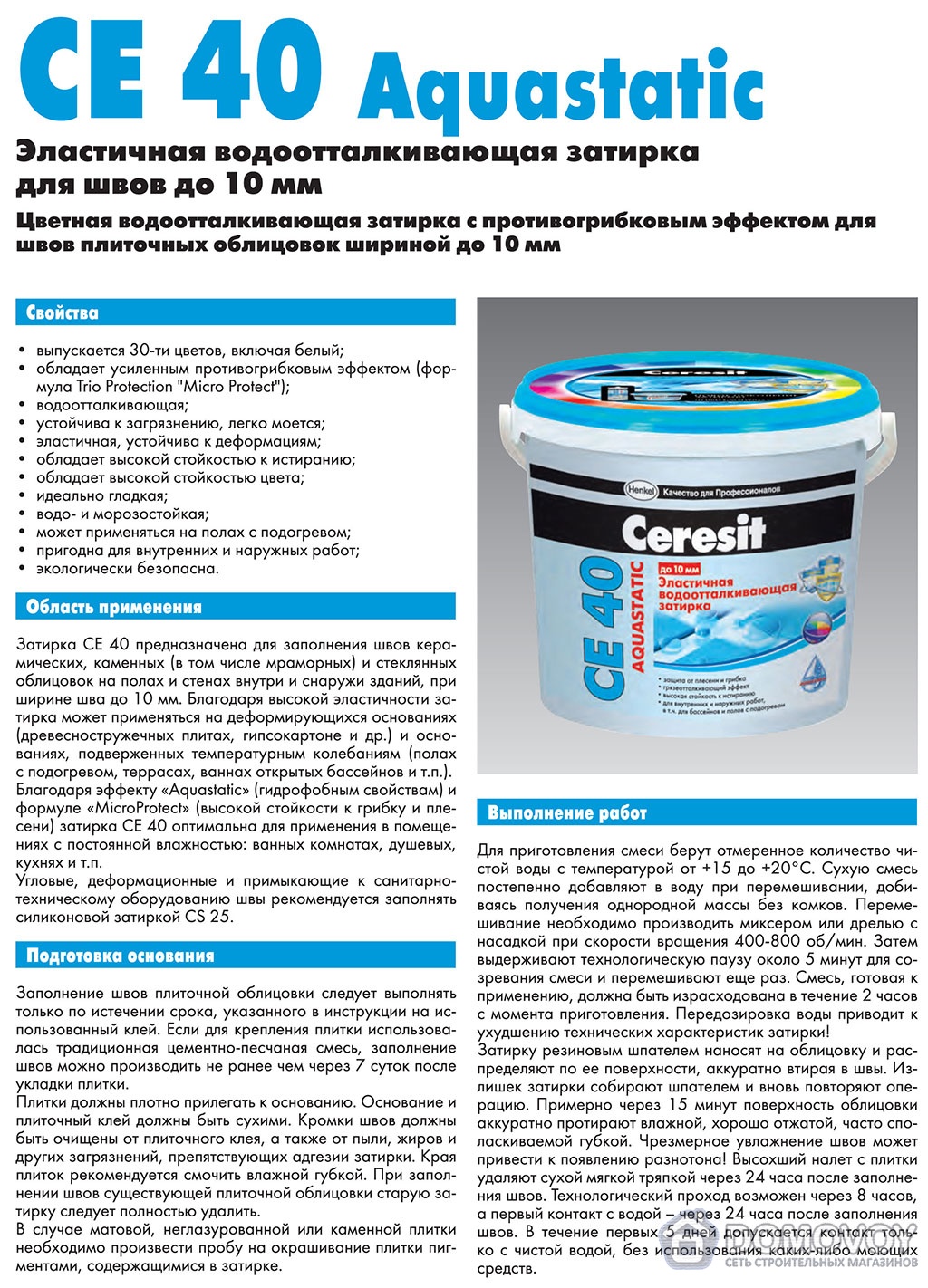

Seams filled with such mixtures have an increased degree of protection against penetration of water vapor and moisture. A striking representative of this type of grout for tiles is the Ceresit CE40 Aquastatic mixture.

