Features of working with some models

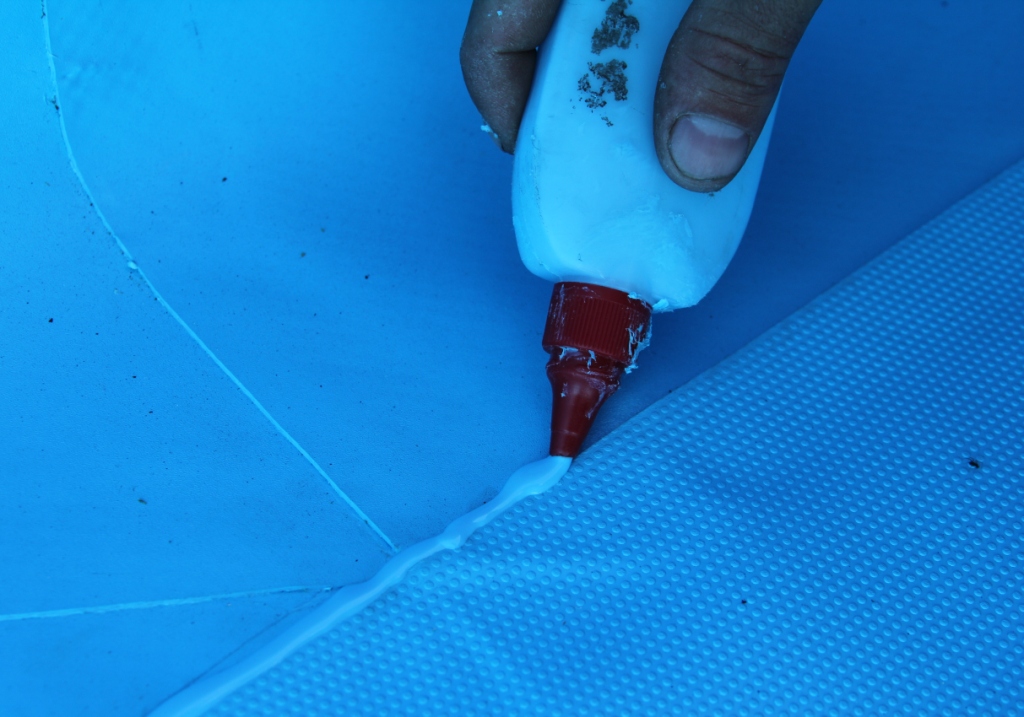

The choice of method for restoring tightness depends on the manufacturer of the pool.

Bestway

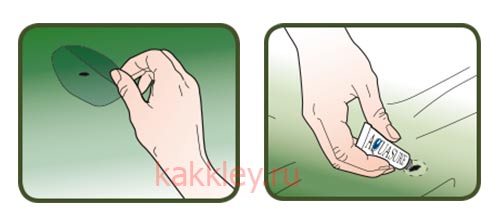

First you need to find the puncture site. You can use a sealant to repair minor cracks. If the hole diameter exceeds 1 mm, then a patch must be used. Before carrying out work, you need to clean the material from dirt with a soft brush. After that, the surface is degreased.

Particular attention should be paid to seams that are subject to high stress. It is necessary to put a load on the sealed area in order to increase the reliability of fixation.

Patches need to be cut in the shape of a circle or oval. The presence of corners will lead to flaking of the material due to the constant movement of water flows. There should be no air bubbles in the connection area. The drying time of the adhesive under the press is 12-24 hours. The owner of the pool can use roofing-bitumen tape, which will restore the tightness. Waterproof sealants are used to fill the small holes. Their composition is resistant to ultraviolet rays and does not lose its qualities in high humidity conditions. To seal the seams, you can use an industrial hair dryer, which reliably glues both sides of the gap.

Intex

To repair your Intex pool, use the dedicated repair kit. The composition contains moisture resistant VinilCement glue, protective gloves, a set of vinyl patches and a sealant. VinilCement contains polyurethane, acetone and chlorinated hydrocarbon. The product released by Intex is highly effective. Apply glue to the patch using a swab stick. Now you need to firmly press the piece of PVC to the damaged area. To speed up drying, the patch is heated with a hairdryer.

