Assembly nuances

To prevent the process from turning into chaos, the following should be observed:

Thinking about how to assemble furniture? The answer is simple - everything should be done sequentially, as indicated in the manual. This will avoid confusion and mistakes. Each type of fastening has its own designation and a special hole in the piece of furniture. The name and purpose of the mounts should be spelled out in the instructions

It is important not to confuse them with each other. Most often, the assembly process begins with the connection of the side elements to the cover and the bottom of the case.

If the furniture assumes the presence of several sets, for example, a kitchen and a living room, then each section should be unpacked and assembled separately. Otherwise, there will be a lot of confusion. Professionals recommend that you first assemble the lower part of the headset and only then move on to the upper parts. Cover the floor with cloth or cardboard from furniture packaging. This is necessary so as not to damage the flooring and parts of the product. When looking for an answer to the question of how to assemble furniture, it is worth keeping in mind that this process will take an inexperienced person much more time than a professional. Therefore, you should be ready to spend not only a fair amount of nerves, but also time. It is possible that you will have to swap parts, sequence and correct your own shortcomings several times. Try not to confuse details. They may look pretty much the same, but differ in one extra hole or length. When assembled, they will have different attachment points. A person who wants to assemble furniture himself should be able to distinguish between the front and back sides of the end. In fact, everything is simple here - the edge is always processed on the front part, but not on the back. It is also very easy to confuse the bottom of the side elements with the top. Holes are usually cut in the bottom side for attaching the legs or base. On factory furniture, all holes are made where they should be. There are exceptions in extremely rare cases. If something doesn't work out for you, then, most likely, it was you who made the mistake. No need to break fittings and parts trying to insert them where they don't fit. Do not rush to drill new holes that (in your opinion) the manufacturer forgot to make. Read again the furniture assembly instructions. Assembling the furniture on the second try, you may be able to do it without any problems.

