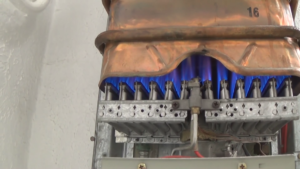

Removing soot from the heat exchanger

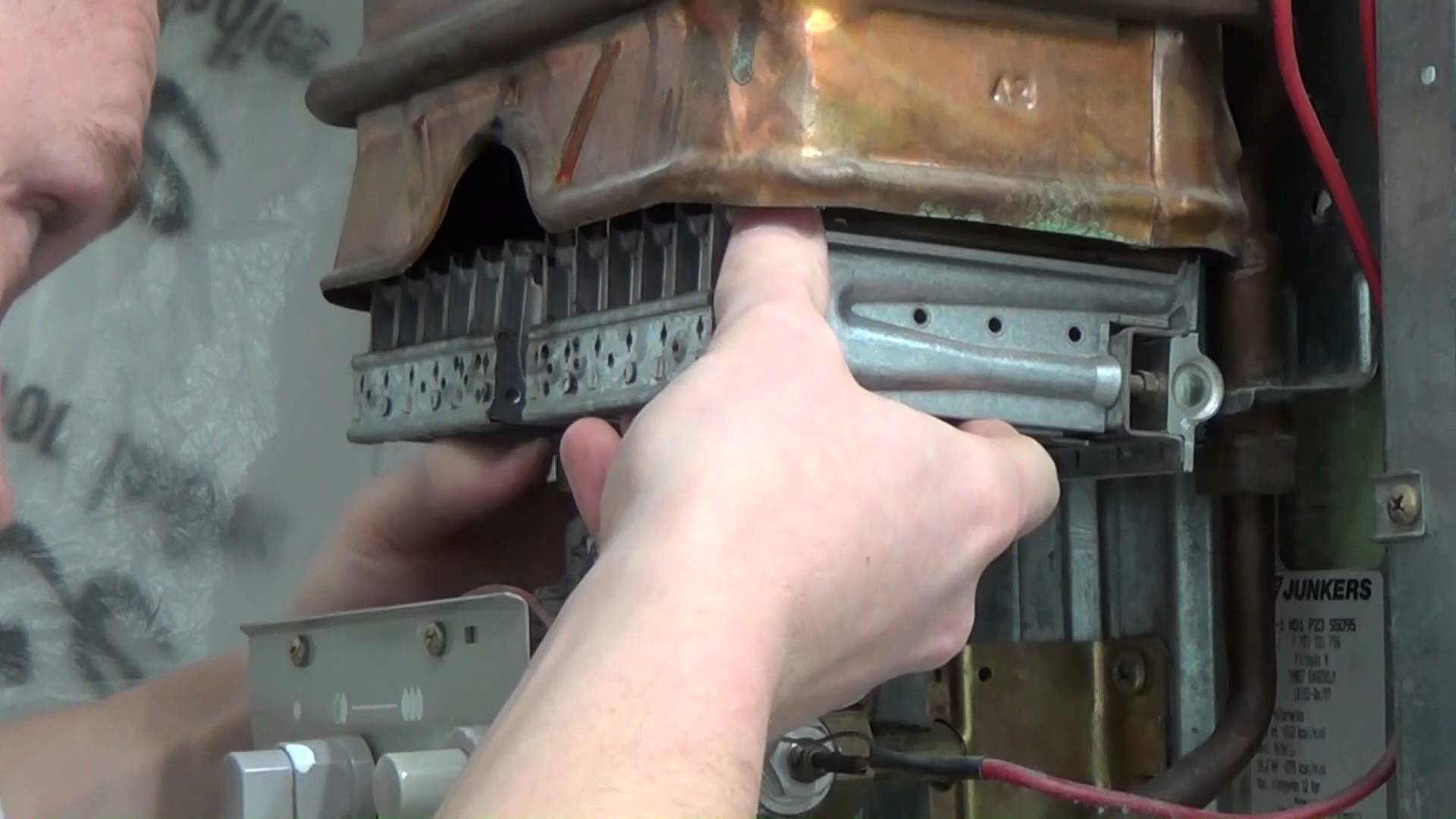

The soot deposited on the heat exchanger is removed with a conventional brush. After that, the inside of the water heater can be vacuumed.

