Multi-zone technology for growing mushrooms

Champignons are one of the most popular mushrooms that are massively cultivated on an industrial scale. But you can grow them at home. You will learn recommendations for equipping premises in this article.

Cultivation on an industrial scale implies the equipment of special rooms not only for the maturation of mushrooms, but also for the preparation of compost and the casing layer. It is also necessary to allocate auxiliary areas for storing inventory and special cultivation chambers with a favorable microclimate.

Figure 1. Premises for mushroom cultivation: a - single-zone complex (1 - cultivation chambers, 2 - utility rooms, 3 - working corridors, 4 - central corridor), b - multi-zone complex (1 - premises for substrate pasteurization, 2 - cultivation chambers, 3 and 4 - corridors, 5 - central passage, 6 - utility rooms), c - a complex for growing mushrooms (1 - cultivation chambers, 2 - pasteurization rooms, 3 and 4 - working corridors, 5 - utility rooms for storing inventory, 6 - ventilation unit, 7 - room for substrate preparation, 8 - casing soil preparation shop, 9 and 10 - warehouse).

Figure 1. Premises for mushroom cultivation: a - single-zone complex (1 - cultivation chambers, 2 - utility rooms, 3 - working corridors, 4 - central corridor), b - multi-zone complex (1 - premises for substrate pasteurization, 2 - cultivation chambers, 3 and 4 - corridors, 5 - central passage, 6 - utility rooms), c - a complex for growing mushrooms (1 - cultivation chambers, 2 - pasteurization rooms, 3 and 4 - working corridors, 5 - utility rooms for storing inventory, 6 - ventilation unit, 7 - room for substrate preparation, 8 - casing soil preparation shop, 9 and 10 - warehouse).

As a rule, single and multi-zone complexes are equipped for industrial cultivation (Figure 1). In single-zone ones, all processes take place in one room, and in multi-zone ones, preparation, compost pasteurization, cultivation and processing of mushrooms take place in different rooms.

For industrial production, not only underground, but also ground-based rooms with heating are used. In addition, there are combined complexes that are used at different times of the year.

A multi-zone system is considered more practical. It was first patented in the United States at the beginning of the last century, and such a system is still relevant.

The main labor costs in multi-zone complexes are spent on moving the compost:

- From the production area to the pasteurization chamber;

- To the zone of further mycelium growth;

- Into the mushroom ripening chamber.

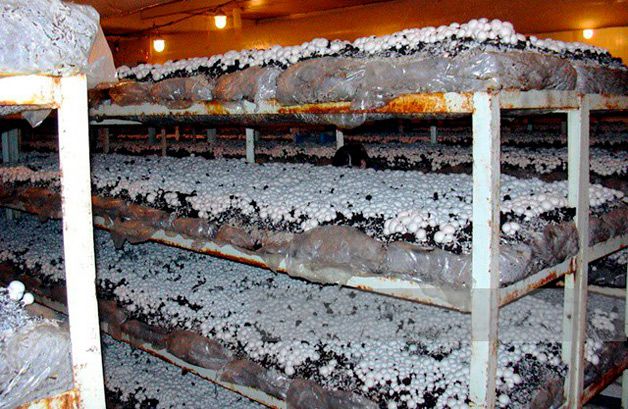

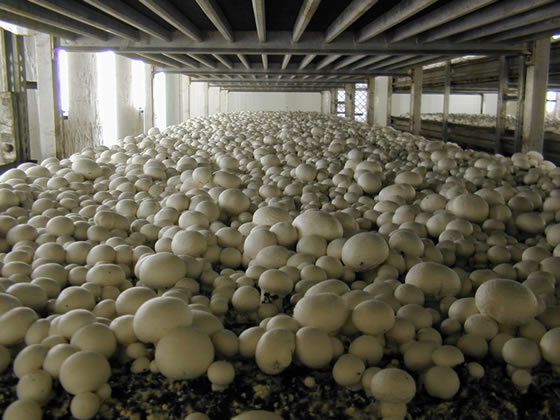

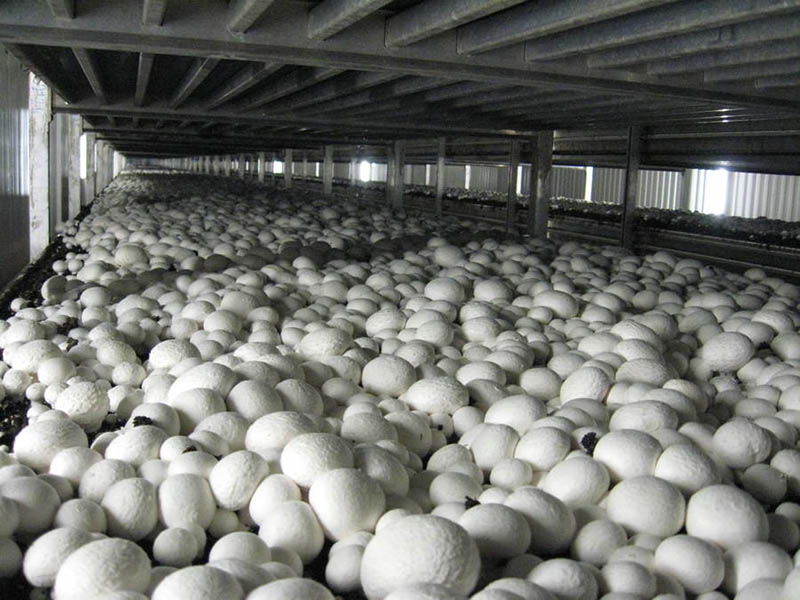

Mushrooms can be grown in ordinary boxes or large bags (Figure 2). Multi-zone ground complexes are cost-effective.