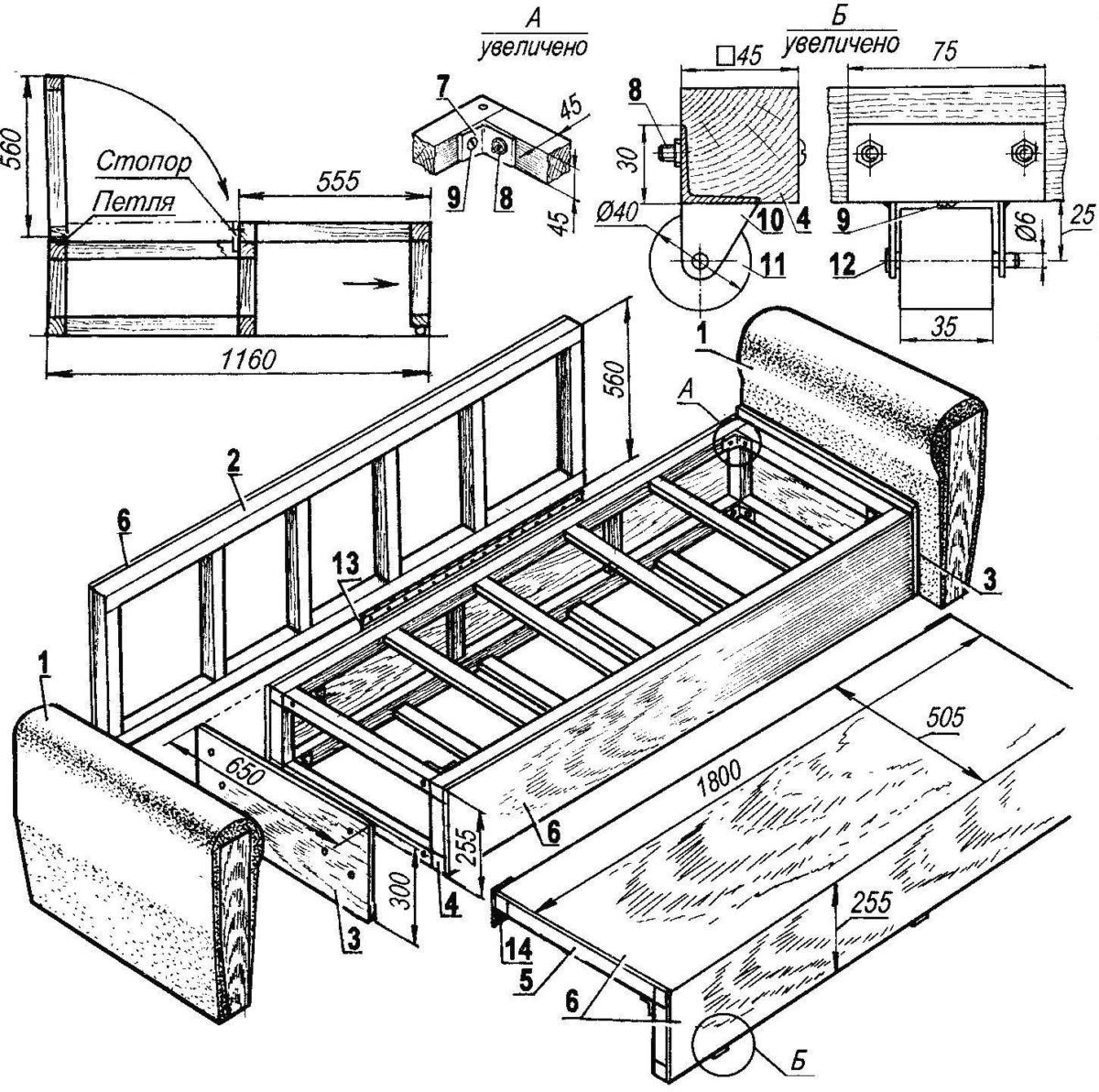

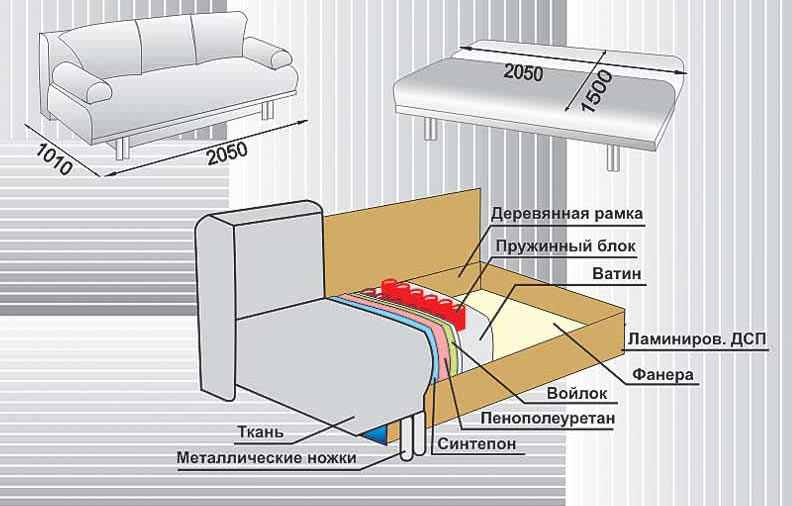

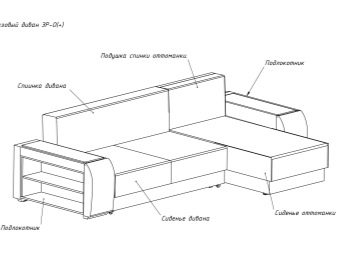

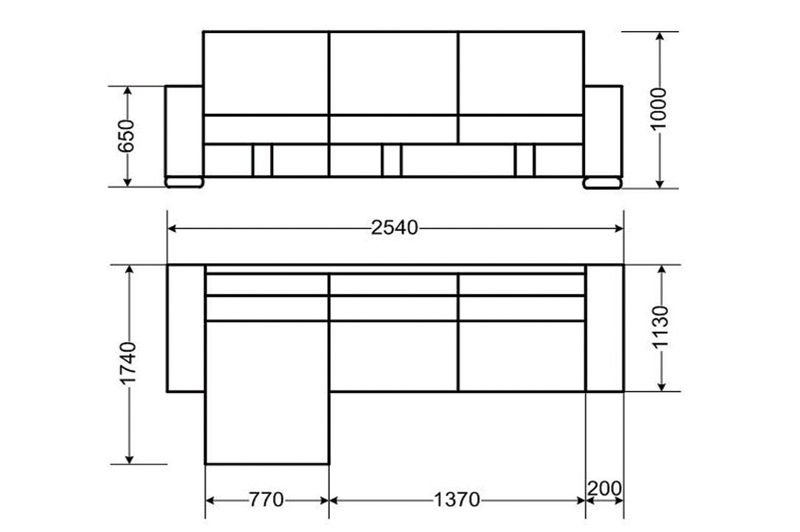

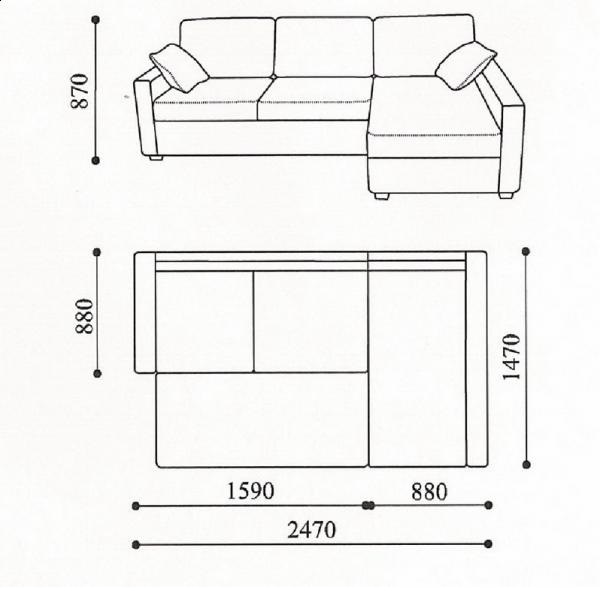

Device and dimensions

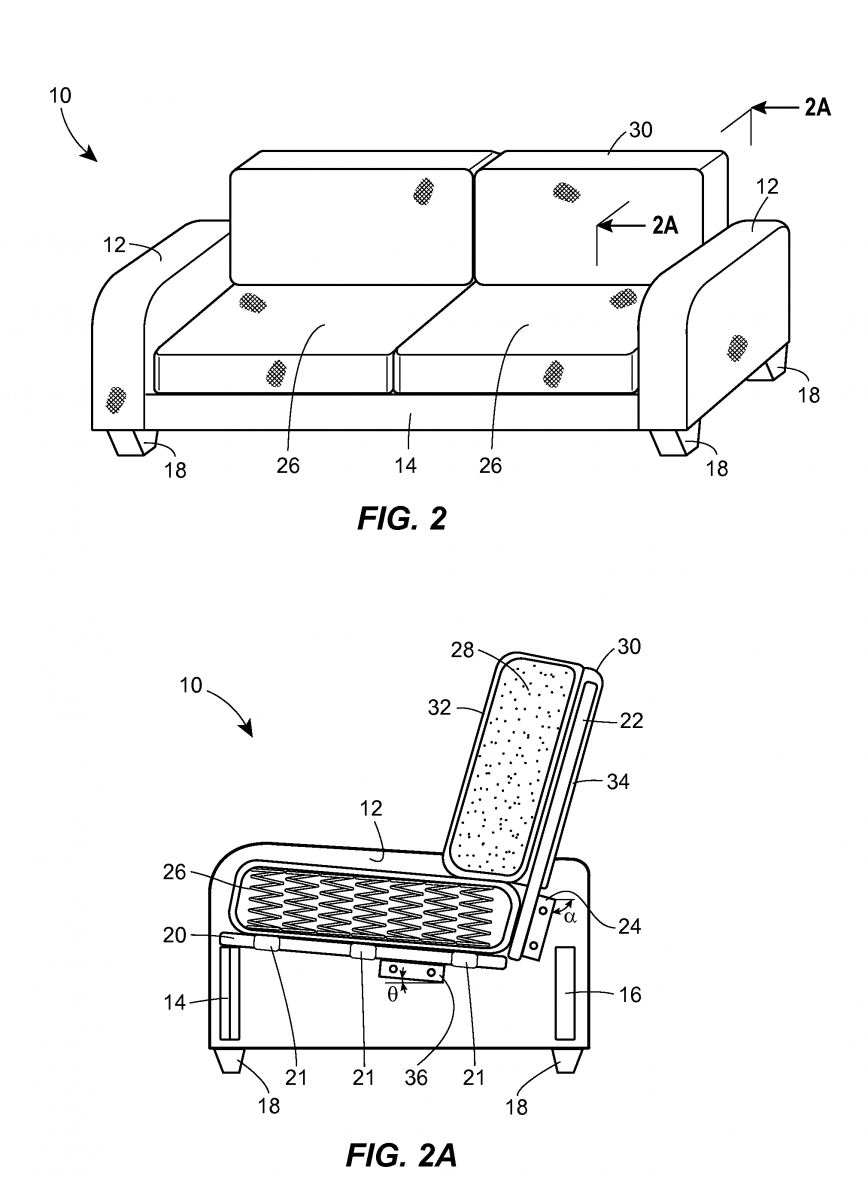

The sofa consists of a supporting (supporting) structure, most often including a box, a bed - a sofa, in the presence of a lifting box, backrest and armrests. In transformable products (sofa bed), a transformation mechanism is added to them and, possibly, additional pillows stored in a drawer. Typical sofa sizes:

- Length - 1200-1900 mm.

- Sofa width - 550-700 mm.

- The height of the armrests is from 100 (ottoman) to 400 mm.

- Backrest height, without add. pillows - 200-700 mm.

- Backrest tilt - 5-20 degrees.

- The height of the seating surface of the sofa above the floor is 400-450 mm.

The last parameter, in turn, consists of:

- Legs - 50-70 mm.

- Carrying frame - 50-100 mm.

- Box - 150-250 mm.

- Sofa base (with frame) - 55-75 mm.

This leaves up to 120 mm for the soft padding with casing. If its thickness exceeds 70 mm, the sofa is considered soft, 40-70 mm - semi-rigid, up to 40 mm - hard.

Benefits of hauling yourself

Upgrading your sofa yourself has the following benefits:

- You can select any material, add different decorative elements.

- During the stretching of the sofa, defects in the spring block or frame can be corrected at the same time. If you entrust the hauling to professionals, then they will only deal with it, and you will not even know that in the course of the work it was necessary to correct defects in the furniture, to repair some units or elements.

- The cost of independent work will be quite low, since there will be no need to pay for the work of a stranger. You will need to spend a certain amount on materials, prepare the necessary tools.

- It is better to repair the sofa yourself within the walls of the house. There will be no need to waste time and energy on transporting it to the workshop, waiting for the craftsmen to restore it. We wrote about the repair of sofas with our own hands here.

- The restoration process of an old sofa will be more budgetary than the option if you had to replace it with a new one.

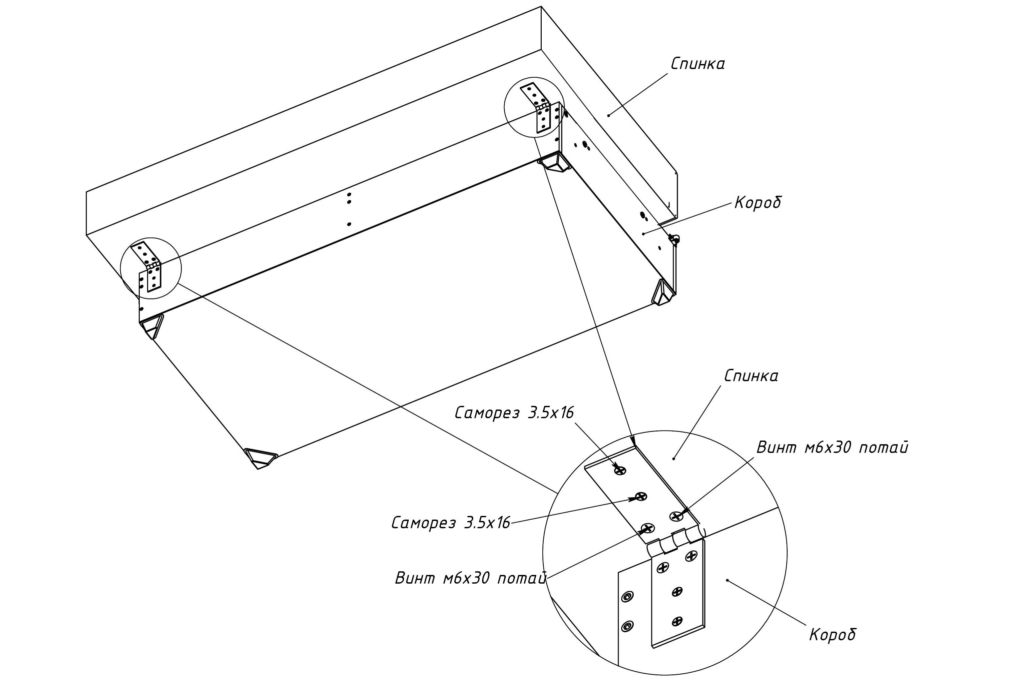

Back wall fixation

After checking the diagonals, it is necessary to fix the back wall. Most often it is made of fiberboard material, so fastening can be done in one of three ways:

- Nails.

- Self-tapping screws and confirmations.

- Furniture stapler.

If the choice fell on the latter option, then it is recommended to take the staples for the stapler, hardened, at least 15 mm thick.

Sometimes a groove is provided for the back wall. In this case, there is no need for diagonal alignment and fastening.

When tightening the screws, try to do it as smoothly and tightly as possible. If confirms are used, then you do not need to press them deeply, otherwise they will not be able to put on plugs.

When fixing, do not tighten the fasteners too much. The final tightening is best done when the product body is completely assembled. Make sure that no gaps are formed at the connection points.

Useful Tips

To make a soft sofa, it is recommended to choose functional models with good quality drawers and filling. Draw-out (pull-out) options with rollers and guides are very popular. They are good because you do not need to exert physical effort to unfold.

You should not save on fittings, because the life of the furniture depends on the reliability of the fasteners. For novice joiners and carpenters, it is better to choose clear geometric patterns. They are suitable for interiors in any style. Also, they are much easier to make clearly and accurately compared to furniture of complex shapes.

Spike joints located at the ends of the boards increase the strength of the product and increase its service life. However, making them at home is impossible; this requires special equipment. For this reason, a novice carpenter should not set himself such a task.

Experts advise against connecting individual elements with nails. Instead, experienced craftsmen use screws or self-tapping screws. If nails are used, the fasteners will gradually loosen.

Recommended wood species for making a sofa at home are spruce and pine. Before work, the boards are carefully sanded - the surface of the material should be flat, without roughness. Do not cut boards indoors, as wood dust accumulated in the air is harmful to health and can cause allergies.

For padding the back, you need to use thin foam rubber, for the seat - more dense. You can glue several sheets together

It is necessary to pay attention to the tightness of the joining of soft parts to each other. A thin layer of padding polyester is laid on top of the foam rubber to protect the filler from external influences

In furniture factories, it is used to make sofas softer.

In order for wood or chipboard products to serve for a long time, all parts must be treated with a special furniture varnish (stain). If the garden sofa is intended for children, the cover must be free from aggressive and allergenic chemicals. Homemade sofas have many benefits. They fit well into any space, look unusual, and are suitable for sleeping and relaxing. The main thing is to choose high-quality material for work and clearly represent the step-by-step sequence of actions. Then making upholstered furniture with your own hands will become an interesting hobby.

Roll-out

Roll-out

Children's sofa in the interior

Children's sofa in the interior

Stained pallet sofa

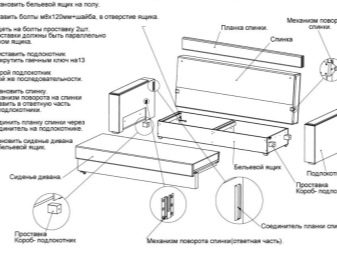

Sofa assembly instructions

It is possible to independently assemble any sofa, be it a modern transformer (for example, a "clamshell", "saber" or a roll-out version) or an ordinary static product, devoid of any additional systems

When preparing these furniture designs, it is important to adhere to their detailed scheme so as not to make mistakes anywhere. We will analyze step by step how you can independently assemble sofas of different types

