We disassemble the washing machine

First, we need to remove the upper part of the case (cover). It is secured with two screws from the back. After you unscrew them, you need to slide the cover towards the back of the case. And we take it off. Then we completely remove the dispenser of the machine. In some models, to remove the dispenser, we need to press down on the latch. Then we need to remove the control panel. To do this, unscrew the fixing screws. The panel can be neatly placed on the side of the case.

Next, open the hatch and remove the outer cuff clamp. Clamps are different. Some are removed with round nose pliers. Others can be removed with a slotted screwdriver. When the clamp is removed, we need to separate the cuff from the front of the body and tuck it into the machine. So she will not interfere with us.

Then we unscrew the lock. It is secured with two screws. We twist them and sticking our hand inside between the cuff and the wall  we separate the locking device from the machine wall from the inside. We remove all the remaining fasteners and remove the front part of the case. We will also remove the rear part of the case in advance, so that later we will not mess around again.

we separate the locking device from the machine wall from the inside. We remove all the remaining fasteners and remove the front part of the case. We will also remove the rear part of the case in advance, so that later we will not mess around again.

Then we disconnect the dispenser hopper with a branch pipe from the machine's tank. To do this, we need to remove everything that interferes and loosen the clamp. We remove everything where it will not interfere. Then we need to remove the counterweight (if it is in front). If he is behind, then we will also get to him and be sure to take off. Usually the counterweight is bolted. We will unscrew these bolts with a screwdriver.

