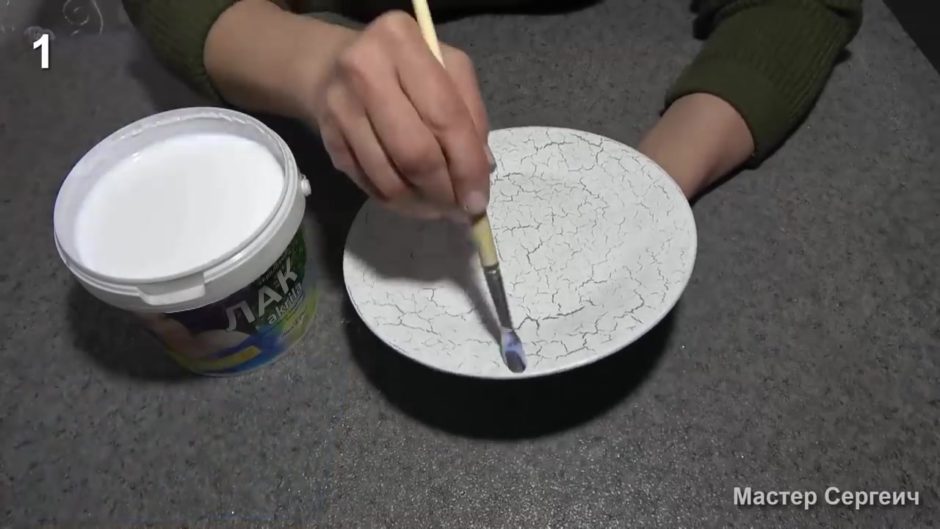

Preparing the primer yourself

How to make a mixture that has the properties of a primer? You need to take the following components:

- PVA glue - 1 part;

- water - 2 parts;

- cement - the amount is determined by the density.

