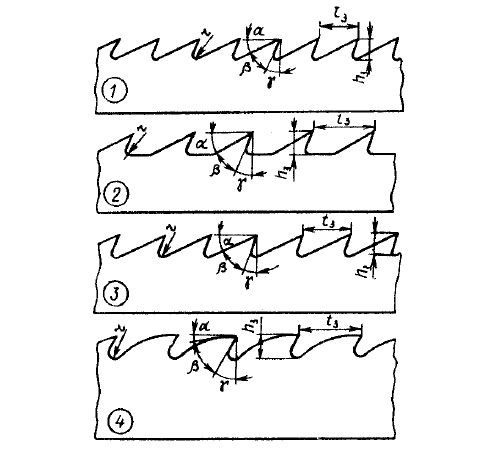

Saw types

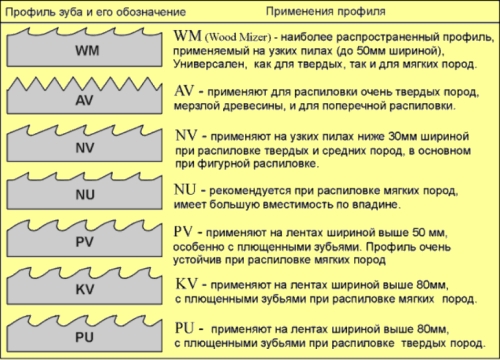

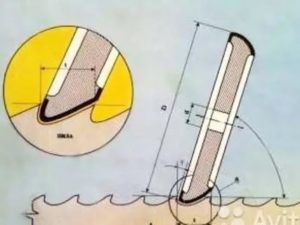

Band saws can be distinguished by the type of teeth, taking into account the configuration of which they select the necessary sample for processing a certain type of material. The selection of the configuration of the saw teeth is based on the characteristics of the sawn timber, in particular, on the parameters of its hardness: the denser the wood, the smaller the front angle of the cutting edges of the tape and the step between them.

Observing this rule, it is possible to significantly improve the quality of the cut and extend the operating period of the tool.

Sawing thin materials is usually carried out using a saw blade, which has a standard or small pitch between the cutters, otherwise the risk of damage to the working tool increases many times. The saw with a large pitch of teeth is designed to use it to cut metal or wood thick-walled workpieces, which must be tightly fixed before starting the processing process.

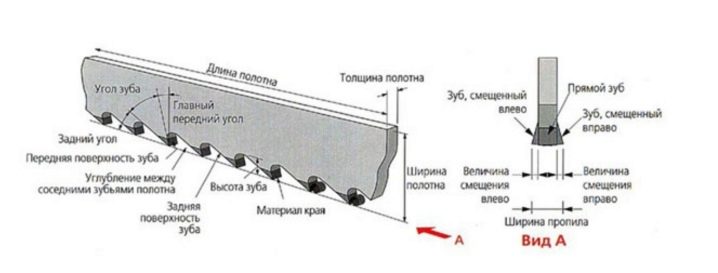

Saw band design

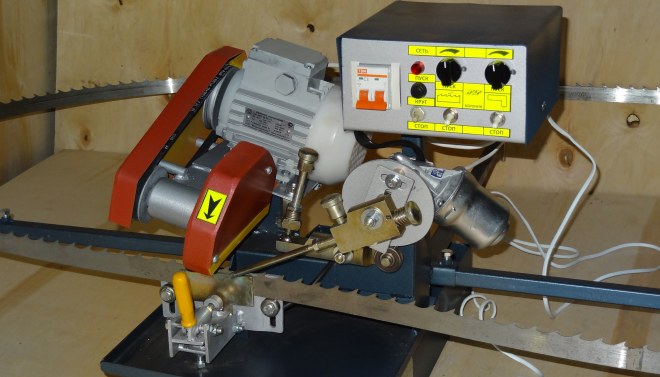

Band saw machine

Band saw machine

The band saw belongs to the category of cutting tools and is an integral part of specialized equipment for wood processing. It is a closed belt with teeth on the outer edge.

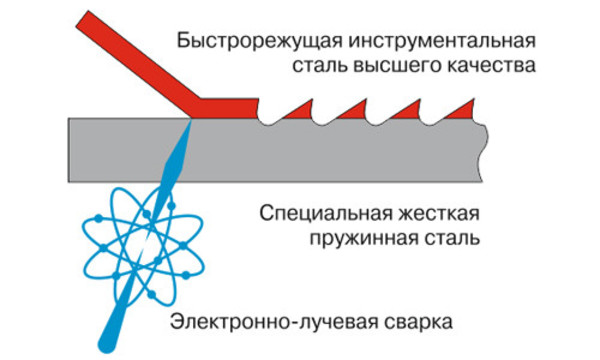

For manufacturing, special grades of steel are used - 9HF, B2F or C75. During the production process, the teeth are treated with high-frequency currents. This increases their hardness. It is this fact that affects the spreading of cutting edges and maintainability. Often, several types of steel are used in the manufacture. The main belt is made of a spring belt, and the cutting part is made of steel with a high tungsten or cobalt content.