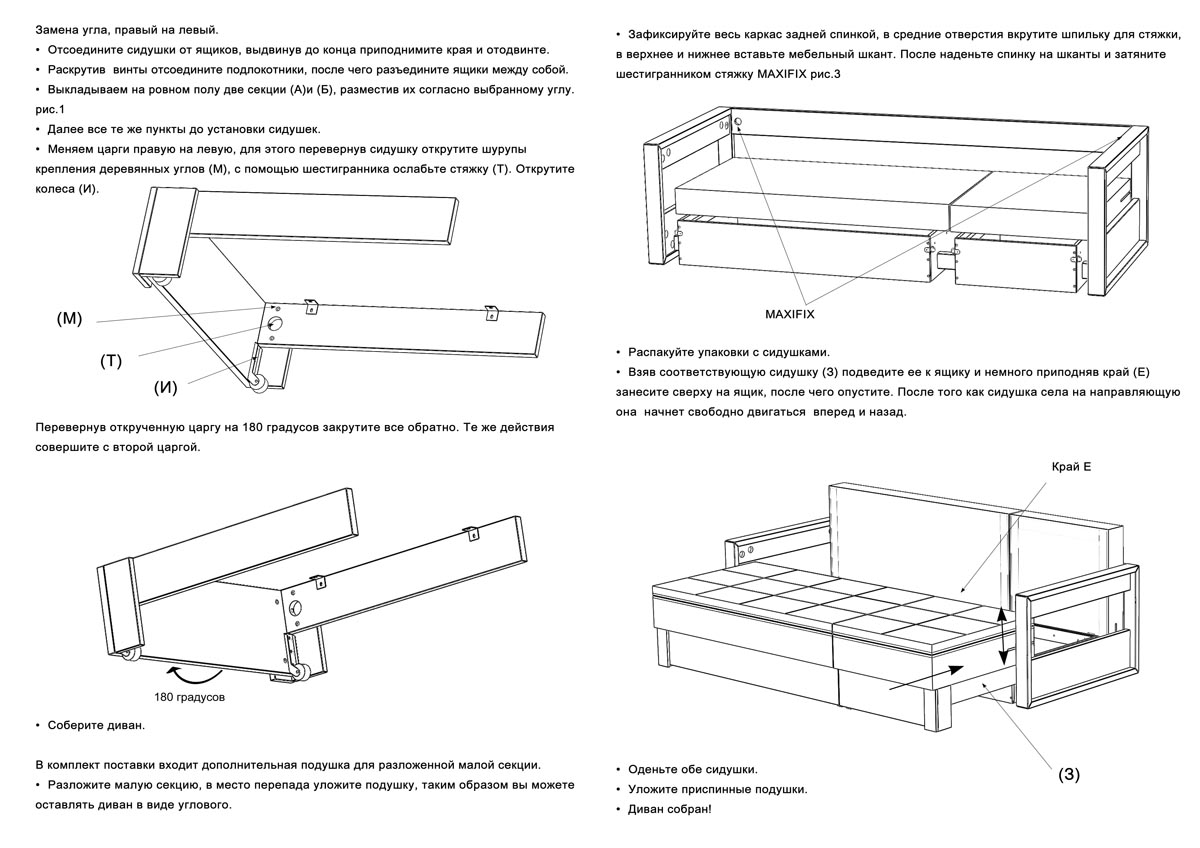

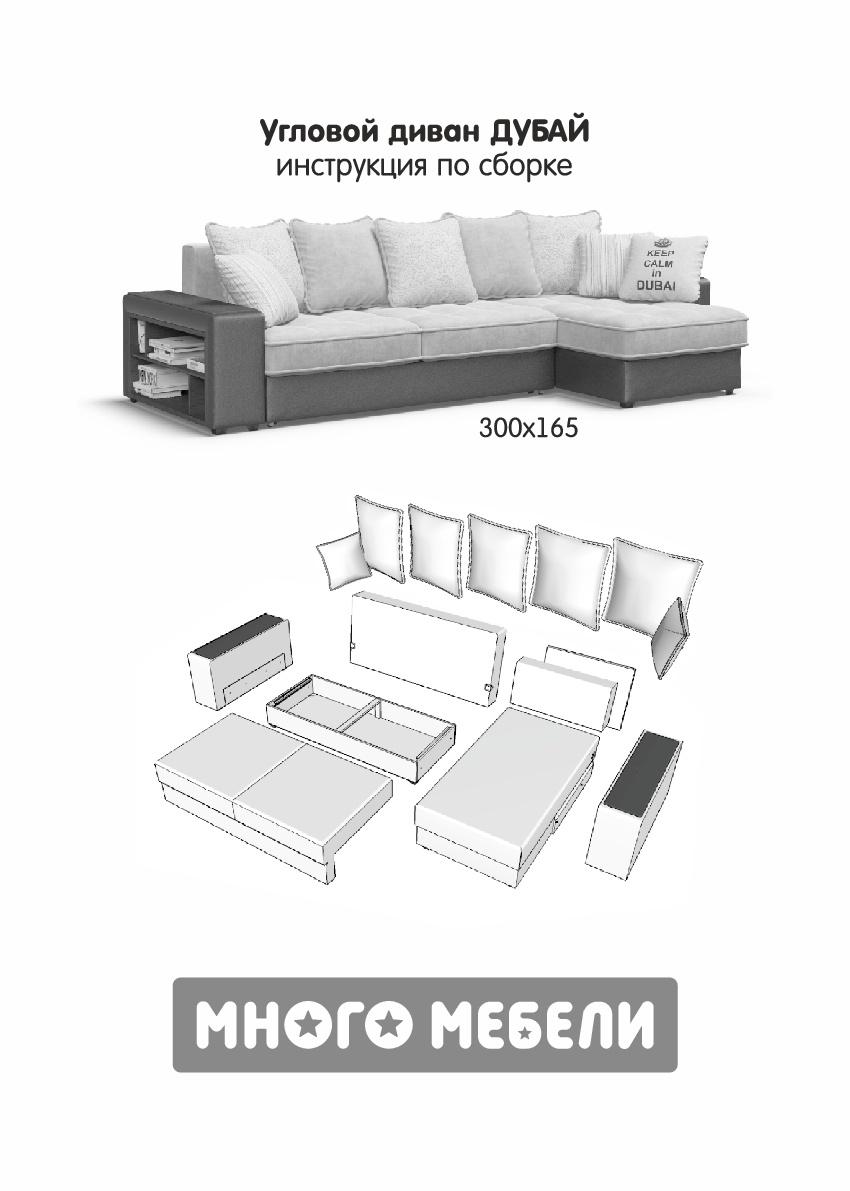

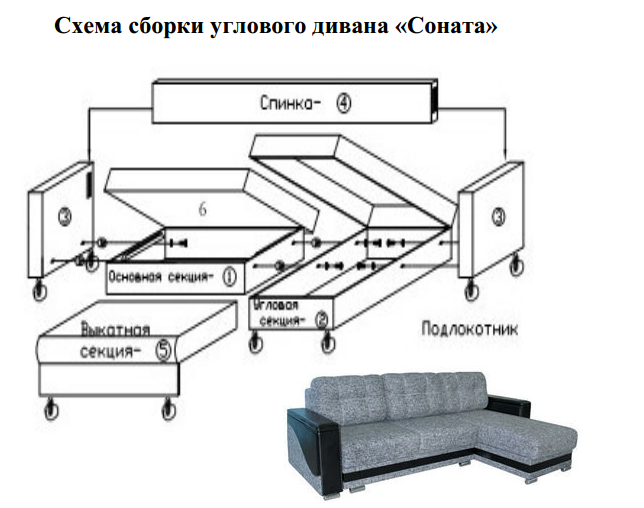

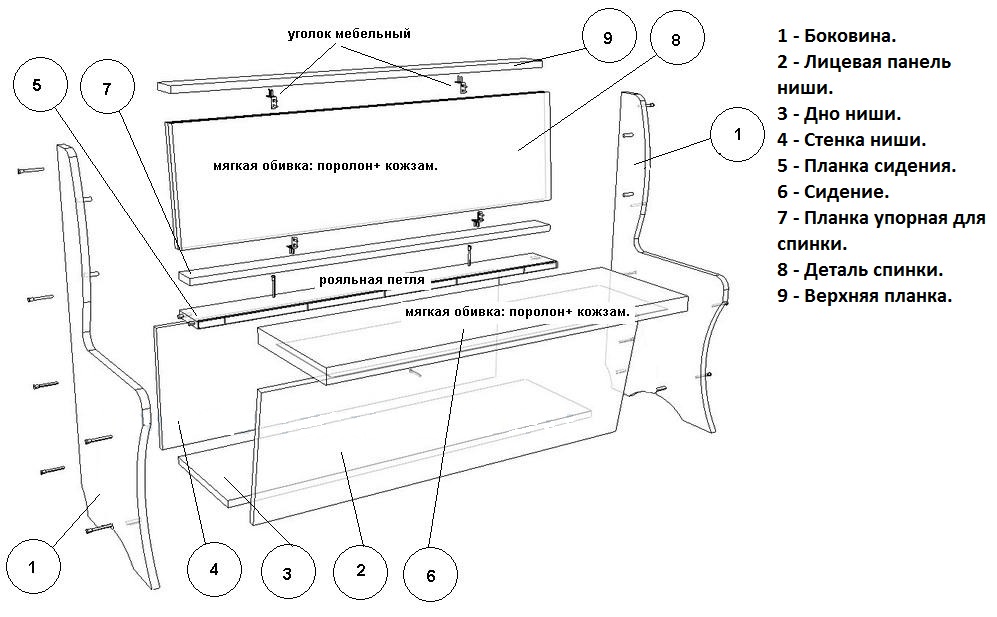

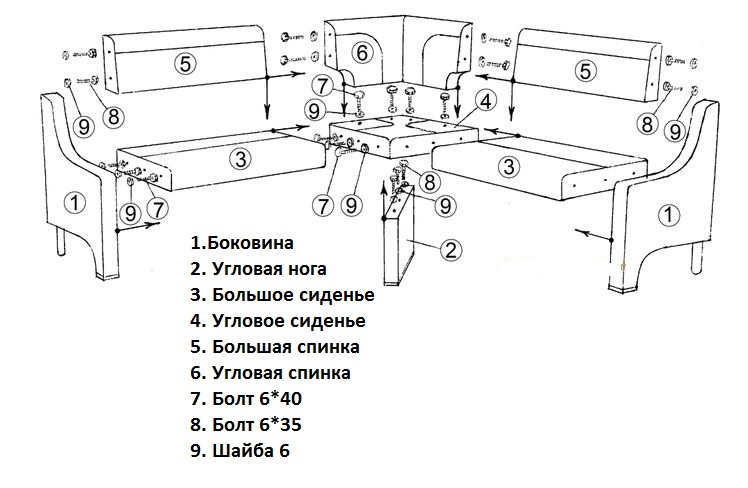

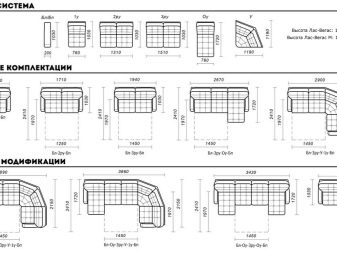

Corner

Nowadays, corner sofa models are rightfully recognized as one of the most popular.

Often, corner models are equipped with additional mechanisms that allow you to organize a full-fledged berth.

Corner models are presented in a wide range. There are both large and mini sofas. To assemble furniture of any size of the specified type, you need to connect 3 main components of the structure:

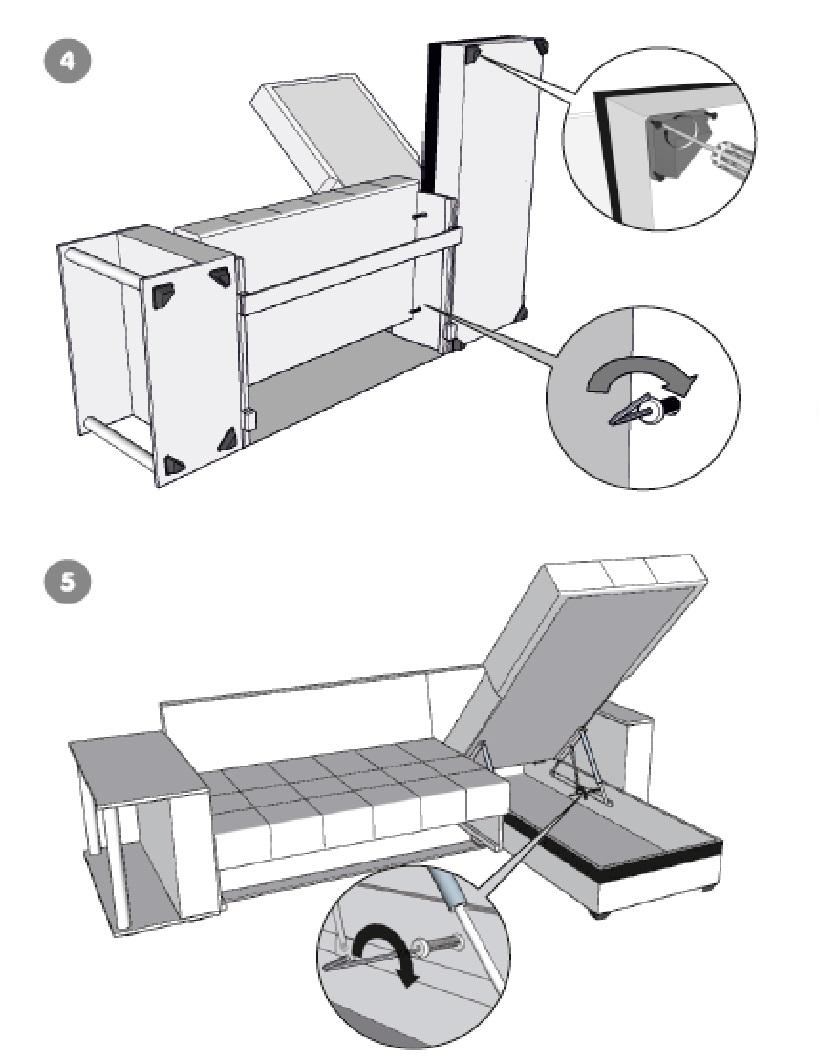

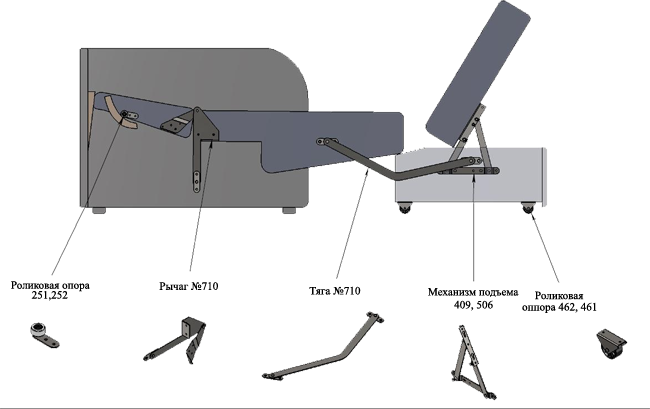

Before starting work, you need to inspect the base. If there is a mechanism in it, it is also worth taking a closer look at. It can be right-sided or left-sided.