Soot is collected not only at the heat exchanger. After a certain service life, it can be found both in the burner nozzles, and on the spark plug electrodes, and on the combustion sensor. The jets can be cleaned with a fine wire, or fine-grained emery paper can be used to remove carbon deposits from the electrodes and sensor.

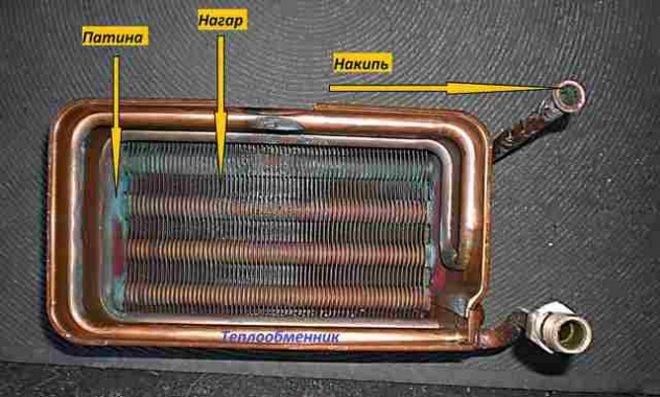

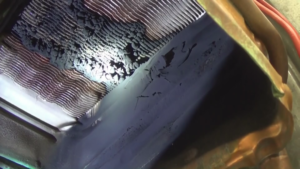

Dirty heat exchanger

Deeper intervention in the gas system of the water heater is not allowed - this should be done by masters from the gas industry. However, some users still dare to flush the burner with soapy water and a brush. In this case, after installing the burner in place, it is imperative to check all connections of the gas supply path for leaks.

Lather is a good indicator. Even the smallest leaks will be immediately detected by inflating bubbles. In this situation, you need to call the gas service.

When is it time to clean the gas water heater?

The following signs indicate that cleaning of the gas column is required:

- the main burner is ignited with difficulty, and sometimes with a strong pop;

- the heater starts up, but does not work for long, the main burner turns off quickly;

- from below, from under the casing, soot begins to pour;

- the unit is operating at maximum power, but the water barely heats up.

Column cleaning symptoms

Cotton in the combustion chamber indicates that a large amount of gas has accumulated in it before ignition. This means that the problem is in the igniter, which ignites the fuel with a delay. A visual sign is a faint yellow wick flame, a sign of a clogged jet. The solution to the issue is to clean the igniter. In most column models, the ignition unit can be easily disconnected from the main burner and debris removed from the nozzle.

The overheating and draft sensors are triggered by soot accumulated between the fins of the heat exchanger. The cross-section of the gas-air duct decreases significantly, and the water temperature increases. In this case, it is necessary to clean the soot from the radiator and combustion chamber walls. Extreme pollution is when soot flakes fall out from under the decorative steel apron, covering floor or items under heater.

Cleaning the igniter

Weak heating of running water is a consequence of a decrease in the flow area of the heat exchanger pipes, whose inner walls are covered with a thick layer of scale. A sign of total "overgrowth" of the internal passage of the tubes is a noticeable decrease in water pressure at the outlet of the column at its normal inlet pressure. These salts, contained in tap water, are intensively deposited on the heated pipe surfaces and form a durable thick coating. Then the gas columns, or rather, the heat exchangers, are cleaned from scale by flushing.

When cleaning is necessary

A gas boiler is a complex device, and it is too expensive to disassemble it without a good reason. In order not to commit unnecessary actions that can cost you a pretty penny, check out a number of signs that signal a clogged heating element:

- The boiler does not produce the required amount of heat, while consuming a large amount of fuel.

- During the operation of the device, extraneous noise appears, the presence of which was not previously observed.

- The water pressure from the tap is significantly reduced.

- The batteries are warming up more slowly than usual.

Gas consumption increased

One of the key reasons due to which gas consumption significantly increases compared to the norm is the clogging of the heat exchanger with scale. The boiler needs more fuel to heat the exchanger to the required level. After cleaning the part, the consumption returns to the baseline values.

Constantly on burner

The clogging of the heat exchanger leads to the fact that the water heats up for a long time, and the turbine constantly pumps new liquid.

Because of this, the burner is constantly working, trying to bring the water temperature to the required value.

Descaling solves the problem by allowing the boiler to operate normally without interruption.