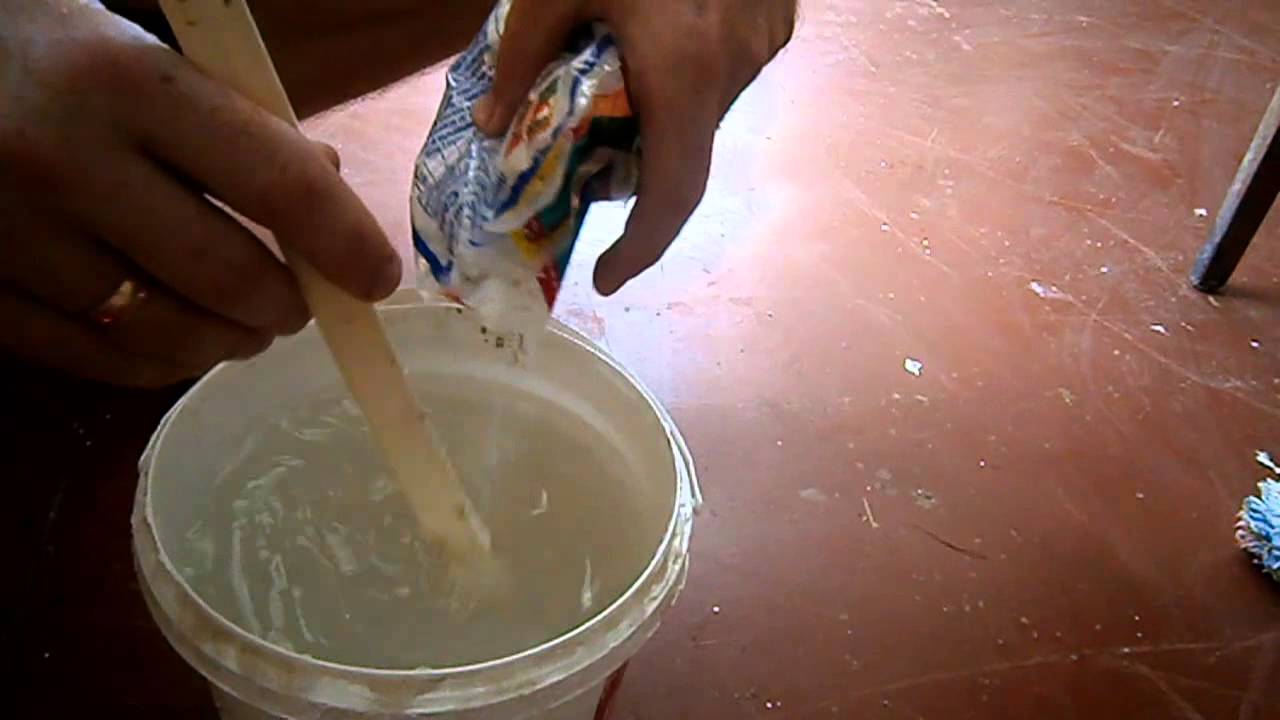

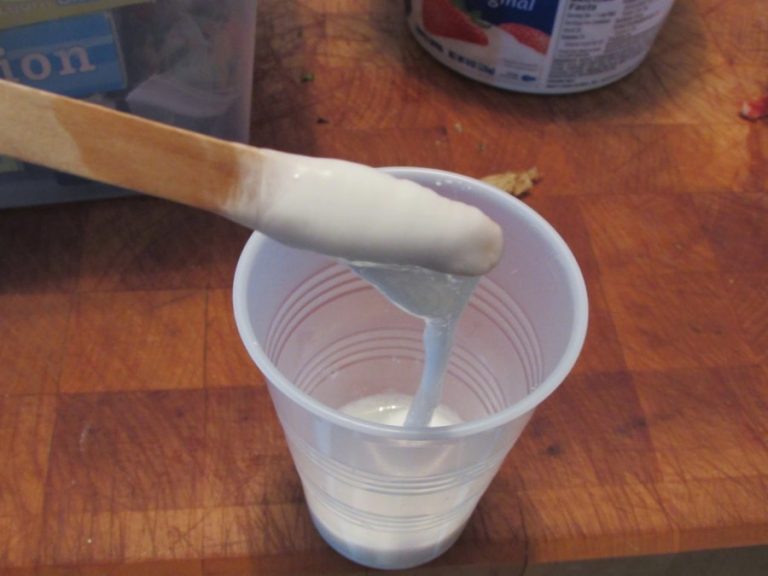

The cooking technology does not cause difficulties: the glue is diluted with water, mixed, the required amount of cement is added. The finished solution should resemble liquid sour cream and lie well on the surface.

A diluted primer is an excellent economical precursor to wall glue, but not sufficient for a reliable finish. Can the quality of the primer be improved? Repair experts advise adding crushed chalk and liquid resin to the mixture with PVA glue. Their mass should not exceed 5% of the total volume of the composition.

Important cooking conditions:

- Work on the creation of a primer must be carried out in a warm room, away from drafts, sources of fire.

- Use a convenient container: a large bucket, a basin, a canister with a wide mouth.

- Water is added to the glue gradually, the classic ratio is 2: 1.

- Constant stirring of the composition will prevent the formation of a surface water layer. For ease of work and to obtain the greatest uniformity, you can use a construction mixer.

Priming the walls with glue differs in that it forms a film on the surface to be treated, without filling small cracks and gaps. But, given the relatively low cost of the components used, an excellent building material is obtained, which is quickly made at home.

In the video:

deep penetration PVA primer.

How to properly apply diluted glue to the surface

So, having figured out how to dilute the thick PVA glue, working with it does not imply difficulties. It's simple enough. The presence of instructions will simplify the task, since the insert contains brief information about what this or that type of product is used for gluing and how to use it correctly. Since the use of glue for wood and paper is somewhat different, some people have a problem when gluing wood surfaces. To prevent unpleasant moments from happening to you, remember a simple rule: apply glue to the side of the product that absorbs the composition more slowly, that is, with a less porous structure.

Is it possible to dilute PVA glue with water, we figured it out. Remember that when working with PVA glue, regardless of the type, adhere to some rules:

Having studied the information provided in the article, you received an answer to the frequently asked question: "how to dilute PVA glue?"

Taking into account the recommendations given, the use of glue will be a rational solution for you if you need to connect any parts to each other.