The pool owner will have to buy VinilCement glue separately from the main product. This is not a cheap pleasure. To save money, you can use other waterproof products. For example, you can use Moment glue. The quality of the repair depends on the nature of the puncture and professional experience.

When carrying out repair work, you must adhere to the following sequence:

- Empty the bowl first and wait for all surfaces to dry.

- For minor damage, a sealant is used that completely fills cracks and crevices.

- Vinyl patches are used to eliminate large defects. Their size should be 2 cm larger than the damaged area on each side. To achieve a tighter connection, a weight must be used.

Additional tips and tricks

In order to correctly repair the awning, you need not only to follow the standard provisions of the instructions, but also to familiarize yourself with the list of additional recommendations. Among them are the following:

- As a patch, it is better to take a fabric from the same material as the canvas itself. The patch should be durable with no frayed edges.

- Scotch tape is not used in place of the damaged area, as this is not a reliable way to solve the problem. Only certain types of adhesive solutions are able to fix the patch.

- Doubting your own capabilities, you can always contact the workshop, where the integrity of the canvas will be restored. In addition, even very large defects can be repaired in specialized services.

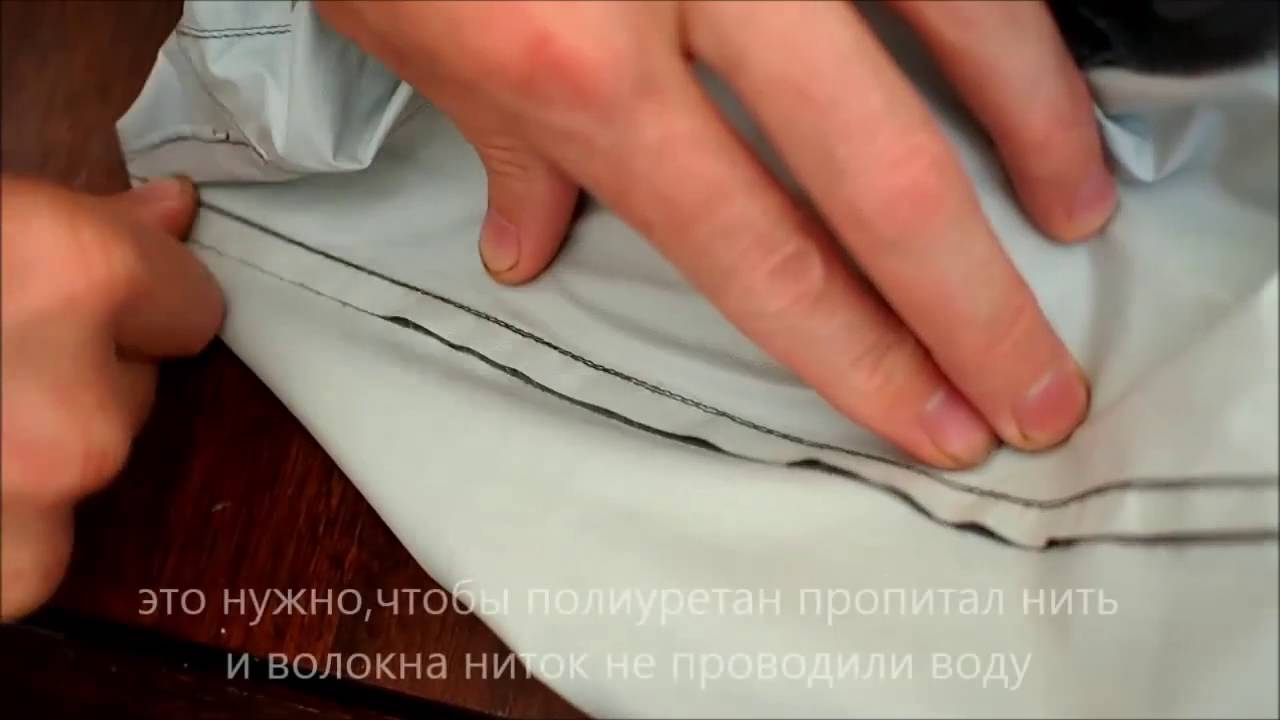

- If the canvas has dispersed along the seam, then after stitching with nylon thread, it is recommended to apply an additional layer of adhesive solution.