Features of the use of band saws for wood:

- wood requirements. The harder it is, the faster the blade will dull;

- installation conditions. The tension indicator must be observed. If it is less than required, sagging will occur. With strong tension, the probability of blade breakage will increase;

- periodic sharpening. This will require a special machine.

The implementation of the last point will increase the service life of the belt structure. However, sharpening on your own is problematic - you need to choose the correct layout, observe the angle of processing of the blades.

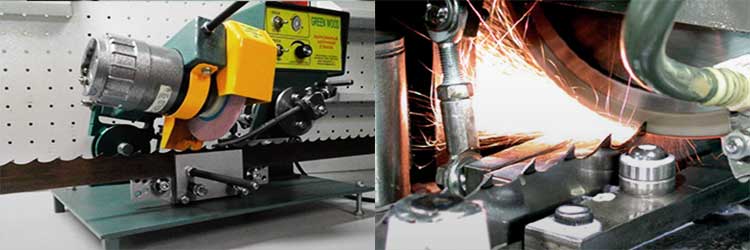

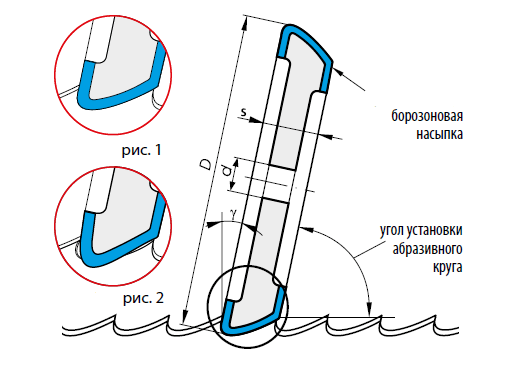

Saw sharpening

During the operation of the saw, there is a decrease in the quality of the cut due to the bluntness of the cutters, a decrease in the width of their setting. Therefore, in order to improve the cutting properties, it is necessary to sharpen the cutting edges of the saw band. Work instructions:

- Wiring.

- Turning.

At home, the setting of the teeth can be done in the following ways:

- classic: sequential bending to the side corresponding to the design;

- stripping: bending two adjacent teeth in both directions, and leaving the third unchanged in the initial position;

- wavy: each tooth is parted by a different amount in the form of a wave.

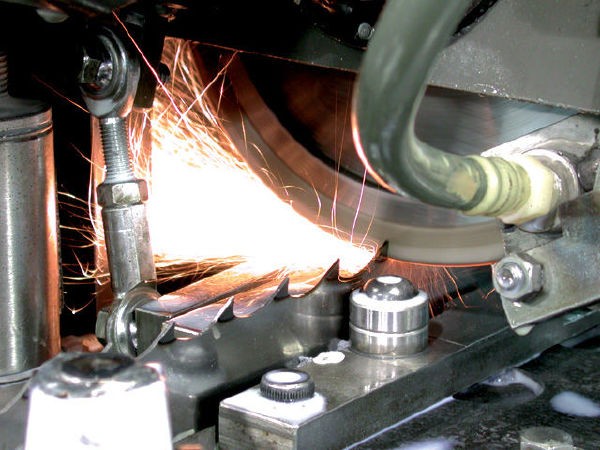

Sharpening is performed in the following sequence:

- Grinding wheels are selected taking into account the hardness of the material. For machining tool steel, corundum discs must be used. You can sharpen bimetallic tools with diamond discs.

- Emery for tape. Available in the following shapes: plate, flat, cup, profile.

- The tape should be cleaned of dirt, oil stains, shavings. Then turn the teeth in the opposite direction and hang in this form indoors for 12 hours.

- Sharpen with prepared tools.

Basic rules for turning saws:

the teeth are sharpened on one or both sides of the blade;

it is necessary to remove the same layers of metal from the teeth so that the cutting line is formed even, the edges are smooth;

when turning with circles, strong pressing of the sharpened edges to the abrasive surface is unacceptable in order to prevent metal annealing and loss of mechanical properties;

water cooling is required to cool the tool during operation;

it is important to maintain the geometry of the blade and teeth;

if burrs are found, they need to be removed.

