Selection Tips

When choosing products, manufacturers recommend focusing on the following criteria:

- Size - buyers usually choose a product by this parameter. For home use, bags of 20 liters are suitable, which are used for a 5-7 liter bucket or an office basket. It is recommended to put a 35 liter bag in a 10 liter tank. For the removal of construction waste, large and dense bags are used - their volume can reach 360 liters.

- Quantity - the most popular are packages containing 20-100 bags per roll. Sets of 5-10 pieces are used much less often.

- Material thickness - 7 micrometers are enough for household needs. For construction work, bags of increased strength are used. It is also permissible to use two-layer products.

- The presence of handles or ties - these models are considered more comfortable, but they are often overpriced.

- Color - the use of modern technologies makes it possible to produce products in bright colors. This allows each person to choose the appropriate option.

Separately, it is worth mentioning biodegradable models that are allowed to be disposed of in euro tanks. The decomposition period of such products is only 3 years, and not 100 years, as in ordinary polyethylene.

Shovel purpose

A shovel is a tool with which different types of work are performed.

With this device, you can dig, clear, transfer soil and other bulk materials.

And this is not a complete list of possibilities, since everything depends on the type of instrument.

Even special equipment is not capable of completely replacing a shovel.

It is used by janitors, builders, and the military.

It is indispensable for firefighters, metallurgists, archaeologists and many other professions.

For the shovels, GOST 19596-87 was developed with technical conditions, which describes in detail the types and all sizes of loading, gardening and building types of tools to the smallest detail.

In fact, there are much more classifications of these products than according to GOST.

general description

Garbage bags are required everywhere - at home, in the office, in industrial premises. Practical bags are used for different types of waste. They are affordable and help isolate bad odors.

> When choosing such products, it should be borne in mind that they are made from different materials:

- Made of low pressure polyethylene. These bags are usually used for collecting waste at home or in the office. They are also suitable for packing small items. The volume of products varies from 20 to 120 liters. The color is also different. Bags can be transparent, colored or decorated with some kind of pattern.

- Made of high density polyethylene. Such models are suitable for storage and transportation of solid and loose substances. It is permissible to pack building materials, soil, fertilizers in them. This type of plastic bags is also used for the removal of small construction waste. The dimensions of the product differ - from 15x20 centimeters to 1.5x2.2 meters.

- Made of polypropylene. Such products are suitable for the removal of large construction waste. Such bags have all the necessary parameters for waste disposal. At the same time, they are cheaper than high-pressure polyethylene bags.

At the same time, ecologists have been sounding the alarm lately, claiming that such products are harmful to the environment. Therefore, special bags of biodegradable materials began to appear. It is also permissible to use nylon models.

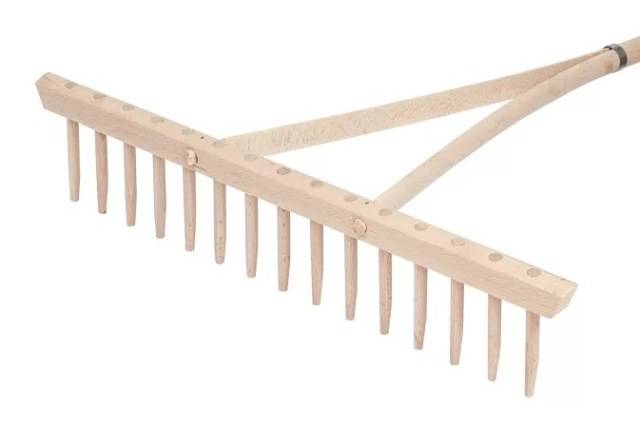

Device, characteristics and principle of operation

Each type of rake has a number of features.

The simplest hand tool is a transverse bar (ridge, working crossbar) with sharpened teeth, planted on a handle.

The teeth themselves are located at an obtuse, acute or right angle in relation to the handle.

Rakes differ in size, weight, number of teeth and their length.

In the production of this tool, various materials are used, which are combined to facilitate and at the same time increase the strength of the structure.

The ridge of the rake is either straight or curved, and the handle is often called a rake.

Types of teeth

The main difference between the rake is in the configuration of the teeth.