- When doing the work, it is imperative to adhere to the instructions for using the adhesive and the basic rules for gluing the patch to the canvas.In particular, it is impossible to carry out repairs without first degreasing the surface, since otherwise the adhesion of materials will deteriorate.

Adhering to simple tips and tricks, it will be possible to carry out high-quality repair work and restore the condition of the canvas. If the wear is so strong that the awning breaks again with minimal external impact, it is easier to replace the fabric.

p> Share link:

Adhesive selection

Some people, to restore the integrity of their boots, without hesitation, buy adhesives such as "Moment", other universal compounds. In fact, many of them are poorly suited for rubber and can even ruin this material. Superglues, despite being water resistant, have low elasticity, so the glue seam will quickly collapse during the use of boots.

You can achieve a worthwhile result only with the help of a special glue for rubber, PVC, EVA, which provides a reliable sealing effect. You can find such funds in shops for fishermen, motorists. They eliminate the hole, protect the shoes in the future, prevent the appearance of new defects in the areas exposed to them.

Good adhesives for shoes are Desmokol and Nairit containing artificial rubbers and urethane resins. They are quite elastic, have high adhesion to most shoe materials, and are even suitable for repairing soles. Of the "Moments", only "Moment Marathon" is suitable for work, which includes special additives and is able to seal any defects in rubber products. Also on sale there is Liquid Patch glue, ideal for PVC: it eats into the structure of the material, tightly merging with it, forming a single whole. When using such glue, there is no need to apply patches.

How to glue EVA winter fishing boots? The best choice would be the glue of the same name ("EVA Shoe Glue") in a white tube, its price is about 130 rubles. The tool is useful for emergency repair of boots on fishing, hunting. The main characteristics of the composition:

- microporous structure of the glue line after drying, which does not release heat even at sub-zero temperatures;

- water resistance, the possibility of direct contact with moisture;

- easy cleaning, non-susceptibility to clogging with dirt;

- yellowish color, which disappears after drying (the seam will be transparent and invisible);

- no spreading, rather thick texture;

- the ability to firmly glue punctures, tears, damage along the folds, on the sides and corners;

- long service life;

- economical consumption.

The glue has a drawback - it cannot be used to repair PVC boots or other PVC products. It will also not work to attach the PVC patch to the EVA with this glue, it will not stick.

Repair instructions for individual elements

We glue the rubber boat at the seam

Fishermen and hunters who use rubber boats are well aware that an element such as seams is the first to fail. What does it look like? The special tape that protects the seam begins to flake off over time, allows water to pass through and can contribute to rotting of the suture material.

Boat repairs along the seam should be carried out in a dry, ventilated and warm room. In the beginning, the boat should be inflated, but not too much. Then, determine the location of delamination or damage. Sand it lightly, degrease it and apply directly the glue itself.

Make sure that the adhesive is evenly distributed over the entire area. Further, the surfaces are pressed tightly against each other and fixed with fingers or a press, for a few minutes. To fully achieve the effect, the boat, with glued seams, is left inflated for the time specified in the instructions.

Glue the transom

The transom of the boat is a special section that can withstand the highest loads, since the motor is attached to it. Under the pressure of the weight of the motor, this element often fails and requires constant repair.

Rubber glue is a popular rubber glue, which contains natural rubber, urethanes, various specific additives, and has proven itself as a means for repairing various surfaces and materials, including rubber.

Due to its increased viscosity and increased elasticity, this glue has the following positive effects:

- corrosion resistance;

- vibration resistance;

- resistance to mechanical damage;

- resistance to abrasive materials;

- resistance to deformation.

How to choose a glue for a patch

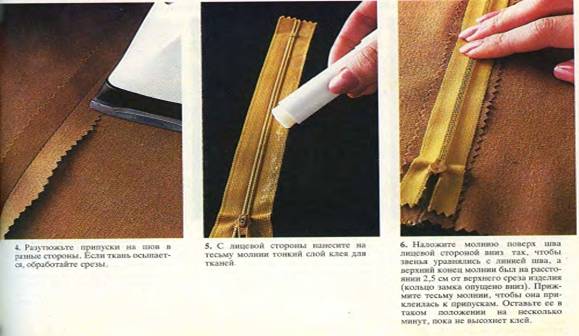

To work with fabric, you should use a special textile glue, which has several advantages:

- it does not spread;

- it is colorless (transparent), therefore it does not stain the glued product, does not leave traces and odor;

- able to withstand not only the effects of rain, but also many washes with aggressive agents.

