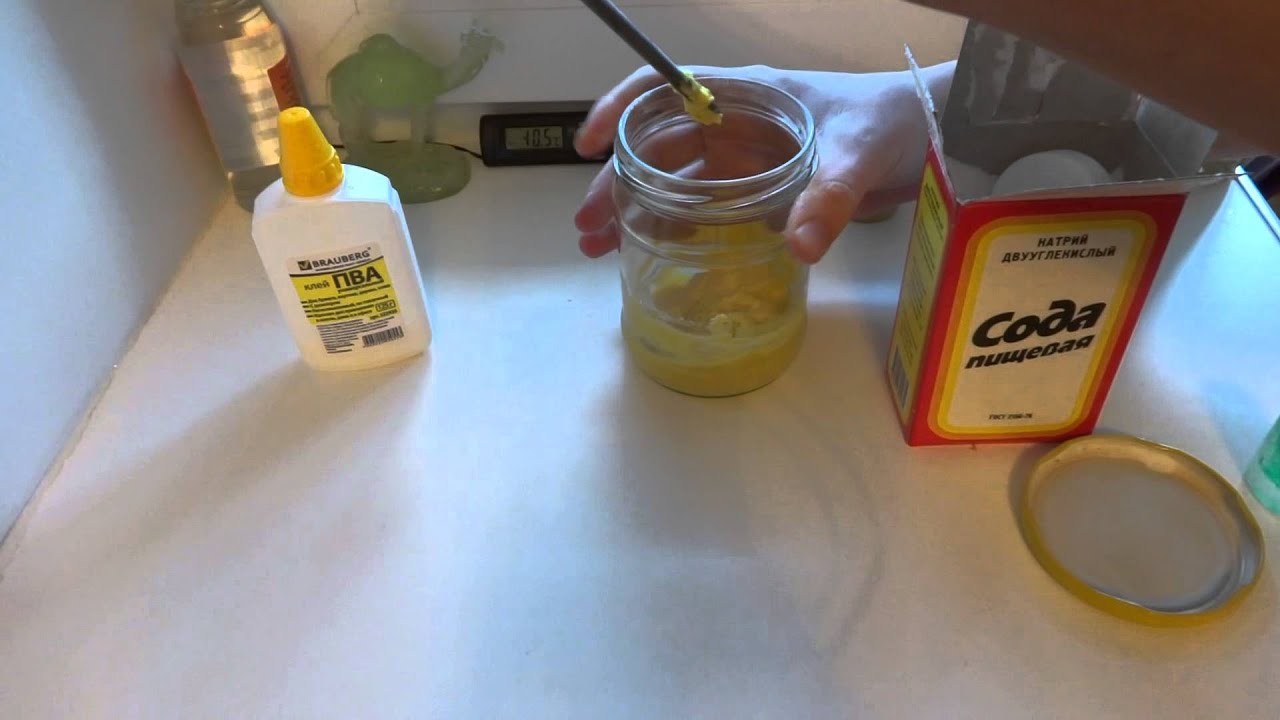

PVA glue

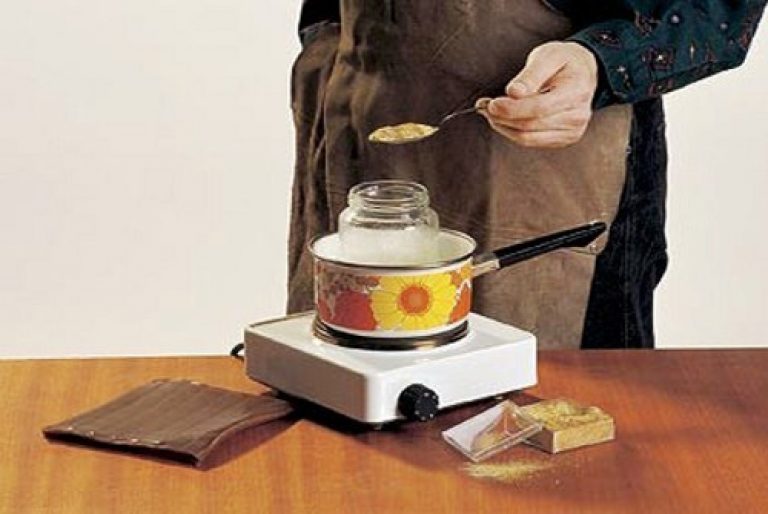

With this method of preparing the base component for slime, it is also important to observe the proportions. Therefore, the amount of all components is determined using a scale and a measuring cup

How to cook

- PVA must be filled with plenty of water.