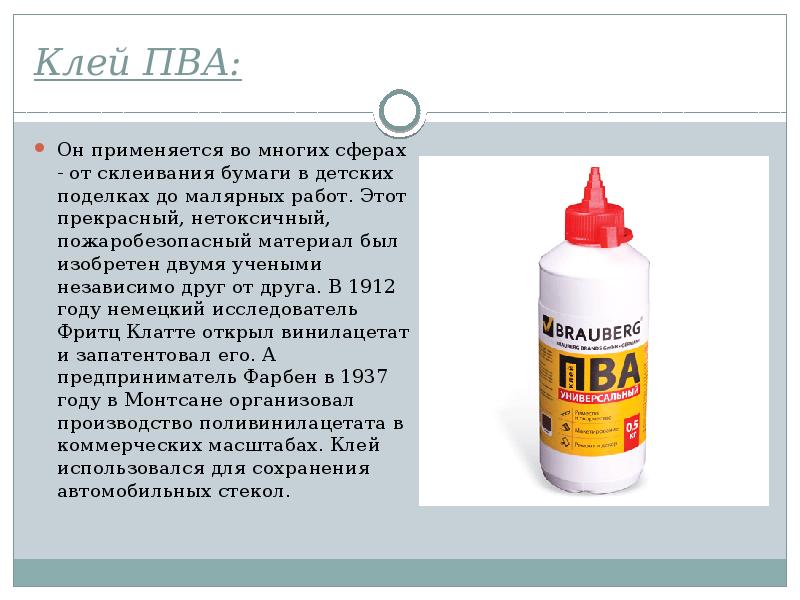

PVA glue is one of the most popular in our country. It is appreciated not only for its affordable price, but also for its excellent adhesive properties, which are indispensable in everyday life and work.

It's hard to find at least one adult who has never encountered PVA. It has become widespread both in industry and in everyday life.

Pva glue includes a polyvinyl acetate dispersion, which hardens in just a day, is easy to apply, as well as a filler, which is water.

In order to remove the composition, special tools are not required. Enough Dilute Pva glue with water.

Water is used to soften the stagnant product, which can be reused for its intended purpose.

How to dissolve PVA glue

The question that most often occurs on the Internet is the question of how to dilute PVA glue and whether it can be diluted with water. Yes, you can. Use warm water (not hot).

Various solvents can have a negative effect on the structure of the adhesive and its performance. Stir the glue with water at high intensity. Pour water in small portions, stirring constantly. Water should be no more than 5-10% of the initial volume of the glue. If PVA glue thickens very strongly, you need to know how to dilute it. The crust that appears on its surface should be removed. It makes no sense to remove jelly-like lumps of glue, they will dissolve on their own.

Such a problem as how to dilute PVA glue, if it thickens, has only one adequate solution - H2O (water). Do not try to dilute the glue with acetone or alcohol - it will be cheaper to buy a new jar of PVA, especially since it is very cheap.

If you suddenly come up with an idea to dilute the glue with acetone, get rid of it as soon as possible. Acetone, if there is too much of it in the glue, will literally "eat" plastic or plastic products if you are going to use it for them.

Hot water is still the best solvent for PVA glue.

If there is a question of how to dilute PVA glue, if it is very thick, then the water is unlikely to be effective here. Anyway, you can try.

There is no solution to the question “how to dilute PVA glue” only if the glue is completely dry - then there is definitely only one way for it. Into the trash can.

Who does not know about PVA glue, which is actively used for gluing products from various materials: wood, ceramics, chipboard, linoleum, paper, glass, fabric and leather bases. The popularity of the glue determines the high-quality adhesion of the material and the glued surface, affordable cost, increased resistance to moisture, but, at the same time, good solubility in water, which in itself answers the question of how to dilute PVA glue? The purpose of the glue is determined depending on its type.

PVA glue is the most popular substance in the world. It is versatile and useful both when studying at school and when carrying out repairs in a house or apartment.

How to dissolve resistant adhesives?

Many do not know how to dissolve Titanium glue, which belongs to the class of very resistant and difficult to remove compounds based on acrylic copolymers. Concentrated acid for plumbing, gasoline, dimethyl ketone, turpentine, methylbenzene, ethyl acetate are effective agents that promote its dissolution. After soaking in these products, it is necessary to remove the residues mechanically.

When choosing a way to dissolve epoxy glue, it should be remembered that this will have a significant effect on the performance properties of the final polymer. The addition of solvents contributes to a decrease in viscosity, the strength and water resistance of the product deteriorate. For dilution, acetone, denatured alcohol, which can evaporate quickly without remaining in the resin, are suitable.

When choosing a means to dissolve rubber or 88 glue in case of drying, you can stop at gasoline, since it is part of their composition. The glue composition is diluted to the thickness of the liquid sour cream so that it does not drain from the roller.

Key factors to consider when breeding:

- 1. The addition of a solvent significantly reduces the viscosity and strength of the polymer.

- 2. The service life of the adhesive and the curing period are increased.

- 3. Dilution causes shrinkage of the resin, which increases microcracks.

- 4. The color of the polymer changes.

- 5. Vertical fluidity increases.

Before puzzling over the question of how to dilute PVA glue with your own hands, decide what kind of work you need it for. Your own self-prepared composition can be justified only if you are not sure of the quality of the material from the counter of the hardware store.

It's not news to anyone that the use of PVA glue is very diverse, both for external work and for internal work.Therefore, below we will talk in more detail about what PVA glue is, how to prepare it at home and for what work you can use it.