- Unpack each piece of new furniture. Check the quality of all components and the integrity of the package.

- Get all the tools you need.

- The support parts must be attached to the base frame, corner compartments and armrests using screws.

- Attach the rollers to the drawer.

- Connect the sides and corner sections with screws. Make sure all elements are well fixed.

- Next, connect the base base and backrest.

- Secure the rear wall and the second armrest.

- On the guides present in the side part, you need to put the roll-out mechanism included in the kit.

Knowing such a scheme, you can build and assemble such furniture yourself using the materials listed above. The main thing is to pre-prepare a design drawing with detailed parameters of the future product.

Direct

Assembling standard straight sofas at home can be simple and quick if you take into account all the features of the purchased model and have its detailed diagram at hand.

We will analyze in stages how to assemble such products according to all the rules.

It is necessary to carefully unpack each of the upholstered furniture parts. Make sure the fittings are of good quality. The unpacked parts are allowed to lie down for a while so that they take their natural shape, adapt to the ambient temperature and humidity of the room.

Place all the necessary tools and accessories near you. Here you will definitely need a hexagon, a screwdriver and a screwdriver.

The first step is to fasten the furniture legs, since the already assembled furniture structure may be too heavy and it will be completely inconvenient to lift it.

Then you can proceed to the main stage of assembling the product. Connect the back and seat to each other by carefully aligning all the necessary holes by inserting and screwing bolts or screws into them. Then, on 2 sides, on a wooden frame, you will need to expose and fix the armrest and other decorative components.

Check how the mechanism works in the assembled sofa after completing all stages of work

It is important that the existing system runs smoothly, without squeaks, crunches and other suspicious noises.

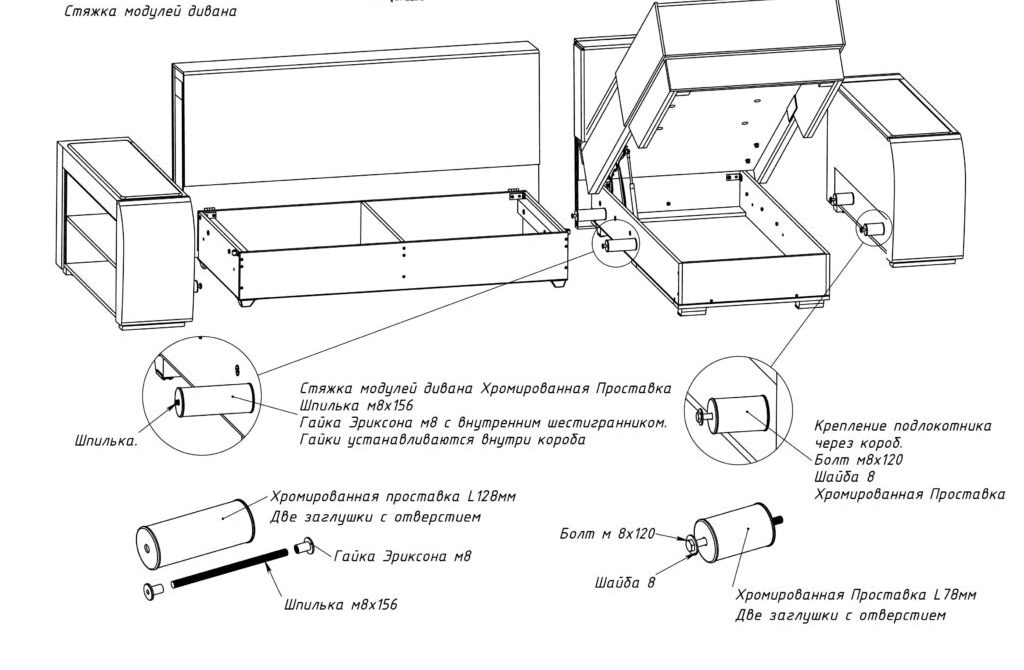

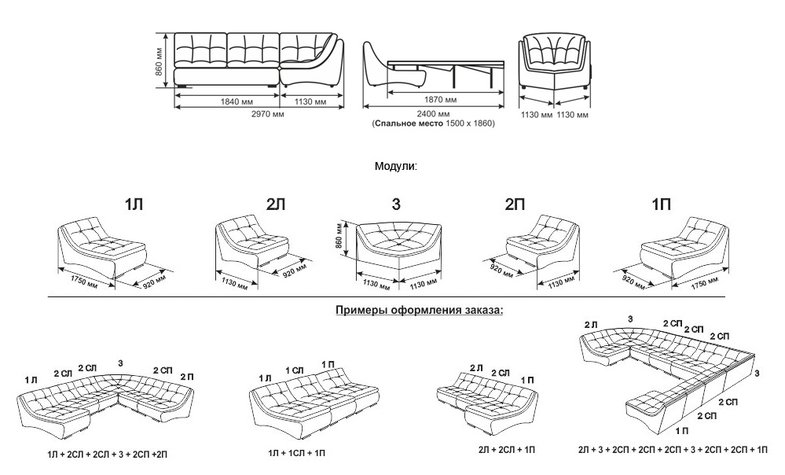

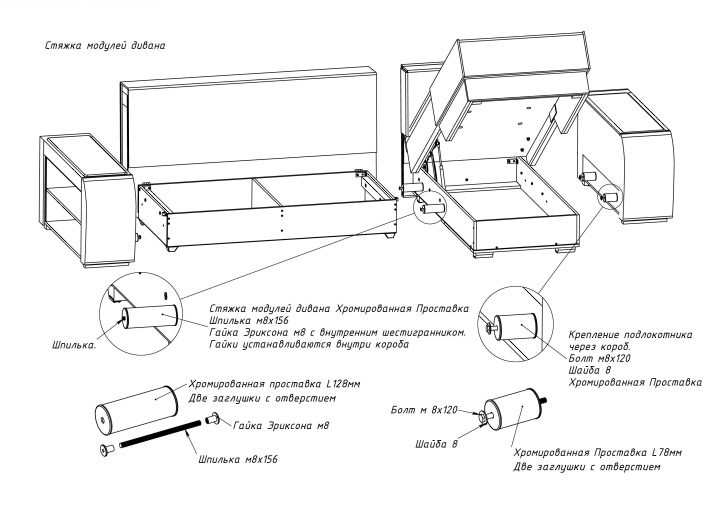

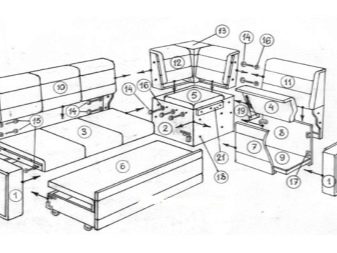

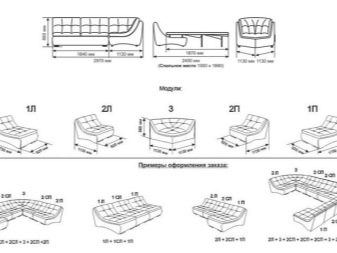

Modular

The new modular sofa is a piece of furniture that will be significantly different from all the models listed above.

Separate sections can somehow be connected to each other, but they can only be shifted (attached) to each other.

Often, modular sofa models come on sale, which are already mounted, and the buyer only needs to combine all the details in accordance with his own wishes. Ready-made modules are usually selected in the store.

As one of the options, a modular sofa can look like a transforming system. If necessary, such a soft product can be quickly and easily transformed without much effort or time, turning into a very comfortable and cozy bed.The sections can also be shaped in a variety of ways.