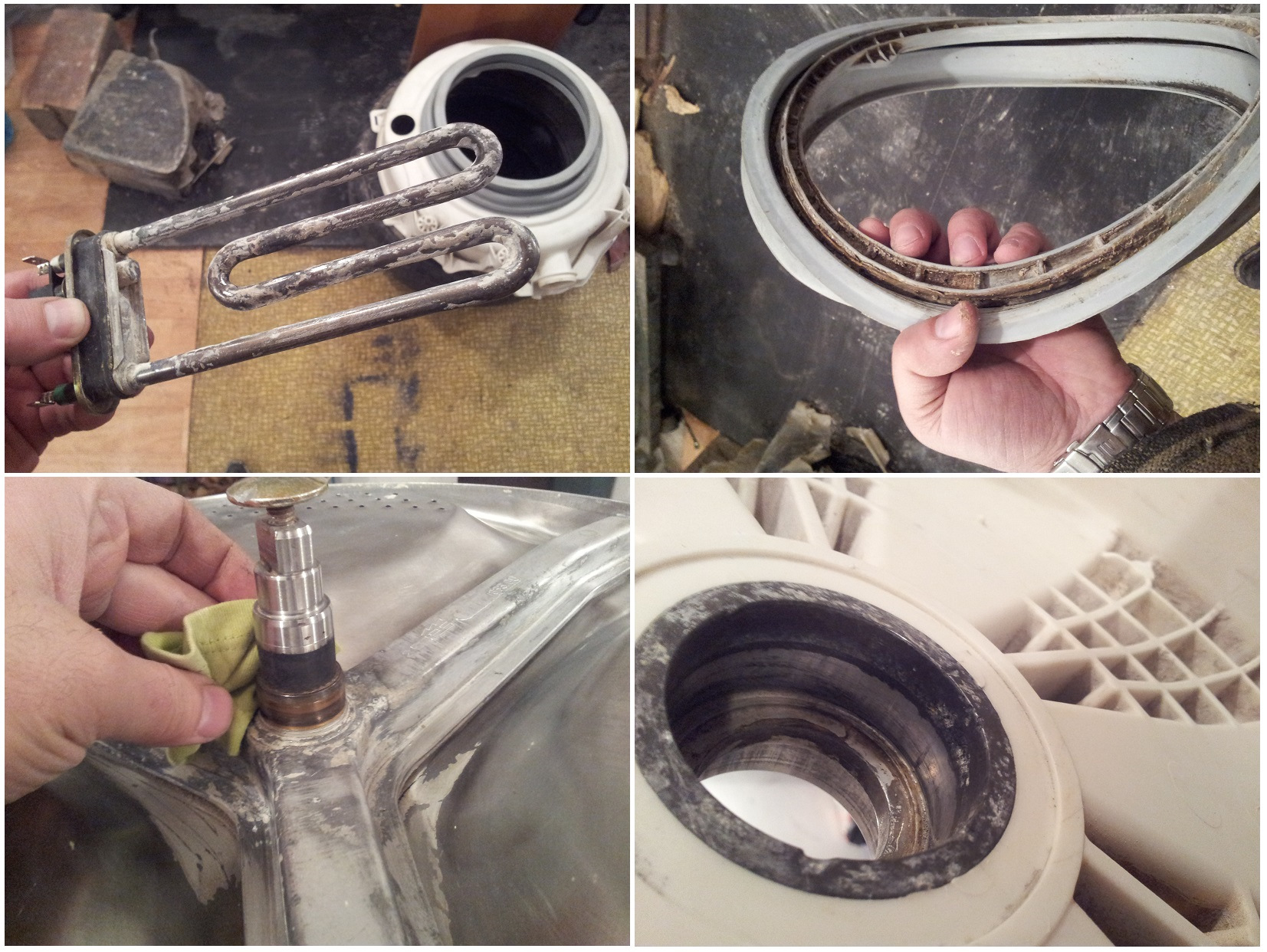

Next, we get to the heating element (heating element). Most models have it at the back. Some have it in front. Before removing it, we will take a photo of the wires so that we can then connect everything in the right order. Then we remove the heating element mountings. More often it is attached to one nut. We loosen it and press the screw. Then we pry it with a flat object (for example, a screwdriver) and take out the heating element.

After that, we remove the pipe that is attached to the tank. We have already learned how to disconnect the clamps, so we do it without any problems. Then we remove the wires that can be attached to the tank.