Rumble and interruptions in the operation of the circular pump

A blockage in the system makes it difficult for the fluid to circulate, causing the pump to overload during operation. Because of this, appear:

- extraneous noise;

- interruptions in the operation of the device;

- overheating of the engine.

Reducing the pressure in the DHW circuit

A decrease in the pressure in the DHW circuit is possible due to:

- incorrect operation of the heat exchanger;

- leaks in the pipeline system;

- the hot water circuit is leaking.

The sequence of measures for cleaning the burner from soot and carbon deposits

Lonely old people or women live in many apartments. It is easier for them to pay the master than to carry out the operations to clean the geyser from soot on their own. This has its positive and negative sides. The latter include only the cost of such services. At the same time, the foreman will carry out all operations without the threat of damaging the gas pipeline and at the same time check its condition.

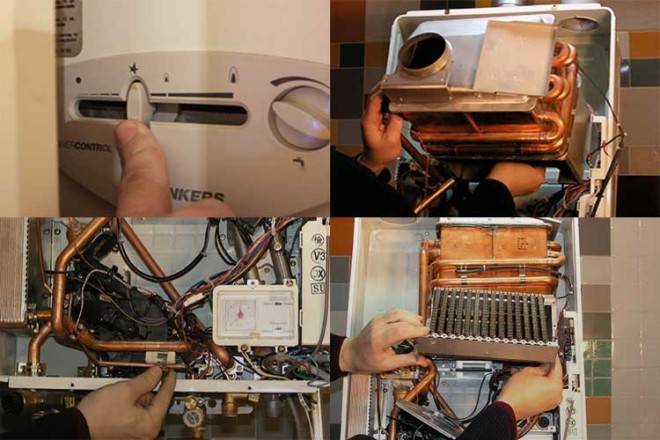

The specialist adheres to the safety instructions. He will turn off the water and gas supply and will carry out the necessary actions in this sequence.

- Remove the casing of the gas water heater.

- Disconnect the wiring.

- Remove the burner.

- Disconnect the manifold.

- Remove soot and carbon deposits from the electrodes.

- Clean the contact block with a stiff brush and wipe with a damp cloth. The inside of the parts is cleaned with a small brush.

- Remove carbon deposits from the jet, sensors and electrodes.

- The openings of the nozzles are cleaned with a thin wire.

- Dust from the inside of the column is removed using a home vacuum cleaner.

- Wash all equipment with warm soapy water and dry.

- Reinstall the parts.

At the end of the work, all the connections of the gas pipes must be smeared with soapy water in order to identify a leak, if any. After assembling the plumbing part, turn on the hot water tap and carefully check its tightness.

Descaling

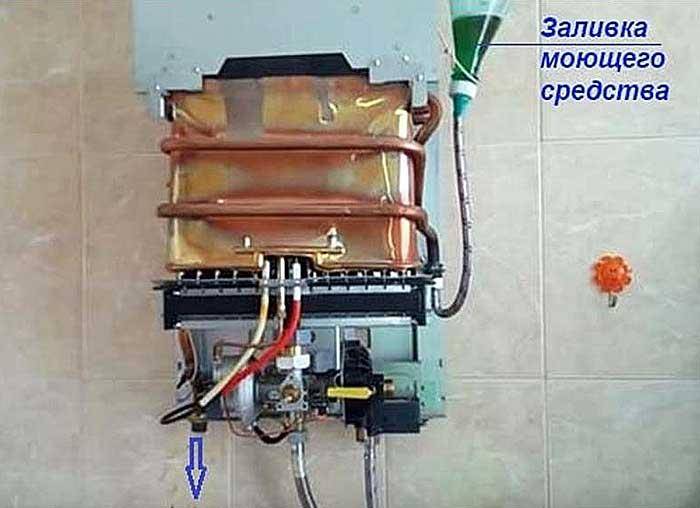

The heat exchanger must be rinsed well, and this business has its own secrets. When the unit is completely dismantled from the column, you need to prepare a detergent specially for it. There may be several options at once.

The heat exchanger must be rinsed well, and this business has its own secrets. When the unit is completely dismantled from the column, you need to prepare a detergent specially for it. There may be several options at once.

