Advantages and disadvantages

The use of accessories for drilling tools has both its supporters and opponents. Nevertheless, it is worth taking a closer look at the advantages and disadvantages in order to objectively assess the usefulness. So, the pros of using such devices.

- Savings on the purchase of equipment. It is quite logical that buying a nozzle or even a whole structure will be much cheaper than a new technical device. For example, an inexpensive set of cutters will cost from 1,500 rubles to 2,200 rubles, and a milling machine will cost from 3,500 rubles and more.

- Saving space. Storage of such devices will require much less space in the garage than bulky new tools.

- Large selection of accessories. You can find not only classic drilling attachments. Wonderful nozzles will turn a drill into a lathe, a metal cutter, and a construction apparatus for screwing in piles - there can be a great variety of options.

Of course, this list is far from complete. Each person can find additional benefits that are meaningful to him. The disadvantages include, first of all, limited functionality. Obviously, the attachment cannot be compared in the quality of workmanship to a full-fledged machine. It is also necessary to check before buying whether this device is suitable for your drilling tool. In our age, when there are an infinite number of manufacturers, it is extremely easy to make a mistake with a choice and buy an absolutely inappropriate thing.

Other useful drill bits

The next group of attachments for an electric drill is designed to help its owner when performing a large volume of the same type of work.

1. Nozzle for installing aluminum rivets.

There are many different designs of them, both for one size of rivets and with replaceable sleeves for different diameters. Such a nozzle will be very useful if such fasteners have to be done often:

And the point here is not only the automation of manual labor, but also the speed of this type of work.

2. Tape attachment for self-tapping screws.

It is even more than the previous one, it allows you to save time when installing plasterboard partitions or large volumes of fastening other sheet materials using self-tapping screws.

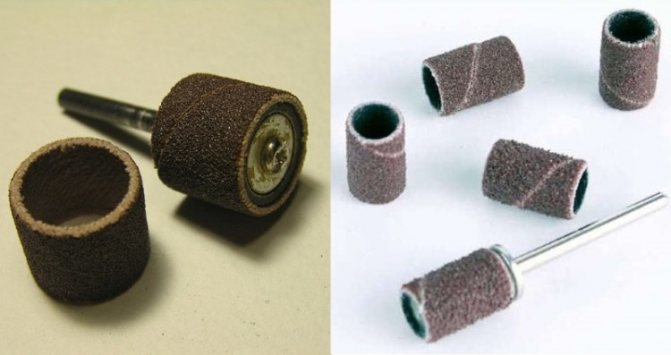

3. Grinding belt attachment.

Such a nozzle costs several times less than a manual one. belt sander, and the work with it can be done the same, which practically neutralizes some difference in convenience in work.

A drill attachment will be useful, allowing you to turn it into a hammer drill. We have already written that an impact drill (link to article), due to the specifics of the formation of a micro-impact, is not able to perform the work of a puncher, and even more so to receive a blow without rotation. The same nozzle is nothing more than the hammer unit of the hammer drill, which makes it one of the most needed in the household for an electric drill.

Just to use it in full, it is worth purchasing a cartridge for securing the corresponding tool.

The pruning shear attachment is useful for cutting thick power cables as well as for trimming fairly thick tree branches.

If you want to save money on the purchase of a jigsaw, and work for it is periodically found, then the corresponding nozzle will help turn your drill into it.

Adaptations for adapting an electric drill to a hand-held circular saw can also be useful to you on the farm.

Not to mention such small but useful attachments, such as a nozzle for sharpening small drills, a pump nozzle for pumping small volumes of liquid or a nozzle for polishing various surfaces.

It is clear that instead of a polishing nozzle, you can insert various cleaning, grinding and other nozzles into the drill, which we will not write about due to their wide popularity and applicability in this article. As well as about the various types and types of drills and drills that are directly used to work with a drill.

Of course, there are more exotic drill bits:

for sharpening pencils;

for cleaning fish;

for plucking bird feathers etc.

But the most commonly used attachments for electric drills are collected in a short video:

Dear readers, if you have any questions, ask them using the form below. We will be glad to communicate with you

Basic classifications and functions

The angle nozzle usually functions according to the following schemes:

- mechanical transfer of the axis;

- flexible axis change.

Attachments of the first type are often located on a professional instrument and are one with it. These drills have no more than 1800 rpm, which allows you to provide enough torque for difficult tasks. These tools are indispensable when working with metal parts, and the attachments themselves can have extended functionality. For example, a vibration reducing agent that makes work easier and faster.

The second type of attachments is usually located in drills and is a flexible shaft, one end of which is attached to a screwdriver, and a bit or drill is installed on the other.

The attachments are distinguished by the following characteristics.

- Manufacturing material. Here, parts are usually used that can withstand heavy loads, and are made of high quality metal, which makes it possible to withstand strong mechanical stress. These attachments can be used to drive screws into hard surfaces.