Select the glue based on the type of fabric.

The following types of glue are suitable for working with synthetic materials:

Moment Crystal is a transparent contact adhesive based on polyurethane. Designed for gluing various synthetic fabrics. The glue is frost-resistant, waterproof, aging resistant.

A patch glued with Moment Crystal glue is not afraid of either solar ultraviolet light or the aggressive effects of natural factors. The glue is considered safe because it does not contain toluene.

The optimum application temperature is 18-25 degrees. The glue is sold in aluminum tubes; a 30-gram package costs about 60 rubles.

Glue 88-NT is a universal elastic glue designed for reliable bonding of fabric (synthetic) and polymeric materials in any combination with each other.

Forms a flexible glue seam, glued products can be used in the temperature range from minus 40 to plus 50 degrees. Glue 88-NT is sold in aluminum tubes; a 45-gram package costs about 50 rubles.

Polyurethane Anles adhesive is a modern polyurethane adhesive based on Desmocoll rubber. Water-resistant, colorless, elastic adhesive provides a secure connection of the glued surfaces.

The glued products are intended for operation in the temperature range from -40C to + 60C. The adhesive is resistant to aging. Served in 40 ml tubes, it costs about 50 rubles.

These patches are intended for quick repair of tents, clothes made of synthetic fabrics, backpacks. It is enough to cut out a fragment of a suitable shape, remove the protective film and apply it to the damaged area on one or both sides and warm it up with an iron.

Any quality rubber adhesive can be used to repair water-repellent polyester products.

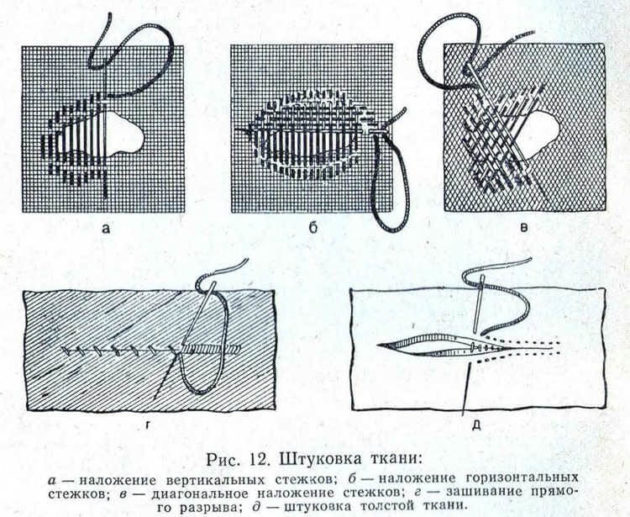

Instructions - glue the hole in the tent in stages

To repair a tourist tent made of raincoat fabric, you will need the following materials and tools:

- Scissors;

- Patch fabric;

- Polyurethane adhesive;

- Cotton swab;

- Needle and thread.

1.Preparation

The surfaces to be bonded must be clean and dry.

Before starting the repair, the materials should be kept at room temperature for several hours. To reliably glue the raincoat fabric tent, the surface should be degreased.

2.Application of glue

The polyurethane glue should be evenly applied in a thin layer to both surfaces to be glued with a cotton swab, especially carefully smear around the edges.

3.Gluing

Withstand a technological pause, you need to carefully and accurately connect the parts to be glued and press the surfaces with force.

VIDEO INSTRUCTION

The quality of the adhesion will depend on the strength of the applied pressure. For reliability, a patch should be stitched around the perimeter.

Sealing rubber boots

To repair regular rubber boots, you can use one of the popular techniques.

Anglers method

Special rubber adhesives are sold in shops for fishermen.They are ideal for repairing rubber products, including those in contact with water. The exact instructions are always included with the glue and must be strictly followed. Usually, first, a careful sanding of the surface is required, then degreasing is carried out with acetone. The patch is glued only if there is a large defect, and small cracks are filled with glue without a patch. Drying time is observed without reduction, otherwise the glue line will not be able to gain the required strength.