Correctly spreading the teeth is not necessary completely with the entire plane, but bend only 1/3 or 2/3 of the top. According to the manufacturers' recommendations, the bend size is from 0.3 to 0.7 mm.

How to sharpen a band saw correctly

Immediately, we note that if there is no experience and skills in performing such work, it is better to entrust saw sharpening to professionals. Violation of the geometry of the teeth of the cutting edge, the appearance of dross on the metal or incorrect setting will significantly reduce the life of the blade.

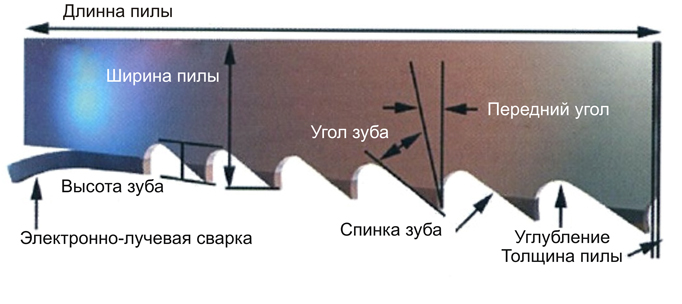

Having decided to sharpen the band saw with your own hands, it will be useful to first familiarize yourself with the key definitions, the knowledge of which may be required in the process. So, for the correct formation of the cutting edge you will need:

- setting - deviation of the teeth from the plane of the main saw blade;

- the height of the teeth is the distance between the top point and the base;

- pitch - the distance between the teeth, usually varies between 19-25 mm.

- sharpening angle - depends on the intended purpose of the tool; for example, the recommended sharpening angle for carpentry saws is 35 °, for dividing saws - 18-22, intended for sawing a bar - no more than 15 °.

The sharpening angle is determined by the manufacturer, therefore, when dressing the saw yourself, it is recommended to adhere to these parameters.

Here are detailed instructions that will help you sharpen a closed saw correctly without resorting to the services of specialists.

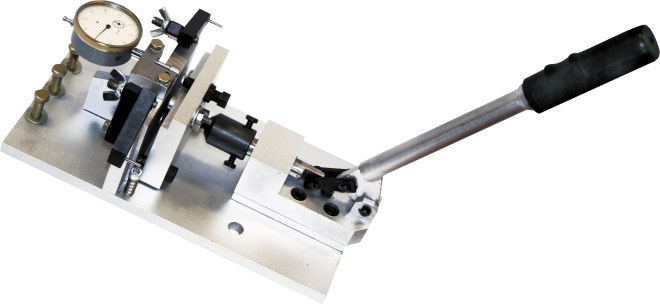

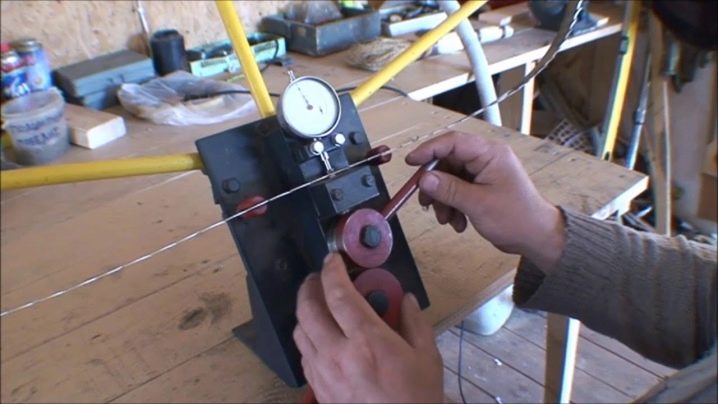

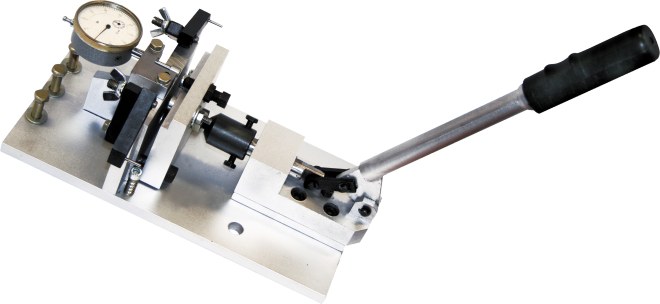

Wiring

Setting band saws into wood is the first step in restoring the profile of the cutting edge. During operation, the location of the teeth can change, so until the correct geometry is achieved, it makes no sense to sharpen the saw part.