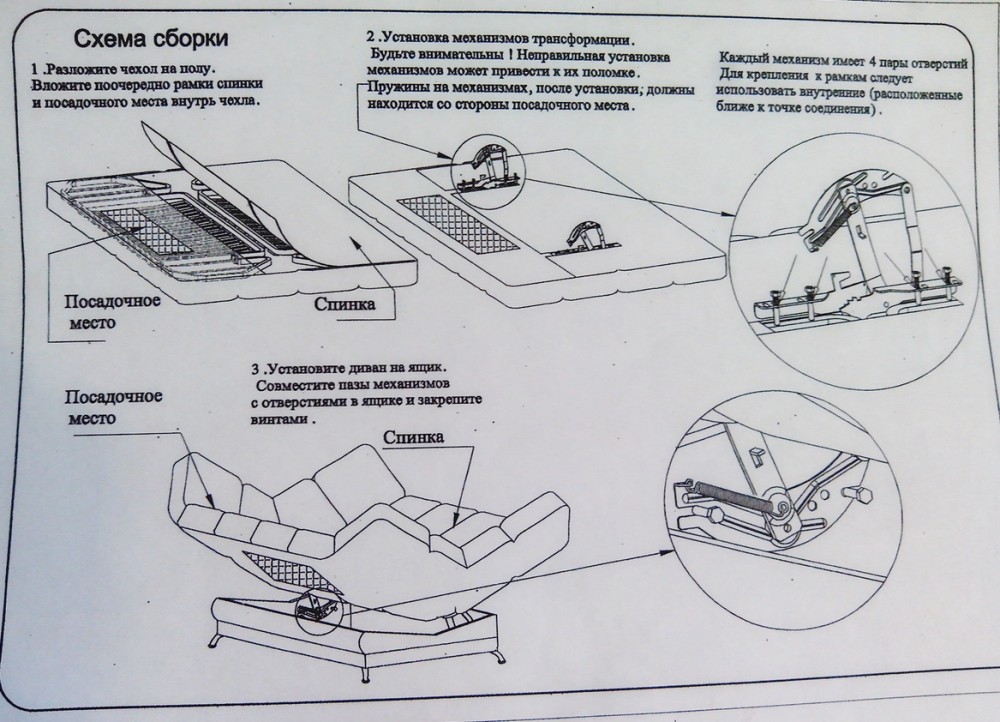

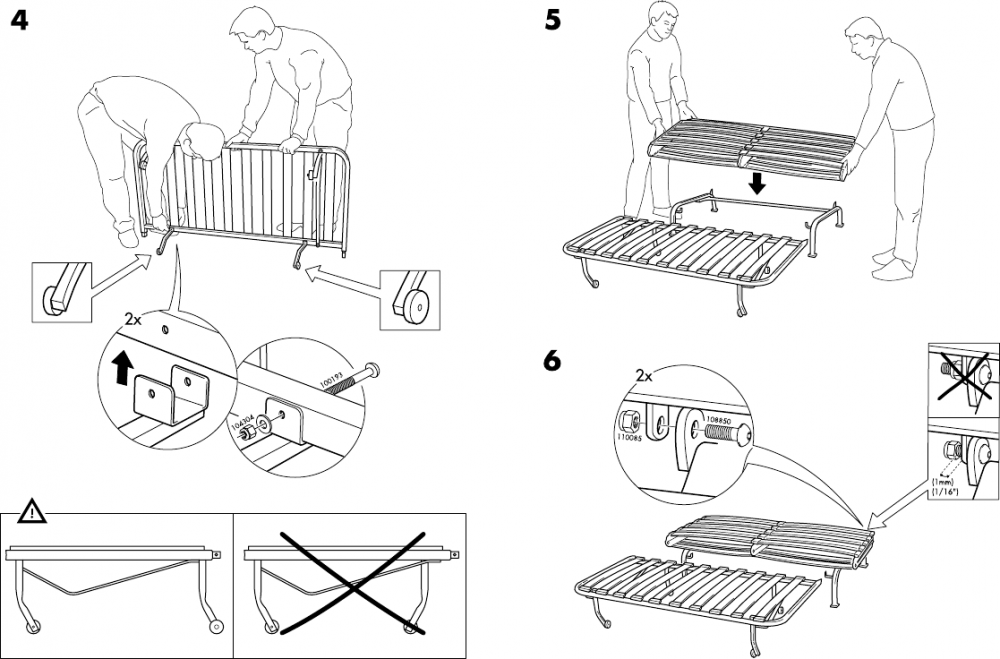

Let us give an algorithm of actions in the case of a modular system.

- Lay out the Euro cover on an even and firm base.

- Place backrest frames and seating parts in the lined cover in turn.

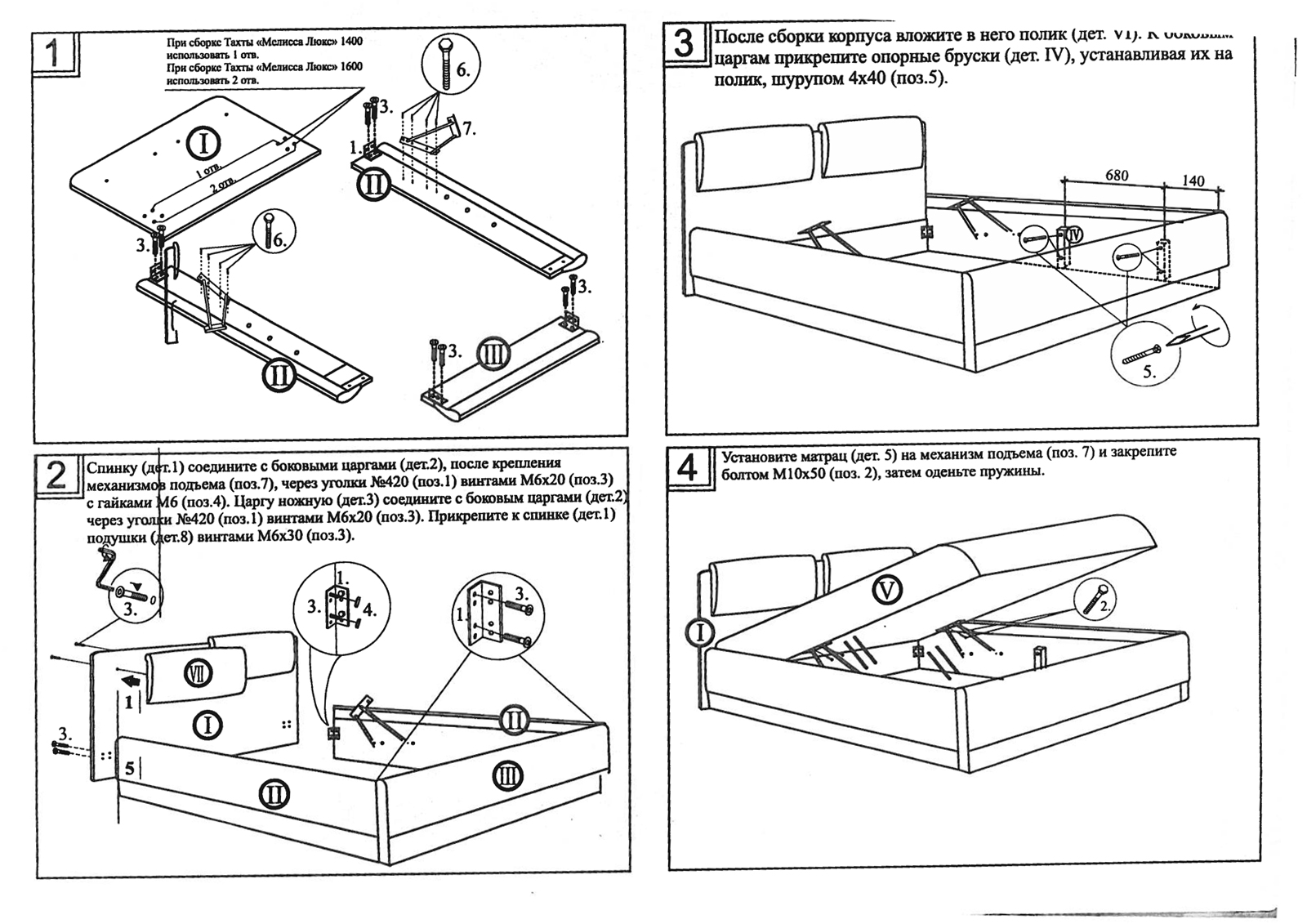

- Place the transforming mechanism. In this case, one must be as careful and careful as possible. The springs on the mechanisms after installation must be located on the side of the seats. Each mechanism has 4 pairs of holes. For fastening to the frame base, use the inner ones (they are close to the connection point).

- Place the sofa on the drawer. Carefully align the grooves in the structure of the mechanism with the holes in the box. You will need to fasten the entire system with screws.

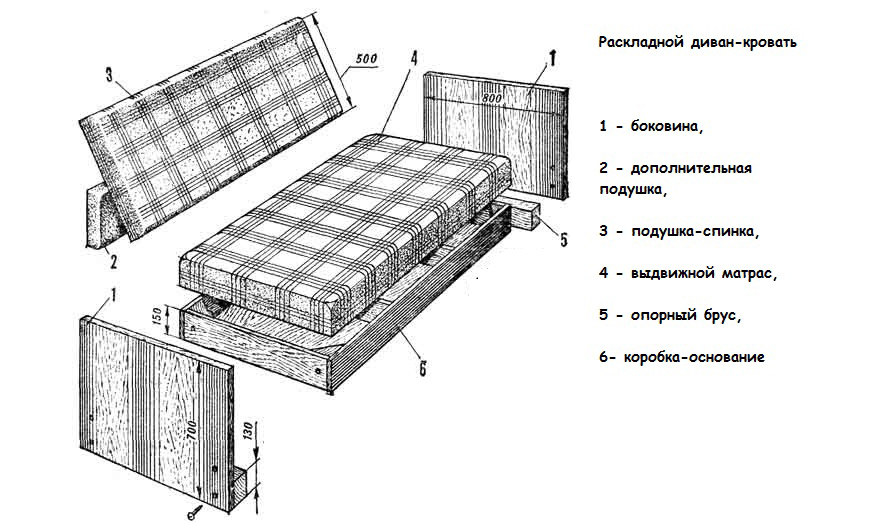

Shieldova

Self-assembly of the sofa

This method is suitable for people who do not have any woodworking skills. This option is a little easier and to implement it you need to stock up on:

- two old door leaves;

- metal staples;

- wood hemp;

- foam rubber;

- upholstery material.

Wooden version The base and back of this sofa model will be two used wooden door sashes. You will need to first clean them from old coatings and dirt, and then process them with a grinder.

Further, the doors are painted in the color of your choice, while trying to match the overall interior of the room in which the sofa will be installed in the future. You can give preference to finishing the wood surface with veneer.

Using nails, fasten one leaf on a wooden hemp of the appropriate size, and then use metal and glue staples to fix the second part (back) to it.

After that, start making the mattress: cut out foam rubber of the same size as the seat and cover it with a thick cloth (mattress is ideal for this). Already on top of this material, a bright, good quality fabric will be stretched.

The main requirement is the construction of the most durable and reliable frame base. It is on him that the whole main load falls, and if you neglect this requirement, you can get injured during operation, and it will not last long. Based on this, you can choose another base material that meets the requirements.

You can beat the finished structure as you like, it all depends on your preferences and imagination.

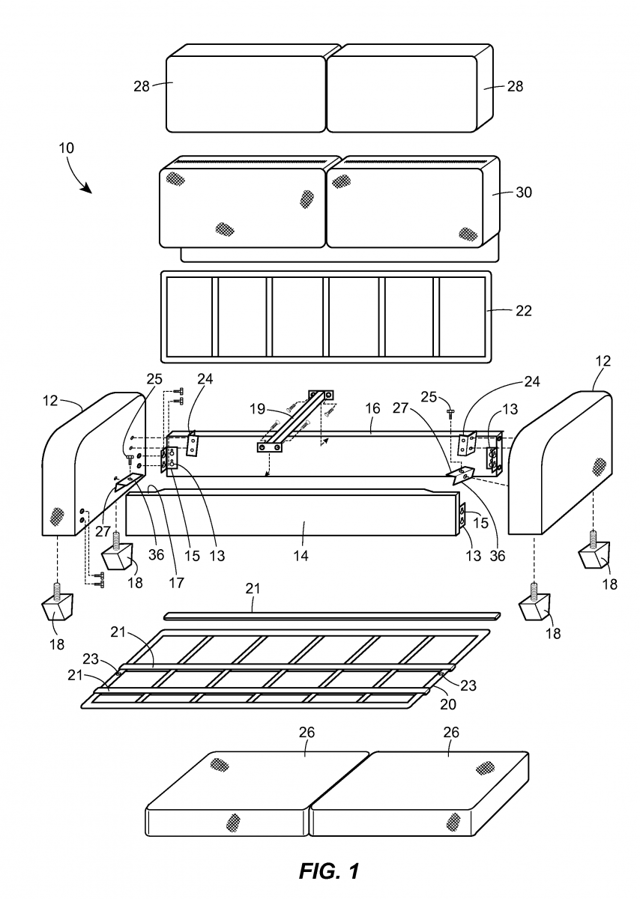

What is needed

Before proceeding with installation work, you should prepare the necessary inventory. To assemble the bed, you will need a set of tools and additional materials.

3> Tools

The bed comes standard with various fasteners, which require screwdrivers, spanners and a screwdriver with a set of attachments. Since modern types of bedroom furniture often use euro screws with a hidden head and an internal hexagon, it is also worth preparing the keys for the confirmation.