Figure 2. Bags and boxes for mushroom cultivation

Figure 2. Bags and boxes for mushroom cultivation

Firstly, one pasteurization chamber with a stable temperature (within 65 degrees Celsius) is enough, one or two growing zones for the maturation of mycelium with a temperature of 22-26 degrees and several chambers for maturation (temperature 12-16 degrees). Conveniently, contaminated compost containers can be easily moved out of the chamber.

Composting room

If you have the opportunity to grow mushrooms in a room with several rooms, you should use it, since the preparation and pasteurization of the compost, as well as the sowing of mycelium and the growth of fruit bodies must be carried out in different rooms.

If this is not possible, one large room is divided into zones by partitions. For composting, it is better to set aside an area with a separate exit to the street. This will make it easier for you to transport the raw materials for the substrate.

Compost pasteurization room

The room or part of it, where the compost will be pasteurized, is separated from the rest. This is due to the fact that already at this stage, it is necessary to observe sterile conditions, if possible, so that pathogens or pest larvae do not get into the substrate.

Figure 3. Features of compost pasteurization

Figure 3. Features of compost pasteurization

The compost pasteurization room is equipped with powerful heaters and an extractor hood. Also, tanks, barrels or baths are installed in it, where the compost will be pasteurized (Figure 3).In some cases, this process can be carried out on a concrete floor, but in this case, the room must be hermetically closed for a certain time.

Room for seeding and growing mycelium

One of the most important factors is the equipment of the premises for the production and sowing of mycelium. It must be strictly sterile, and all personnel must change their shoes at the entrance.

Inside, they will equip racks and tables where mycelium will be prepared and sown. Mushroom blocks are transferred to the room, into which the mycelium is placed. After that, the finished blocks are transferred to the chamber for ripening fruit chalk. In this room, the main equipment is installed: irrigation systems, fans and heaters.

Home business profitability

To determine the profitability of a mushroom growing business at home, you need to clearly determine what is needed for full development:

- lease of premises or construction of a new one;

- purchase of mycelium and the necessary equipment (racks, containers, etc.);

- purchase of funds for processing the premises;

- purchase of equipment for ventilation and air purification;

- sanitary examination of finished products.

Calculating costs is easy. The purchase of 5 tons of compost will cost 5 thousand rubles, mycelium - 2.5 thousand rubles. Heating the room - about 25.5 thousand rubles. Waste for employees is mandatory - up to 30 thousand rubles can be spent on wages for two people. In total, the cost part will be about 63 thousand rubles.

Calculating your profit is just as easy. Up to 1 ton of finished product is obtained from 5 tons of compost. The average cost of mushrooms is 200 rubles. From the sale of 1 ton, it will be possible to get 200 thousand rubles. The net profit will amount to 137 thousand rubles.

But these estimates do not include the investment in equipment, premises and costs that may arise during the growing process. Therefore, the mushroom picker can receive the payback of costs and the receipt of the first profit no earlier than in a year, observing all the requirements.

The following video will tell you about the nuances of growing mushrooms for business purposes:

It is not difficult to grow champignons on the territory of your house or apartment if you know all the subtleties. Compliance with all requirements and conditions will help to get a high-quality crop in large volumes. The use of some methods allows you to get a crop not only for personal consumption, but also for sale.

Planting mushrooms in the open field

Some gardeners spend the entire summer season in the country, so they grow field mushrooms

For landing, I choose a place protected from the sun and a windless place on the site. It is better to arrange the garden bed from west to east. Additionally, protection from the sun's rays is installed.

Ridges for mushroom cultivation have been prepared since autumn. At the end of the dacha season, a trench is dug up to 1 m long, 30 cm deep and convenient for harvesting. When arranging several beds, leave a passage of 0.5 m between them.

At the bottom of the trench, pour drainage from sand, gravel or crushed stone, 10 cm high, to ensure the outflow of excess moisture.

Then fill the trench with mown grass and weeds, tamp, pour slurry on top. A sod layer is laid on top, but with the grass down. Leave the ridge in this form until spring.

In the spring, a ridge is filled with a special compost prepared with a layer of 25 cm. The main component of compost

- Buckwheat straw, which should not be sunken. For 1 m2 you will need 2-3 armfuls. Put this straw in a box, add rotted cow dung - 3 buckets, chicken droppings - 5 kg, ammonium nitrate 2 handfuls.

Mix all ingredients well and spread in trenches. After a week, the mixture will settle, it is compacted. As a result, the layer should turn out to be 25 cm.

The planting of the mycelium is carried out when the temperature drops to 27 degrees. If it is higher, then there is a possibility that the mycelium will die or not take root.