There are 3 ways to open the saw:

- classic - the teeth alternately deviate to the right and left sides;

- stripper - the 1st and 2nd teeth deviate in different directions, the third remains even. This profile is created for sawing hard materials;

- wavy - the most difficult option, resembling a wave in shape. Here, each tooth is individually shaped, and this type of setting is usually only done in specialized workshops.

It should be noted that when wiring, not the whole tooth is bent around, but about 2/3 of the upper part. The procedure is performed on a special band saw setter. The cost of such a tool is quite high, so they buy it if you need to adjust several tools. Its availability can become the backbone of the sharpening business.

Of course, the first time you can do everything correctly, even on an adjustable machine, it may not work, so at least the geometry of the profile should remain the same as before the start of work.

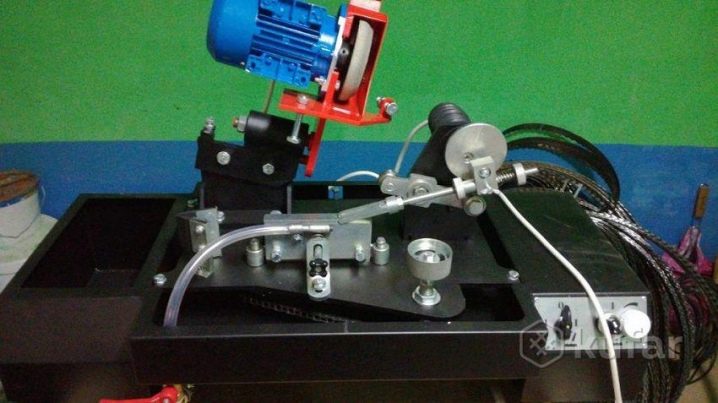

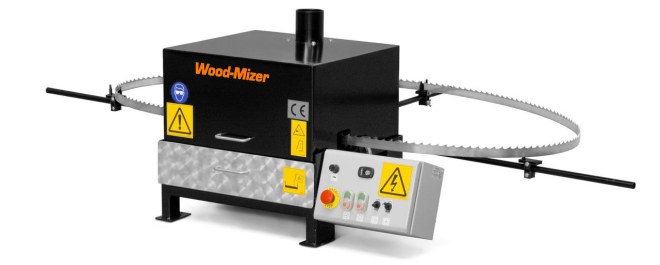

Sharpening

This is the main step in cutting edge dressing and can be done in two ways.

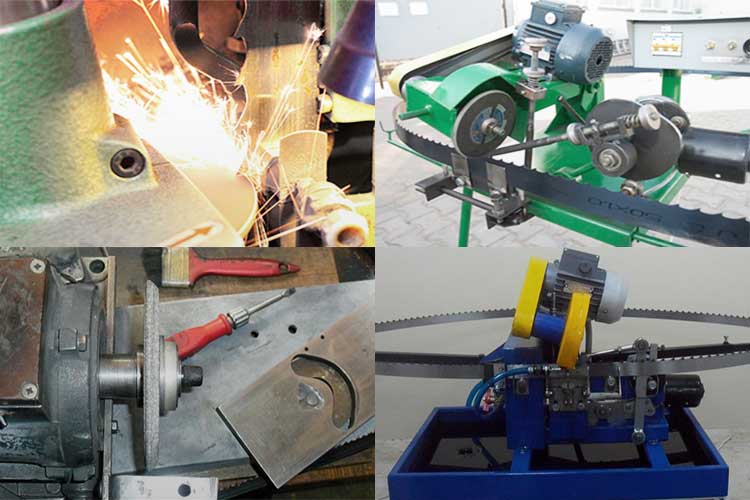

Full-profile saws are sharpened with an CBN wheel installed in a special sharpening machine.

This is a fully automated operation used by professionals. The work of the machine for sharpening band saws for wood is controlled by electronics, and the sharpening wheel processes the entire band in one pass. The disadvantage of this method is that the CBN wheel is selected individually to the profile of the saw, therefore, for dressing different tools, the sharpening element must be present in the assortment.

Sharpening of teeth is carried out manually or on specialized equipment.

In the first case, the sharpness of the teeth can be restored in the shortest possible time, but the work requires certain skills. In the second - painstaking work: 4-5 movements along the edge of each tooth.

For automatic sharpening, diamond, CBN and corundum wheels are used.

It is important to understand that when performing this procedure, only sharpness is given to the teeth, the geometry created after setting the blade should remain unchanged.

It is interesting: Glass interior doors made of frosted glass: we consider it in detail

How to sharpen the canvas correctly?

