DIY riveter

In some work situations, when you have to deal with large diameter fasteners, the power of a conventional hand tool is not always sufficient. You can get out of this situation if you make a manual riveter with your own hands in advance, taking into account frequently occurring tasks. A steel bolt of the same cross-section as the rivet can be used as the basis for this fixture.

In some work situations, when you have to deal with large diameter fasteners, the power of a conventional hand tool is not always sufficient. You can get out of this situation if you make a manual riveter with your own hands in advance, taking into account frequently occurring tasks. A steel bolt of the same cross-section as the rivet can be used as the basis for this fixture.

A nut should be hung on it, and then a small thrust ball bearing should be put on top. This part will help to ensure an even distribution of pressure when the tool is exerting force on the rivet and will also help prevent the nut from jamming. When assembling a homemade manual riveter, be sure to put on a pair of washers between the fasteners and the bearing, for the correct calculation of the number of which you should be guided by the depth of penetration of the fasteners into the material.

Installation of fasteners using a homemade riveter is performed according to the following algorithm:

- First, the tool must be aligned with the hole of the required diameter, and then, holding the nut with one wrench, unscrew the screw head with another wrench.

- Under the influence of force, which will force the bolt to leave the fastened surface, the rivet will be deformed, so that it can easily take the correct position in the seat.

This method of installing fasteners should be resorted to only when the master does not have enough time or opportunity to purchase a branded tool for threaded rivets. A homemade riveter has only one significant drawback - during operation, the bolt can jam inside the fastener. This is most often due to excessive pressure on the tool handle or too soft surface of the bolt material. Therefore, such a thread does not cost anything to cut off a harder nut.

This method of installing fasteners should be resorted to only when the master does not have enough time or opportunity to purchase a branded tool for threaded rivets. A homemade riveter has only one significant drawback - during operation, the bolt can jam inside the fastener. This is most often due to excessive pressure on the tool handle or too soft surface of the bolt material. Therefore, such a thread does not cost anything to cut off a harder nut.

If you have the opportunity to use lathes, you can try making an improved version of the mechanical riveter. This version of the tool looks like a bolt with threads of different diameters. In a head with a through hole, a lever of a certain length must be placed so that the tool can be securely fixed. It is imperative to put on a wide washer between the clamping nut and the rivet.

As in the previous case, the washer is needed here in order to ensure an even distribution of pressure. The main advantage of such a self-made riveter is that the clamping nut can move along a large-diameter bolt, which is more reliable in contrast to fasteners of the size M2-M4, and this will prevent the appearance of deformation.

Home craftsmen, who have to regularly perform various kinds of household work, should have in their arsenal a lot of different tools. Among them should be a riveter, with which you can create reliable connections with minimal effort.

But to ensure the proper connection of the elements, it is necessary to choose not only the riveter correctly, but also the rivets for it. After all, the manual version of the tool is able to provide a reliable connection only when using aluminum or copper rivets, which few know about. It is also necessary to ensure that the manual riveter has sufficient power and can effectively perform its main task.

Sometimes, when problems arise with this, some home craftsmen begin to think about making this tool with their own hands.Although this approach to solving the problem that has arisen can be considered, however, sometimes during the installation of fasteners, the bolt, which is the main working unit of the homemade riveter, can jam. Therefore, it is not recommended to constantly use such a tool.

Features of working with the tool

To quickly learn how to handle a riveter and easily perform a reliable connection of elements, it is enough to learn a simple procedure for working with it:

The first step is to select the rivets of the correct diameter. Most often, fasteners with a diameter of 2 to 4 mm are used. When working with large diameter rivets, you will need a specialized tool, which is best suited as a pneumatic or pneumohydraulic rivet.

A hole is drilled in the working surface taking into account the outer diameter of the rivet. In the case of using fasteners with a countersunk head, it is often necessary to pre-countersink the surface, which makes the rivet invisible.

Before working in the riveter, install a threaded rod of the required diameter and screw a threaded rivet onto it.

It is important to make sure that the rivet is securely fastened, otherwise it may unscrew during installation.

It is necessary to insert the fastener into the hole until it stops, making sure that its head fits snugly against the surface of the material.

The riveter is positioned strictly at right angles to the surface and begins to exert force on the handle. During operation, the stem will begin to move inside the tool, providing the necessary pressure to deform the fastener.

After installing the rivet, unscrew the threaded rod from its seat and make sure that the rivet is seated in the hole correctly

This can be judged if there are no distortions and gaps, as well as deformation of the thread.

How to remove a rivet

Sometimes there are situations when the hardware was installed incorrectly or in the wrong place and needs to be removed. This can be done in several ways.

Sometimes there are situations when the hardware was installed incorrectly or in the wrong place and needs to be removed. This can be done in several ways.

In the first case, you will need a drill with a drill of slightly larger diameter than the internal thread size. During the installation of the rivets, you need to monitor the process and promptly change the drill to a larger size. When the problem is solved, the fastener is divided into two halves - the head and the inner part.