- Further, the composition is supplemented with citric acid.

- Now it needs to be mixed for a more even distribution of the components in the liquid and put to cook on the stove until the grains of polyvinyl alcohol dissolve.

- After the finished mass has cooled for 20-30 minutes, you need to remove the film formed on top.

- The remaining water and titanium dioxide are mixed in a separate small container.

- A teaspoon of this mixture is poured into the previously prepared transparent glue.

- After mixing, the PVA-like product is ready.

We recommend reading about how to make a slime out of glue. From the article you will learn about recipes for making slimes from PVA glue, glue stick, Moment glue and Titanium.

And here is more about how to make a slime without glue.

Homemade glue, with the correct proportions of the ingredients, turns out to be one hundred percent working, which cannot be said about the one bought in the store. Therefore, those who are fond of making slimes should try to cook it yourself. The process is simple and fast enough, but children should do everything only with the participation of adults.

Be sure to watch the video recipe for white slime glue:

Basic recipes and instructions

You can make a homemade adhesive from simple products and inexpensive chemicals sold at any pharmacy or home improvement store. The preparation of homemade glue takes a minimum of money and time.

Flour

Wallpaper glue has been prepared from flour for several decades. Over such a long period, the recipe has been modified and improved more than once. True, the main components of each composition are flour and water.

First

The composition of wallpaper flour glue includes the following ingredients:

- 4-5 st. tablespoons of flour;

- 1 liter of liquid.

How to cook:

- pour all the flour into a bowl;

- pour flour with 0.5 liter of cold water and stir;

- pour the remaining 0.5 liters of liquid into a saucepan, put on fire and bring to a boil;

- introduce the flour mixture into hot water in a thin stream;

- mix the composition, then bring to a boil again and remove from the stove;

- cool the mass.

Second

An adhesive is prepared from flour according to this recipe:

- 2 tbsp. tablespoons of flour;

- 1 liter of water.

How to cook:

- pour flour into a saucepan;

- pour cold water;

- stir the mass;

- put the saucepan on low heat;

- with constant stirring, bring the powdery mass to a boil;

- remove from the stove and cool.

Third

Flour glue is prepared from the following products:

- 5 tbsp. tablespoons of flour;

- 1 liter of liquid;

- 50 ml of PVA glue.

How to cook:

- pour the flour with cold water;

- put a saucepan with the mass on the fire;

- simmer until boiling;

- cool the mass;

- add PVA glue to the cold mixture and mix thoroughly.