Making PVA glue

How to dilute PVA glue with water

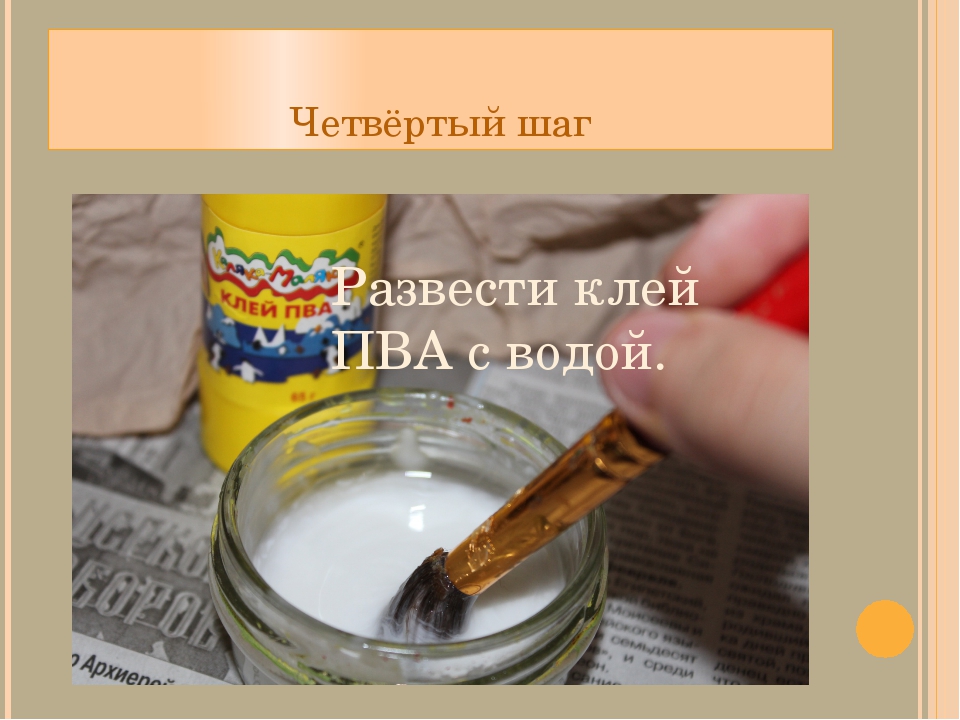

It is possible to dilute PVA with water, but it should be borne in mind - the more water, the less durable the glue seam will be, and its elasticity will also decrease after hardening. The addition of water also reduces the water resistance of the adhesive.

It is allowed to dilute PVA household and stationery glue. Do not do this with all-purpose glue and PVA-super.

Mixing order:

- Prepare a container, add one part glue and two parts water to it. Carry out work only in a warm room.

- Mix thoroughly with a spatula or stick. Stir until the water is completely dissolved.

- You should have a thin, white mixture. It will be easy to apply to the surface and will allow, for example, to prepare the walls for painting.

Why PVA is afraid of water

The main reason is the loss of its properties by the glue; it soaks and dissolves. The more water there is, the worse the glue will connect the parts.

It is possible to prepare PVA glue from water from other improvised means, for example, using a simple and inexpensive ingredient that every housewife has - ordinary starch.

- To do this, you also need to take potato flour or wheat flour, pour cold water over it.

- Then the contents are mixed and the water is boiled.

- A mixture of water and starch is poured into boiling water.

- The composition is stirred for ten minutes, and when it is half ready, put on the stove and cook until the mixture acquires the consistency of a jelly.

- As a result, you get a translucent glue, analogue of PVA with good adhesive properties. This option is easier to make at home, but slightly less effective than flour-based glue.

Who does not know about PVA glue, which is actively used for gluing products from various materials: wood, ceramics, chipboard, linoleum, paper, glass, fabric and leather bases. The popularity of the glue determines the high-quality adhesion of the material and the glued surface, affordable cost, increased resistance to moisture, but, at the same time, good solubility in water, which in itself answers the question of how to dilute PVA glue? The purpose of the glue is determined depending on its type.

PVA glue is the most popular substance in the world. It is versatile and useful both when studying at school and when carrying out repairs in a house or apartment.

Features of the dilution of specific varnishes

When thinning a matte varnish or enamel with glitters, the question arises as to what products can be used in this case. It is worth considering all the options that apply.

How to dilute glitter varnish

It is allowed to dilute the varnish with glitter both with special thinners and folk remedies. They have no effect on the glitter. They do not change their color and do not fade.