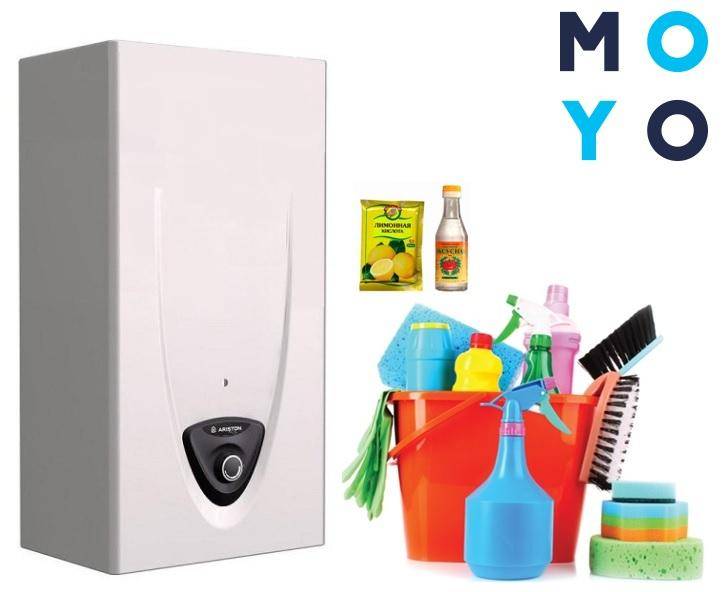

For example, you can buy special products for flushing gas columns in the household. store. You can use citric acid or even lemon juice for high-quality rinsing of the assembly. In this case, 100 g of powder is dissolved in 500 ml of water and stirred. All parts of the assembly are treated with a working solution. You can use a vinegar solution, which in this case is very effective for cleaning. Vinegar is diluted 1: 5 with plain water and the knot is washed.

The heat exchanger can be filled with vinegar or acetic acid from a watering can. The solution must be kept for at least three to four hours for more effective cleaning. The easiest way is to leave the heat exchanger soak overnight.

In the event that you still remove plaque and scale with special compounds and mixtures from the store, then the proportions and duration of the composition must be observed according to the instructions for the preparation. At the end of the treatment, contaminated water they are simply poured into the sewer, and the heat exchanger itself is rinsed with running water from the tap. For this, it is convenient to use a simple water hose, which can be taken from the shower by unscrewing the head from it.In the process of flushing the unit from scale, there is nothing complicated - even a young, inexperienced owner can cope with this.

Why does the column need cleaning?

The peculiarity of this water heater is that it is connected with two household systems at once: gas and water supply. Therefore, in the part where the gas burner, igniter and other elements of this system operate, soot and carbon deposits are formed. To improve the functioning of the unit, it is imperative to clean them and remove combustion products.

Even more dangerous is scale, which disrupts the operation of the water supply of the column. Limescale is the salt found in tap water. They precipitate as the water evaporates and settle on the walls of the column heat exchanger tubes. For water heating equipment, such consequences are very detrimental, since they reduce the efficiency of its operation or further lead to breakdown.

Advice! Scale deposition occurs when the water temperature rises to 80 ° C. But 60 degrees are enough for bathing, washing dishes and washing. Therefore, in order to protect the column from salt deposits, you do not need to constantly leave it working on the igniter, reaming it, and even more so to reduce the water pressure. All this leads to the appearance of high temperatures.

Flushing the gas column with citric acid. Flushing the gas column heat exchanger: do you want to do it yourself?

If you are the owner of a gas water heater, then sooner or later the question arises before you: “Why did it start to heat worse and where did the pressure go?”. With a probability of 99%, the matter is in the scale that forms inside the heat exchanger.

The quality of your heating system operation directly depends on how dirty the column is. With constant circulation and heating of the liquid, deposits are formed in the form of scale and scale, which impede heat exchange and the passage of the water flow.

The answer to these problems is flushing the heat exchanger of the gas column, which can be entrusted to a specialist, or, with minimal technical skills, can be carried out independently. Heating equipment manufacturers advise to carry out a similar procedure at least once a year. Much depends on the quality of the water in your area, though.

By the way, one of the indicators that it is time to start cleaning is the color of the flame. If the flame becomes smoky and yellow, it is simply dangerous to delay the moment of the gas column.

If you nevertheless decide to carry out the cleaning yourself, then you should adhere to a few simple rules:

- Turn off the gas.

- Check that the gas is off. (Check that there is no smell of gas, do not take unnecessary risk).

- Disconnect the control device.

- Unscrew the supply pipes.