Cyclists method

Cycling enthusiasts often have a special repair kit available, which includes glue, a patch, a brush for applying the product, and sandpaper. These devices are suitable not only for repairing a punctured bicycle tube, but also for sealing torn boots. The technology of work will be similar:

- sanding;

- degreasing with acetone;

- trimming the patch in accordance with the size of the defect (plus 1 cm allowances on each side);

- uniform application of glue to the surface and patch;

- applying patches;

- fixation;

- waiting until the glue dries.

Some adhesives allow the product to be applied after a couple of hours. Although it is better to wait a day to improve the quality of adhesion, this will make the glue seam stronger and more durable.

Automotive method

Sometimes boots, boots made of rubber or EVA crack at the folds. In such a noticeable place, the patch will not look aesthetically pleasing, it will ruin the appearance of the shoe. For a more accurate repair, it is worth purchasing an automotive adhesive sealant, polyurethane or epoxy compound and applying it without applying a patch. The easiest way is to buy a transparent composition, it will not be noticeable at all on the product. Done Deal's Crazy Handles car glue, which is sold in any car dealership, has proven itself to be excellent. It firmly holds the place of gluing, protects the shoes from moisture penetration inside, due to its elasticity, it does not collapse with further bending of the material.

Hot method

Hot-bonding requires a vulcanizer and a piece of raw rubber. Despite the complexity, the quality of the repair will be at a high level, the patch will stick tightly. The crude rubber is soaked in gasoline for 10 minutes, laid out on the defect, clamped with a vulcanizer press. The device is turned on for half an hour, then turned off. After complete cooling, the press is removed, and the product will be ready for use.

Features of gluing the soles

The most difficult repair is to be done if the sole is damaged. Of course, you can simply patch up a crack, puncture, and fill them with glue, but the quality of the bond will be low, as will the durability. Enough of such a "patch" for 1-2 outings in wet weather. You can also carry out repairs in a different way:

- take a piece of nylon;

- insert material into the crack;

- heat up the soldering iron, solder the crack.

If the defect is glued in this way, the sole will last longer, but it is unlikely that even one season will be able to leave in boots. It is better to pre-grind the puncture on a sharpening machine to make the place smoother. After that, you need to degrease the sole, fill the hole with epoxy glue from the outside and from the inside. After a day, an insole should be placed inside the boot, and the shoes can be used.

In order for the repaired boots to serve for a long time, it is important to take proper care of them in the future. Shoes must be washed and dried after returning from the street, periodically treated with a water-glycerin solution

Drying should be done away from the battery to prevent deformation of the boots. It is better to store them out of season in the box in which they were sold, stuffed with newspapers - this way the couple will retain their shape and attractive appearance.

What glue will help

When choosing a glue for repairing a jacket, several principles must be followed. The composition should be:

- waterproof;

- elastic;

- colorless;

- resistant to light and temperature extremes;

- do not change the structure of the fabric;

- have a thick consistency;

- do not spread;

- do not freeze instantly in order to have time to make changes.

Among the wide variety of adhesives, you can choose the option suitable for the specific fabric and nature of the tear.

Polyurethane

This type of glue reliably connects surfaces, since it is created on a synthetic basis. It is produced in a tough and elastic form. For the repair of jackets, down jackets and other fabric products, the second option is suitable. He has high adhesion rates, excellent resistance to temperature extremes.

Rubber

The adhesive composition, based on rubber, has high elasticity and can be used for working with leather, fabric, rubber, glass, wood. Latex rubber glue contains casein, which gives it additional elasticity and water resistance. Seams can be glued with styrene rubber glue. The composition, which includes natural rubber, glues leather and fabrics. It has high elasticity.

Polyvinyl acetate

This type of glue is well known to users as PVA. It can be used for “temporary” and “permanent” fixation. Usually, such glue is washed off after washing, since it does not tolerate moisture. But at present, polyvinyl acetate glue with high moisture-resistant characteristics is being produced. If desired, you can even find two-component adhesives on sale that can withstand direct contact with water. They are best suited for repairing down jackets and jackets.

Neoprene

With neoprene adhesive, repairs can be made easily on site. It dries no longer than a minute, forms a strong adhesion, characterized by elasticity and durability. Adhesive composition based on neoprene easily tolerates temperature rise, it is recommended for gluing elements from leather, fabric, rubber. The glue is transparent, waterproof, can be used to repair jackets and down jackets.