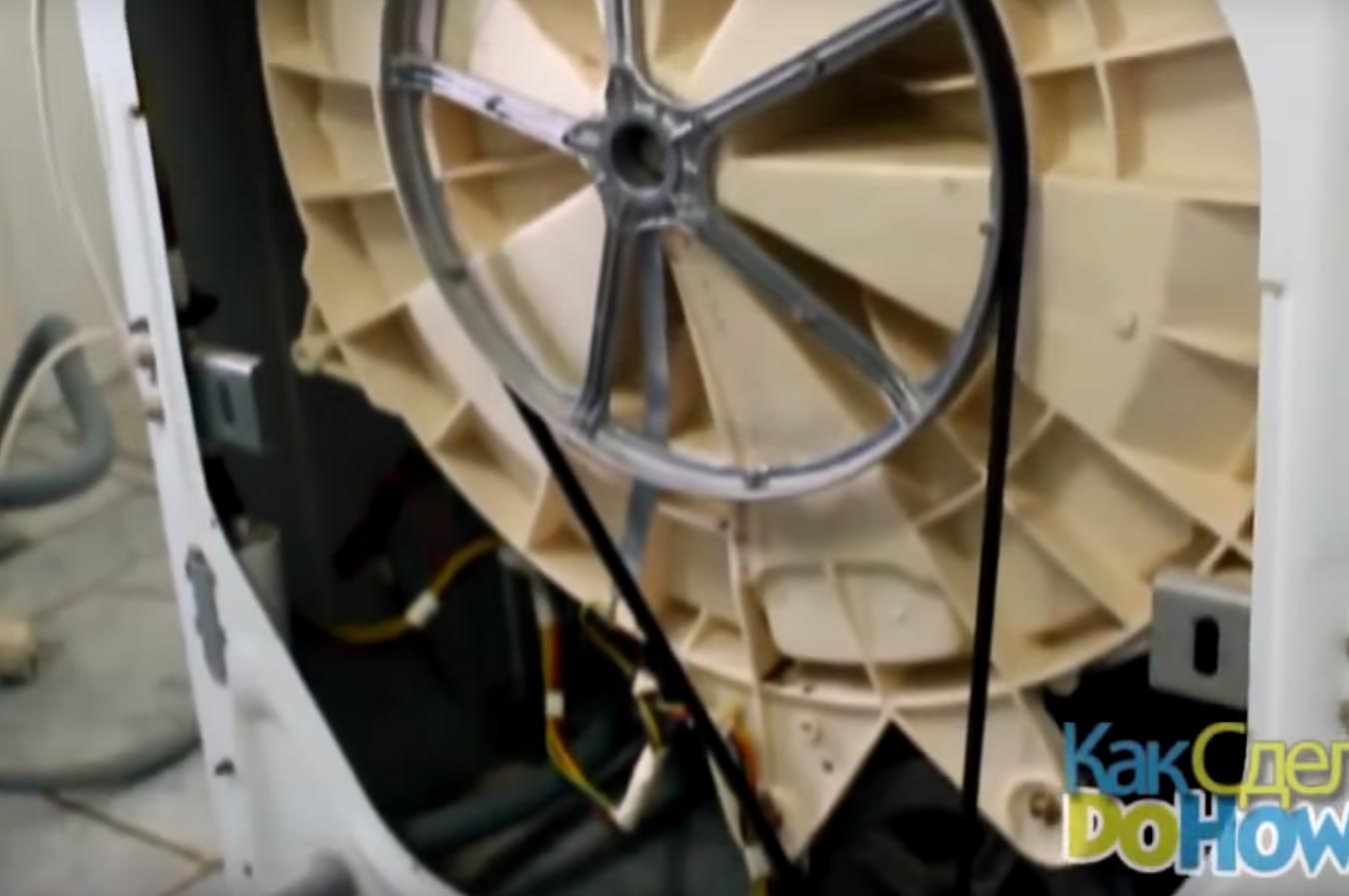

We get to the back of the machine and remove the drive belt. Next, we disconnect the connector of the wires leading to the motor of the machine. Then we twist the screws that fix the engine. Then we take out the engine by pulling it in our direction.

Then we twist the screws that fix the shock absorbers. And we separate their lower parts from the wall of the car. It remains only to remove the springs. And the tank can be taken out. All this should be done carefully so as not to drop the tank.

Replacing a bearing in a washing machine

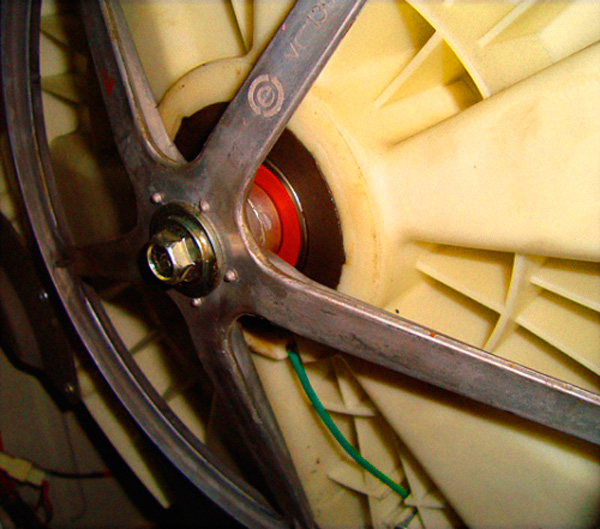

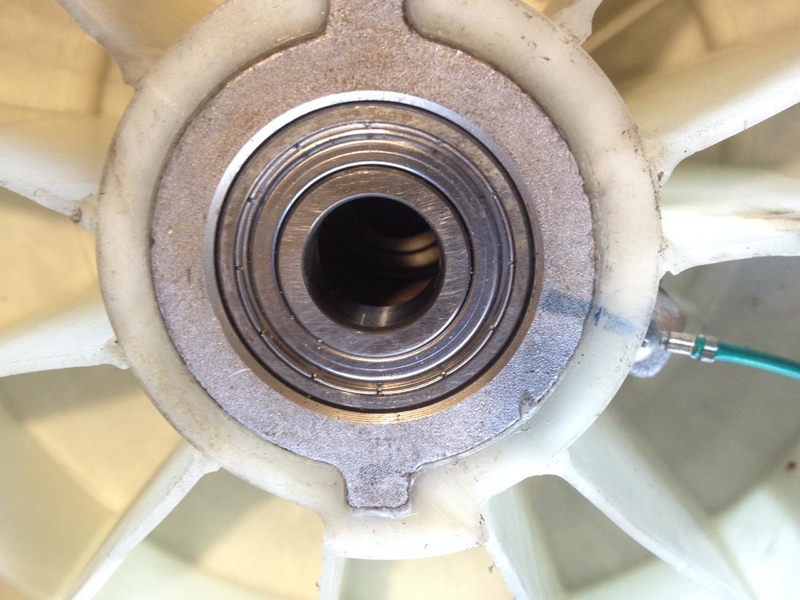

Having finished with the shaft, we proceed directly to replacing the bearings in the washing machine. They are, as you might have guessed, in the rear wall of the drum and they need to be pulled out from there, but before that, let's remove the oil seal.