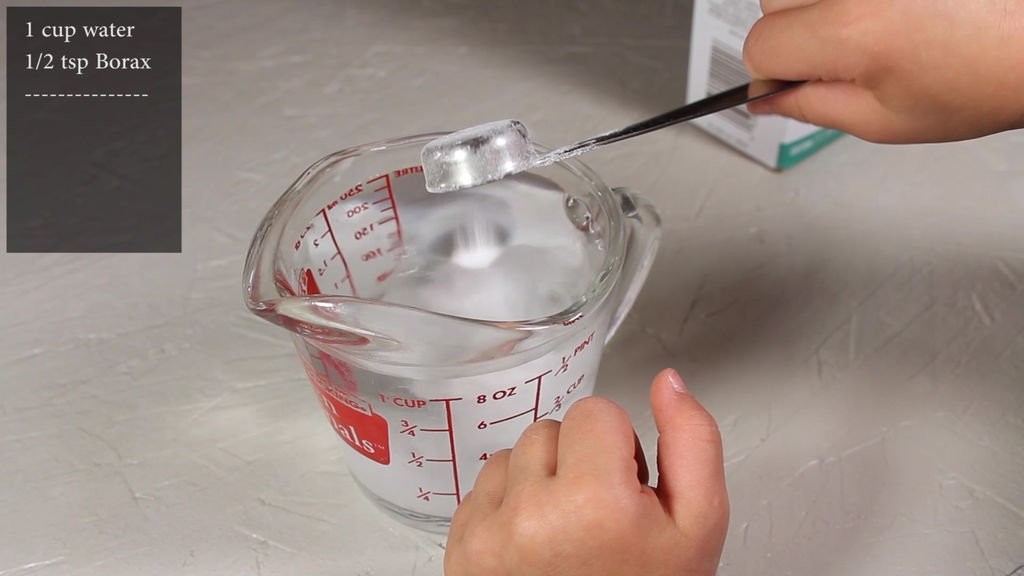

From starch

Composition:

- 1-3 st. spoons of starch;

- 1 liter of water;

- 45 ml of PVA glue.

You can weld the adhesive like this:

- pour starch with 0.5 l of water at room temperature;

- mix the mass;

- add 0.5 liters of boiling water to the mixture;

- put the mass on fire and bring to a boil;

- Cool the mixture and add PVA.

PVA

Purchased PVA glue is added in a small amount to a homemade adhesive made from flour or starch. This additive improves the quality and adhesive characteristics of the home glue. You can make your own PVA paste.

Composition:

- 105 g flour;

- 25 g of ethyl alcohol;

- 5-10 g photographic gelatin;

- 7 g glycerin;

- 1 liter of water.

How to cook:

- pour gelatin overnight with 100 ml of water;

- Dissolve flour in 100 ml of liquid until smooth;

- add 800 ml of water to the gelatinous mass and put the mass in a water bath;

- add the powdery mixture to the warm loose gelatin;

- with constant stirring, bring the mass to a boil;

- remove the mixture from the stove;

- add alcohol and glycerin.

Joiner

To prepare the carpentry paste, you need to buy dry ingredients. Granules or briquettes are sold at any hardware store. On the packaging they say: a substance for the preparation of wood glue.

Before preparing homemade paste, the semi-finished product must be crushed into powder, soaked in water at room temperature. The granules are completely filled with the cooled boiled liquid and left for 11-12 hours. The swollen mass is heated in a water bath, brought to a boil and cooled. For 100 grams of granules, take 105 ml of liquid. In the process of preparing the paste in a water bath, hot water is added to the mixture to make the mass more liquid.

Universal paste

For wallpapering walls, you can make a universal paste of syndeticon. His recipe appeared at the end of the 19th century. Such glue can replace an expensive commercial product. It is prepared from wood glue (125 g), sugar (125 g), hydrated lime (35 g) and water (495 ml).

First, the sugar is dissolved in the liquid. Then lime is added. The mixture is boiled over low heat for an hour. The clear solution is cooled, pieces of wood glue are poured over it. Then the mass is boiled again in a water bath until the wood glue is completely dissolved. The mixture is constantly stirred and not brought to a boil.

Dextrin based

The paste is made from dextrin. This substance can be ordered online or made yourself from starch. However, a homemade product will not fully have all the qualities of dextrin. But it is suitable for preparing an adhesive solution for wallpaper.

Homemade dextrin is prepared like this:

- Pour 100 g of starch on a baking sheet and put in a warm oven;

- the substance is slowly dried for 1.5 hours at a temperature of 70 to 160 degrees;

- dried yellow starch is poured into 0.5 liters of cold water and stirred quickly;

- add 30 ml of glycerin.

At home, you can make excellent moisture resistant glue. The composition of such a sticky mass includes wood glue and drying oil (linseed oil). Respect the proportions - 4: 1. A little drying oil is poured into hot joiner's glue and the mass is thoroughly mixed.