According to statistics, more than 80% of cases of breaks in the device occur due to failure to perform sharpening techniques. The need for sharpening is revealed visually - by the appearance of the teeth themselves or the state of the cut (increased unevenness of the plane).

Stones for sharpening tape blades are selected based on the stiffness of the teeth. For sharpening products made of carbon and alloy steel, corundum stones are used. Bimetal blades require borazon (CBN) or diamond discs. The configuration of the blade grinding wheel must be determined based on the characteristics of the tool. It can be dish-shaped, flat, cup, profile.

Before starting work, it is advisable to let the canvas hang in the unscrewed position for 10-12 hours.

Conditions for sharpening canvases with your own hands:

- ensuring the systematic removal of metal according to the shape of the section of the tooth;

- avoidance of excessive pressure on the disc (this can cause annealing);

- ensuring the integrity of the height and shape of the section of the tooth;

- the indispensable presence of liquid for cooling;

- control of the absence of scoring.

By and large, regardless of the abundance of rules and conditions, these devices are quite undemanding in terms of sharpening. You can deal with them both by means of a specialized sharpener for tape blades, and by hand. In addition, circles of various configurations and substances can be used for processing.

Before sharpening the tape, it is advisable to familiarize yourself with the key methods for performing this procedure.

Method 1: full-profile sharpening

This method is considered especially high quality and is performed on automatic equipment. Elborovy (Borazon) disc, precisely matched to the configuration, processes the entire interdental cavity together with the corresponding planes of adjacent teeth with a single pass. In this case, obtaining an uneven configuration at the base of the teeth is excluded. One drawback of such a sharpening is to constantly have a specific number of spheres at hand for canvases for different purposes.

Method 2: sharpening the edges of the teeth

It can be performed on specialized equipment or manually.

If special equipment is selected, then it is necessary to competently select a circle - as a rule, these are flat samples. By and large, it is advisable to turn to professional sharpening equipment only in those situations when the scale of work is quite large. It is preferable to carry out irregular "household" work by hand - by means of an engraver or on an ordinary machine. During work, for your own safety, it is imperative to use a mask or goggles.

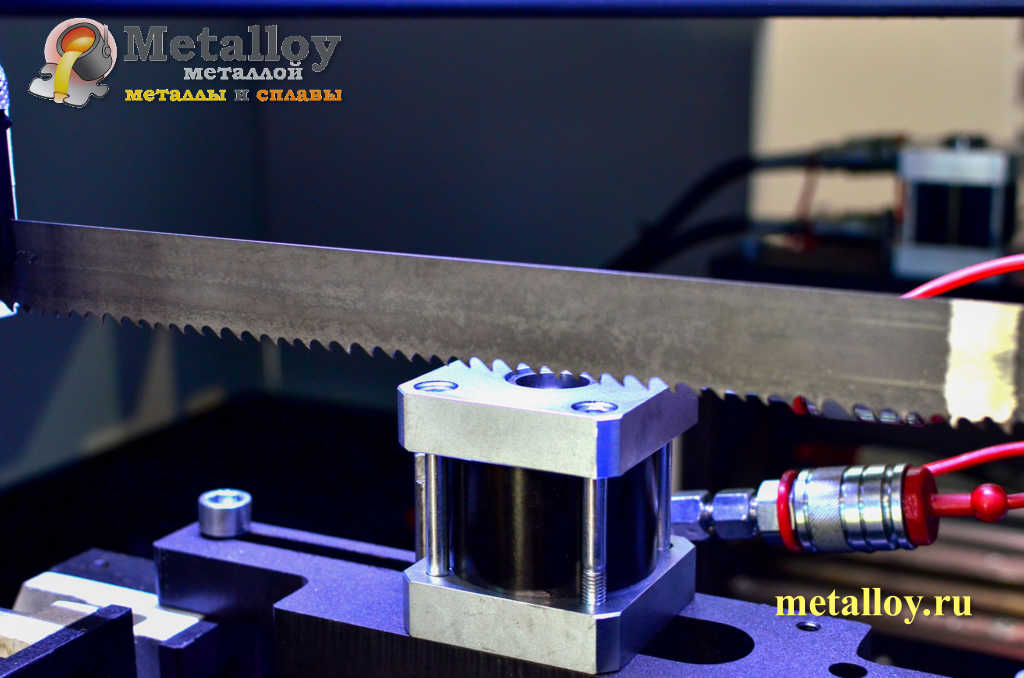

Basic information about band saws

A band saw is a cutting tool made in the form of a toothed belt having a closed contour. To maintain it, you need a special sharpening machine for band saws. In addition, band saws have a number of other significant differences from traditional circular models. The most significant of these differences is the ability to cut with such a tool with a minimum width. It should be noted that this is especially true when it is necessary to cut wood of valuable species and blanks from expensive metal.