The mycelium is planted to a depth of 5 cm in a checkerboard pattern with a distance of 20 x 20 cm, sprinkling with earth. Lay a layer of straw 30 cm thick on top of the myceliums to protect the earth from drying out.

In a couple of weeks, it will be known whether the myceliums have taken root or not. During this time, water the layer of straw with water so that it does not end up in the compost.

After 2-3 weeks, the mycelium will grow, it can be seen. If a week after planting there are no signs of growth, it is necessary to spray the substrate itself with water, possibly a lack of moisture in the mycelium.

After myceliums have taken root

you can remove the protective layer of straw and add a layer of turf soil 3 cm high, slightly compacting.

The first harvest of mushrooms will appear 1.5 months after planting. In hot weather, the growth of mushrooms stops.

In the open field, mushrooms can bear fruit for up to 4 months.

Growing in the basement

The cellar and basement are an ideal place for growing mushrooms with proper arrangement and adherence to agricultural technology.

Growing parameters

Air humidity control, for this you will need hygrometer

... To increase the humidity, spray the room with water, to lower it, ventilate.

To control the air temperature, set thermometer

... When growing mushrooms in summer, heating is not required. When grown throughout the year, heating or insulation will be required.

Growing champignons in the basement will need forced ventilation

, because this is a closed room. Compost constantly emits carbon dioxide, which, if accumulated in large quantities, will lead to mustiness. But ventilation should not create drafts.

Preparing the cellar for growing mushrooms

First, you need to process the cellar to prevent infection with pests and diseases. Light in the basement for disinfection sulfur checker

, the ceiling and walls are defeated with the addition of copper sulfate. Then ventilate the cellar.

Cooking compost

The composting technology is standard: horse manure and straw with the addition of nitrogen-containing mineral fertilizers.

The mycelium is planted to a depth of 4-5 cm when the temperature of the compost drops to 27 degrees.

The distance between adjacent pieces of mycelium will be 20 cm. If you have grain mycelium, you just need to spread it over the soil surface.

After two weeks, the myceliums will take root, they are sprinkled with soil with a layer of 3 cm. Soil mix

consists of peat, limestone (chalk) and garden (garden) land in a ratio of 5: 1: 4.

4 days after sprinkling with soil, it is necessary to lower the temperature in the room to 12-17 degrees. The surface must be regularly moistened, the room must be ventilated.

Making compost for champignons with your own hands

Unlike many mushrooms, champignons are undemanding to light and heat; they can actively grow in semi-dark basements. Optimal conditions for growing mushrooms are between 13 and 30 ° C. Moreover, these fungi do not need a host plant for nutrition and growth, since nutrition occurs due to the absorption of decaying organic matter. Therefore, compost (the so-called champignon compost), which is prepared on the basis of horse manure or chicken manure, with the obligatory addition of fresh rye or wheat straw and gypsum, is often used as a soil for growing mushrooms. Manure feeds mushrooms with nitrogenous compounds required for growth, straw provides mycelium with carbon and is an additional source of nitrogen, gypsum supplies mushrooms with calcium and at the same time structures the compost, preventing its caking. As additional additives, you can use chalk, complex mineral fertilizers, meat and bone meal.

Any mushroom farm, each mushroom grower develops his own formula for the best compost, as a basis for which you can practice the classic recipe for mushroom compost based on horse manure.

To prepare compost for champignons with your own hands, for every 200 kg of fresh horse manure, take 5 kg of straw, 0.5 kg of urea, superphosphate and ammonium sulfate, 750 g of chalk and 3 kg of gypsum.

With year-round cultivation of champignons, the composting technology is established in specialized rooms with a constant air temperature of at least 10 ° C. With seasonal mushroom cultivation, only in the warm season, compost can be laid under a canopy on a concrete area in the open air.

The main conditions for preparing compost for growing champignon mushrooms is to prevent contact of its constituent parts with the ground, since natural pests can get into the mushroom compost from the soil.

At the first stage of composting, the straw is crushed and abundantly moistened with water until completely moistened. After two days, it is combined with manure, laying it in successive layers. In the process of laying, the straw is watered with mineral fertilizers diluted in water. The formed roll-shaped pile with dimensions of 1.5 m in height and width is left to warm up. The folded pile must contain from 100 kg or more of straw, otherwise the fermentation process will either be too slow or will not start at all due to the low heating temperature. After 5 days, it is necessary to make a break of the formed heap, while adding water. The re-mixing helps to align the fermentation processes that are running at different rates in different parts of the compost heap. On average, composting requires 4 cuttings, and the full compost production cycle takes 20 to 23 days. In 3 days after the final cutting, subject to the compost preparation technology for growing compost, ammonia will gradually cease to be released from the heap, the characteristic smell will disappear, and the mass itself will take on a dark brown color. After that, the finished compost is placed in special containers or beds are created from it for sowing mushrooms.

How to prepare compost for growing mushrooms is shown in this video:

Growing champignons in different ways

There are different ways of growing mushrooms, but not all are used by summer residents to obtain mushrooms for personal use.