You can also remove the incorrectly installed fasteners by grinding the head. A drill will also help in solving this problem, and when the head is destroyed, all that remains is to knock the rivet out of the seat.

Installation nuances

Before installing the fasteners, special attention should be paid to the choice of its length. To correctly calculate this parameter of the rivet, you need to add the thickness of the material and the diameter of the rivet.

For example, if the cross-section of the fastener is 4 mm and the material thickness is 2 mm, then it is recommended to use a rivet with a diameter of 6 mm to make a reliable connection. After installation, it will reliably "sit" in the seat and will allow, if necessary, to screw in a bolt there.

It is no coincidence that the riveter is very popular, because it has such advantages as ease of use and practicality. Although home craftsmen very rarely share their impressions of the practical use of this tool in the domestic environment. In many hardware stores, the riveter is a rarity, not to mention the fasteners for him, which many are forced to order through the Internet.

This tool has only recently become popular among the population. Most often it is used for reliable installation of license plates. It is also perfect for installing fences made of sheet materials, as well as fixing electricity meters on the thin walls of the shields. This mounting method was able to surpass in popularity even such a common type of fastening as welding, due to its reliability.And this is not surprising, because even under conditions of high loads, if rivets begin to fail, it will not happen to everyone at the same time.

How to do it yourself?

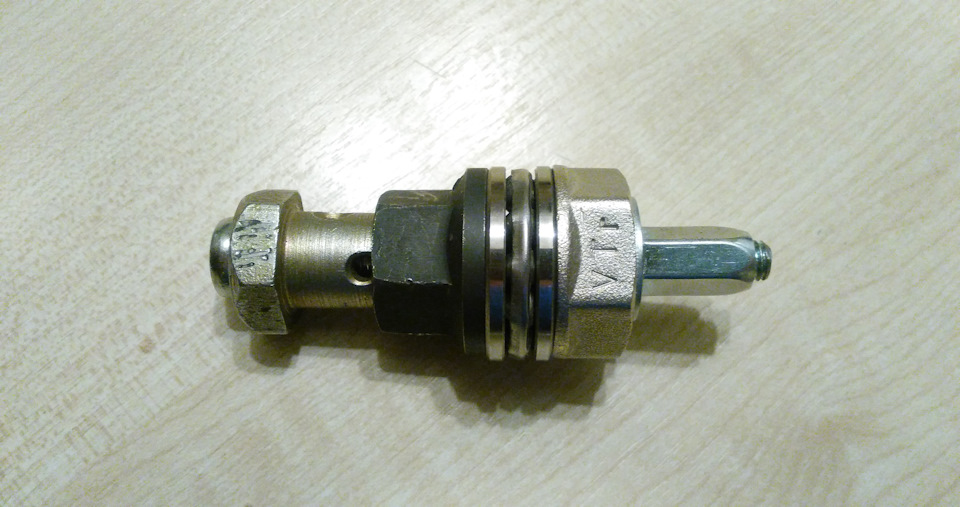

If you do not have a suitable ready-made tool at hand, it is quite possible to make it yourself. This does not require drawings or complex diagrams. The simplest device for installing threaded rivets can be made from an ordinary bolt and nut, and an ordinary bearing, which is used for bushings, is also useful. Let's consider the order of work.

- Select the bolt according to the rivet diameter. It should fit freely into its thread.

- Fasten the nut to the surface of the bolt.

- The bearing is installed as a shock absorber, preventing uneven pressure supply, eliminates seizure. Washers are placed between the rivet and the bearing on the surface of the screw. Their exact number depends on how deep the fastener must enter the surface of the material.

- The surface of the rivet is aligned with the hole. Inside it is the construction of a homemade riveter.

- The nut is wedged with a wrench at the bottom. The screw is turned out, creating a force applied to the rivet. The fastener is flattened by squeezing the edges of the hole.

A bolt with an internal hex head is optimal for such a homemade tool. It is convenient to use as a lever. In any case, such a design cannot be altered, it is designed for 1 time.

General procedure for installing threaded rivets

Before riveting the threaded rivet, preparatory work is performed. It is necessary to select a drill, the diameter of which should be 0.1 mm larger than the outer diameter of the rivet, which will make it easy to install it in the hole. After that, a hole is drilled in the place where the fasteners are installed. In addition to threaded rivets of round cross-section, similar hardware with a hexagon-shaped cross section is also produced. This shape makes it possible to exclude the possibility of turning the part during installation. To make holes for such rivets, special hexagonal punches are used. However, they are only suitable for working with sheet metal, which somewhat limits the scope of application of hardware of this shape. Manufacturers recommend using a special tool for mounting fasteners - a riveter. Therefore, the installer must have the appropriate skills and understand how to install the threaded rivet with the rivet driver. Such tools can be mechanical (hand), electrical and pneumatic. The mechanical riveter design consists of a working part and two handles. The working part contains a movable screw mechanism, at the end of which there is a thread. To make a threaded rivet with a rivet, perform the following sequence of actions:

- The rivet is screwed onto the thread of the screw mechanism of the tool.