Equipment equipped with a band saw can be successfully used to process parts made of different materials and having different configurations. Such processing is characterized by the minimum amount of waste of the processed material, exceptional cut quality and high process speed. However, such processing parameters can be achieved provided that the sharpening of the band saws on the machine is performed not only correctly, but also regularly. When servicing a tape tool (especially if you cope with this on your own), you must strictly adhere to the recommendations of qualified specialists.

BOMAR automatic band saw

Band saws, depending on the characteristics of the material being processed, can be made of different materials, differ in the geometry of the cutting teeth. If we talk about the separation of metal blanks, here the most widespread are two grades of steel used for the manufacture of saws: 9HF and B2F. Equipment for sawing wood is equipped with saws made of wood, the hardness of which on the HRC scale is at least 45 units.

Band tools for sawing wood are additionally divided into three types: carpentry, dividing, for processing logs. Tools of different types naturally have different parameters (blade dimensions, shape and sharpening angle). Harder types of wood are processed with a tool with a smaller sharpening angle.

Today, bimetallic band saws are increasingly used, which are necessary for separating workpieces made of hard steel grades. Such saws are called bimetallic because they consist of two different metals: the cutting teeth are made of steel with a high content of tungsten and molybdenum, and the blade itself is made of spring steels. Of course, such canvases are much more expensive than standard models, since special equipment is needed for their manufacture, in which the connection of two dissimilar metals occurs under the action of an electron beam.

Bimetal Band Saw

Sharpening canvases in winter

If everything is clear with the sharpening of canvases in normal conditions, then sharpening in the cold season must be said separately. There is a difference in sharpening tape blades in the summer and winter cold. It consists in changing the degree of sharpening. The angle that is valid for canvases in winter should be 90 degrees, unlike in summer, when the sharpening angle is 120 degrees.

Recommendations from experts.

When sharpening the blade with a machine, before starting the process, you need to make sure that the grinding wheel is positioned accurately in relation to the tool.

It is extremely important to remove such a volume of metal from the recesses so that all microcracks are reliably eliminated.

If the blade has been functioning without normal maintenance for a longer time than allowed by the manufacturer, the volume of metal removed in one pass must be increased.

Always use a new blade as a reference to test the effects of sharpening.

- The configuration of the blade tooth is an indicator that has been worked out and adjusted over the years. Therefore, it is a huge mistake to rely on the tool to cut “without a knot, without a hitch,” no matter what you do with the teeth.

- If operating standards are followed, the belt will work conscientiously until the width is reduced to a value equal to 65% of the initial parameters. The width decreases, of course, during sharpening.

- There is absolutely wrong advice that there is no particular need to remove scuff marks after sharpening. If you take it into account, then the occurrence of microcracks in the saw is ensured.

- At the end of the work, the tape blade must be cleaned of shavings and resin without putting it in a long box, and carefully inspected before sharpening.Otherwise, the risk of contamination of the grinding discs is very high. And this will certainly lead to a poor-quality sharpening process.

Correct tool sharpening process

It has been proven in practice that over 80 percent of tool breakage cases are due to improper sharpening of band saw teeth. The need for sharpening is determined by eye - according to the condition of the cut walls or the appearance of the teeth themselves.

Grinding wheels for band saws are selected depending on the hardness of the tooth. For sharpening tools made of tool steel, a corundum wheel is used. Bimetallic saws are sharpened with diamond or borazon abrasive. The shape of the circle for the tool should be determined based on the parameters of the saws. It can be cup, profile, plate and flat.

Before using the saw in work, it is necessary to hold it in a suspended, inverted state for about eleven hours.

Requirements for sharpening a tool with your own hands:

- it is necessary to evenly remove the metal along the tooth profile;

- exclude excessive pressing of the circle (this can lead to damage to the tooth);

- mandatory use of coolant;

- to ensure the safety of the geometry of the tooth;

- avoiding the formation of burrs.

The standard instruction states that the sharpening of the tool should be carried out either along the front face of the tooth, or both along the back and front. In practice, many craftsmen, and even professionals, sharpen exclusively along the rear edge - this is how, in their opinion, it is more convenient.

This tool is quite unpretentious in terms of sharpening, despite a lot of requirements and rules. Sharpening can be done both manually and using a special sharpening device; apply for processing circles of different material and shape, etc.