Growing mushrooms in the open field

Cultivation of mushrooms in open beds is a rather difficult task due to the specifics of champignons: they do not tolerate sunlight. Therefore, for sowing them, you will have to choose a place that is well shaded by trees, tall shrubs, or choose a site behind the house. You will also have to additionally build a protective shelter, build a canopy. It will not only provide the necessary shade, but will also protect the area from rapid drying.

Cultivation of mushrooms in open beds is a rather difficult task due to the specifics of champignons: they do not tolerate sunlight. Therefore, for sowing them, you will have to choose a place that is well shaded by trees, tall shrubs, or choose a site behind the house. You will also have to additionally build a protective shelter, build a canopy. It will not only provide the necessary shade, but will also protect the area from rapid drying.

Before starting planting work, you should prepare the compost mixture. It can consist of straw (10-12 kg), chicken manure or normal manure (7-8 kg). The components are distributed in layers in a special pile, after which they are moistened every day, making sure that the mass does not dry out. While the compost “ripens” for 20-25 days, it will need to be loosened 5-6 times.

On the territory chosen for planting, the soil is thoroughly loosened, then the mycelium is evenly scattered over it, covered with a compost mixture on top with a layer of 6-8 cm, and thoroughly watered. Next, they monitor the humidity of such a bed and moisten it as it dries. If everything is done correctly, then the first mushroom harvest can be obtained after about 2-2.5 months. At the same time, up to 12 kg of fruit bodies per month can be collected from 1 m2 of a mushroom bed. Without transplanting on the same bed, the mycelium will bear fruit for up to 5 years in a row.

To equip such a garden, horse or cow manure is introduced into the beds 1.5 m wide, and then zucchini and squash are planted. Be sure to stretch the film over the beds. When the seedlings take root well, the mushroom mycelium is sown. These cultures get along well on the same territory.

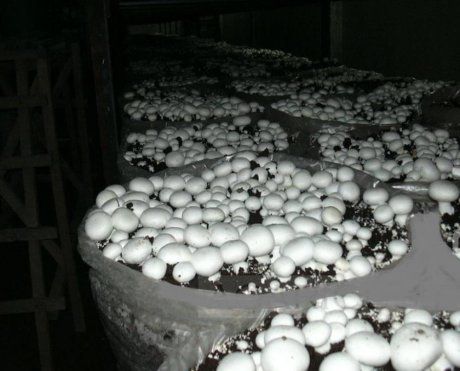

Growing mushrooms on the shelves

This is a Dutch mushroom growing technology. The shelves are essentially the same beds, simply arranged vertically in the form of a multi-storey structure.Due to this arrangement, the production area is used as efficiently as possible. But there are several drawbacks to this method: in case of infection, the infection spreads very quickly along vertical and horizontal rows. Also, the method of growing on shelves requires special mechanisms and expensive equipment, which is more applicable for industrial growing of mushrooms. This technology is too expensive for private households.

This is a Dutch mushroom growing technology. The shelves are essentially the same beds, simply arranged vertically in the form of a multi-storey structure.Due to this arrangement, the production area is used as efficiently as possible. But there are several drawbacks to this method: in case of infection, the infection spreads very quickly along vertical and horizontal rows. Also, the method of growing on shelves requires special mechanisms and expensive equipment, which is more applicable for industrial growing of mushrooms. This technology is too expensive for private households.

Growing in containers

This method of mushroom cultivation is also more suitable for large farms, mushroom business, rather than for cultivation only for personal purposes. This technology is practiced in Canada and the USA.

This method of mushroom cultivation is also more suitable for large farms, mushroom business, rather than for cultivation only for personal purposes. This technology is practiced in Canada and the USA.

For cultivation, containers made of wood are needed, which have undergone special treatment against mold and fungal infection. The containers are filled with a substrate and inoculated with mycelium. Different phases of fungus development take place in different rooms in which the necessary conditions are maintained. If desired and using 1-2 containers, it is quite possible to organize such a growing process at home.

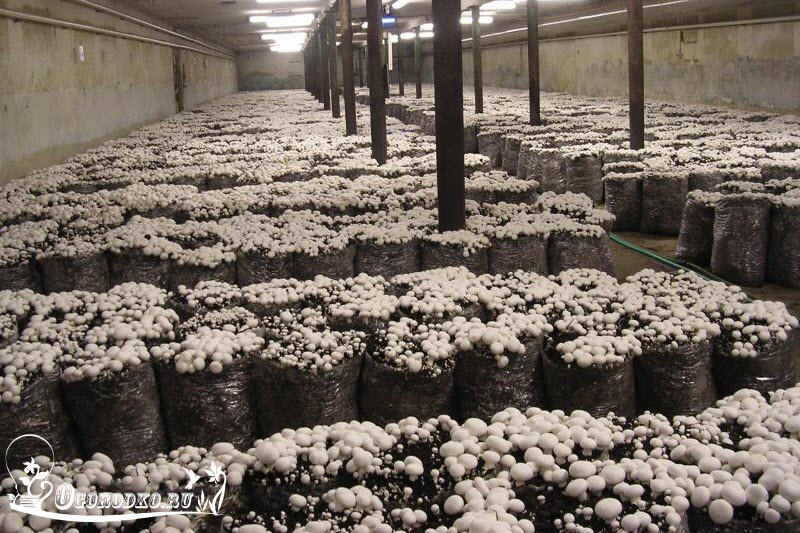

Growing mushrooms in bags

A popular and convenient cultivation method, it is suitable for small and medium-sized farms as it is not as expensive as other cultivation methods. In this case, polyethylene bags are used. For example, 25 kg each, which is filled with compost and sown with fungal spores. They are installed in such a way that it is easy to approach them. Also placed in vertical tiers. It is best grown in a poultry house or vegetable store.