Short models with a narrow comb are designed for hard-to-reach places and can have 2-4 teeth, while standard long rakes have a minimum number of teeth of 8 pieces.

Variants with close-set teeth are also produced, the number of which on the crossbar can reach 18 pieces, that is, twice as many as in standard variants.

The shape of the teeth are:

- Straight - the simplest metal flat teeth located across the working bar, thereby increasing the area of their impact during operation. Effective in shoveling up debris, leaves and grass.

- Twisted - similar to the previous ones, but pointed towards the end, and turned at 90 degrees at the base or closer to the center. Such teeth are used to loosen the soil.

- Crescent - the teeth are made in the shape of a sickle, located, like others, perpendicular to the working crossbar, pointed, and bent towards the handle. When working, they carefully cut through the soil, ensuring its better saturation with oxygen and moisture.

- Nails - resemble the shape of nails.

All of the above teeth are flat, however, in some rakes they are pin (perpendicular pins of a circular cross-section, analogue of straight flat models), wire or plate.

The last two options are installed on fan models.

Material

The working part of the simplest rake is made of painted iron, and the handle is made of wood.

This design has many disadvantages, including high weight and rapid tooth wear, but this is perhaps the cheapest option.

Steel models are a direct competitor, which are also massive, but more durable.

There are also wooden rakes, despite the apparent fragility of the structure, such a tool is quite effective.

Wooden tools are quite difficult to find on the market, as most often they are made by home craftsmen for their own needs or for their friends.

The neatly assembled ash and birch structure is a worthy replacement for metal models, for example, when harvesting hay.

The main advantage of wooden rakes is their lower weight.

The rake is a tool, in the production of which there were attempts to lighten the structure.

The models, which use hardened aluminum for the manufacture of both the working part and the handle, weigh 800 grams, while their strength remains at a high level.

However, the manufacturers did not stop there and offer customers plastic options weighing, depending on the cutting, 200 - 400 g.

It should be noted here that elastic, but at the same time durable plastic is used in the manufacture, so you don't have to worry about the reliability of such a tool.

Dimensions and weight

In terms of the dimensions of the model, a rake of the same type may differ from each other.

A common garden tool is often 1400 mm long, with a working width of 280 mm and a total weight of 1.2 kg.

Moreover, as a rule, such a rake has 8 teeth

If we take into account the main range of species on the market, we can talk about the following characteristics:

- Length: 1.3 - 1.8 m.

- Working bar width: 28 - 46 cm.

- Handle diameter: 25 - 40 mm.

As for the size of the teeth, their height ranges from 65 to 90 mm, and the distance between them is 40 to 60 mm.

At the same time, on the rake, depending on the type of tool, from 2 to 18 teeth are installed, but there are models with a large number.

Flower rakes differ from standard models in their compact dimensions, they are about 8-15 cm long, and the width of the bar with teeth is about 5 cm, their weight, as a rule, does not exceed 150 grams.

What you need to know about shovels?

Shovels also include scoops for cleaning garbage.

The handle of such a tool is fixed across the plane of the canvas with sides.

Plastic and metal are used as materials for the manufacture.

The first option is monolithic.

In other words, the plastic scoop has a non-separable molded construction.

For harvesting potatoes, a special shovel is used, which looks like a pitchfork.

At the end there is a baffle with rollers.

Used in conjunction with a wooden tool on vegetable bases.

Shovels are also called various scrapers for cleaning hard-to-reach places from debris and dirt, intended for raking.

Modern tourist shovels are equipped with additional attachments.

Their design allows you to remove the standard blade from the handle, attach an ax, saw or other useful travel tool that comes in the kit in its place.

In addition to ordinary hand tools, various modifications of it can be found on the market:

- Pneumatic shovel (pneumatic bucket, hopper bucket, plaster shovel) - a device for applying plaster. It is a handle on which a scooping container is fixed. Inside it are nozzles for supplying solution, and air nozzles. In the handle there is a tube that supplies compressed air from the connected compressor.

How to choose a rake?

The rake is a simple tool in design and operation.

There are usually no problems with his choice, however, a few simple tips are still able to dot the possible questions:

- Steel and galvanized tools are considered the most durable, and plastic and wooden models are considered the most durable.