- The working part of the riveter with the rivet installed is placed in a prepared hole in the metal base.

- The handles of the tool are compressed. This creates a force due to which a bead is formed in the inner part of the rivet. As a result, the fastener is tightly fixed with the formation of a reliable and strong connection with the mounting hole for the screw or bolt.

- The working part is removed from the rivet by unscrewing it.

The advantage of the mechanical riveter is its simple and reliable design, as well as its low price. However, to install threaded rivets with it, it is necessary to apply a significant amount of force. If it is necessary to carry out a large amount of installation work, it is advisable to use riveters with an electric or pneumatic drive. These are professional tools that ensure the installation of threaded rivets by tightening the set screw. This creates a force sufficient to form a shoulder, after which the screw is unscrewed from the hole.The tools are simple and easy to use, so there is no problem in understanding how to use the rivet rivet.

Types of manual (mechanical) riveters

There are three types of manual rivet setters:

- one-handed;

- two-handed;

- harmonic.

One-handed ones are designed for small fasteners - up to 5 mm. They differ in that their operating handles are at an angle of 90 ° to the installation axis. That is, the handles are pointing down. Convenient because you can work with one hand. The disadvantage is the small "range" of sizes with which the device can work.

Two-handed ones are large in size, they can also be installed with rivets of large diameters - up to 8 mm. You can distinguish by their appearance - long handles, which are in the same plane with the working jaws. It makes sense to choose a two-handed riveter if you plan to use large diameter rivets.

Types of hand riveters: one-handed, two-handed, accordion

Mechanical accordion riveters are more often used with large fasteners. The presence of the same "accordion" allows you to install large-sized fasteners with less effort. Such a device usually has a more expensive tool and is more often used by professionals.

Select hand riveter type not too difficult. If you are looking for a reliable clipper, choose from two-handed models. Their device is simpler, there is almost nothing to break there. With normal quality, they are indestructible. If you will only install small fasteners - no more than 2-3 mm, then it is more advisable to take a one-handed one. It is more convenient for them to work.

How to choose a riveter: manufacturers and prices

When choosing a specific model, many rely on prices. Here are just a very large spread - there are very cheap and, almost one to one in appearance, but many times more expensive. Even ten times more expensive. It should be said right away that even for one-time work, buying a very cheap riveter is too much of a risk. It may not work at all or work through a stump deck.

If you only want to rivet a fence, for example, even in this case, you will have to install more than one hundred rivets. If you have to disassemble the tool after every 2-3 rivets, you will definitely not like it.

To choose a riveter that works well, pay attention to the mid-range price range.

- Stanley MR 99. Stanley is the oldest American company.

- NOBUS. An inexpensive tool that works reliably.

- Gesipa. A well-known company, but not everyone praises it. There are definitely cheaper ones that work, at least, not worse.

-

YATO handles steel rivets better than Chinese rivets with aluminum ones.

- NWS is a German company. The quality of the tool is excellent.

- Topex. In some models, I liked the ability to rearrange the "nose" by 90 degrees. Convenient if you have to work in hard-to-reach places.

- KRAFTOOL. The whole tool is good, and so are the riveting tools.

If you intend to use a riveter in professional activities, you need to choose a more expensive one. Firm - at its discretion, but from the category of professional or semi-professional models. Perhaps they do not differ structurally, but they have a greater resource, service life. That is, they are made more reliably and of high quality. And this explains the difference in price - more expensive / high-quality materials were used.

Installation process

The installation algorithm for a threaded element can hardly be called overwhelming, but it is important to know certain nuances. If possible, it is better to use a factory riveter

If you wish, you can assemble it yourself, one option will be discussed below. The first step is to determine the type of metal on which the rivet will be installed. Next, you need to know what is the diameter of the bolt or the module, which will be fixed thanks to this rivet. The corresponding rivet is selected according to the indicated diameter.Its outer diameter is measured and a drill is selected that will exceed the rivet by one tenth in diameter. This is necessary in order for the latter to fit in its place without much effort and obstacle.

Electric or cordless drill. Drilling is carried out in the metal in the required place. After that, the fastener is inserted into the seat. If it needs to be placed in a certain position, then it is better to hold it with your hands. For hex holes, special punches can be used for thin metal. If the metal is thicker than the length of the fastener, then the hole needs to be drilled slightly deeper than the fastener, but there is no need to drill through. After that, the rivet core is selected, which is threaded to the element to be installed. The handles are brought together or the bolt is rotated so that part of the rivet is deformed and fixed in the hole.

Don't make too much effort worth it, because you can tear off the thread, which will later be used to fix the required part. Make sure the rivet is in the correct position. After that, you can fix the desired product with a screw or bolt.