How to make wood glue with your own hands?

This glue is ideal for wood. Also, he

effectively glues paper and cardboard, other cellulose materials, and in

in some cases even plastic. However, for such glue, you need to highlight a couple

disadvantages:

- firstly, it is not stored for too long in liquid form and

perishable;

- and secondly, it has simply disgusting and harsh

a smell that you can only come to terms with.

Partially, this problem disappears if it is previously

boil and make a gelatinous mass. Then, its validity period increases, and

if necessary, you can cut off a piece of the required size, heat it over low heat, and

exploit. There are several recipes for making such glue. Most

elementary and affordable for you, we will describe below.

Way

first. Take regular wood glue. Grind it up and soak it in

water until it swells completely. So, it will soften, and become like

jelly. In the same condition, place it in a melting container, under

the name of the oilcloth. The easiest way to make such a container is from an ordinary

cans (condensed milk or canned pineapples). Ship

gelatinous mass in such a jar, and put it in a water bath (while

should be very low fire). Stir the warming mass with a wooden spoon,

or with a stick (for example, from sushi). You need to stir constantly, because in

in the event of burning, the mass will acquire a yellowish color, while losing

its adhesive qualities. After the mass turns into a liquid state, dilute it

vodka with the following ratio: 720 grams of glue needs 950 grams of vodka.

Then, for every 100 grams of glue, add 12 g of powdered alum.

The resulting homemade wood glue will have a high degree of adhesion.

and have excellent water repellency.

Method two.

in the same glue, mix wood glue and water in a ratio of 1 to 1. After

after the mixture starts to boil, it will thicken a little, and at this stage

it must be poured into a ceramic mortar, and rubbed with a pestle until a gelatinous

masses. Then, put the glue on a plate, cool, and cut into the required

pieces. If necessary, mix the glue with vodka in a different ratio -

720g (glue) / 360g (vodka). Bring the mixture to a boil, then cool and use.

Method three.

Boil a mixture of one liter of water, kilogram in a water bath

wood glue, and one liter of 9 percent table vinegar. After,

while stirring this consistency, gradually add a liter of vodka to it.

Method four. Dissolve wood glue with water

the ratio is one to one. Heat it in a water bath until

the mixture will not completely thicken. After, add one part of glycerin (equal to

part of the glue that was originally taken). Put on low heat and wait until

water does not evaporate completely. It remains only to put in a mold and dry

glue. Stir 1 to 1 with water before using.

Composition

The described material consists of three main components:

- most of it is natural fiber - cellulose, cotton or silk - is chosen at the discretion of the buyer, since in finished form they are somewhat different from each other;

- natural fiber is mixed with a water-based dye (pure white formulations are commercially available);

- The composition is complemented by a binder - an acrylic dispersion or glue, which makes it easy to apply the mixture to the walls with a spatula.

If desired, when the master himself makes the composition, he can add marble chips, mica sparkles or colored flocks, if required by the design of the room where the repair is being made.

The disadvantages of liquid wallpaper are insignificant, so they do not talk about them. The only unpleasant aspect is washing them off with water, although this material is also suitable for the bathroom.

So, the wallpaper is afraid of a direct hit of water, but do not rush to put an end to it. If you wish to use this material for bathroom walls, do not apply directly over the bathtub or within the shower area. Otherwise, a protective varnish can be applied to the surface of the dried wallpaper. It is colorless, not susceptible to moisture, it is purchased in hardware stores along with decorative materials.

DIY carpentry adhesives

All technologies, regardless of the selected recipe, consist of 2 main stages - softening the original substance (to the consistency of jelly) and its subsequent cooking. For cooking, you need raw materials. It is sold dry in granules, tiles of different colors, sometimes powder or small fractions ("scales"). When applied to carpentry glue, the phrase “do it yourself” should not be interpreted literally. Even if there is a desire (and opportunity) to grind bones, how much of this mass is needed, for example, per liter of water? By what technique to cook (temperature, duration), what to mix with, proportions?