Before sharpening the tool, you need to familiarize yourself with the basic types of implementation of this operation. You can also watch a video on the Internet.

Sharpening types

-

Full profile view. It is the highest quality type, produced automatically on specials. the machine. Precisely matched elbor circle, passes the entire interdental cavity together with the edges of adjacent teeth in one motion. This excludes the formation of angular shapes at the base of the teeth. The only drawback of this type of sharpening is the need to carry a certain number of different circles for saws with different profiles.

- Sharpening the edges of the cutting part. It can be made manually or on a professional machine. If you want to sharpen with a machine, you need to choose the right circle - in most cases these are flat samples. Based on practice, contact the specialist. sharpening equipment is necessary only in cases where the volume of work is very large. With a small amount of work, it is better to sharpen manually - on a conventional machine or using an engraver. When performing sharpening work, for safety reasons, you must use protective goggles or a mask.

If you do not have an engraver or a machine tool, then you can sharpen the tool in the old-fashioned usual method - using a file. With diligent and regular execution of the operation, the skill of manual high-quality sharpening will very quickly appear.

Professional advice

- When sharpening a tool on a machine, before starting sharpening, you need to make sure that the sharpening disk is correctly positioned relative to the saw.

- It is necessary to remove such a layer of metal from the sinuses in order to guarantee the elimination of all microcracks.

- If the saw was operated without high-quality maintenance, longer than the manufacturer's prescribed, the layer of metal removed in one sharpening must be increased.

- Always use a new tool as a reference to check the sharpening results.

- The shape of the saw blade is a parameter verified and developed over the years. Therefore, it is not worth displaying your parameters and hoping for a good quality of work.

- Subject to the rules of operation and the requirements of the manufacturer, the band saw will serve you until its width is reduced to 65 percent of the original crimp. The width decreases as the teeth are re-sharpened.

- It is imperative to remove burrs when sharpening the tool, otherwise it will lead to the formation of microcracks during the cutting of materials.

- After finishing work, the tool must be immediately cleaned of sawdust and resin, and before sharpening, the saw must be carefully inspected. Otherwise, chips will clog the sharpening wheel, which will result in improper sharpening of the saw band.

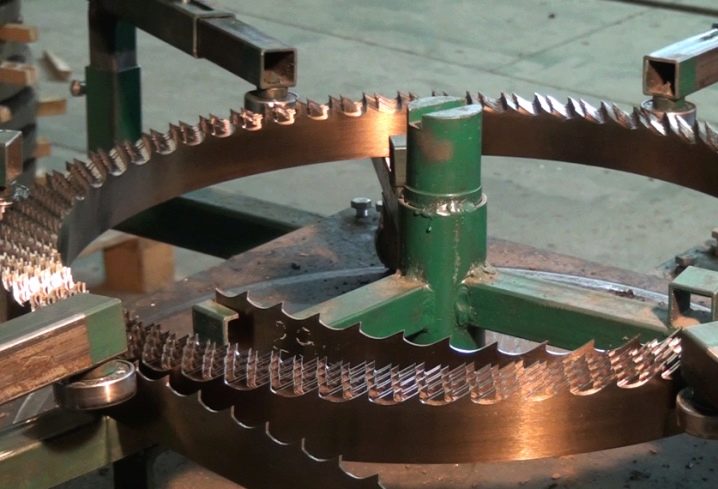

Band saw set types

Like any other tool, a band saw is subject to wear after every cutting cycle. This is a natural and inevitable process. That is why every band saw needs regular and qualified maintenance - setting and sharpening. Such maintenance allows not only to keep the cutting blade in working order, but also to significantly increase its service life.

Correct routing allows to increase the service life of the cutting blade and significantly improve its functionality. The meaning of such an operation is as follows: the cutting teeth of the saw are bent in different directions, which reduces the friction force during the cutting process, and also minimizes the risk of the blade being pinched by the workpiece. The band saw can be set in three ways, the choice of which depends on the type of material being processed.

- With the so-called stripping type of setting, the teeth are bent in such a way that every third of them remains intact. This scheme is used if the cutting blade will be used for cutting extremely hard metals and alloys.

- The classic type of setting involves the alternate bend of each cutting tooth.

- With a wavy setting, each cutting tooth is bent at a certain angle. It is clear that this type of layout is the most difficult of all.