A popular and convenient cultivation method, it is suitable for small and medium-sized farms as it is not as expensive as other cultivation methods. In this case, polyethylene bags are used. For example, 25 kg each, which is filled with compost and sown with fungal spores. They are installed in such a way that it is easy to approach them. Also placed in vertical tiers. It is best grown in a poultry house or vegetable store.

Of the minuses, it is worth noting the complexity of self-filling containers with compost mixture, but on sale, if you wish, you can find polymer bags already filled with the substrate along with mycelium.

Block cultivation of champignons

Many mushroom lovers now use this technology - they grow champignons from compressed substrate. Its role is played by peat, sawdust and wood, husk from seeds, manure. All this is pressed into blocks.

Many mushroom lovers now use this technology - they grow champignons from compressed substrate. Its role is played by peat, sawdust and wood, husk from seeds, manure. All this is pressed into blocks.

This method is good because:

Pressed blocks are laid out on the shelves, several holes are made in their surfaces. To prevent moisture from evaporating so quickly, cover with burlap, film, paper. It is necessary to wait until the mycelium appears on the surface. After that, the blocks are sprinkled with casing layer, no longer ventilated. Moisturize only by spraying and wait about 2.5 months until fruiting bodies appear. After that it will be possible to harvest.

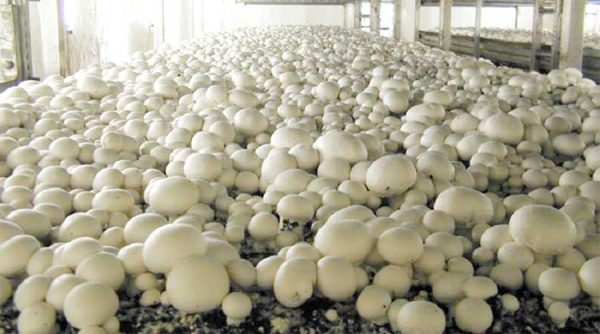

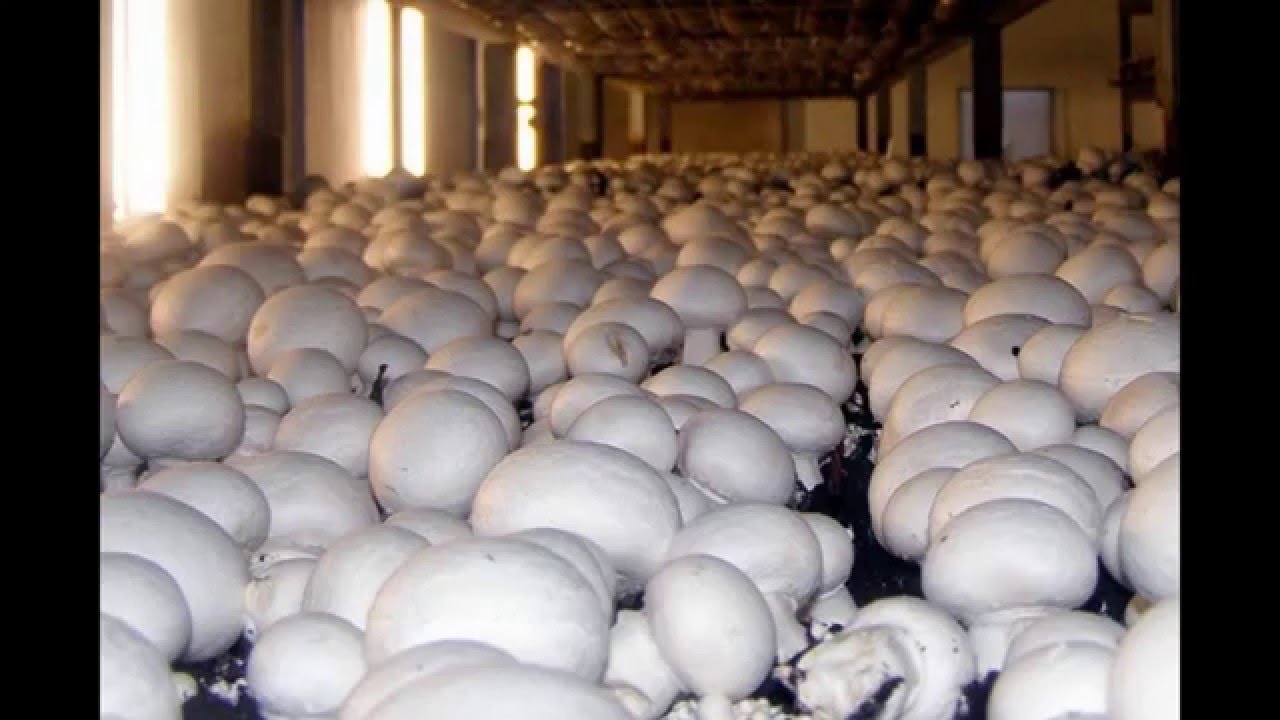

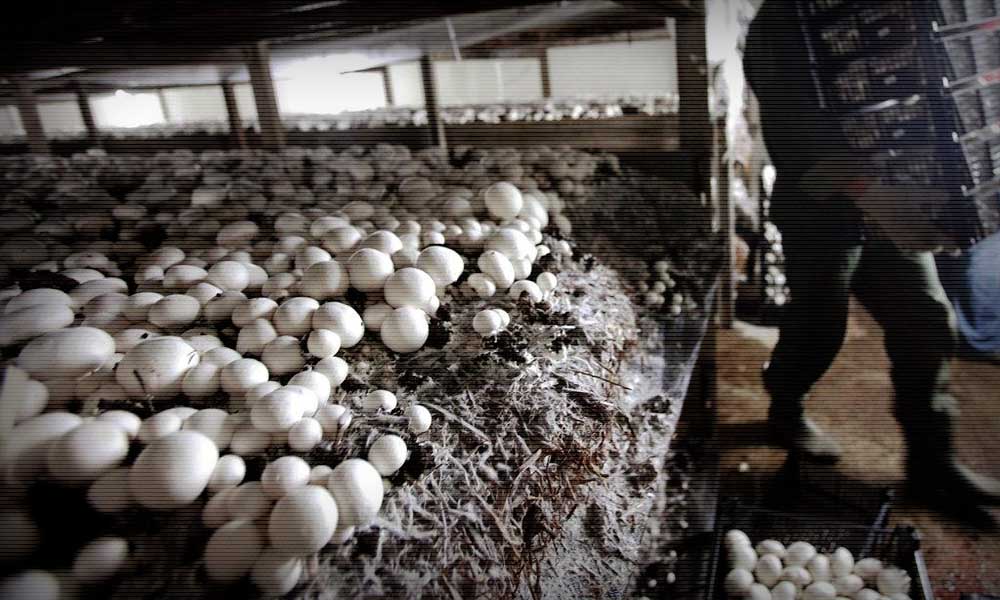

Growing champignon mushrooms on shelves (with video)

It is possible to cultivate champignon on multi-tiered shelves. In a standard cultivation chamber with an area of 200 m2, measuring 11 x 18 m with a ceiling height of 3.8 m, designed to accommodate 40 tons of compost, 4 five-tier racks 1.4 m wide and 15 m long are installed. shelves, fenced with bumpers so that compost and casing layer do not fall out. The first tier of the bookcase is at a height of 0.25 m from the floor, the subsequent ones are 0.6 m from each other.