There are so many questions that even experienced craftsmen use store products as raw materials to obtain the final composition in practice. Not a shortage, and it is never superfluous to purchase with some margin (given the low prices). Moreover, the shelf life of dry joiner's glue is practically unlimited.

Recipe 1

The original product is crushed. If it is a tile, then it is pre-broken into pieces. The resulting fragments (or granules) are wrapped in a dense material, and then with a hammer. Nothing complicated. It is only necessary to ensure that there are no large pieces left, since they dissolve much more slowly in water, and the process of making wood glue will take a long time.

The resulting "powder" is poured into a suitable container. For a small amount of work, an ordinary bowl or tin can is enough. Above - water, but always boiled and cold. It should completely cover the loaded mass. After that, it is necessary to wait until it goes into a state of jelly, that is, it swells and becomes like jelly. How long it will take depends on the quality of the "grinding" of dry joiner's glue and the temperature in the room. But this should happen naturally. There is no need to accelerate the process artificially, with the help of heating devices.

"Steam bath". It is easy to organize. Jelly is loaded into a container of appropriate capacity, and it is placed in another, larger one (for example, a basin). Water is poured into it, and all this is on the fire. To be able to regulate the intensity of the flame, it is more convenient to prepare wood glue on a gas stove. The mode is selected so that the jelly temperature is within 70 ± 10 ºС. Within a quarter of an hour, constantly stirring the composition, you can achieve its transformation into a thick monotonous mass, without lumps and bubbles. At this stage, hot water is added to speed up the process, but little by little, dosed.

The readiness of the joiner's glue for use is judged by the formation of a "light" film on its surface.

Recipe 2

It is somewhat simpler. In addition, it allows you to prepare a certain amount of "semi-finished product" for future use.

- Dry glue is crushed as much as possible.

- Dilution in water (1 to 1).

- Boil (15 - 20 minutes).

- In the process of cooling, the mass is ground to a paste (for example, with a spoon in a metal bowl).

- The cooled composition is cut into pieces.

Before direct use, it is enough to soak in water (until dissolved) and heat well.

Additional tips and tricks

A few more recommendations:

- When adding wood glue to the paste, which is more suitable for hand-made crafts or making papier-mâché, it is not recommended to use it for pasting wallpaper, otherwise it may leave streaks and yellow spots.

- When the paste thickens during storage, it is recommended to add a small amount of boiling water to it and carefully move it, and then strain it. It is necessary to ensure that the composition does not contain lumps, then it will be possible to apply an even and thin layer of glue.

- The greatest stickiness can be achieved using a freshly prepared and cooled paste, where it is better to add a little PVA.

- If traces are formed in the area of the joints when wallpapering the walls, they can be easily removed with a cloth soaked in warm water.

- If, in the preparation of the adhesive, not only starch is used, but flour is also added, you should not take dark varieties so as not to spoil the color of a light, almost transparent suspension, which will not leave traces when it dries.

Homemade PVA glue

The second, no less popular and effective, is homemade

PVA glue. If you think that the glue is made at the factory according to some special

technology, you are mistaken, because exactly the same glue can be made at home

at home. Agree, this type of glue is one of the most common.

It is used as a stationery

sphere, and in the construction, that is, in fact, it can be called universal

glue. Well, it's time to move on to how to make it all the same. For this

would need:

1.Distilled

water in a volume of 1 liter;

2.Photographic

gelatin (can be purchased at any camera supply store) in quantity

5 grams;

3.Pharmacy

glycerin (4 grams is enough);

4. Wheat

flour, about 100-150 grams;

5.Ethyl

alcohol in a volume of 20 ml (can be bought at any pharmacy).

Conventionally, manufacturing can be divided into two stages:

Is a preliminary preparation, during which gelatin

need to be soaked in a glass of water;

- and the cooking process itself.

So, a day after the gelatin swells, you can

start making PVA.