Band saw setter

To bend the teeth of the band saw, special equipment is used, which makes it possible to perform such a technological operation quickly and as accurately as possible. According to generally accepted standards, the maximum set of teeth should not exceed 0.7 mm, but usually its value is in the range of 0.3-0.6 mm

It is important not only to choose the type of setting, focusing on the characteristics of the material to be cut, but also to execute it correctly, bending the teeth only 1/3 or 2/3 of their height

After setting, the cutting blade can be sent to the band saw sharpening machine. As statistics show, band saws most often lose their functionality due to the fact that their sharpening was performed incorrectly or out of time. An indicator that the band saw needs to be set and further sharpened on the machine is the increased roughness of the cut surface. The need for such a procedure can also be determined by the appearance of the cutting teeth.

The main elements of any grinding machines are wheels, the choice of which, first of all, depends on the hardness of the material used to make the cutting teeth. In order to sharpen hard materials, you must use the appropriate wheels. So, for sharpening bimetallic blades, sharpening tools consisting of borazon or diamond elements are chosen, and corundum wheels are quite suitable for tidying saws made of tool steels.

Tools for sharpening band-type saws are chosen both in composition and in design. For blades of various designs and sizes, the following types of circles can be used in machines:

- disc configuration;

- cup-shaped;

- profile;

- flat.

Wood-Mizer Band Saw Sharpening and Setting Kit

According to the instructions, when sharpening the band saw on the machine, observe the following requirements.

- No burrs should remain on the surface of the tooth when sharpening it.

- The grinding wheel should remove the same metal layer over the entire tooth profile.

- To avoid overheating of the teeth when turning them on the machine, it is imperative to use a special cooling fluid.

- When sharpening, the profile and height of the machined teeth should not change.

- It is imperative to monitor the pressure exerted by the grinding wheel on the tooth being processed. If this requirement is neglected, the pressure can be too great, which can lead to annealing of the teeth.

Do-it-yourself sharpening of band-type saws has some features. In such cases, as a rule, the back surface of the teeth is sharpened, although if you use the manufacturer's instructions or watch a thematic video, you can also sharpen their front surface.

Do-it-yourself divorce and sharpening of band saws on wood

The service life of a band saw for wood directly depends on the quality of its sharpening. It can be performed both independently and by resorting to the services of specialized companies. In the first case, it is necessary to familiarize yourself in detail with the technology and a number of features.

Cutting shape and sharpening angle

Types of band saw profiles

In the first step, the type of saw band is determined. The main indicator is the shape of the teeth.

Depending on this parameter, they are divided into dividing, carpentry or intended for sawing logs. The manufacturer determines the initial geometry and routing angle.

It is recommended to find out these data at the stage of purchasing components. They are needed to determine the parameters of the machine.

For hardwoods, the rake angle should be as low as possible. This ensures optimal contact of the processed material with the metal. If you plan to process soft grades, to increase the processing speed, you can use models with a large value of the rake angle.

The defining parameters for self-updating of the cutting edge are:

- tooth pitch. This is the distance between the cutting elements of the structure. Common values are 19, 22 and 25 mm;

- tooth height. The magnitude from its base to the top;

- injection. The main value that you need to know for the formation of the cutting plane. For joinery models, it is 35 °. In dividing saws, the angle is 18 ° to 22 °. In structures for processing timber - 10 ° -15 °;

- divorce. Defines the deviation of the tooth from the general plane of the blade.

Ideally, these characteristics should remain unchanged after working on the machine. For each model, the manufacturer determines the maximum deviation value. If it is achieved during operation, it is necessary to purchase a new model.

In order to eliminate resonance in some types of cutting tools, a variable pitch of the teeth is made. This does not affect manual sharpening, but requires careful parameter setting during automated sharpening.

Saw band setting

Band saw geometry

Before forming the cutting edge, you must make the correct setting of the teeth. During the entire period of operation, due to constant loads, their location may change. Therefore, the geometry is adjusted first, and then sharpening.

The setting is a bend of the teeth relative to the plane of the main blade. This procedure is performed only on a special machine. In case of large discrepancies along the entire length of the belt, premature damage or breakage of the belt is possible. Therefore, before that, you should decide on the type of wiring.

The angle of inclination must correspond to the initial one. The type of wiring is also taken into account, which can be as follows:

- classic. Alternate bending of the teeth relative to the blade to the right and left sides;

- cleansing.The first and second teeth are deflected to the right and left, while the third remains unchanged. This technique is used for saws that are designed for processing hard rocks;

- wavy. The setting angle for each tooth is individual. As a result, they form a cutting edge that resembles a wave. The most difficult type of wiring.

During the bend, not the entire tooth is subjected to deformation, but only a part of it. Often, the deviation occurs at 2/3 of the total height.

The average divorce rate is limited to values from 0.3 to 0.7 mm. This applies to standard wood band saws.