- Remove the speaker from its hinges and place it upside down on a flat surface.

- Using a syringe or rubber bulb, pour the cleaning liquid inside (we will dwell on them separately).

- Leave it on for a couple of hours.

After the required time has passed, collect everything in the reverse order. That is, hang the column in place, install the device, connect the pipe through which the water is supplied, and place a bucket or any other container under the gas water heater to collect the flushing water.

After that, gradually turn on the dispensing, and rinse until the water is clear. This may take some time, depending on how dirty it is. As a rule, a few minutes are enough.

After the water has cleared, you can connect the rest of the hoses.

Here is the finish - you can enjoy hot water with a normal pressure.

Returning to the question of liquids for flushing gas column heat exchangers, it is worth immediately saying that it is better to take a specially designed product for. However, without having it on hand, you can use vinegar or citric acid. There are many tips for flushing with hydrochloric acid on the internet. Remember - flushing with hydrochloric acid can damage your equipment.If vinegar leads to a safe acetic decalcification reaction, then stronger acids can damage the inner surfaces of the heat exchanger. If you decide to use citric acid for washing, then the ideal proportions would be 200-250 grams per 5 liters of water.

Also, while cleaning the column, since it has already been disassembled, it is worth paying attention to the gas nozzles. Soot is formed there from combustion and it can get clogged, as a result of which the flame begins to burn unevenly and the heating efficiency is lost.

If you invited the master for the gas column, then ask him to clean the gas nozzles. If you clean them yourself, then it is enough to remove the lid from the gas column and collect the soot and dirt with a vacuum cleaner. For the best effect, you can take a soft brush and walk along the inner surfaces under a vacuum cleaner.

As you can see, there is nothing complicated in the process of cleaning and flushing the heat exchangers of gas columns. It is enough to have a couple of hours of time and be able to unscrew a couple of valves. But nevertheless, if there is an opportunity to entrust the work to a professional, it is better to do just that. A specialist will do everything the same, only faster, with a guarantee and with the use of products specially designed for cleaning and flushing gas columns.

And one cannot but say that the most effective method of combating scale and pollution is to prevent its appearance. Today there is a huge selection of filters and magnetizers for heating systems that will ensure normal operation for a long time. It is much more convenient to change the filter filler every two years than to fiddle with flushing every year.

How to descale a gas water heater. Rinsing the column from scale.

After removing the casing from the gas column, shut off the water supply at the inlet and open any of the hot water taps closer to the column. Further, we unscrew the supply tube from the heat exchanger of the flow-through water heater, and take it a little to the side. A copper heat exchanger and a tube will allow us to do this without difficulty. As soon as you unscrew the nut from the heat exchanger, water starts to leave the heat exchanger - the tap is open, we drain a little water, about a liter. To be precise, you can find in the passport of the column the volume of water in the heat exchanger and drain a little more.

Then we do this: put on the hose at the inlet of the heat exchanger, raise it higher than the column, insert the funnel into the hose and pour the prepared solution into it in a thin stream. Pour on slowly, otherwise a reaction may start and the solution will be pushed back. Hydrochloric acid is present in the solution, it can cause burns. Take special care of your eyes.

The anti-scale solution should remain in the heat exchanger for a couple of hours. If you did not turn off the gas, and we did not recommend you to do this, you can warm up the solution on a burning igniter. The reaction will go faster, it will take less time.

Substitute a plastic bucket or basin under the tap, and open the water supply to the column. Only slowly. See what comes out of the hose. If there is a lot of sludge and the pressure after flushing is not bad, then everything went well, if not, repeat the entire flushing procedure again. But in the case of using anti-scale, you will hardly have to do it. If you haven't found an anti-scale agent, you can use a 100-gram package of citric acid, dissolving it in 500 ml of water beforehand. They say the nine percent vinegar rinse works pretty well. But we, frankly, have not tried other solutions.

The thing is that in addition to the heat exchanger, there are other parts in the gas column. The heat exchanger itself is copper and nothing will happen to it, but the so-called reducer is usually aluminum, you can ruin it. Therefore, if you do not find antiscale, do not experiment with other solutions according to our technology, it is better to remove the heat exchangers and rinse it separately.