Trowelling mixtures of the German company Henkel Ceresit (Ceresit), when applied correctly, do not leave stains on the tile, and also do not stain its edges.

The water-repellent elastic grout for tiles Ceresit CE 40 Aquastatic must be used within two hours from the moment of mixing.

This material is suitable for use on substrates subject to deformation (eg drywall, particle boards, etc.).

The Aquastatic grout can be used to join the joints between wall and floor tiles. The width of the tile joints can be up to 10 mm.

In addition to this filler, there is a silicone grout from the Ceresit CS 25 series, which is applied to joints that are exposed to intense water exposure.

Elastic water-repellent grout Ceresit Aquastatic is available in plastic buckets ready for use.

Color matching options

There are several ways to choose the appropriate fugue color for the tile:

- the tone of the jointing mixture corresponds to the tone of the tile;

- the seam has a color that contrasts with the tone of the ceramic;

- the color of the grout corresponds to the color of the furniture or the interior of the room;

- colorless seam.

To create the impression of a solid surface, the fugue must be chosen strictly in the color of the tile. In addition, this method allows, if necessary, to hide small ceramic chips or to mask a poorly executed seam. When emphasizing certain elements, as well as creating a volume of the room, the tone of the grout should only slightly differ from the color of the ceramics. If you want to get bright accents, use completely different colors of fugue and tiles.

The safest option, especially for use in the bathroom, the seam is treated with a white mixture that will be successfully combined in tone with the equipment and plumbing of the room.

Epoxy grout is completely waterproof and stain resistant

Also, a universal method of selection is the use of jointing mixtures of achromatic colors, namely beige, light gray and the already mentioned white shades. The main advantage of using these mixtures is the ability to use them with ceramics of any color.

Fugues of white and other light colors, it is undesirable to use in rooms where there is a possibility of rapid contamination of the joints, especially when processing the floor.

If single-color ceramics were used for veneering, the color of the jointing mixture can be selected a few shades darker or lighter. When using tiles of a neutral color, contrasting fugues will look advantageous. But if the facing, or individual fragments of ceramics, have a pattern or ornament, then the grout can be chosen for any of the colors present.

Recently, new types of jointing compositions with interesting properties are gaining popularity. These are various transparent and translucent fugues with sequins and pearlescent and even glowing in the dark.

Just do not forget that when using transparent or translucent compositions, tiles must be laid on white glue solutions.

How to choose a bathroom tile grout?

It is not easy enough to grind the tiles, as this process is rather painstaking and takes a lot of time.In addition, at the very beginning of the repair, many people have a question about grouting for tiles in the bathroom, which one to choose from the variety presented. The main condition for its choice is the orientation towards the chosen interior and the compliance with the stylistic orientation of the room.

Today there are 2 main types of grout that can be successfully used for the bathroom:

- cement;

- epoxy.

Both of these options can help in completing the renovation of the bathroom, make it truly unique.

However, working with each of them contains its own characteristics, which you should definitely pay attention to.

Cement-based grout

Choosing a cement grout means getting a high-quality and reliable material that is easy enough to apply. In addition, the variety of colors and shades makes it possible to select the type of material that best suits a particular interior. By their structure, such grout consists of cement and additional fillers that are responsible for the color ensemble. Such products are sold in 2 main forms: a dry mixture that requires dilution with water, or a ready-made solution. In general, cement grout and its application have the following positive qualities:

- versatility;

- rich palette of colors;

- ease of use;

- the strength of the finished coating;

- relatively low cost.

Rich palette of colors for LITOCHROM 1-6 cement grout

All these qualities make cement grout one of the most popular and affordable materials used for finishing ceramic tiles. However, in addition to advantages, it also has some disadvantages due to its structure. As you know, cement is a porous material, which inevitably affects the operation of the coating and determines its following properties:

- high moisture absorption;

- violation of integrity;

- difficulty in cleaning.