- Ways to change the axis. They are a gearbox enclosed in a plastic case and capable of withstanding high loads. When working with such tools, the stress on the hands can be reduced, but the torque in the drill will be small.

- Bit extension height. Affects the functionality of the attachment.

- The angle of rotation of the handle. Increases usability and enables two-handed operation.

- The presence of a reverse. You can remove the self-tapping screws, and not just screw them in.

Cutting attachments

Surely those who used a grinder in their work noticed how inaccurately this tool cuts the material being processed, jags remain. But if you use a special drill bit that is capable of cutting metal, you will notice that the work will be done more delicately and without damaging the metal. Such a device is activated by means of the tool holder on which it will be installed. If it is necessary to cut metal, then it is better to choose a drill with a number of revolutions, which is approximately 2800 rpm.

Surely those who used a grinder in their work noticed how inaccurately this tool cuts the material being processed, jags remain. But if you use a special drill bit that is capable of cutting metal, you will notice that the work will be done more delicately and without damaging the metal. Such a device is activated by means of the tool holder on which it will be installed. If it is necessary to cut metal, then it is better to choose a drill with a number of revolutions, which is approximately 2800 rpm.

Benefits and types

The cut will always be very smooth, work comfortably, the attachments are easy to maintain and use, no adjustments are required.

There is a very convenient attachment for a drill, called "Cricket". It is a nibbler with two cutting heads. Such a device is used in order to cut thin sheet metal:

- profile metal sheet;

- metal tiles;

- profiled or sheet plastic;

- polycarbonate.

"Cricket" will greatly help the owner of the site, who decided to install a fence made of metal profiles.

Apply "Cricket" for sheets of materials that have the following parameters:

- The sheet thickness should not exceed 1.5 mm.

- Stainless steel up to 1.2 mm.

- Aluminum, copper and plastic no more than 2 mm thick.

After processing, the surface will be smooth, no chipping will remain, the coating will be completely intact.

If you need to make a good even internal cut, then first you need to drill a hole there.

The nozzle matrix is constantly rotating, which means that you can work with it on both vertical and horizontal surfaces. To use a rig, it is recommended to buy a drill that has 3 thousand revolutions per minute. The minimum number is 1500 rpm.

The Steel Beaver bit can be used to cut metal profiles or shingles.

The principle of operation will be similar to the previous nozzle, but the cut will be carried out with the help of frequent reciprocating movements of the punch, which will bend the metal and break it off against the matrix. With the help of such equipment, it is very easy to make straight cutters, as well as, if necessary, curves.

The cutting radius is - 1.2 cm. Such equipment differs in that it is possible to work with it from absolutely any angle. If we compare it with "Cricket", then it is able to cut metal, which has a large thickness - 1.8 mm. The advantage of the nozzle is considered to be a very smooth cut, and during operation there will be no sparks at all, the metal will not deform.

When the metal is finished cutting, you need to move it very carefully, as the cut edge will become very sharp.

Features of choice

Before purchasing a large and expensive set of drill bits, you need to think about the advisability of such a purchase. First, you need to know the purpose and operation of each nozzle. Secondly, you must have a minimum of experience with such a tool. And thirdly, you need to know the estimated frequency of use of each of the attachments.

If such a purchase is deemed appropriate, you should pay attention to the following features

- Price. Quality tools cannot be too cheap. However, the highest price on the counter is not a guarantee of a long service life. It is best to stay at the middle price segment.

- Manufacturer. It is better to choose products from trusted manufacturers than new and unverified brands. In this case, you should carefully study the documentation and beware of fakes.

- Place of purchase. The risk of running into a manufacturing defect and fake is much lower when buying construction tools in a specialized store, and not in a regular market or in a supermarket.

- Package. A quality tool is always well packed. The box contains all the necessary information both about the product itself and about the manufacturer. All accompanying documentation, including instructions, must be inside the box.

- Guarantee. The manufacturer, confident in its product, will always provide a guarantee for any attachment. If the store does not issue it at the time of the sale, the purchase should be carried out elsewhere.

Advantages and disadvantages

In addition to converting a conventional drill into a variety of other tools, various attachments have many other advantages.

- A familiar tool. It is enough to get used to working with the drill itself, after which it will be much easier to work with any attachment. There is no need to get used to the new handle, weight and features of the independent tool.

- Saving. Even if you purchase absolutely all types of attachments in all variety of sizes and materials, such a purchase will still be much cheaper than purchasing several separate tools for each type of work.

- Ease of replacement. All attachments are very easy to remove and fasten, while in terms of reliability they are not inferior to a conventional jigsaw, grinder or milling device.

- Convenient storage. In order to lay down all the individual tools that are needed for construction and repairs, it will take more than one room, but maybe a whole hangar.You can store drill bits in a regular drawer or a special suitcase. So they will always be at hand and at the same time fit even in a regular drawer under the sink or on a shelf in the pantry.

Unfortunately, like any additional equipment, along with the advantages, the attachments have their disadvantages.

- Low efficiency. Compared to expensive professional tools, the attachments are not able to cope with such a volume of work and maintain such high productivity.