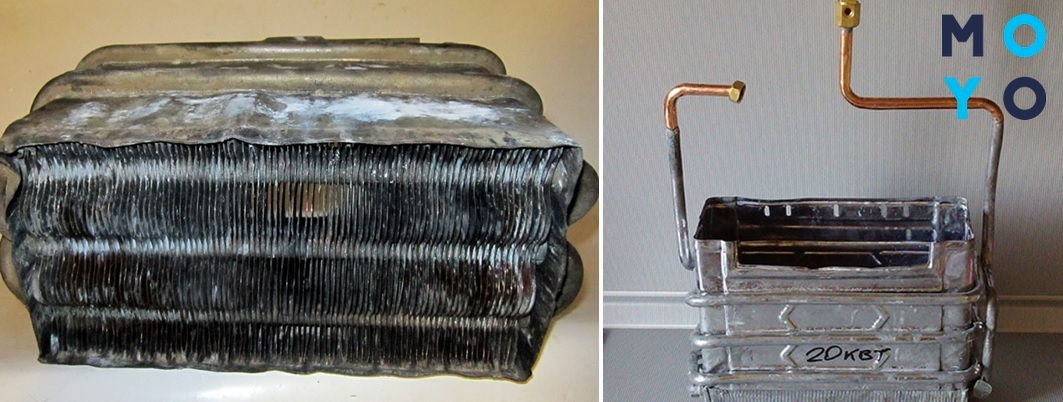

What causes the heat exchanger to clog up with scale?

Of course, with a complete disassembly of the gas column heat exchanger, you will have to do a lot of unnecessary work, but you definitely won't ruin it this way. You can also rinse the flowing part of the water heater of the gas column with other solutions, for example, I was told that Pepsi Cola washes off scale well, so if you want, experiment, especially if you have your own home and have the opportunity to use household antifreeze. Good luck!

3 Flushing with complete disassembly

Having pliers and the necessary set of wrenches, you can disassemble and clean the gas water heater with your own hands.

| Description of actions | Explanation | The photo |

| Removing the front cover | The adjusting knob is pulled towards itself. The lid rises from the bottom and is attracted to itself |  |

| Removing the protective cover | A protective cover separates the burner and heat exchanger from the front cover. It rests on screws that are unscrewed. The cover is removable |  |

| Gas cut-off | A gas supply pipe is connected to the igniter, which is unscrewed |  |

| Removing the igniter | The igniter is held by 2 screws. They are unscrewed, and the igniter is retracted to the side. |  |

| Covering the gas inlet | The hole is plugged to prevent the ingress of soot |  |

| Removing the burner | The burner is removed by unscrewing the nut with a gas wrench. |  |

| Cleaning the radiator | After removing the burner with a brush from below, the radiator is cleaned. Soot is poured onto the lined oilcloth |  |

| Dismantling the burner | The burner is disassembled for cleaning purposes. To do this, 4 self-tapping screws are unscrewed on each side |  |

| Cleaning the injectors | Dust that accumulates at the ends of the nozzles is removed with a dry cloth or finger |  |

| Flushing the channels where the nozzles are inserted | The channels in the burner, where the nozzles are inserted, are flushed with running water |  |

| Build and run | All cleaned parts are reassembled in the reverse order. A test run of the unit is in progress |  |