∙

Place the distilled water in a water bath in a container. Further,

add gelatin to it, and stir with flour, stirred in a small

the amount of water (again, without lumps);

∙ Bring the mixed consistency to a boil, but not in any way

boil

Notice how the mixture becomes thick and white, like sour cream.

Stir it so that in the end the glue is homogeneous, without lumps.

∙ It remains to add only glycerin and ethyl alcohol.

Stir constantly and stir the mixture again so that it turns out as much as possible.

thick. The stirring time should be about 10 minutes, so do not

think that two stirring with a spoon will be enough. You can use glue

only after its complete cooling.

Common mistakes

Sometimes, a few days after the repair done, the wallpaper begins to swell, move away, fall off. In this case, the glue is not always to blame. Although its quality plays an important role in the repair. Before wallpapering the walls, you need to carefully prepare the surface. It is necessary to remove old paint, lime, all peeling plaster, loose particles. Before pasting the wallpaper, the wall is cleaned of old finishing materials, leveled, and must be primed. A commercially available acrylic primer is usually used.

Glue is smeared over the entire surface of the canvas. Make sure that no area remains uncovered with the adhesive mass. Before gluing the wallpaper to the wall, they are given time to soak in the adhesive mixture. It is impossible to glue it to the wall surface immediately after applying the glue to the canvas. During the renovation, make sure that all windows and doors are closed. Any draft, temperature fluctuations at the drying stage of wallpaper just glued to the wall can lead to disastrous consequences.

Paste preparation rules

- wallpaper paste is not prepared from wheat flour, since this leads to yellowing of the paper material after drying;

- considering that the product contains food products, it can attract insects, add a small amount of karbofos;

- when a paste is being prepared, how to make its properties better - you also need to think about it, for example, a warm microclimate contributes to a decrease in the effectiveness of the composition, you need to know in advance how to store the glue correctly - the temperature should be within + 18 ... + 20 ° С;

- too thick paste will not provide the desired effect, the change in the structure of the substance is due to its prolonged cooking, in this case the agent is diluted with water again (a small amount is introduced) and heated, but for a short period;

- when the paste is being prepared, the heating temperature of the liquid should not be higher than + 40 ° С;

- to improve the properties, PVA glue is introduced into the composition, but its content should not be higher than 5%;

- as it is used, the substance will lose its properties (it will gradually thicken); hot water will help restore its original structure - it is added in 1 tbsp. l., constantly mixing the product with a blender or mixer - you should act quickly, since the composition will soon thicken again.

Additional tips and tricks

Paper wallpaper in a children's room or hallway can be glued to homemade flour or starch glue. A self-prepared composition can turn yellow over time, so materials for finishing are chosen in brown or pastel colors.

For non-woven or vinyl wallpaper, it's best to buy ready-made glue and not experiment with homemade products.After all, such wallpapers are always expensive, they can be easily ruined by low-quality adhesive mass.

Homemade glue can be used to glue the walls in the country. True, you first need to add a little fungicide or insect repellent to the sticky mass so that fungi and pests do not start under the wallpaper. True, the toxicity of such an adhesive will increase.

It is better to use ready-made glue with antifungal and antiparasitic additives for repairs. The time when homemade adhesives were prepared is long gone. Once upon a time it was impossible to buy good glue in a store, so the glue mass was prepared by hand at home using an artisanal method. Today, in any store that sells goods for construction and renovation, there is a huge amount of quality adhesives for any type of wallpaper.

p> Share link:

Benefits of using homemade adhesives

You can make wallpaper glue from what is in the kitchen cabinet or pantry. Homemade adhesive cannot be an alternative to a purchased product. Chemical plants produce various types of wallpaper adhesives with important technical features and improved composition. The purchased adhesive product contains substances that prevent the wallpaper from dampening in conditions of high humidity, prevents the development of mold and mildew, and has insecticidal properties.

Household glue does not have all of these qualities. After all, it is prepared from simple substances, the main property of which is to form a sticky substance in the process of thermal, chemical processing or when mixing various ingredients. True, homemade glue has its own advantages. It is made from simple, often inexpensive foods. A ready-made composition made at home in the kitchen will be 10 times cheaper than purchased adhesives. A homemade adhesive is being prepared from natural raw materials. This means that such glue can be used in any room, even in a children's room.