The above criteria do not appear immediately, but only after long-term operation of the coating. To renew the surface it is necessary to completely remove the old grout and apply a new layer. This is the only way to preserve the visual qualities of the bathroom and ensure the solidity of its walls.

How to choose the color of grout

With the help of a special putty, you can not only simplify the design, but also give it a brighter and more interesting look.

trust the designer when choosing a grout color.

Before choosing a color, there are a few important tips to consider:

- for plain masonry, a lighter or darker grout is suitable, within 1-2 tones (if decorative inserts are present, the color of the mixture should match the color of the additional plates);

- a dark color will favorably emphasize every slab, pattern, pattern or color of a cladding element;

- visually increase the area and combine the picture with light shades;

- a transparent grout or with a chameleon effect is suitable for a multi-colored facing element;

- it is more practical to choose dark colors for flooring (the surface retains its clean appearance longer);

- to give expressiveness, preference should be given to contrasting shades;

- multi-colored grout or fugue with the addition of decorative elements (for example, with the addition of metallic impurities) will help to transform the interior.

In addition to metallized fugues, mixtures with silver, golden or mother-of-pearl elements are realized.

Types of grout for tiles in the bathroom

Tile grout (fugue) is a pasty mixture or powder, which is diluted with liquid to a certain consistency. Such compositions differ in color, drying time, plasticity and other criteria, but they are all divided into only two types - mixtures based on epoxy resin and mixtures based on cement.

Tile grout colors

Cement grout

The main advantage of cement grouts is the combination of good quality and low cost.These versatile mixes contain finely ground cement, color pigments, plasticizers and hydrophobic additives. They are diluted with plain water or liquid latex, which increases the adhesive properties of the grout. The finished solution is a plastic mass, with which it is easy and convenient to work, but it is used only for joints up to 5 mm wide.

Properties of cement grouts

For wider joints, grout with the addition of sand is used, and the larger the width, the larger the grains of sand. The sand reduces the shrinkage of the mortar after drying, so that the joints do not crack. At the same time, it is not recommended to use sand-cement mixtures for tiles with a glazed surface, since sand can leave scratches on the glaze.

Quality of cement grout

Cement grouts are produced both in dry form (powder) and ready-to-use. It is convenient to buy ready-made mixtures, but not always profitable: if you do not have time to use everything up within the specified time, the mass remaining in the bucket will simply dry out. This will not happen with the powder, the main thing is to store it in a tightly closed container in a dry place. If moisture gets there, it will no longer be usable.

Cement grout from the manufacturer Litokol

There are few disadvantages of cement compositions, but they are quite significant. Firstly, this grout has a low resistance to moisture and dirt. Soapy foam and dirt that gets on the tiles will eat into the seams and spoil the aesthetic appearance of the cladding. Secondly, under the influence of household chemicals, which are used for cleaning, the fugue gradually collapses, and after a while it is necessary to process the seams again.

Epoxy grout

The main quality of such formulations is durability. In addition, this bathroom tile grout is moisture resistant and will not shrink. Even after 10 years, the tile joints retain their original appearance. In addition to epoxy resin, the composition contains a filler, modifying additives and a hardener. Quartz sand of various fractions is usually used as a filler. The hardener is always packed separately from the rest of the components, and is added directly when mixing the grout. After mixing the components, a very viscous dense mass is formed, and it is quite difficult to work with it, even for specialists. But all the inconveniences are fully paid off by the quality of the seams obtained, their rich color and high strength.

Epoxy grout for tiles

Due to their low porosity, dirt does not bite into such joints, and it is much easier to clean them than cement ones. In addition, epoxy bathroom tile grout is mold-free and can tolerate any cleaning agent. Its waterproofness contributes to an increase in the service life of the entire cladding, which cement compositions cannot boast of. Well, the disadvantages, in addition to the difficulties in application, include the high cost of such grouting and restrictions in use: the minimum joint width must be 6 mm, otherwise the viscous mass simply cannot penetrate deeply into the depth.

Epoxy grout