It is possible to cultivate champignon on multi-tiered shelves. In a standard cultivation chamber with an area of 200 m2, measuring 11 x 18 m with a ceiling height of 3.8 m, designed to accommodate 40 tons of compost, 4 five-tier racks 1.4 m wide and 15 m long are installed. shelves, fenced with bumpers so that compost and casing layer do not fall out. The first tier of the bookcase is at a height of 0.25 m from the floor, the subsequent ones are 0.6 m from each other.

The width of the aisles between the racks for champignons is 110 cm, between the racks and the walls - 100 cm.

When placing compost in the form of beds poured onto shelves, 100 kg of finished compost can be placed on 1 m2 of shelf area. The thickness of the compost with proper compaction is 20 cm. With a bed width of 1.4 m, 1.4 x 15 x 5 x 4 x 0.1 = 42 tons of compost will fit on 4 five-tier shelves with a length of 15 m.

The compost is placed on racks for champignon mushrooms, then leveled and compacted. Grain mycelium is poured evenly onto the surface of the compost, then it is embedded to a depth of 1 cm. The seeding rate of grain mycelium is 0.4-0.5% of the mass of the finished compost.

The surface of the compost is leveled and covered with paper. Moisten the paper by spraying it with water (up to 0.2 liters per 1 m2 of the garden), preventing water from seeping into the compost.Using this method of growing mushrooms, the incubation of mycelium at a compost temperature of + 20 ... + 26 ° C ends in 14 days. After that, cover soil is applied and overgrown for 10 days. Watering on the casing layer up to 2 liters per 1 m2 of the bed.

After the mycelium has mastered the casing layer, the formation of fungi begins. The temperature in the cultivation chamber is regulated in the range from +14 to +17 ° C at a relative air humidity of 85-95%. For permanent removal of carbon dioxide during the period of setting and fruiting of mushrooms, ventilation with fresh air in a volume of at least 250 m3 / h per ton of substrate is required. The ventilation system should supply 10,000 m3 / h to the chamber.

To create an air flow over the mushrooms, in each odd passage, there is a special equipment for growing mushrooms - an air duct with downward nozzles. In the simplest case, the duct is a 15 m long air-inflated polyethylene sleeve suspended on wire rings in the middle of the aisle so that the nozzles are 40 cm above the compost surface on the top shelf and the air flow from the nozzles is directed vertically downward.