To remove the oil seal from the back of the washing machine, take a flat screwdriver and pry it off.

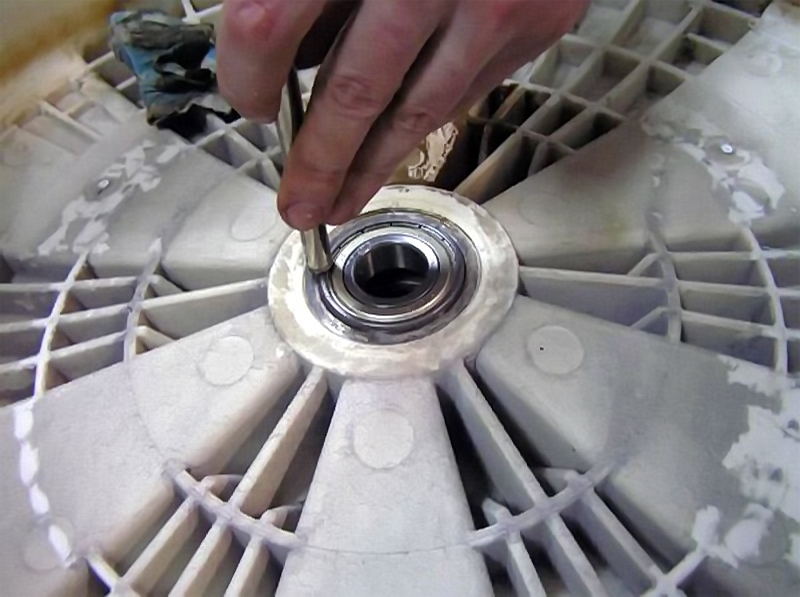

Now we need to knock out both bearings, for this we set up a metal rod as thick as a pencil and hit it with sharp, confident movements with a hammer, moving it to different sides of the bearing, cross to cross. Thus, we knock out both bearings.

A small bearing is knocked out from the inside of the tank, a large one, on the contrary, is outside.

The washing machine tank is quite fragile, so it is best to knock out the bearing by resting it on one knee to prevent damage to the tank.

After you knocked out the bearings, you need to clean the back cover itself and the bearing seats. Not the slightest dirt should remain in them, and they should simply sparkle with cleanliness.

Now let's take the new bearings out of the packaging.First, we insert a small bearing and also, by guiding the rod, we hammer it, rearranging the rod on different sides of the bearing cross to cross. Hammer in the bearing until it stops, when the bearing "sits" in place, the sound from the impact will become more sonorous.

Further in the same way, but on the other side of the tank, hammer in a large bearing.

After that we “stuff” the oil seal with special waterproof grease and insert it into place. You can lightly hammer the oil seal with a hammer similar to the bearing, but be extremely careful not to damage it.

It is best to use a specialized waterproof lubricant, but if you can't get it, you can use Litol-24, which can be found in any car store.

Why you need to change the bearing

As a permanently stressed part, a bearing has a limited life, typically 6 to 10 years. The oil seal is the first to fail - the rubber is deformed, water begins to pass from the tank to the bearing, the grease is washed out, and the unit can no longer ensure smooth rotation of the shaft. If the part is not replaced in time, destruction of the shaft, drum and tub of the washing machine may occur.

An additional factor affecting bearing wear is the overloading of the washing machine drum. If you regularly wash too much laundry, the unit may fail after several years of use. Do not discount the possible factory defect of the part or errors in its installation.

Thus, if you hear a knocking and grinding noise during the operation of the washing machine, which intensifies during the spin cycle, get ready to replace the bearing. A noticeable play in the drum relative to the tank will also be a symptom of a problem.