Materials (edit)

The assembly kit consists of fixing elements, body parts, lifting mechanism, mattress and decorative components. Before starting the installation, it is worth checking the presence of all materials and spreading them out at the work site.

Instructions

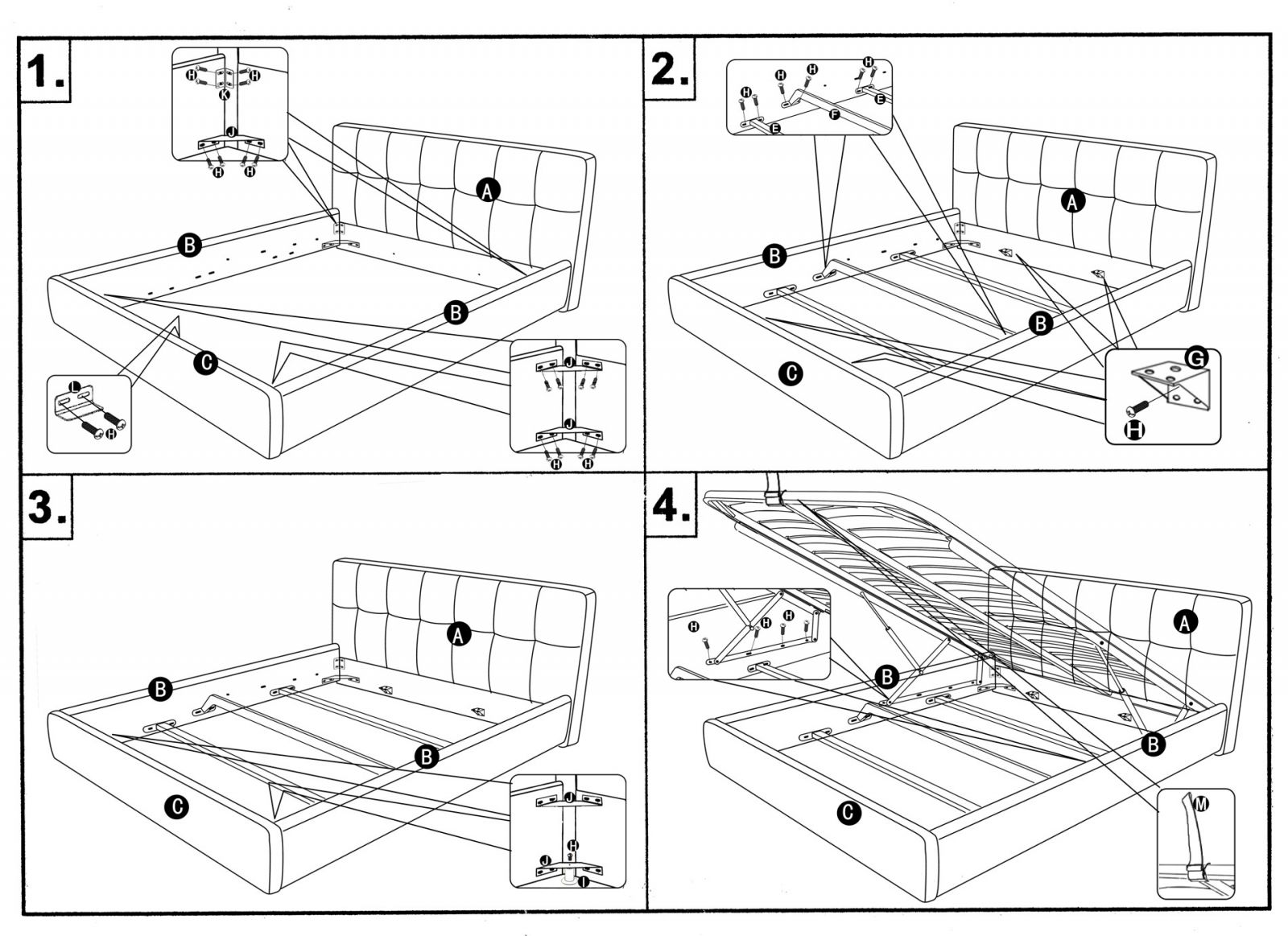

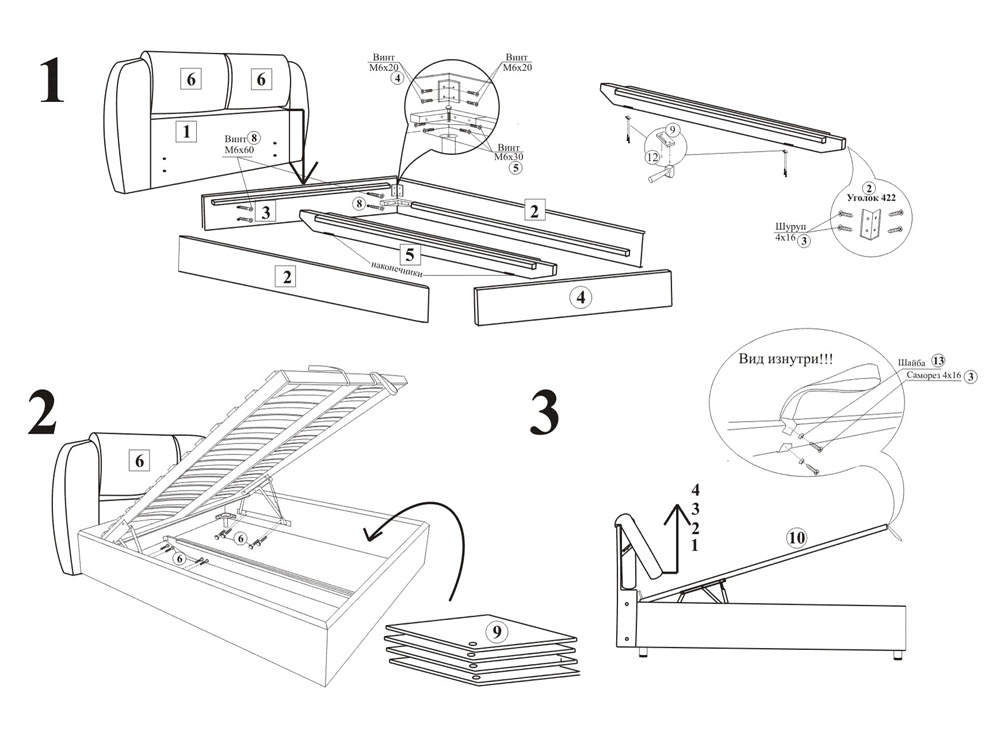

In order to properly assemble a bed with a lifting mechanism, it is imperative that you familiarize yourself with the provisions of the instructions. Typically, installation instructions are included with the bed. Having previously studied the manual, you will be able to get a general idea of the work ahead and calculate your capabilities. If necessary, assistants can be involved for further assembly.

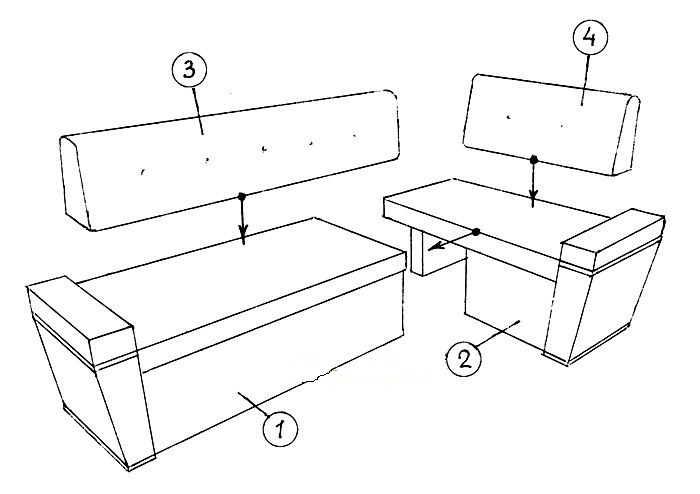

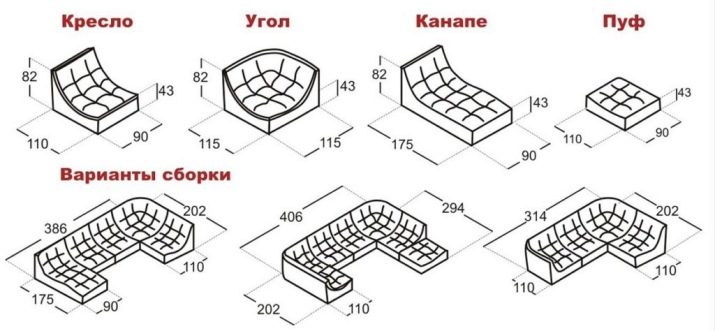

Drawings and diagrams

Competently drawn up drawings and diagrams for assembling a corner sofa with your own hands determine the quality of the final result. Sketches should be as simple and straightforward as possible.The basic principle is to describe the size and location of all the details of the future furniture. After the drawing of the future cushioned corner has been drawn, a detailed diagram of the location of all fasteners, reinforcing parts, partitions, and, if necessary, drawers is signed.

Some recommendations of experts will help you to do everything correctly:

when choosing the dimensions of furniture, it is important to measure in advance the place where it will be installed;

first of all, a sketch is drawn, which must indicate the length of the two halves of the sofa, its depth and the height of the back (this parameter can be arbitrary);

the width of the sofa frame is calculated as the difference between the total length of the two halves and the depth.

The main points that are taken into account when creating a drawing of the sofa:

- backrest angle;

- dimensions of the entire structure and its individual parts;

- the need to install folding mechanisms;

- the need to equip storage compartments;

- the height of the sofa legs.

For example, the base of the timber is shaded with yellow, the surfaces of chipboard are gray, the upholstery with foam rubber is pink. The diagram of the direction of screwing is drawn with red arrows. This will help you quickly navigate and significantly reduce time costs.

The main stages of assembly

Before making furniture, prepare a drawing of the future product. It is necessary to reconcile the dimensions of the cabinet schematically indicated on paper with the proportions of the prepared parts.

- Mark the extra centimeters of chipboard panels with a simple pencil, saw off along the lines with a hacksaw on wood, clean the edges and close them with an edge.

- Attach the side, bottom and top panels to the back panel using a screwdriver and self-tapping screws.

- Before hanging the doors, mark the hinge spots. If the sashes are heavy, increase the number of fasteners, otherwise, over time, the panels may warp under their own weight. The distance from the edge to the bottom and top loop should not be less than 12-13 cm.

- Fasten the hinges and check the door operation. They should fit snugly, without gaps and displacements. Don't forget to cut in the mini lock.

- For a wardrobe with sliding doors, a roller mechanism should be selected, which will be located at the top and bottom of the panels. Most often, aluminum elements are used for this.

- If legs are supposed, then they need to be done before hanging the doors. After the assembly of cabinet furniture with your own hands is completed, check the stability of the structure, how level the cabinet is and whether it "sinks" in one direction or another.

- Use self-tapping screws and strips to make supports for the shelves. The latter are adjusted to size after assembly of the cabinet body. For glass shelves, special holders are sold that will not damage the base.

- It is better to equip the boxes (if expected) with guides, then they will slide out easily and freely, without the possibility of warping and getting stuck.

Selected material - chipboard, chipboard or solid wood panels - must be properly processed

In the manufacture of cabinet furniture, pay attention to the fact that chipboard can crumble during the insertion of fasteners. The material requires accuracy and precision in the outline and actions

It takes time to dry after each coat.