Thinner for matt varnish

The matte version is no different from the glossy one. To restore it, it is allowed to use similar means. But it should be borne in mind that this coating is very moody.

It is not recommended to experiment with it, so the choice should be stopped on special thinners.

Super glue is afraid of acetone

It is important not to miss the moment when the "super" product hardens on the surface. In this case, the task becomes more complicated, and in rare cases, the thing loses its original appearance irrevocably

You can dissolve the stain using ordinary acetone, which is freely available at any hardware store. This substance interacts very poorly with varnished surfaces and some synthetic substances. Therefore, in pursuit of perfect cleanliness, even more harm can be done. This fact must be taken into account before starting any type of cleaning work.

Super glue is gradually removed from the effects of Dimexide - it can be purchased at the pharmacy. If we consider the time interval, then even the most difficult stain can be dealt with in just a few hours, taking into account the drying of the surface.

How to dilute PVA for a primer - a recipe for home brewing

And yet, being able to prepare a primer from glue will not hurt. Indeed, after repairs in an apartment or house, you may have enough of this material, and you are reluctant to spend money on purchasing an expensive primer, say, for the walls of the utility room where you store the tools. Before diluting the PVA for the primer, prepare the necessary tools and ingredients: water, a stirring spatula, container and the glue itself.

Dilute the glue from a ratio of 1 part glue to 2 parts water. The resulting liquid mass should be easily applied to surfaces, leaving a white mark behind. To improve the qualities of a homemade primer, it is recommended to add crushed chalk to its composition. The components should be mixed in a warm room, glue should be poured into the container first, and then water

It is very important to mix the components as vigorously as possible so that the water quickly dilutes the glue without leaving an independent layer on the surface.

First, try priming on a small area - if after drying the primer does not form a visible film, then you guessed right with the proportions. If the opposite is noticeable, then you also need to add water to your solution. Before making a PVA primer, weigh its amount - it is not recommended to prepare too much solution at once. The longer the glue stays idle in the diluted state, the worse its bonding qualities will be. Therefore, do the work in stages. After doing the work, make sure that the primer does not flake after drying. Let it dry before proceeding to the next stage of work.

Varieties

PVA glue is distinguished by its remarkable qualities, which have created a positive reputation for it. But when using it, you need to remember that there are different types of this tool. For example, office glue will not take wood. Therefore, it is necessary to take into account the planned work and buy the appropriate version of the product.

- Household (wallpaper). Designed for working with paper and paper wallpaper that needs to be glued to one or another surface - plastered, wood, cement. Has a white color, in which yellowness may be present. If the product is old, then the yellow becomes more pronounced. The smell is not harsh. If, when you press the tube, only a certain amount of yellow or clear liquid is poured out, then the product has lost its quality. Discard the packaging.

- Clerical. It is used to glue paper and cardboard. Has a fairly liquid consistency, white or beige color. Differs in low resistance to moisture and frost.

- Universal (MB). A viscous substance of white color, sometimes with a yellowish tinge. Adheres well to slippery surfaces. Most often it is used when working with paper, glass, leather. Its technical characteristics allow even some floor and wall coverings to be glued.

- "Super M". Its use makes sense if there is a need to glue vapor-permeable materials, maintaining a high seam quality, and there are no special requirements for gluing technology. This type of PVA can be used when installing flooring and ceramic tiles. It can be used to join fabric, leather, glass, porcelain. The product is frost-resistant.

- E3. Effective when working with wood and plywood.

- Building. It is rarely used in its pure form, except for gluing certain types of wallpaper. More often it is added to mortars for brickwork and some other materials to improve their quality.

How much dries and how to speed up solidification

For quality work, it is important to know how to dry the adhesive quickly.Of course, there is nothing difficult in this process if small paper parts are glued.

When applied in a thin layer, drying takes 10-15 minutes.

On average, PVA glue dries for 24 hours

To get strong adhesion of surfaces, it is important to press the products strongly against each other. For example, put under the press from books when it comes to paper

Or clamp it in a vice for a couple of hours.

Small tricks for quickly drying PVA:

high-quality adhesion and drying takes place on clean surfaces - remove particles of dust and debris;

to apply the glue evenly, pre-treat the work surfaces with alcohol or acetone;

the thinner the layer of glue, the faster it dries - use a brush or roller to work with the glue;

it is worth considering that for quick drying it is important to use quality goods from trusted manufacturers;

PVA dries faster when the temperature rises moderately - use a hair dryer, place the product near a heat source, or place it in the microwave for a few seconds.