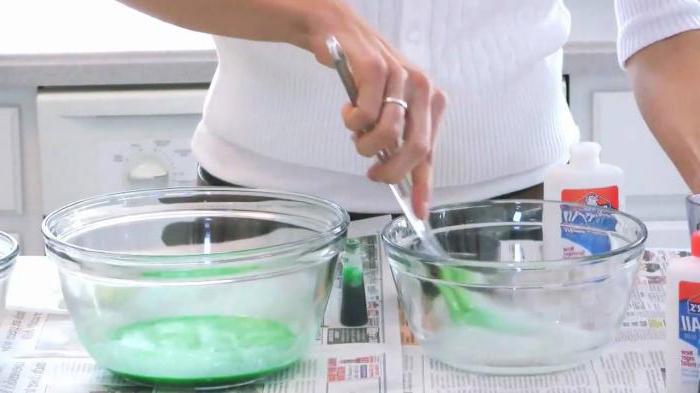

Traditional flour paste recipe

Such glue is used quite often in a variety of

situations. Most often, its preparation is resorted to when urgently needed, for example, when

running out of glue from the store during the wallpaper update. Therefore, so as not

run to the store for a new pack (which apparently will be used

only 1/3), it is easier to make your own glue, which will not

worse. Plus, such glue is not toxic, and it is quite safe for

use at home. The main component is flour, which

probably in every home. The relationship of the glue is as follows - 1 liter of glue is enough for

2, 3 rolls of wallpaper.

Prepare the following components:

- the container in which the glue will be mixed;

- 6 tablespoons of flour per liter of water;

- water, according to the amount of flour (1 liter per 6 tbsp.

spoons).

You need to prepare the glue as follows:

1.Heat

water to a boil;

2.B

in a separate container, stir the flour with cold water until a mixture is formed,

like liquid sour cream (and always without lumps);

3.Now,

pour boiling water into this mixture in a thin stream, while constantly stirring it

spoon;

4.After

mixing, boil the mixture again and leave to cool.

The finished consistency should resemble a thick jelly.

Similarly, you can prepare such a glue using starch.

instead of flour, and it will not differ a bit from flour. In some cases

such glue can even prove to be much more effective than glue from the store.

If you are afraid to apply such glue to the wallpaper, test it on small

pieces of wallpaper by gluing them together. In general, this glue can be used

with any wall surface, glue paper with cardboard and other types

paper. In short, experiment and see everything with your own eyes.

The composition of the paste for creativity

In a domestic environment, various crafts are made with the help of paste. Different recipes are used for each variety. For example, you can prepare glue for fabric crafts in this way:

- Prepare 2 glasses of water, 2 tbsp. l. flour (any), 1/4 tsp. sugar and a small amount of vanillin (pinch).

- Take the recommended amount of flour, 1/2 glass of water, stir until the lumps dissolve.

- Use the remaining amount of water and sugar. The container must be put on fire.

- A thick flour-based substance is introduced into the liquid (in a thin stream).

- When the product boils, you can remove it from the stove and add vanillin.

Another recipe is used to create papier-mâché crafts:

- Take 1 glass of flour, 3 glasses of water, 1/2 tsp. salt.

- First, combine flour and water in one container, mix until the lumps disappear.

- Salt is added to the composition. Mixing continues.

- The remaining amount of liquid is heated separately.

- Pour the thick substance into a container of hot water.

The duration of the preparation of the paste according to the second recipe is 10 minutes. Then the product should cool completely.

Ready mix prices

Isn't it easier to buy ready-made mixtures for liquid wallpaper? Let's calculate how much they will cost. Of course, we cannot talk about the approved price, since there is a differentiation of the bases in the form of the composition of the material.

Depending on the content of silk fiber, liquid wallpaper costs from 300 to 600 rubles per package (10% and 100%, respectively).