- To collect large debris, it is better to buy a tool with large powerful teeth, and for small debris, it is better to buy a tool with densely planted small teeth.

- For work in a large area, it is more efficient to use wide models, and for flower beds, a narrow grip is preferable.

- The telescopic handle will allow you to set the optimal length of the tool for the height of each family member.

- The wooden handle should not have any visible damage, such as chips, twigs, burrs.

- The handle should have a backlash-free fit, and the tool itself, even when assembled from separate parts, should feel monolithic.

As for the transformer rake, before buying the model you like, be sure to make sure that the handle is securely attached to the working attachment, as well as its ease of use.

When purchasing an expensive rake, for example, made of titanium (and there are also such rakes), you should definitely ask the seller to provide a quality certificate for the corresponding model.

It should be remembered that the ideal tool does not exist, and neither its type, nor the material of manufacture, and therefore the consultant of the outlet must necessarily indicate even the most insignificant shortcomings of any chosen model.

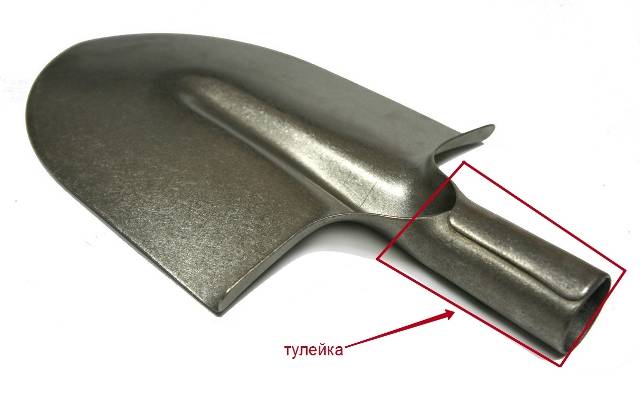

Device and characteristics

A standard shovel consists of the following elements: blade, shank, tulle.

Canvas

This is a working part, the shape, dimensions and parameters of which indicate the type of work for which the tool is intended.

So, for example, a conventional digging shovel has an almost flat, pointed blade with a sharpening.

And for grain tools, the working part is bent in the shape of a bucket, longer and wider.

It is used for picking up and loading bulk materials with a low specific weight.

The sharp edge of the blade is called the blade.

Its sharpness corresponds to the purpose of the shovel.

The bend at the top of the canvas is called an offensive (not every tool has).

It is on him that the foot of the foot is pressed when the canvas is introduced into a solid environment.

Shank (grip, handle)

The part of the tool by which it is held during operation.

For convenience, at the end of the handle, some models have a so-called fork or T-shaped handle.

The holder can be made of a single piece of material (monolithic), or it can consist of several tubes - knees, which, when transporting the tool, fold, like modern fishing rods.

Telescopic options are good because they allow you to adjust the length of the handle to improve the convenience of working with the tool.

Tuleyka

A detail that holds the handle firmly in contact with the blade.

It can be structurally an integral part of the web, and a separate part in the form of a sleeve.

The latter option is mainly equipped with folding models.

Canvas material

The blade of the shovel is always made light, while it must be strong enough.

The only material that meets these characteristics, but at the same time has a low cost price, is steel.

For this reason, steel products are the most common.

There is a store classification of the characteristics of this material:

- • Rail (spring) steel, similar in characteristics to that of which railroad rails are made. The tool is not subject to corrosion, strong and durable; only titanium shovels can compare with it, which, among other things, are also much lighter.

- Red-hot - used mainly for gardening and horticultural purposes.

- Polished is a great choice when working with sticky materials such as clay. Polishing the blade significantly reduces friction on its surface.

- Stainless steel - it is quite rare, it is indispensable when working with aggressive materials (cement and other solutions).

- Teflon coated or powder coated. Neither clay nor viscous soil sticks to the canvas with such a coating. Often found on "American".

Metal shovels are used for those jobs where increased tool strength is required.

Where serious loads on the canvas are not expected, but lightness is needed, for example, when clearing snow, aluminum products are used.

A cheap and at the same time quite suitable for use analogue is wooden shovels, where the canvas is made of a sheet of thick plywood.