The main types of compositions

Depending on the purpose, PVA glue is divided into the following types:

- stationery - for paper and cardboard;

- household or wallpaper - mainly used for gluing paper materials to cement and wood surfaces;

- construction - for materials based on fiberglass, vinyl and paper, it can be used as an additive in primers, which increases the technological properties and adhesion of subsequently applied materials (putty, plaster and dry building mixtures);

- super M - for products made of vapor-permeable materials, ceramics, porcelain, fabric, glass, leather, also used for the installation of various floor materials;

- extra - wood, plywood, construction nets, wallpaper (cork, vinyl, paper, fiberglass), serpyanka, can be used as an additive to increase strength;

- universal - for gluing paper and decorative paper-laminated plastic on products made of wood, glass, metal.

Can PVA glue be diluted with water?

It is necessary to dilute PVA with warm water, since solvents negatively affect the technical characteristics and destroy its structure. Mixing is carried out as intensively as possible.

With a strong thickening - a crust or dry flakes have formed on the surface - the impurities contained are removed from the solution. Clots with a jelly consistency do not need to be removed - they will dissolve during stirring.

Dry mixes are diluted in a ratio that should be indicated in the manufacturer's recommendations for the use of a particular solution.

Adhesives that cannot be diluted with water, in most cases, are sold already in a diluted state and in an appropriate container, since they have a strong and unpleasant odor, and are also prone to quick hardening. Such substances may not be diluted at all or only with the use of special solvents.

Bituminous mixtures

Bituminous varnish is a mixture of special grade bitumen, various resins and oils. After drying, a strong black film forms on the surface, moisture resistant, resistant to chemical attack. It is considered a fairly new material in household use. Belongs to the category of inexpensive. It is more commonly used as an anti-corrosion protective layer.

For wooden surfaces, it is used when it is not required to emphasize the natural texture of the base (instead of paints). Bituminous material has found application as a decorative coating for the effect of aging of surfaces (patina). Another unique feature of bituminous mixtures is cold bonding. The bituminous solution is diluted with white spirit.

To prevent it from thickening during storage, the container must be airtight. The storage area should be dark (no direct sunlight), moderate temperature and humidity.

Bituminous varnish protects the surface very well from moisture and chemical influences, diluted with white spirit

How to make your own glue?

Making PVA glue at home

To dilute or prepare 1 liter of glue with your own hands, you will need the following set of components:

- 100 g white, well-sifted wheat flour;

- 20-30 g of ethyl alcohol (technical);

- 5-10 g of fine gelatin;

- 5-10 g glycerin;

- if necessary, organic dye of a light shade.

And so, how to cook glue from flour? First of all, you need to dilute the gelatin with water and leave the gruel for 24 hours. If the substance is too thick, you can stir it with hot water, breaking all the lumps. All subsequent actions will be carried out after the expiration of the day.

For the preparation of glue, we need 2 containers (preferably enameled). I would like to immediately note that the glue is boiled in a water bath. For cooking, pre-soaked gelatin is poured into a smaller container, and water is poured into a large container and put on fire.

Bring the gelatinous mass to a boil, then add flour little by little. Work technology is similar to cooking semolina, so be prepared for constant stirring so that no lumps form. It will take you about 60 minutes to cook.

When the solution is cooked and you get the required consistency, you will need to add alcohol, pigments and glycerin to the gruel. After adding these components, the glue is kept in a water bath for about half an hour, stirring all the time.

Upon completion of all manipulations, the product is cooled and checked whether the adhesive properties have been achieved.

If the mass is cooked correctly, it can be stored in liquid form for six months by tightly closing the neck and preventing hypothermia.

If cooking glue from flour is unacceptable for you, as it is time-consuming, familiarize yourself with how to boil glue from starch. For this you do not need any additional components - only hot water and starch, the adhesive characteristics from such a small variety of ingredients will not diminish.

If you plan to use the substance only for wallpapering, prepare KMTS glue, which is also easy to make at home.

Well, now you know how to make PVA glue at home, and we hope that our tips will help you cope with this task. The main task is to observe all proportions and do not forget to mix the mass thoroughly - this is what will help you create a homogeneous and effective substance.

PVA glue is often used for gluing items made of paper, cardboard, leather, wood, fabric. Its price is low, and the level of strength and adhesive bonding is good. The glue is resistant to high humidity indoors, and also has a high frost resistance. It is non-toxic, fireproof. If the glue is applied in a thin layer, it is almost invisible.

But despite all the advantages, like all other liquid adhesives, PVA glue can thicken. In this situation, do not rush to throw away the glue and run to the store for a new one. You can still save.

Why does the slime not thicken?