Required tools and parts

For this task, we need to practically completely disassemble the washing machine. And naturally, we need tools. What exactly do we need?

- Pliers.

- Screwdrivers (slotted and Phillips).

- Special screwdriver with various attachments.

- Round nose pliers.

- A set of keys of various sizes.

- Waterproof sealant.

- Chisel (blunt).

- Rubber hammer.

- Large regular hammer.

We also need an oil seal and bearings. They can be purchased at various services and specialty stores. If you do not know any such organization, then just type in Yandex, Google or another search engine: "Buy bearings for a washing machine" it is better to add the name of your city to this query. For example, “buy bearings in Moscow”. In the search results, you can find firms selling parts. Tell them the make of your car. Then they inform you about the cost of spare parts. As a last resort, you can first remove the old parts, and only then pick up exactly the same new ones.

We also need an oil seal and bearings. They can be purchased at various services and specialty stores. If you do not know any such organization, then just type in Yandex, Google or another search engine: "Buy bearings for a washing machine" it is better to add the name of your city to this query. For example, “buy bearings in Moscow”. In the search results, you can find firms selling parts. Tell them the make of your car. Then they inform you about the cost of spare parts. As a last resort, you can first remove the old parts, and only then pick up exactly the same new ones.

Preparing for repair

Prepare to replace the bearing on the washing machine. It is necessary to buy bearings and seals for the original production of the Indesit machine in advance.

It is important to purchase exactly the original, as this guarantees that they will fit a specific model of the washing machine.

Why not just buy bearings? The purchase of oil seals is due to the fact that their replacement is necessary when repairing bearings, which are often broken directly due to broken oil seals. The breakdown of one part inevitably leads to the failure of others.

Also, repairing a washing machine is impossible without a standard set of tools, which is certainly available in every home.

You will need:

- Phillips screwdrivers with long and short shafts;

- small hammer;

- block of wood;

- set of heads and open-end wrenches;

- hex key;

- preparation WD-40;

- chisel;

- pliers.

In addition to the tools, it is recommended to carefully prepare the workplace, which should give freedom of movement and the ability to neatly fold all the removed parts of the machine.

It is important not to lose or confuse anything during the repair process, which is why all wires, fasteners and contacts must be in order.

Malfunction symptoms

In the Indesit washing machine, bearing replacement is not an easy task. However, you can change this part yourself if you prepare in advance. Of course, first it is worth determining that the malfunction lies precisely in worn out or damaged bearings. This is easy to understand if you are careful.

It is worth paying attention to the bearings if the washing device makes noise, buzzes and rumbles. Moreover, the unit emits excessively loud sounds during the spin mode

You can also understand that the failure is related to the bearing by the behavior of the drum. It is enough to twist it away from yourself to feel the presence of backlash. You can also visually notice the skew of the drum.

Bearing failure symptoms

Disassembly and assembly of the Indesit washing machine is, after all, a rather time-consuming process. Therefore, without an urgent need, no one will do such work with their own hands. How can you make sure that the bearing of the machine is really time to replace without climbing into its housing? In this case, blind diagnostic techniques will help us. What should be done?

- First, we need to get the drum to rotate at maximum speed. To do this, we set the appropriate spinning mode for things (for example, 1000 rpm) and carefully listen to the sounds emitted by the machine - the bearing will give itself out.

- Next, you need to make sure that this is really a bearing, for this we disconnect the machine from the network, remove things from the drum and try to twist it with our finger, then in one direction, then in the other. Hear a knock or a metal grinding sound - another circumstantial evidence in favor of bearing failure.

- Check the area under the bottom of your Indesit washing machine regularly for moisture. If puddles regularly appear there, it is possible that the problem is in the moving element of the drum.

In conclusion, we would like to point out that any person who is not averse to working with equipment can replace a bearing in a "washing machine" from Indesit. The main thing in this matter is to do without amateur performance and act strictly according to the instructions, then everything will surely work out. If you do not understand any stage of the work, you can watch a video on this topic, where the replacement of bearings is illustrated in more detail.