Such a tool can be made independently, and factory modifications are used in bakeries.

Another material suitable for such purposes is plastic.

Durable plastic shovels are used both for clearing snow and for picking up various small debris.

Household scoops, by the way, are made of just this kind of plastic.

Unlike the iron versions, nothing sticks to the plastic, tk. everything glides well on its surface.

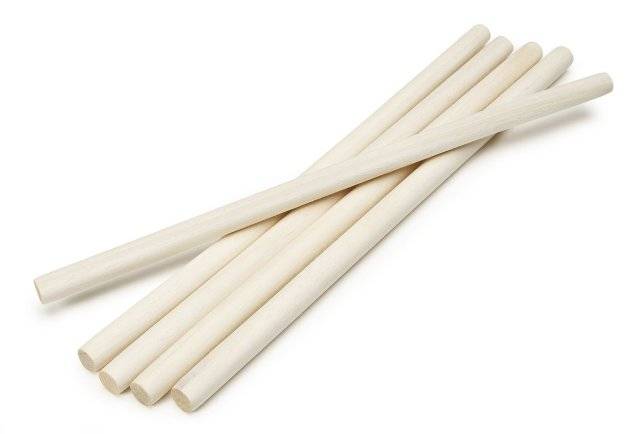

Handle material

Only two materials are used to make the cutting:

- Metal. A tube made of steel or lightweight alloy, reliable and comfortable, has a low weight. Nevertheless, it is expensive, cannot be repaired, it “freezes” your hands in the cold, has only 3 dimensions.

- Wood. The shank has a diameter of 45 mm, it is easy to replace it in case of breakage, and it is cheap.

It is also easy to cut the tree to the desired length.

On the other hand, the handle can only be straight, and its weight is greater than that of the metal version.

Dimensions and weight

In everyday life, the following shovels are more common than others, standardized in accordance with GOST:

- Digging pointed. Width, height and thickness of the canvas - 210/285 / 1.6 mm. Weight - up to 0.98 kg.

- Solution: 240/270 / 1.6 mm. Weight - up to 1.3 kg.

- Scoop grain: 235/305 / 1.0 mm. Weight - up to 0.75 kg.

- Carbon: 340/350 / 1.6 mm. Weight - up to 1.64 kg.

- Pedigree: 325/350 / 1.5 mm. Weight - up to 1.29 kg.

- Snow removal: 330/375 / 1.0 mm. Weight - up to 1.4 kg.

Review of some popular models and their cost

Let's consider different types of presses with specific examples.

Press STATICO-12

Refers to professional vertical hydraulic baling machines. This device is suitable for organizations that generate medium to large amounts of waste (30-50 tons / month).STATICO-12 is purchased for hypermarkets, entertainment centers, hotels, tobacco factories, railway stations. This equipment is equipped with European-made hydraulics. It is installed near the source of waste in order to reduce the time for their transportation. The model requires 1.5 m2 of floor space. The mass of bales from waste paper at the outlet is about 130 kg, from plastic film and plastic boxes - 150-160 kg. The eurotruck with a cargo capacity of 92 m2 (13.6m x 2.5m x 2.5m) can be filled with 208 bales. The power of STATICO-12 is 5.5 kW. Assembly - Russia. The cost of the model is 140 thousand rubles.

PRESSMAX 750

It is used in the processing of numerous types of solid waste: paper, PET bottles, aluminum cans, etc. This press is a horizontal hydraulic baling press. It can be included in the production line: the raw material to be pressed is fed by a belt conveyor. This model is acquired by large processing enterprises, reception centers, and retail chains. The weight of a briquette, for example, made of plastic, is 300-400 kg. The power of the PRESSMAX 750 electric motor is 11 kW. Production - Russia. The cost of the model is 930 thousand rubles.

Mobile compactors SPB SEN-E, SPB SEL-E from Husmann

They are monoblocks that exclude contamination of the adjacent territory and the appearance of an unpleasant odor. According to the manufacturer, these models have high reliability, good construction quality, long service life. Among such equipment, SPB SEL-E monoblocks have the largest loading window. Compactors handle mixed waste. The presented models have a volume of 16-24 m3. Their driving power is 5.5 kW. Production - Germany. The cost of standard presses is from 18 thousand euros.