When ventilated with fresh air, the carbon dioxide content in the upper casing layer is much lower than in the depth. This leads to the formation of fruit chalk primordia on the surface of the casing layer. On the 15-20th day, counting from the day of application of the casing layer, white stars from the mycelium appear on the surface of the casing layer, and after a few days - the rudiments of mushrooms in the form of white peas. Watering up to 1 l / m2 should be started the next day after the appearance of the buds-peas.

The video "Growing champignon mushrooms on multi-tiered racks" shows how this process takes place:

How to grow mushrooms in briquettes

Mushrooms are quite successfully cultivated on briquettes. The main advantage of this method is that mushroom cultivation does not depend on weather conditions, and the crop can be harvested all year round (Figure 8).

If you are interested in how to grow mushrooms in the country, we recommend using the briquetting method. To make a briquette (mushroom block), you need to compress the finished compost so that its layer does not exceed 4 cm.

The inclusion of peat in the compost makes it possible to maintain a constant moisture content in the mixture and prevents fungal diseases. Mycelium is sown on the surface of the briquette and the mushrooms are provided with an optimal microclimate. For this, at the stage of germination of the mycelium, a constant temperature is maintained at + 20-24 degrees, and after the appearance of the first fruiting bodies, it is reduced to 15 degrees.

Figure 8. Briquettes for growing mushrooms at home

The briquettes can be placed on special racks, and after the completion of several fruiting waves, new briquettes are made, and the old compost is disposed of.

Step-by-step instructions for beginners

There are several basic step-by-step rules that you need to know when planting and growing mushrooms at home. If done correctly, it will be possible to regularly obtain large yields of mushrooms.

Landing

After preparing the substrate and placing it in boxes or bags, it is planted with mycelium, which is deepened by 5 cm. A distance of 20 cm between the recesses is maintained. It is recommended to land in a checkerboard pattern. After planting, sprinkle the mycelium with soil.

If mushroom spores are planted, they are sown on the surface of the soil. After sowing, it is not required to sprinkle them with soil and moisten them. Cover the soil with a cloth and moisten it regularly. The mycelium grows within five days. At this time, the room maintains a humidity of 80-95% and a temperature of 22-27 degrees. After 12 days, the surface is covered with 1 part of limestone, 4 parts of soil and 5 parts of peat. The thickness of the layer should be at least 3 cm. After that, another 5 days should pass, the soil is periodically moistened.After another 5 days, the temperature is lowered to 13-16 degrees.

Growing and care

Although there is no need for constant care for the mushrooms, it is required to first prepare the room and create special conditions in it:

- Growing equipment. Depends on the way the mushrooms are grown. Growing in bags is considered the best method. For this, special supports with hangers are useful, on which the bags with the substrate are suspended. The use of plastic equipment is recommended - it does not deform, does not corrode, and is much cheaper.

- Optimum temperature. Champignons do not require high temperatures, therefore they do not create greenhouse conditions. You just have to insulate the room, carry out thermal insulation, which helps to retain moisture. Heating devices must also be installed - the temperature should not fall below 13 degrees. The elevated temperature is set only at the initial stage. The use of infrared lamps is permitted for additional heating.

Humidity level. Champignons love moisture, so the air in the room must be constantly humidified. It's simple: use sprays or special electronic humidifiers. The humidity level is not lower than 70-90%.

Ventilation and lighting. Be sure to regularly ventilate the room. It is better to use hoods that deliver fresh air. But if you do not plan to grow in large volumes, it is permissible to manually ventilate the room. Several garden lamps are installed for lighting.

It is equally important to take care of fertilization. As the mycelium grows, it gradually appears on the surface, and after a couple of weeks it will be completely above the soil

To avoid drying out and destruction of the still fertile mycelium, a fertile substrate poured on top will help. Also, fertilizer is introduced into the soil, consisting of 9 parts of peat and 1 part of chalk. For 1 sq. m evenly scatter 40-50 g of the mixture.

Harvesting rules

3-4 months pass from the moment of sowing to the first harvest. Young mushrooms of medium size are collected, those that have a whole membrane that connects the stem and cap. As a seed, it is recommended to collect mushrooms with strongly opened caps - they lose their useful properties.

It is forbidden to pick mushrooms with a darkened light brown cap - they can cause intoxication of the body and lead to severe poisoning.

Champignons are not cut like wild mushrooms, but twisted. The hole remaining after collection is slightly sprinkled with compost. A mushroom will grow again in this place. Active fruiting of mushrooms lasts 8-14 weeks. During this time, the crop is harvested up to 7 times. Further, the yield decreases, therefore, the mycelium is removed, and the substrate is disposed of.

After the cessation of fruiting, the mycelium is removed and used as a recharge for the next generation. The remaining substrate is not reused, because it loses its fertile properties. From 1 sq. m collect up to 60 kg of mushrooms.

Harvesting

Champignons ripen several times, the entire fruiting period takes from 8 to 14 weeks. Usually, the first waves bring most of the harvest (about 75%), and in total, mushrooms are harvested 3 to 7 times. Champignon yield from 1 sq. m on average 15 - 20 kg.

It is necessary to collect champignons when the film connecting the cap and the stem of the mushroom has not yet torn. If the film is damaged, and the inner side of the cap has darkened, the champignon is overripe and not suitable for food.