When making a slime, it is difficult to achieve the desired consistency. You need a proven recipe, strict adherence to proportions, high-quality components and the correct order of their connection. When one of the conditions is violated, it is difficult to understand why the slime does not thicken.

Craftsmen rarely pay attention to such trifles.

But the reasons why the slime did not thicken are compelling, and they should be figured out:

- Expired ingredients... Glue is often used to make slimes. The viscosity and elasticity of the product depends on its quality and density. If the glue is old or too runny, this is the answer why the slime does not thicken. The spoiled substance curls up and looks like cottage cheese. It is impossible to thicken such a slime.The shelf life is also important for other ingredients: shampoos, gels, creams, shaving foam.

- Liquid base... The decision of what to do if the slime does not thicken depends on the density of the starting ingredients. Shampoos, gels should be viscous, jelly-like: they play the role of thickeners. When activators (starch, soda, salt, sodium tetraborate) are added, they thicken even more. If a liquid base is chosen, a quality slime will not work.

- Non-observance of proportions... When wondering what to do if the slime hasn't thickened, remember if you mixed the ingredients correctly. The lack of a thickener affects the quality of the slime.

- Wrong order of introduction of components... Another reason why the slime does not thicken is that the elements of the composition were mixed in the wrong order. For example, when making a handgam from shaving foam, glue and salt, the foam and glue are added first, then the salt. If you combine glue and salt, you will not be able to add foam, and the slime will remain liquid.

Clay Moment

The moment is also extremely popular during construction and renovation work.

The range of its application is wide. To dilute the Moment, acetone and dimethyl sulfoxide, which are readily available in the pharmacy, can be used.

Tile adhesive

Anyone who is busy renovating an apartment needs to know how to choose a tile and glue for it, and quickly and efficiently glue the tiles.

There are three types of tile adhesive:

- based on cement, for its preparation, it is necessary to carefully observe the proportions and follow the instructions;

- ready-made one-component glue, sold in the form of a ready-made paste, does not dry out for a long time;

- two-component adhesive. Prepared just before using it. Its advantages include flexibility and manufacturability.

To properly prepare tile adhesive, you should know a few rules:

- the temperature of the components should be approximately equal, i.e. you cannot bring the mixture from the frost and fill it with hot water;

- add water to the mixture in small portions with thorough mixing;

- in the process of work, it is necessary to periodically stir the finished glue to prevent delamination.

It is necessary to dilute the tile adhesive with warm, clean water. The number of components of the mixture: for 5 liters of water there is 20 kg of dry mixture.

So, you need to glue something to something. What opportunities do we have and how do some adhesives differ from others?

Let's try to consider the main types of adhesives, their disadvantages, areas of application and, most importantly, areas where they cannot be used.

General properties of all adhesives:

- thinner adhesive layer - higher strength

- excess glue must be removed before the glue dries

- try on seven times, once attach the parts to be glued to each other and press

- there are no universal adhesives; in any case, this is a compromise.

Moment

.

The main method of application - as with almost all adhesives of the "old classical school" - apply a layer on both surfaces to be glued, dry, then apply a thin layer and press firmly. Dries completely in about a day. Good coarse glue.

Pros:

Good adhesion to many surfaces, that is, a really universal adhesive.

After gluing, it can be re-glued, if it did not work out (with reservations, since sometimes it can "unstick" in the form of such a terrible "lunar landscape" that it can only be washed off.

It is well diluted with solvents (I tried toluene) to a liquid form. Then it can be applied with a brush in a very thin layer. This trick is used to stick the foil on the surface.

With metals and glass can be removed completely without damaging the surface; it can also be removed from some plastics.

As a rule, it is used for gluing transparent plastics such as polycarbonate and acrylic, since the modern version does not harm these polymers (you can glue them to bait protective plates on optics).

Minuses:

Even in a dry state, it is slightly plastic, therefore, rigid fixation cannot be achieved.

The glue line is thick due to the gluing principle.It is impossible to achieve precise bonding in the moment.

The bonding area should be relatively large.

The most affordable solvents

The most versatile natural remedy, when using which you can remove dried traces of carpentry, vegetable, stationery and polyvinyl acetate composition, is water. To clean the surface, it is enough to quickly blot the fresh residue and rinse with water until the sticky marks disappear. Unfortunately, if the stain is old and deeply ingrained, then it is not realistic to remove it using such a solvent.

Another popular remedy for dissolving glue has proven itself excellently - these are sunflower and baby oils. Each of them needs to rub the dried residue with grease several times and wait a while. It will gradually lose its adhesive qualities and the solvent will mix with it, since many types of adhesive mixtures are made from oil. At the end of the procedure, the remaining traces are easily erased, and the surface is rinsed with water. Vaseline has a similar property, its high fat content contributes to the rapid breakdown of molecules.