Hot glue

Safe and non-toxic hot melt glue can be used for gluing fabrics. It is applied with a glue gun, which allows the composition to be distributed evenly over the surface. Hot melt glue is in the form of rods melted in a gun, or powder for preparing an adhesive composition. The advantage of hot melt glue is its speed of action.

Aerosol adhesive

The difference between aerosol glue from other types is the possibility of applying it using a spray can. The spray gun allows you to make an even layer of glue and fix materials in places that are difficult to reach for other types of glue. The connection he creates is elastic, the can is hermetically sealed, and the consumption is economical. Multiple layers of adhesive can be applied. Complete drying occurs after 20 minutes.

Polyvinyl chloride

It is this glue that is released in the form of an aerosol. It is sprayed with an even layer on one surface, the second is applied on top and pressed with a press for two hours. Complete drying occurs after 6 hours. Adhesion of PVC glue is high, it can be used for different textures of fabrics.

FAQ

When repairing rubber boats, owners often face difficult moments in the process of work.

To resolve controversial situations and to find answers to extraordinary questions, most beginners, and even professional fishermen, turn to specialists for help or are looking for answers on the Internet.

Is it possible to use Moment glue in the repair of rubber boats?

One of the most exciting issues is the possibility of using Moment glue when repairing a rubber boat.

In fact, the answer to this question is quite simple.

It is possible to use Moment glue when repairing rubber boats.

The main advantages of such a tool are as follows:

- fast bonding of two surfaces;

- ease of use.

However, when choosing Moment glue, be prepared for the fact that it is sensitive to high temperatures. Also, it dries instantly when exposed to direct sunlight.

Working with him, you will need to perform all gluing actions very quickly. Moreover, the final effect will also be poor.

The boat, glued with Moment glue, will not serve you for long, and, most likely, after a while, it will fall apart and become unstuck again. It is for these reasons that more experienced fishermen do not recommend using it.

How to wash old glue from a rubber boat?

It is quite difficult to wash old glue from a rubber boat. It should be borne in mind that when gluing two surfaces, rubber glue is quickly absorbed into the rubberized surface of the boat itself.

You should also not remove old dried glue with aggressive solvents or other substances, if you do not want to permanently ruin the fabric of your own boat.

Shoe glue for rubber boat repair

Some specialists use shoe (nairite) glue to repair a rubber boat. It is mainly used for bonding not only rubber, but also leather, wood, fabric and other materials. It is used for repairs, like the others.

The thought of an upcoming fishing trip haunts you? In this case, quickly check your boat for mechanical damage.

If you accidentally find a small crack or gap, do not be upset. Believe me, together with rubber boat glue, you can get your boat in order in a short period of time, and at the same time, without much effort.

Basic requirements for glue for working with fishing overalls

The main requirement for the product is a reliable, durable connection. The seam must remain intact and not unstick while moving in the water

Therefore, when choosing a composition, it is recommended to pay attention to the following product characteristics:

you should not purchase cheap compounds - such a group does not differ in quality, reliability, glue components can aggressively affect the material of the overalls and, instead of repairing, will only increase the seam rupture area;

the purchase of superglue also does not solve the problem - the composition firmly fixes the cuts on fishing suits, but the connection does not withstand temperature changes, and the equipment again requires repair;

when choosing an adhesive, you need to pay attention to characteristics such as heat resistance, resistance to changes in temperature indicators. It's no secret that fishing often takes place in extreme weather conditions, the seam should not diverge under the scorching sun and at negative temperatures;

it is better to focus on special formulations designed for a specific material

Universal products can glue anything, but the issue of quality and durability remains open;

the glue must be elastic enough to maintain the integrity of the seam during movement;

water resistance is a mandatory requirement for products. The main purpose of the fishing overalls is to be protected from water, the equipment must maintain its integrity even after many hours of stay in the reservoir.

2> How to catch a lot of fish?

Fishing gives pleasure with its process - each of us knows about it. But in addition to this, we always want to get the result from fishing - to catch not three perch, but a dozen kilogram pikes - this will be the catch! Each of us dreams of this, but not everyone knows how.