Causes of problems with bearings of the Indesit washing machine

When the bearings deteriorate, this indicates that most likely the seals have become unusable, as a result of which water begins to spill through the aforementioned bearing assembly. Although the opposite situation often arises. Due to the fact that the oil seals fail, water penetrates into this unit, and then there are malfunctions with the bearings. It is extremely rare, but it also happens that the drum wipes holes in the tank, after which it is generally impossible to make any repairs.

How to change bearings in the Indesit washing machine? To do this, you need to have strong nerves, a sufficient amount of time and at least a little experience in this field of activity. It must be said that if you give the washing machine for repair in connection with this particular malfunction, then they will take a fairly decent amount of money from you, although in fact there is nothing complicated in repairing. Replacing the bearing and oil seal of the washing machine can be done with your own hands.

Troubleshooting

Most often, malfunctions in Indesit washing machines (models wisl 102, wisl 105, wiun 81) and other models can be conditionally divided into two types:

- Household. Such malfunctions often arise through the fault of the user himself. These include the extra weight of the loaded laundry, and various mechanical damage from foreign objects entering the tank, and any blockages. In general, non-observance of the user's instructions for the washing machine;

- Technical.This damage occurs during long-term operation of the equipment due to the natural wear of parts and mechanisms. Damage data is shown on the display as an error code. In case of such malfunctions, replacement of damaged parts is required.

Dismantling and installation of any technical device is always a time-consuming task, which is sometimes not always possible to solve with your own hands, without resorting to the services of specialists in the repair of household appliances. Therefore, in order to determine the cause of the breakdown, you first need to apply the method of the so-called blind diagnosis, that is, assessing the condition of the machine without disassembling it.

The essence of this method:

- We start the spin mode at the maximum available speed. A faulty bearing will immediately give itself out with increased noise or knocking;

- Then, to make sure that the drum bearing is damaged, disconnect the machine from the power supply, drain the water, take out the laundry and try to rotate the drum by hand in different directions. The presence of a knocking or grinding noise during this action proves that the drum bearing must be replaced with a serviceable one;

- Moisture under the bottom of the machine during operation can also indicate a defective seal or bearing.

How to change a bearing on a washing machine. Preparing for replacement

So, you are convinced that your washing machine needs a bearing replacement, and you are sure that you can do this work yourself without involving a master. Where to begin?

Before proceeding with the repair, it is necessary to purchase a new set of bearings, including the oil seal. It is best to choose original spare parts from the manufacturer that match your model, even if they cost more than their counterparts.

A new set of bearings must include a rubber seal

A new set of bearings must include a rubber seal

Also, for repairs you will need:

- flat and Phillips screwdrivers;

- chisel or impact screwdriver;

- hammer;

- pliers;

- nippers;

- socket wrenches;

- WD-40 tool;

- glue;

- sealant.

Before disassembling the body of the washing machine, you need to free up enough space for both work and storage of parts. Disconnect the washing machine from the power supply, disconnect the hoses, move the equipment away from the wall so that it is accessible from all sides. If possible, transfer it to a utility room (closet, garage) in case the repair drags on.

How to change the bearing on the drum of a washing machine is an Indesit machine. Instructions for replacing bearings of an Indesit washing machine with a glued (welded) tank with your own hands:

- flat and curly screwdrivers,

- spanners,

- tubular wrenches or heads,

- hammer,

- pliers,

- bearings,

- oil seals.

- Remove the top cover. To do this, unscrew the two self-tapping screws from the back of the Indesite washing machine. After that, the cover must be shifted back a little. Lift up slightly and remove it. Then set it aside so that it does not get in the way during further disassembly. Some models have plastic clips that secure the front of the cover. In such cases, remove from the latches with light blows from yourself.

Remove the cover

- Next, unscrew the six self-tapping screws on the back wall. It should detach itself, freeing access to the motor. In principle, the engine will be removed at the end. But in any case, the wall had to be removed in order to disconnect the wiring and the strap from the tank so that it would not cling anywhere.