Harvest

In order not to damage the mycelium and maximize the fruiting period, it is necessary not to cut the mushrooms when harvesting, but to carefully twist them. The wells are covered with a mixture of earth, peat and limestone, then moistened with water using a spray bottle. In this place, new mushrooms will grow in 12 - 15 days.

After the entire crop has been removed, the substrate is disposed of. It is not reused, as it completely loses its nutritional properties.

What equipment is needed

If you want to open a large-scale business, then at the initial stage, mushroom growing will require certain investments from you. But with the correct organization and compliance with all technological standards, the costs pay off quickly enough.

Manufacturers call the biggest expense item the purchase of special equipment, without which the productivity of your labor will be too low. Indeed, in most production processes, special equipment is involved, thanks to which the necessary conditions for obtaining high-quality products are provided.

Air conditioning and ventilation systems

Maintaining the correct microclimate is an important aspect affecting the quality and quantity of the final crop.

Consider the main components of HVAC equipment:

| № | The constituents | Functions |

| 1. | Mixing chamber | Regulates the amount of carbon dioxide in the room. Mixes street air with special air masses in the cultivation chamber. Creates an optimal concentration of CO2. |

| 2. | Air cleaning system | Equipped with two filters - coarse and fine. The former trap dust particles, the latter - various microspores that are contained in the air. |

| 3. | Supply ventilation with dampers | With the help of dampers, it controls the volume of air coming from the street. |

| 4. | Air heaters | The air is dried with excessive humidity in the summer months and heated in the winter. |

| 5. | Heat exchangers | Effectively reduce the air temperature in summer, dry it out with excessive moisture. |

| 6. | Air flow redistribution system | Since champignons do not perceive direct air currents well, the system pushes the air masses forcefully through movable nozzles into the floor. |

Example: Climate control to maintain optimal air parameters  With the help of the climate system, you can increase the yield both quantitatively and qualitatively.

With the help of the climate system, you can increase the yield both quantitatively and qualitatively.

Refrigerating chambers

Several types of refrigeration chambers are used in the mushroom farm. Some are for quick cooling, the other are for storing products.

The first mushroom growers are called "shocker". Since mushrooms are rapidly losing their presentation, and their transportation and sale takes time, manufacturers increase the shelf life of freshly picked mushrooms by placing them in a shocker for 1 hour. The temperature in it is from +5 to 0 degrees.

The chilled products are subsequently immediately transferred to the refrigerated storage chamber.

Wherein:

- fill it only halfway so that there is free space between the containers for the unhindered movement of air;

- store products as much as possible in such conditions for 3 days, since after its commercial quality will begin to decline;

- the number of refrigerators is determined by their size and the volume obtained per day, multiplied by 3.

Steam generators

Steam generators perform several critical functions:

- pasteurization of the substrate;

- humidifying the air in the chamber;

- disinfection of the premises after working off the substrate.

The steam generating system consists of two steam lines - larger and smaller diameters. The first is needed for the main supply of steam, and with the help of the second, the air in the room is humidified.

Lighting systems

Although mushrooms grow beautifully in complete darkness, the light in the pavilion is essential for the staff. The most economical option is fluorescent lamps. They are installed on the ceiling along the aisle and on the walls near the refrigerating chambers.

How to grow champignons - 5 main ways

There are several ways to breed a plantation. Each of them has its own advantages and disadvantages.

Let's take a look at the most popular techniques from scratch.

Method 1. On the ground

Growing outdoors is the easiest way. All that is needed is to form special mushroom beds. This is not a familiar elevation for everyone, but, on the contrary, a deepening in the soil of about 30 cm, and the seeds are replaced by mycelium.

Next you need:

- Lay drainage from a layer of small stones at the bottom of the bed.

- Place and tamp compost on top.

- Cover everything with foil (protects the mycelium from drying out and excess light).

Method 2. On the shelves (Dutch system)

The shelf system resembles a bed system, but it uses the entire volume of the room more efficiently and rationally. The method is called Dutch because it was developed and patented in the "land of tulips". They also came up with a special set of equipment that almost completely automates the production process.

Method 3. In bags

A friend of mine bought bags filled with mycelium and placed them in his greenhouses. He could only periodically water them and constantly cut the crop. Others use premises that are "at hand": vegetable stores, poultry houses or pigsties.

Bag cultivation is a convenient way to minimize the risk of disease and pest infestation.

Bag cultivation is a convenient way to minimize the risk of disease and pest infestation.

Growing in bags is not only a minimum investment. Among the advantages is an effective fight against diseases and pests. You simply throw away the affected bag, the rest of the myceliums remain intact.

Method 4. In containers

For this method, special wooden containers are used. Usually they have already been treated with a special solution that prevents the occurrence of mold and other diseases. Such cultivation is also subject to mechanization, although the cost of the equipment is higher than usual.

Method 5. In briquettes

The briquette method is easy to set up in any utility room, and the blocks are easy to make yourself. All you need to do is compress the prepared compost and shape it into blocks that are convenient for you.

This method requires peat. So for one square. m of compost, you will need 30 kg of it. It is laid down with a layer of 5 cm, after which it is loosened and compacted.