A good catch can be achieved (and we both know this) thanks to good bait. It can be made at home or bought at fishermen's shops. But in stores it is expensive, and to prepare groundbait at home, you need to spend a lot of time, and, frankly, homemade bait does not always work well.

Do you know that disappointment when you bought groundbait or cooked it at home, and caught three or four perches? Of course familiar.So maybe it's time to use a really working product, the effectiveness of which has been proven both scientifically and practice on the rivers and ponds of Russia?

Of course, it's better to try once than hear a thousand times. Moreover, now is the season! A 50% discount when ordering is a great bonus!

Hurry up to order Fishkhangri!

Step-by-step bonding of boots: instruction

To make the correct gluing, you must follow all the subsequent steps provided for in the instructions.

Rules for working with Eva

For high-quality restoration of elements from EVA, adhesives with the same elements are used. Only a special Eva glue can penetrate into the structure of the raw material, merge with it.

All work is carried out in the means of IZ. To glue the EVA boots, the following steps are performed:

- The puncture site is cleaned and dried.

- Fine-grained sandpaper is processed, which contributes to better adhesion.

- The glue is applied in a thin layer.

- If a patch is glued, then it is better to perform the action from both sides, fixation is needed.

- In a day, the product is ready for use.

Useful video on the topic:

How to glue PVC boots

If you use liquid patch glue for the repair, the patch will not be needed. But if there are other compounds, then it is better to glue a double-sided patch.

The place of violation of integrity is cleaned, processed with sandpaper, degreased, dried. The adhesive layer is applied to both surfaces to be glued. If a polyurethane compound is used, then the heating method is applied with a hairdryer, which will provide better fixation.

How to glue rubber boots

There are several ways to glue rubber boots at home:

- The angler's way. Specialty shops for fishermen sell rubber repair kits that are suitable for reconditioning rubber boots. If the defect is significant, then a patch is applied.

- Cyclist way. Special repair kits are sold for gluing bicycle cameras that can be used for safety shoes. The package contains instructions and detailed repair steps.

- Automotive way. If the boot is torn at the fold, the patch will be very noticeable and ruin the look. Then it is worth resorting to the use of automotive glue-sealant. For this, the composition "Crazy Pens", which is sold in car stores, is suitable. The resulting seam will be flexible, durable, which will ensure the longness of the wear.

- Hot way. To perform such a restoration, you will need a piece of raw rubber, a vulcanizer. Of course, the method is one of the most difficult, but the highest quality. The crude rubber is placed in gasoline for soaking, it is counted for 10 minutes, then placed on the cut, the vulcanizer is squeezed. The patch is glued tightly. After the pressing has cooled down, the product is ready to wear.

We recommend a video on the topic:

Repair with liquid leather

Liquid leather - chem. composition that, after drying, is similar to natural leather. Small repairs are repaired with liquid leather: scratches, small cuts, abrasions.

For repairs with such a composition, it is enough to apply it to the desired place and wait for it to dry. It also covers the glued patch, then it will not be visible.

This method has some nuances:

- There are many more colors of products made of genuine leather than liquid ones. Therefore, it is not always possible to choose the desired shade.

- The applied composition will stand out on an expensive product.

- After hardening, the place with liquid skin has a smooth surface.

- Such material is not sufficiently resistant to constant friction or other mechanical stress.

Preparation of boots for repair and selection of accessories

Shoe masters often refuse to repair rubber boots. If a cut has formed, it is better to seal the hole yourself.

Before proceeding with the main process, the shoes must be thoroughly washed from dirt, then dried.The place of the defect must be degreased with an alcohol solution. If this is not available, then the surface is washed with detergents.

To dry products made of Eva, PVC, rubber, room temperature is suitable, without the use of heaters. This is necessary so that heat flows do not deform the broken integrity, gluing is optimally fast and beautiful.

For restoration, you need to prepare in advance tools, raw materials:

- Fine-grained sandpaper to roughen the joint surface for better adhesion.

- Dry, clean rags to remove excess adhesive.

- Patch material (waterproof).

- Gloves to protect the skin.

- Adhesive with a strong bond.

- Hair dryer for warming up.

If it is difficult to buy components separately, there are repair kits on sale with everything you need to restore.