Removing the back cover

- In washing machines, the indesite tank is pulled out of the body through the top. To remove it, you must disconnect the front panel, powder receptacle, concrete weight, rubber cuffs and disconnect the water level sensor tube. This is for the top. From below, you need to disconnect all the wiring, the drain pipe that goes to the pump and connects it to the tank and turn off the shock absorbers that hold the tank so that it does not loosen much during the wash process. After all this is turned off and disconnected, it will be possible to remove the tank. Look

Washing machine device

- It is easy to remove the wiring from the heating element. To do this, pull the clamps down. Do not mix up the wires later during assembly. The yellow wire in washing machines is always yellow. The wire that plugs into the temperature sensor has a plastic connector. The remaining two wires are power wires. They can be interchanged as they are supplied with alternating current.

- Remove the power chip from the motor and the ground wire.

Remove the power chip

- To disconnect the shock absorbers and the branch pipe, you need to access the bottom of the washing machine. To do this, tilt the washing machine to the front or to the side.

- Using pliers, remove the clamp and disconnect the drain tube from the pump. Before that, it is recommended to unscrew the filter and drain the water from it. Unscrew the two nuts on the left and right sides. This will release the shock absorbers. Squeeze the shock absorbers and move them closer to the tank so that they do not interfere in the future. Make sure nothing is holding at the bottom of the tank.

- Reset the washing machine. Using a pipe wrench or a socket, unscrew the bolts from the weight located on the top of the machine. Then take it off.

We remove the load

- Unscrew the self-tapping screw from the back that holds the powder receptacle. Remove the detergent drawer. To do this, lift it slightly and pull it towards you. At the front, the powder receptacle is screwed on with three self-tapping screws. One at the bottom and two at the top. Before removing it, you need to unscrew the screws securing the control panel.

- Remove the powder receptacle and panel by lifting it up. Disconnect the wires from the panel.

- It is not necessary to remove the wires from the powder receptacle. Remove the rubber loop from the hook and disconnect the nipple. In some models, the branch pipe is not held on a hinge, but with a spring clamp.

- Remove the cuffs from the tank by disconnecting the clamp securing it and pulling towards you. Removable from the front using the same method.

Removing the cuff

- Detach the tube from the water level sensor. It is advisable to remove the pressure switch so as not to break it off when removing the tank. To do this, use a thin screwdriver to disconnect from the latches.

- Pull the tank out of the body. Further, all manipulations will be carried out only with the tank.

The removed tank

- Remove the springs and weight from it.

- Disconnect the motor.

- Drill holes around the perimeter at four centimeters intervals to fit the screws, as assembly will be done with screws. Where you can't drill, skip.

We cut the tank

The next step is to unscrew the pulley. To do this, you need a T40 star wrench. Remove it gradually by loosening it.

Replace the screw and knock the shaft out of the drum. Assemble in reverse order.

Preparation for work

If you also faced the question of how to change the bearings in the Indesit washing machine, then you must stock up on some parts and prepare the necessary tools, among them you should highlight:

- metal hammer;

- pliers;

- screwdrivers;

- waterproof grease;

- set of open-end wrenches;

- metal rod;

- silicone sealant.

If you have not previously encountered the repair of a washing machine, then you should also prepare a camera with which you can capture the stages of disassembling the device. Subsequently, you will not have any difficulties with assembling the car. When preparing spare parts for repair, you should take care of the availability of an oil seal and a bearing, these units must be purchased. In order to be sure that you purchased the spare parts correctly, you need to take the old bearing and oil seal to the store, which will allow you to find the necessary units by number.

Before changing the bearings in the Indesit washing machine, you must prepare original spare parts, only this approach will ensure a long service life of the appliance.When purchasing bearings, you should prefer those that are specifically designed for washing machines, as they usually have a closed design.

Breakdown prevention

The operation of any household appliances, including a washing machine, must be carried out strictly in compliance with the rules of use. Remember that it is precisely the respect for the equipment that can extend its trouble-free service life. To replace damaged parts less often, you need to follow some tips:

- Clothes with metal parts should be washed in a special bag. Washing small parts should be done in the same way;

- After finishing washing, be sure to disconnect the washing machine from the mains to protect the unit from power surges;

- It is better to install the machine in a room with less humidity;

- Try not to overload the washing machine tank to prevent breakage during spinning;

- If there is low-quality water in the system, install a water purification filter;

- Use only high-quality detergent for washing.