Assembly instruction for straight model

Before assembling a straight sofa, you need to read the instructions.

Unpacking

First you need to start unpacking the product. For this, a protective film is removed from every part of the sofa. It is quite durable and therefore it is better to remove it with a knife.

This must be done carefully so as not to damage the surface of the furniture.

After unpacking the product, you need to check the package contents. The kit should contain all the details of the bed, as well as the fasteners that will be needed for the assembly.

Instrument preparation

There are several tools that will come in handy when assembling a new sofa.

Scotch

Scotch tape is a common adhesive tape used for gluing small parts. When assembling the sofa, it can be useful for gluing the protruding upholstery of the product.

Construction stapler

A fairly popular tool for attaching plywood, chipboard, fabric and other thin materials is a construction stapler.

Adjustable or wrench

An adjustable wrench is a multifunctional tool that can replace open-end wrenches. It is used if you need to screw on parts that are fastened with bolts.

Screwdriver

Some elements of the beds are fixed with small screws. To attach them to each other, you need to use a regular screwdriver. For work, you may need straight and cross-type screwdrivers.

Screwing the legs

First, you need to fix the legs on which the structure will be installed. They are attached to the bottom of the bed with metal bolts or screws. The legs must be screwed on carefully so that they do not get loose.

Assembly diagram

Having screwed the legs, proceed to the assembly of the rest of the structure. The side walls are installed first, if the sofa has them. They are fastened with special screw fasteners. Then you need to screw on the backrest.

It is quite easy to check the assembled bed. To do this, you need to spread it out and lie down. If at the same time there are no creaks and other extraneous sounds, then everything is assembled correctly.

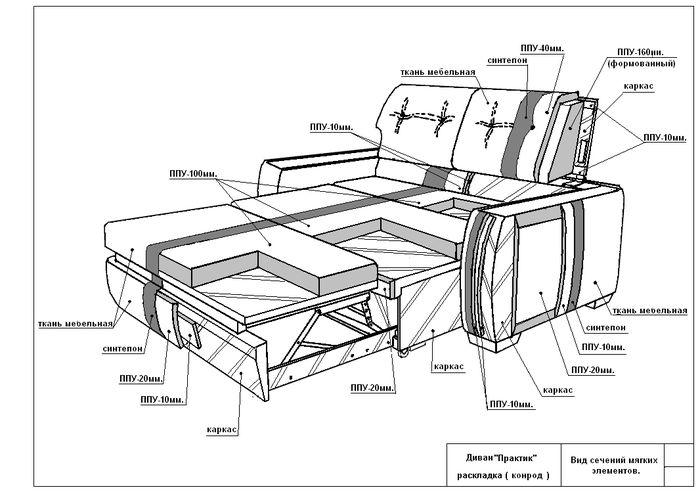

About cutting and sewing

The most difficult and responsible part of the work on the manufacture of a sofa is its padding, upholstery and covering. These are different manufacturing operations; each of them separately and all of them together determine the consumer qualities of the product and its durability more than the carpentry. True, in Runet, masters are strenuously promoting themselves, promising to pull the sofa in an hour or even 20 minutes, but, firstly, they work mainly with non-woven materials (fleece, etc.), which are short-lived in themselves. Secondly, they are fitted according to a simplified system with turning the corners from the inside out, which is unhygienic and guarantees quick abrasion of the skin. And most importantly, according to this method of work, there is no reliable information about: a) the durability of the product before the need for constriction; b) whether any of the primary clients contacted this specialist again.

To properly sew the covers for the sofa modules, you will need serious preparatory work. Its essential subtleties will be described below; beginners are advised to fit the sofa in the old amateur way with a saddle fitting. Pros do not work for them, tk. it takes a long time, but who will pay for it? But at the time of the heyday of stagnation (or stagnation of flourishing?), When it was necessary to register for the furniture hauling in a year, and even give a bribe, it was successfully used by "full teapots". Sadly, the sofa is covered in stages like this:

- The wooden base is covered with technical fabric - canvas, matting, burlap (you can use propylene);

- Install a soft padding, most often - foam mats;

- Tighten soft, in order of preference, spandbond, padding polyester, batting;

- On a cut of decorative fabric, the wings are swept under the cords, if decorative scars / tightenings are provided, see below;

- A decorative cut, not cut, is thrown over the product with the wrong side out, pulled, as described below, and the corners are swept away with a harsh thread (now reinforced with propylene) with a scar outward;

- A day later, they check whether it is wrinkling where, whether it sags, whether the drawing, especially the geometric one, has led, and, if necessary, correct the angles;

- If everything is OK, mark the seam lines, cut and sew;

- Tighten the cords into the wings for tightening, if necessary;

- Throw in a cover, make the final tightening, starting from the corners;

- After another day, check the drawing, correct the tension threads ;;

- Everything is OK - fix the lapels;

- Forms decorative straps.

The procedure, as we can see, is rather complicated and time-consuming. This is explained by the fact that the properties of tissues, incl.upholstery, differ markedly and within the piece. Previously, upholsterers were guided by intuition and experience, now the technical parameters of a specific sample are directly entered into professional computer cutting programs. Homemade patterns from wallpaper newspapers do not provide this and do not take into account the initial tightening of the fabric. However, it is useful to make them - for determining tissue consumption. A rough estimate according to the method: the length of a cut with a width of 150 cm is equal to 2 widths of the sofa + 2 its lengths, it gives a big deviation. Determination of the cut length by templates (allowance - from 15 cm) gives a length saving of up to 1 m (!); how much it is in money - see the store.

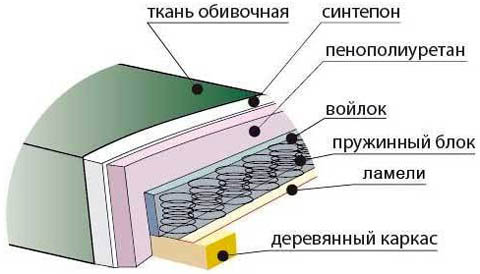

The scheme of stuffing upholstered furniture with a spring block

Clauses also require additional clarification. 1-3. If you stuff the trim hastily, wood-glue-synthetic winterizer-foam rubber-decor, then after a while you will find that the trim is greasy, to the touch, especially in summer, sticky, and the dearest parts of the body are uncomfortable on it. Let it be "some" 3 years, but what is this lifetime for furniture? Therefore, soft mats need padding on both the bottom and top of the porous gaskets, which wick away evaporation / sweat / dirt from them. In furniture with spring blocks, by the way, too, see fig.

Making a corner sofa with a retractable mechanism

The design of such a piece of furniture, although it has impressive dimensions, will perfectly fit into any interior. The corner arrangement saves space. The creation of an independent project has a lot of advantages - the ability to choose a suitable high-quality material for the frame, the size of the structure.

It is better to make the base of wood; coniferous timber, fiberboard, chipboard, plywood are suitable. To work at home, you will need a large space, a set of necessary tools (circular saw, furniture stapler, screwdriver).

You should start with the preparation of the drawing. The manufactured construction parts must be numbered and laid out on the floor. We start the assembly with the largest parts, gradually adding them. It is better to fix the tree with screws and glue. To fix the lifting mechanism, it is necessary to drill holes in the bottom and screw on the boxes. The finished structure is pasted over with foam rubber, agrotextile for tightening and upholstery.

Types and classifications of sofas

Under one general name "sofa" there are various types of this furniture. And corner, and books, and even round. To understand which sofa is suitable for an apartment, it is worth understanding the classification of this type of furniture. First of all, we will consider sofas by the type of how they unfold (or transformations), that is, according to the type of folding structure.

Sofas are different in the type of transformation

Table. Varieties of mechanisms.

| View | Description |

|---|---|

Sesame |

It is easy to turn such a sofa into a full-fledged and fairly spacious and comfortable bed, however, only for one, moreover, it will have a comfortable mattress resting on an orthopedic hard surface. It is perfect for both a nursery and a hall or other room. To unfold this version of the sofa, you must first pull out the part hidden in its depths, and then raise the sleeping place itself. This is Anderssen's original development. |

Junior |

This is a great option for a small room, often placed in a nursery. It looks like an ordinary sofa, but when unfolded it turns into two beds, one per person. There is a small seating area between the sleeping sections. Such a sofa can be folded out very simply - you need to pull out the sleeping places for special hinges. |

Tango |

Such a sofa resembles a variation of the "click-gag" book and is suitable for those who want to sleep together. It is easy to unfold it - you need to raise it a little, and then lower the upper part-back. It turns out a fairly spacious place to spend the night. The sofa has armrests, they can be positioned at the desired angle and make a headrest. |

Coupe |

This sofa can be easily converted into an analogue of a bunk bed.He is the author's development of one of the furniture companies. This is a great option for a nursery, as well as for those who often host guests for several days. To unfold it, you need to lift the upper part of the structure up, fix the side for the upper seat, install a ladder and raise the lower sleeping place in the depths of the bed. |

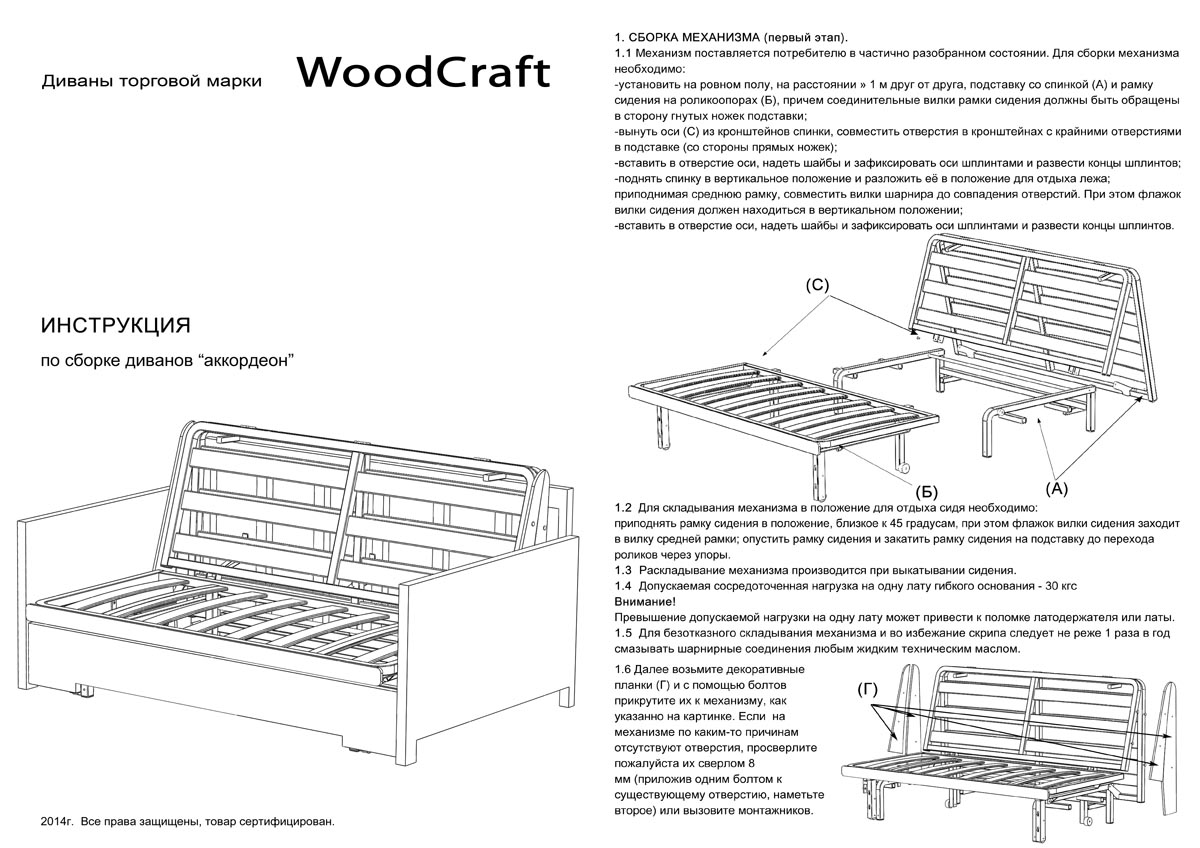

Accordion |

This is a classic version, which is a kind of accordion of three elements - two halves of the back and a seat. By expanding it, you can get a spacious place that can accommodate up to 3 people. Folded, it does not take up much space, but it requires a lot of free space in front of it. |