It also takes into account the consumption of material per 1 m2. Based on the above example, the contents of the package will be enough for 8 or 3.5 m2, respectively. Now you need to calculate the area of all your surfaces and divide it by the expense. We get the number of packages, multiply by the cost of the selected mixture and we get a decent amount. Repair is always expensive, you see, it will be nice to save on liquid wallpaper. Moreover, to realize that he himself made them.

The video below discusses this issue in more detail, and will also tell you about the rich assortment of mixtures.

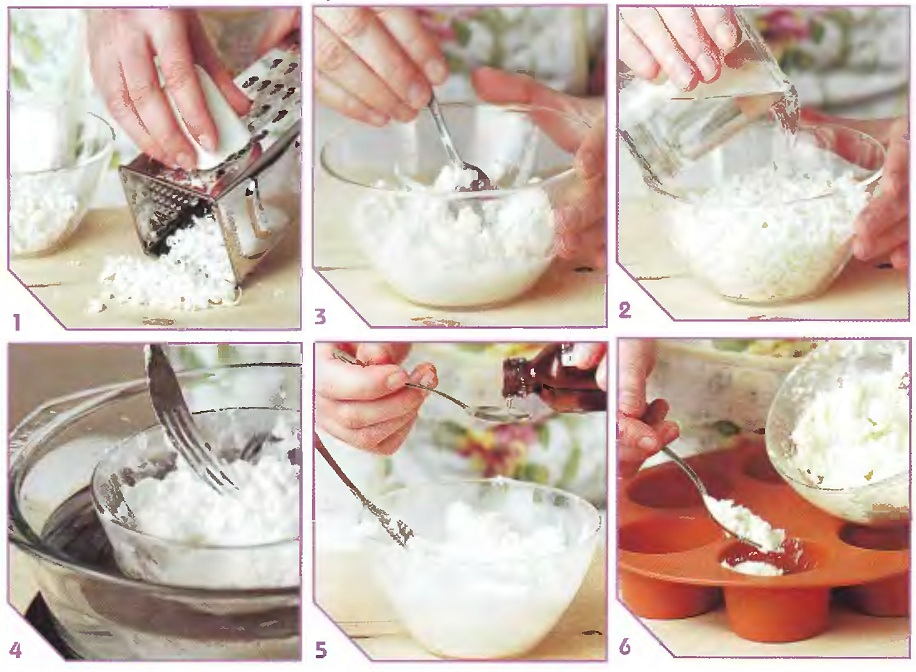

Curd mixture

At home, it is realistic to make a binder solution for foam, used as insulation and sound insulator. It is necessary to mix regular cottage cheese and slaked lime in equal proportions. The peculiarity of this glue is that it hardens quickly, so you need to use it as soon as possible.

For wood and leather goods, casein glue is suitable, which can also be created at home using the available ingredients. Its basis is cottage cheese, which goes through a certain processing process before cooking. It needs to be soaked in a soda solution for 20 minutes.

It is necessary to make a mixture based on the proportions of 2 tablespoons per liter of water. As soon as a quarter of an hour has passed, you need to thoroughly rinse and squeeze the cottage cheese so that it becomes dry and hard. This is how casein is prepared. Next, a powder is prepared from dry cottage cheese. It should be poured into a bowl and add water in a thin stream.

It is important to stir the mixture constantly.

The liquid is added at the rate of one part casein for two parts water. The whole process goes on until the glue reaches a homogeneous state. On average, its preparation takes half an hour. The better the casein is stirred, the higher its adhesive properties will be.

This glue is excellent for repairing shoes and wood items. However, it is worth remembering the life of the composition, because after 2 hours, the substance becomes unusable.

General recommendations

Making glue at home is a simple and affordable process. The best option includes a mixture of flour and water. It has excellent binding properties and will be an indispensable tool when updating wallpaper. By adding glycerin and gelatin, you can get excellent quality homemade PVA. Glue preparation not only saves in unforeseen situations, but also significantly saves the budget.