Where is the filter in the gas column. How to remove soot from a heat exchanger

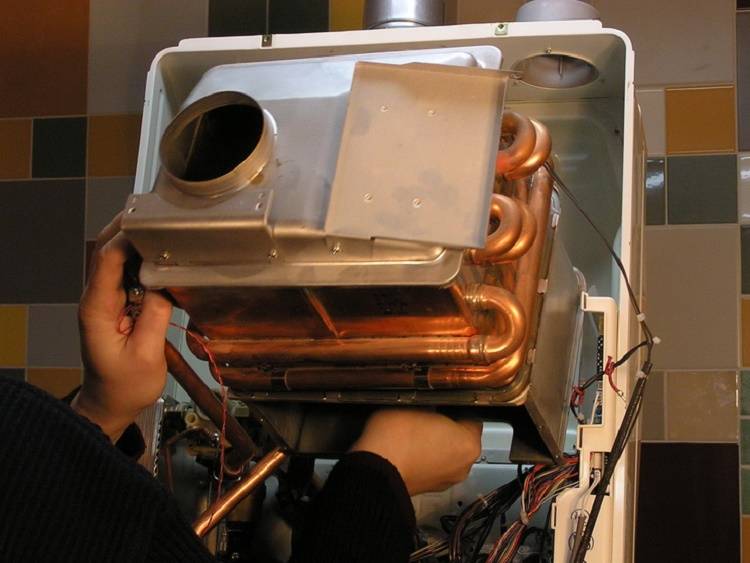

We wrote above where the heat exchanger is located; before starting maintenance, it is advisable to remove it from the unit, having previously shut off the gas and water, by opening the hot water supply tap (the one located near the flow heater). Then, using a gas or open-end wrench, loosen the nut securing the tube to the water unit, unscrew it a little (a couple of turns will be enough). The contents must be allowed to drain through the mixer, which is left open.

Helpful advice. Before cleaning the gas water heater from scale, prepare a special tool and means. The most convenient way to solve the problem is to use an aerosol agent to loosen boiled threaded connections. You can ask for the WD40 product at any car dealership or hardware store.

How to clean the gas column heat exchanger further:

- Unscrew a pair of union nuts, dismantle the assembly.

- Disassemble other elements, details that interfere with easy dismantling. Their number depends on the specific model, the design features of the column. In some cases, it is necessary to remove the flue gas diffuser, in others - the ignition group, in the third - overheating and draft sensors. All parts may need to be removed.

- Cover the burner nozzles with a rag to prevent soot from entering.

- Take the heat exchanger to the bathroom, thoroughly clean it with a long-bristled brush to remove all soot, rinse and dry.

- Return the unit to its place, reassemble the unit in the reverse order described above.

Do not forget to install new sealing rings at the pipe joints. It is not difficult to clean the gas water heater, most of the time is spent on assembly and disassembly. Work should be done strictly according to the rules. If you are not sure that you will do everything as needed, call the wizard.

Helpful advice. If the installation is clogged, you have already removed the heat exchanger, it makes sense to immediately rinse and clean the gas water heater from scale. The service will be more efficient and will not take a lot of extra time.

Before starting the unit, check it for leaks.To do this, open the water supply valve, wait for the filling of the heat exchanger from the open mixing valve. Then the feed is closed again, the assembly is inspected for the degree of permeability of its connections. In the absence of serious problems, the gas valve is opened again and the apparatus is started up for testing in standard operating mode.

Use the liquid for flushing, softening the joints during maintenance at your discretion. Chemistry simplifies the work, but it is not necessary to apply it.

Flushing helps not only to remove carbon deposits, but also to remove dust.

Prevention of scale formation

Hard water is not the only cause of scale formation inside the heat exchanger tubes. For its appearance, not only salts are needed, which are contained in water, but also a high heating temperature. The more the gas burns, the more intensively a solid precipitate forms inside the device. A temperature of 80 degrees or higher is considered critical.

Obviously, such strong heating is not needed for domestic use. For a shower, 40-42 degrees is enough, for washing even the dirtiest dishes 45 degrees are enough. An automatic washing machine will heat the water up to 95 degrees, if necessary, but the gas water heater does not participate in this process.

Therefore, if hot water constantly has to be diluted with cold water, it is worth revising the settings of the gas column for heating temperature. Some amateur craftsmen are reaming the igniter of the gas column. This is done in order to increase the heating rate of the water flow.

In older models, such a modification allows you to get rid of the need to fire up and adjust the device every time you turn it on. Finally, a reamed igniter is needed so that the gas ignites even with a very low pressure of the water flow.

In this case, a very dangerous situation can arise when a small amount of water in the heat exchanger boils and turns into a gaseous form. As a result, the pressure in the heat exchanger will rise sharply and it will simply burst.

Of course, gas workers consider such interference dangerous, and manufacturers refuse to fulfill warranty obligations for devices with such alterations. To improve the pressure in the system, you can select and install a conventional circulation or boost pump. And the quality of the water supply will improve, and the appliances will not suffer.

We fight scale

To clean the gas water heater from scale, dismantle the heat exchanger. The task is complex and rather painstaking, but it is precisely in it that the success of the entire operation lies.

It is worth preparing in advance all your tools for disassembly and cleaning:

- screwdrivers,

- adjustable wrench

- pipe wrench

- rubber hose with metal clamp.

In addition to tools, you will need a cleaning agent. You can buy it both in the store and cook it at home.

Here is one of the recipes for such a remedy: Dissolve 100 g of lemon powder in 500 ml of water. The resulting solution will help you descale the pipes.