Broan Elite Compactor 15BLEXF

Household waste press (except food) with mechanical control. Its width is 0.37 m, which makes it possible to install the device under the countertop of a kitchen set. One press bag holds the equivalent of 180 liters of uncompressed waste. The raw materials for Broan are waste paper, aluminum containers, plastic and glass. The mass of the device is 75 kg. Production - Italy. Cost (fabulous) - 190 thousand rubles.

The work of a home press for non-food waste from another manufacturer and the result of pressing are presented in the following video.

Types of presses for recyclable materials

Presses can be briquetting, container and baling. Let's consider each of these types in more detail.

Briquetting presses

The debris loaded into the device is compressed under the influence of the pressure of a hydraulic or mechanical press. In the process, the initial waste volume is reduced by about 75%. The result of the operation of such devices are rectangular or cylindrical briquettes (the specific shape is determined by the design of the installation). The resulting compressed product is convenient for storage and transportation to a processing plant.

Container, or press - compactors

The design of this type of equipment includes a receiving tank (hopper) and a hydraulic press. Waste thrown into the container is compacted, thereby freeing up space for the next batch of recyclable materials. Pressing allows to increase the intervals between garbage disposal, which contributes to a good saving of money resources. A special terminal is built into the compactor, which serves to notify about the fullness of the container.

Such equipment (unlike conventional garbage cans) eliminates unpleasant odors and unsanitary conditions. In this regard, a waste compactor press is of interest not only for industrial enterprises, but also for municipal services.

As mentioned above, such equipment can be mobile or stationary. There are also bio-compactors designed for the compression and temporary storage of wet waste. Their design allows for the removal of liquid using a drainage system.

Baling presses

They are widely used for packaging PET bottles, cans and barrels made of metal, porous materials, waste paper, etc. The units are popular in hotels, collection points for secondary raw materials, large stores and other retail outlets, in food, textile, leather and footwear enterprises, etc. etc. industry. Such presses are used to obtain compact bales from waste, which are then sent for recycling.

Also, all types of pressing equipment are divided into horizontal and vertical installations.

Vertical presses

These are installations with a sufficiently high performance, designed to work in confined spaces. They are excellently used by hotels, restaurants, offices, shops, recycling companies. Such presses do not take up a lot of space and allow 80% of the waste to be pressed.

Horizontal presses

The main difference of these presses from the installations of the previous type is the direction of movement of the pressing plate. Her work in this case, i.e. pressing of the material is carried out horizontally. For horizontal presses, a larger area is required. But in them, tying of the bale can be done automatically (in vertical ones - only manually). The horizontal presses are characterized by a higher compression force.

Video about the process of pressing various waste (plastic, paper, etc.) and what is obtained as a result of the process.

Rake: purpose

Garden rakes are used in the garden and in the garden, depending on the type of this tool, they can perform various tasks, from cleaning lawns from mowed grass to breaking up clods of soil, thereby improving its aeration, that is, saturation with air and moisture.

Also, the tool is used to collect garbage, loosen beds, shovel leaves, pick out weeds and stones.

Loosening, leveling the soil, setting the beds are performed with a rake.

The dacha is not the only place where the rake is used. Agricultural types of this tool are attached or trailed equipment for field work.

Depending on the design, they are used for raking and tedding hay and grass, wrapping and spreading windrows.

Purpose and principle of operation

A waste baler is a device that compresses accumulated waste into dense bales. This type of equipment is designed to solve a number of problems. The main purpose of the press for recyclable materials:

- Reduction of the area occupied by the generated waste.

- Reducing the frequency of garbage disposal at solid waste landfills or recycling plants.

- Saving money for the organization (source of waste) by reducing transport costs.

The principle of operation of the pressing equipment is based on the squeezing of raw materials by a mechanical, hydraulic or screw press. The material is loaded through a special chamber of the device, then the garbage is strongly compressed and turns into a dense briquette. The result of the process is assembled waste, the volume of which is up to 20 times less than the original. After compression, the garbage is transported to the disposal site.

The classification of presses consists of different types and subspecies of installations, differing in purpose and technical characteristics.