Common vinegar can be isolated from natural solvents. You should wipe the stained area with it and wait half an hour. During this time, the stain will begin to lose strength, dissolve in acid, and the remains will need to be wiped off.

A mixture of baking soda and water in a 2: 1 ratio is very effective in this matter. This pasty substance is applied to the contaminated area, waiting for the complete dissolution of the curd and rinsed with water.

An effective solvent is alcohol, which can decompose many adhesive compositions. When applying this drug to the stained area after 5-10 minutes. the firm clot will soften. Further, the remnants are freely removed in the process of wet wiping.

Acetone has a similar effect, but should be used with caution to clean synthetic surfaces. Other well-known solvents are: gasoline, turpentine, white spirit, ammonia

When using them, for greater efficiency, the glue clot is preheated with a hairdryer. Thus, the process of its removal is accelerated.

How to remove dried varnish

Above, basically, are listed ways to improve the consistency if the varnish has thickened. And what should be done to remove varnishes and paints from painting tools? Can synthetic material be removed from wood after application?

It is simply impossible to remove old furniture or parquet varnish from the surface of the wood. Usually, where possible, sanding or sanding is used. For non-mechanical removal, the type of solvent is selected individually. The basic composition and chemical properties of the varnishing are taken into account.

The simplest way to remove an already unusable parquet protective coating is to use a special remover. The substance is a chemical mixture. You can use liquid, gel, or powder. Acetone copes with the simplest types of paints and varnishes. Denatured alcohol is more suitable for removing shellac.

First, liquid, gel or powder is applied to the varnish surface. Then you need to wait for the film to soften. To speed up the process, it is recommended to cover the treated surface with polyethylene. After some time (from 40 minutes to 4 hours), the old varnish will begin to swell and darken. What to do next?

It is more convenient to use a spatula to remove softened varnish. You need to work carefully so as not to damage the wooden surface. What if the old protective coating is not completely removed the first time? If necessary, the processing can be repeated.

To remove the residues of the substance from the painting tools, the following are used:

- Water-based parquet varnish is washed off with a warm water-soap solution on a fresh one;

- White spirit, kerosene, turpentine are suitable for most paints and varnishes based on organic solvents.Residues of substances are well rinsed, then the instrument is washed with some household chemical and rinsed thoroughly in water.

Do not forget about personal protective equipment, especially if you have to work with strong-smelling, quick-drying formulations. Airing the room during and after work will protect you from toxic fumes. Keep these materials out of the reach of children.

Applying home methods

Thinking about how to dilute the varnish at home, you should pay attention to the means at hand. You can revive your favorite cosmetic product in several ways.

Alcohol

If the varnish is dry, it can be diluted with regular rubbing alcohol. Just a few drops should be added to the bottle and mixed with a toothpick. If the consistency still remains thick, the process must be repeated.

Acetone

This tool has been widely used since Soviet times, but it is unlikely that it will be possible to save dried cosmetics with its help. Indeed, the varnish will become more liquid, but at the same time its structure and density will change. It will no longer adhere properly to the nails.

In addition, acetone has the following disadvantages:

- mixes up unevenly with varnish components;

- the durability of the manicure decreases;

- the structure of the applied coating is heterogeneous;

- color change is often noted;

- negatively affects the structure of the nail.

Micellar water

Micellar water is also used to dilute thickened varnish.

There are just a few steps to follow:

- Pour 1 tsp into the bottle. liquids.

- Without shaking, stir the mixture with a brush.

- Wait about ten minutes and do a manicure.

Hot water

It is enough to place the bottle in a container of hot water for ten minutes to make the consistency of the cosmetic product more liquid.

The main thing is not to use boiling water at the same time: as a result of a sharp temperature drop, the bottle may crack.

Nail polish remover

Nail polish remover is intended for removing varnish from nails. It can also be used to liquefy a cosmetic. By adding a few drops, it will not only become more liquid, but also acquire an attractive shine.

There are several nuances to consider when applying this method:

- If you overdo it with the amount, the consistency will turn out to be watery, and the varnish will spread unevenly during application.

- After a while, the release of pigment is noted, so the bottle must be shaken before use.

- It is allowed to use only that liquid that does not contain acetone, otherwise the desired result will not be achieved.

Clear nail polish

This method only helps to solve the problem for a short time. After 1-2 uses, the product fades. This is explained by the fact that the transparent version of cosmetics is not able to change the structure, it takes some of the dyes onto itself.