You do not need to use hydrochloric acid as a purifier, you will only aggravate the situation with it, because it will react with the metal part.

How to quickly flush the gas column.

After you have prepared the solution, pour it inside the heat exchanger. There are quite a few types of heat exchangers, so the required amount of substance may be different. If you made the cleaner yourself, leave the part for a few hours, preferably overnight. During this time, the scale will partially dissolve and can be easily removed. If the product was purchased, then follow the instructions on the package. Then drain the solution. Any hose will work well for this. Rinse the heat exchanger well, preferably several times, until clean water starts to flow out of it. It is also recommended to change the paranite gaskets. Ready! Your gas water heater will now work as before.

Getting rid of soot and soot

Above all, remember that gas must be handled by professionals. Therefore, if your column needs serious cleaning, then call a specialist. Never disassemble the gas supply part. It is very dangerous.

Of course, it also happens that you can do the cleaning yourself. As a rule, this is the elimination of small blockages. For example, if the nozzle holes are clogged, you can clean them with a metal wire.

Carbon deposits are a sign of a gas leak

Carbon deposits are sometimes a sign of a gas leak. You can use regular soapy water to make sure there is no danger.

Lather the details with it, especially pay attention to the places where the connection goes, and if you do not see bubbles, then there is no leakage. If bubbles appear, turn off the gas and call the special service.

Other types of pollution

In addition to scale and carbon deposits, parts are susceptible to other contamination. To eliminate them, it will be enough for you to rinse the part under running water or simply vacuum it.

If you still did not dare to carry out this process yourself, then special services will help you clean the column. This method of solving the problem has its advantages: cleaning will be safe, all parts, even those that you could not clean yourself, will be cleaned. And besides, you will be able to observe this process in order to repeat the same actions in the future.

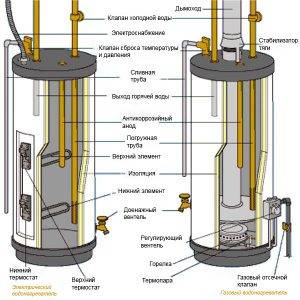

Details of the gas water heater

What might need cleaning? There are many types of gas water heaters, but they all work the same. ... There are a lot of different parts in this device that could get clogged or become unusable. To determine which part is dirty, you need to know how the column is arranged. If you open the "locker", you will see a few basic details in it:

... There are a lot of different parts in this device that could get clogged or become unusable. To determine which part is dirty, you need to know how the column is arranged. If you open the "locker", you will see a few basic details in it:

- Heat exchanger

- Igniter

- Main burner

- Gas column radiator

Each part on this list is responsible for normal operation, so if problems arise, it is worth checking each of them.

We are looking for a part that needs cleaning

It doesn't take much cleverness to understand which detail needs cleaning. Contamination is usually visible to the naked eye. If you could not determine the contaminated part by eye, then it is worth checking everything. Most often, details such as are clogged:

Heat exchanger

The heat exchanger of the gas column is clogged with scale. To clean this part, you will have to disassemble it. This alone is the hardest part. Next, you will need to use a special tool.

Water intake unit

Particular attention should be paid to the intake unit. First, it needs to be cleaned regularly.

Secondly, when cleaning, pay attention to its shape: in a normal state, the water intake unit looks like a cylindrical body with a flat membrane

If you notice any bulges, then this part needs to be replaced. Another important part in the water intake unit is the filter. It is not difficult to detach it, and it can be cleaned under a powerful stream of water

Conductive hoses

Conductive hoses become clogged with limescale, which makes the water pressure weak. It should be noted that this pollution can be avoided if the gas column is used rationally. It is generally accepted that scale forms due to hard water. This is undoubtedly true. But the real reason for the formation of scale is high temperatures, which a person usually does not need in everyday life. So remember, the more efficiently you use your speaker, the longer it will last you.

Gas-burner

It doesn't take much time and effort to clean this part. You just need to turn it off and vacuum up the accumulated soot.

All these parts can be easily removed and cleaned from carbon deposits or scale.

Attention: before starting cleaning with a gas column, turn off the gas and water supply!

To completely clean your column, you will need several types of products, because each part gets dirty in its own way.

| Gas water heaters with different types of ignition |

|---|

| Columns with piezo ignition |

| Columns with electronic ignition |