American clamshell |

Easy to fold out version. The "bed" is twisted inside, and you just need to unfold it and you can get ready for bed. Moreover, such a place does not have bends and seams, which means that it is very comfortable to sleep. Ideal for a guest. |

Breeze |

To unfold such a piece of furniture, you need to roll out the sleeping section forward. It will not take up much space, but it will provide sleeping places for two people. |

New Roller |

One of the easiest options. If you pull the backrest, a place for dreams rises from the depths of the sofa. There are no rough joints on it, it is very comfortable and cozy to sleep. |

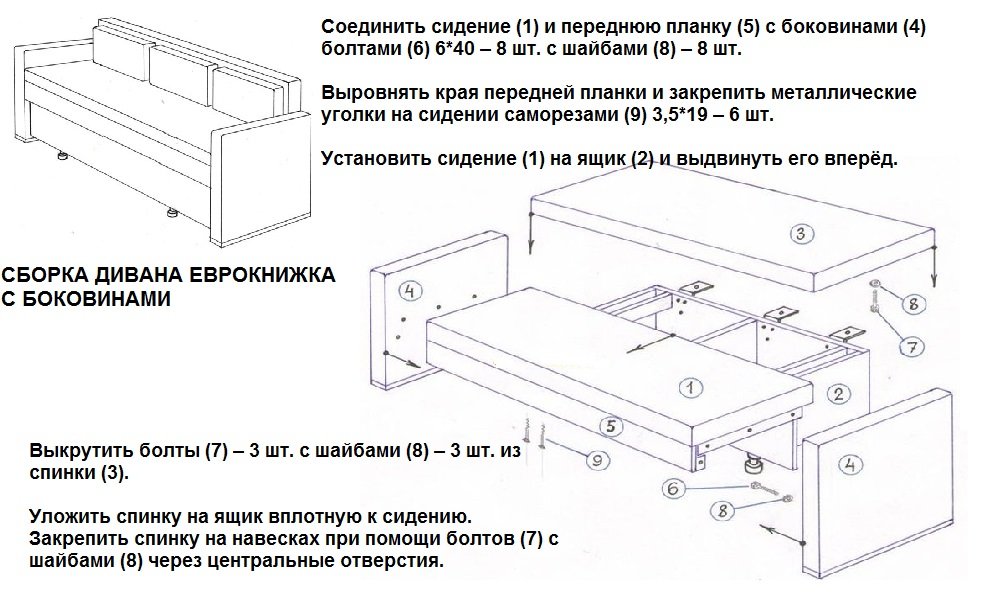

Eurosophus |

Easy-to-fold comfortable sofa. You just need to pull out the laundry drawer, on top of which to lay part of the seat. The furniture takes up little space, and the joint between the halves of the sofa is almost not felt. |

Transformer |

Such sofas can be hidden for a day when they are not needed, in a closet or table. And only for the night to get them again and turn them into a sleeping place. |

Sofa-book

Also, sofas can be divided into several types according to the type of design.

- Straight - a sofa that has a flat seat and a flat back. Can be expanded. Book sofas belong to this type.

-

Chair-bed. Compact and takes up very little space when folded. Designed for one person's sleep.

-

Angular. For a long time, these sofas were very fashionable. But they take up a lot of space. They have an angular shape, turn into a bed by unfolding or extending the straight part of the sofa.

- Couch. A small sofa that can be easily converted into a bed for one occupant, just by moving the seat and raising the lower part.

- Roll-out. Such a sofa is laid out by rolling out its part forward or sideways.

- Unfolding. To unfold such a sofa, part of it must be unfold.

- Unfolding - a sofa that can be unfolded and turned into a sleeping place for 1-2 people.

Sofa "Book-Finca"

Why is self-assembly better?

So after all, you can order an assembly and the problem will be solved by itself. Indeed, this is the simplest and physically not costly option (you do not have to be surrounded by drawings and diagrams, select the necessary screws, look for holes for fasteners under the upholstery - all this will be done by the master).

There are at least two things to consider here:

- first, sofas are assembled for free in isolated cases (not all stores can afford such a function, or this is a very simple sofa model);

- second, it can take from one to several days between the delivery and the visit of the furniture assembler (and while you wait, the sofa will take up space in your apartment in disassembled form).

But don't be discouraged. You can assemble a sofa with your own hands. This is not difficult.

What does a chair-bed consist of?

In general, there are several varieties of the described device. However, each of them has those components that are similar to each other. Thus, the following aspects can be distinguished:

Frame. It is also possible to view it in several proportions. By choosing steel material, the user is assured of durable operation.

If we talk about aluminum, then it is very important to emphasize its inherent qualities such as reliability and guaranteed strength.

ATTENTION! However, the product is not suitable for daily use. With regard to wood, special conditions are required for use here.

This includes not only a certain temperature, but also a special indicator of humidity.

- Folding mechanism.

- Bed.

- Filler. When choosing it, it is recommended to make a special emphasis.

- Laundry box. Often, manufacturers equip the structure with such a product, which gives additional positive aspects.

How a chair bed works

The answer to the question directly depends on the bed model. Thus, the following can be distinguished:

- Eurobook. The process takes place by pulling out the bottom of the furniture. Due to this, it becomes possible to expand the other part.

- Harmonic. Two sections fold out, and a third is found, which serves as a seat.

- Draw-out mechanism. The name speaks for itself. The inverted base forms two sections.

- Click-gag. The main part rises, that is, the blockage is removed and a one-piece mattress is formed.

- Dolphin. The part that unfolds is under the base, after its extension, it transforms into an ordinary sofa.

Assembly diagram of the sofa "Monaco"

Buyers who purchased a sofa without assembly service may have questions about the order in which to produce it. The instructions for assembling the sofa "Monaco" ("A lot of furniture") have step-by-step actions. She describes in detail the sequential steps you need to take to assemble the sofa. It is quite simple to install the product. Disassembled sofa "Monaco" has the following elements:

- main part;

- corner part;

- retractable part;

- back;

- two armrests.

The first step is to install the supports on the base, corner and armrests. The rollers should be screwed to the retractable part. Then it is necessary to connect the armrest with the corner section using euro screws. It is necessary to check that all elements are tightly fastened to each other. The next step is to connect the main part to the back and the second armrest. After these actions, the resulting structures should be connected to each other, fixing the rear wall with armrests, after which it is necessary to tighten all the euro screws to tightly fix the elements.

Further, on the guides of the main part, you need to install a sliding one. This completes the assembly of the corner sofa. The instructions for assembling the sofa "Monaco" ("A lot of furniture") contains a detailed description. After reading it and reading this article, the owners of the sofa should not have any questions about self-assembly.

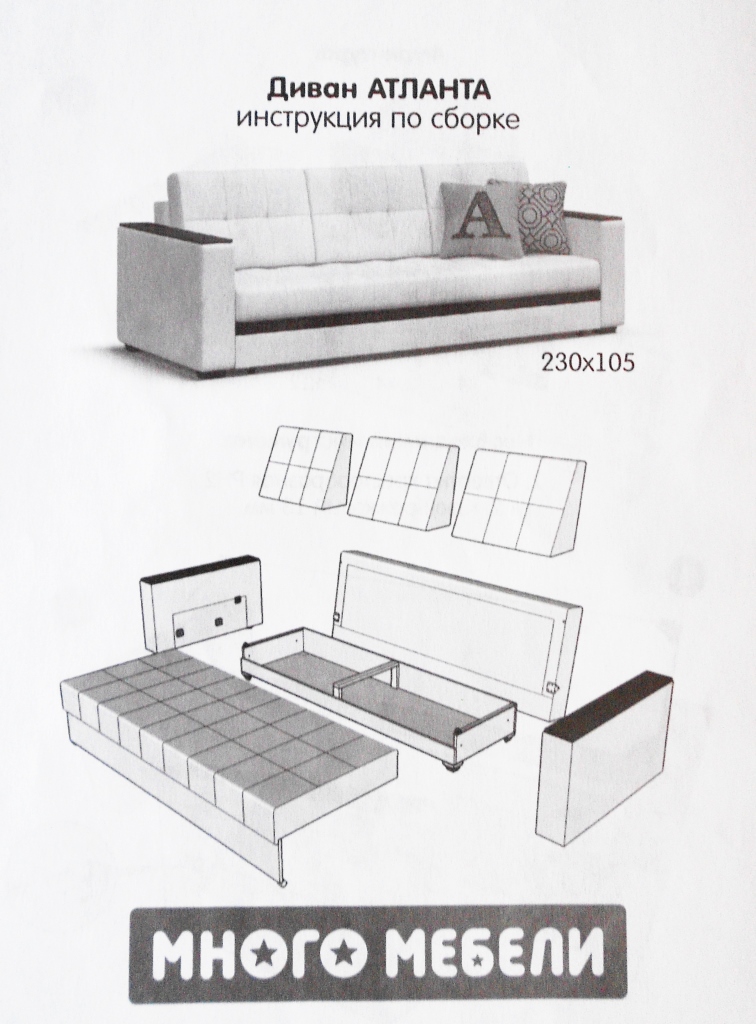

Atlanta corner sofa is one of the most popular models of corner sofas. Made of high quality materials, it has strict and harmonious forms that will adorn the interior of almost any style.

Upholstery types are represented by two main materials: eco-leather and textiles.

Eco leather

Textile

A built-in side table and a wide armrest on the other side allow you to comfortably place all the necessary things, be it a laptop or a cup of hot coffee. And its angle can be changed, depending on the layout of the room. When assembled, this piece of furniture is just over 2.5 m long, and when unfolded it turns into a comfortable double bed.

Unfolded sofa

The combination of all these features makes many buyers choose the Atlanta model.

Professional furniture assemblers will deliver and assemble it as soon as possible. But if you decide to assemble the sofa yourself, then the assembly instructions attached to each product, in which everything is written and illustrated in detail, will help here. In addition, if you decide to do the assembly yourself, find visual photo and video examples that will allow you to exactly figure out how to assemble an Atlanta sofa yourself by direct modification.

After you have made sure that the delivered parts fully correspond to the ordered sample and have been brought in full, you can proceed to the process of assembling the Atlanta sofa.

Make sure you have all the necessary tools prepared:

- hex keys of different diameters;

- crosshead screwdriver;

- open-end wrench.