- The complexity of the job. It is much more convenient to work with a special tool for cutting or grinding than with a conventional drill, which is equipped with an additional attachment. In order for the cuts to be even, more than one sheet of metal will have to be spoiled while the skill is acquired.

- You have to use both hands. Often this can lead not to simplification, but to complication of the operation (and even to danger). For example, during roofing work, busy hands mean that you cannot hold onto a fence or rope.

Types of nozzles

There are a huge number of drill attachments. Some of them are designed for easy drilling, others allow you to create large diameter holes, and still others help in grinding and polishing. There are also highly specialized devices, for example, a milling cutter for a mini-drill for wood, which turns a hand tool into a mini-milling machine.

It is not always necessary to have a strictly vertical hole going through the entire workpiece. There are times when you need to drill at exactly the right angle, besides, several parallel holes. Here the drill angle limiter will come to the rescue of the master. These are mainly lightweight designs that slide over the drill and provide precise positioning.

Another useful attachment for an electric drill is the depth gauge. The limiter is included in the basic package of almost any drill. The device is extremely simple - it is a metal rod that does not allow drilling deeper than the specified value.

Types of attachments for the grinder

The processing of a wooden house takes place in stages: first, a rough surface treatment is carried out, then a finishing one, and at the final stage, a finishing grinding is performed. Accordingly, the nozzles on the market today are divided into varieties that differ in purpose, shape and material of manufacture.

Coarse attachments

- Roughing wheels structurally consist of a disc with soldered metal wire. The steel bristles can be parallel or perpendicular to the tool. Wheels do an excellent job not only for roughing, but also for stripping old paint or varnish.

- Cord brushes are a disc with metal fibers, horizontal arrangement. The abrasive brush is suitable for coarse sanding and surface leveling.

- End discs are used for processing bevel cuts and leveling the ends of logs.

- Metal brushes are made of stiff wire bristles that are perpendicular to the tool. Used for initial processing and removal of old paintwork.

Gentle sanding and polishing attachments

- Lobe nozzles on angle grinders are the most common. They consist of many trapezoidal blades of abrasive material that overlap each other. Thanks to this design, the tip wears out slowly. Depending on the degree of processing, you can choose discs with different grain sizes.

- Grinding wheels are made from sandpaper, felt, sponge, dense fabrics and are usually sold as a set. The discs are equipped with Velcro, with which they are attached to the plate attachment. The set for grinding wood consists of five discs made of the same material.They are very convenient in work, the worn-out disc can be easily removed from the main nozzle, and another abrasive is put in its place. Wheels with Velcro are used for fine and finishing sanding. Soft cloth and felt discs can be used to polish wood by applying a special wax-based polishing paste to the surface.

- The cup heads are a nylon brush made up of a plurality of abrasive nylon bristles. It is used for fine sanding of wood.

How to replace the drill chuck with your own hands?

To mount the chuck on the drive shaft of the drill, a threaded connection or Morse taper is used. A visual inspection of an electric drill does not always help to tell about the method of fixing the drill chuck... The marking on the cartridge can inform about this: it is knocked out on its surface.

Replacing a Tapered Part View

The standard size of the Morse taper (according to GOST 9953–82) consists of 9 values: from B7 to B45. The larger the number after the letter B, the larger the diameter of the cone.

The markings on the chuck indicate the type of fastening

The markings on the chuck indicate the type of fastening

Thus, having found the marking "B" on the surface of the cartridge, we can conclude that this is a device with a tapered mounting base. With this method of attachment, the cartridge can be easily removed. It is enough to use a drift and a bench hammer.

Video: how to remove a chuck with a cone from an electric drill?

Replacing the Reverse Threaded Chuck

Two types of threads are used to secure the drilling chuck to an electric household drill using a threaded joint:

- inch (for foreign models);

- metric (from Russian manufacturers).

On the electric household drill, there are two types of threads using the threaded joint

On the electric household drill, there are two types of threads using the threaded joint

Markings of the following type are applied to the surface of the body of the threaded chuck: 1.5-13 1/2 - 20UNF or 1.5-13 M12x1.25.

The reversible threaded chuck has a left-hand thread for fixing. You need to know this nuance when removing a broken cartridge. In order to get to the screw head, it is necessary to sink the cams into the collet to the point of failure. Once the screw head is visible, use a hardened Phillips screwdriver to unscrew it clockwise to the right. Then clamp the hex key into the cams and hit it sharply in the counterclockwise direction. After the cartridge is ripped off, it can be easily unscrewed.

Video: how to remove the chuck from a reversible drill or screwdriver?

On other models, there are other options for fastening the cartridge to the thread. In some cases, the chuck is twisted entirely from the threaded end of the shaft. In other cases, the screw can be fixed with a special thin wrench using a narrow groove. The main difficulty is to move the cartridge from its place when unscrewing. This is sometimes very difficult to do. In any case, to remove the cartridge you need: a locksmith tool, the necessary skill and patience.